LTCC-based CGA integrated packaging structure and realization method thereof

A technology of packaging structure and implementation method, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of low system integration density, large edge space, and low packaging efficiency, so as to improve system integration density , High I/O port density, the effect of meeting the design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

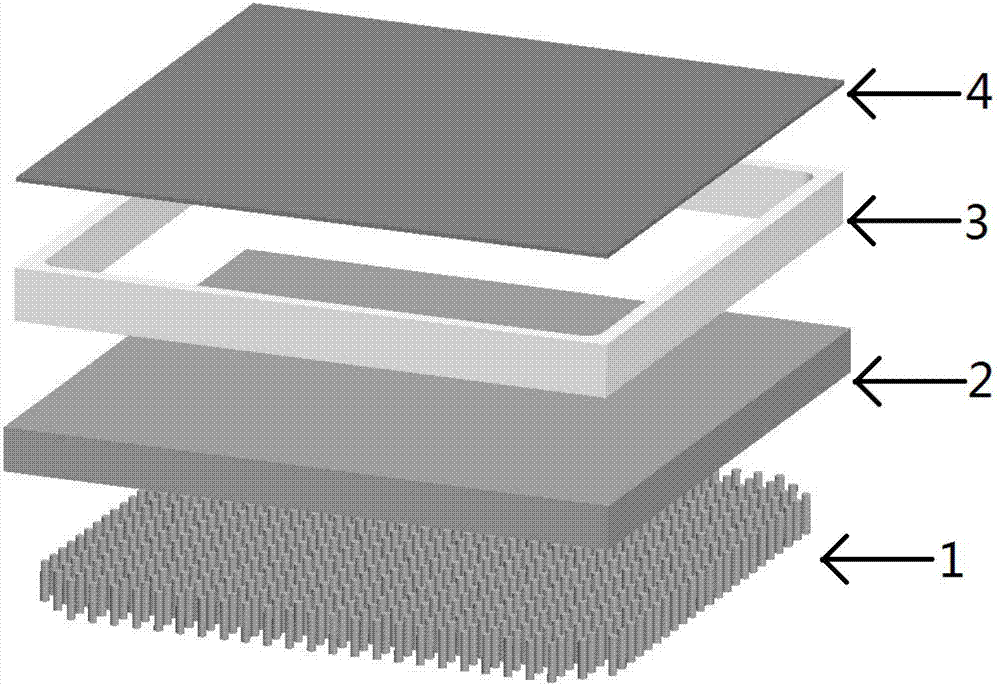

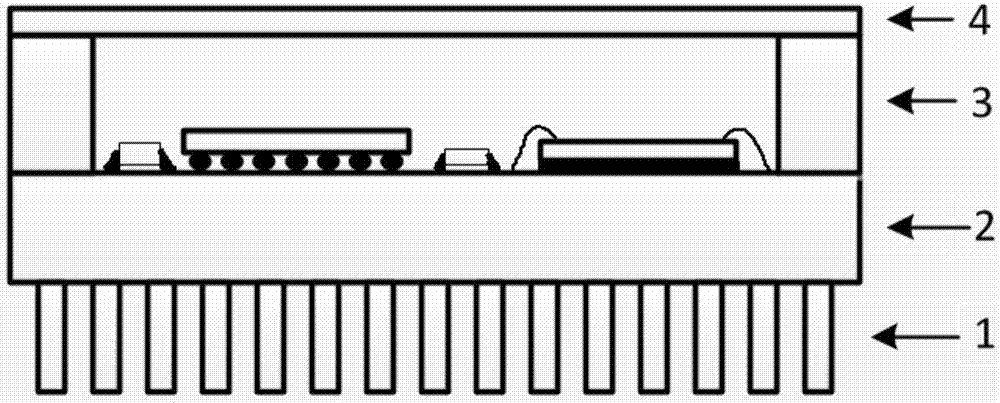

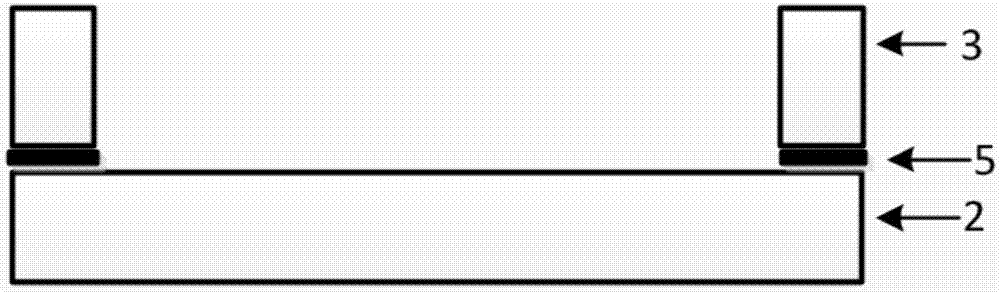

[0046] like figure 1 As shown, the packaging structure of the present invention includes a CGA array 1 , an LTCC substrate 2 , a surrounding frame 3 and a cover plate 4 . The frame 3 is welded on the upper surface of the LTCC substrate 2 , the CGA array 1 is welded on the bottom surface of the LTCC substrate 2 , the LTCC substrate 2 is electrically and mechanically interconnected with the lower PCB through the CGA array 1 , and the cover plate 4 is welded on the frame 3 . The upper surface of the LTCC substrate 2 is used for assembling components.

[0047] The LTCC substrate 2 is a plane structure with n blind cavities on the plane, where n is a natural number.

[0048] The surrounding frame 3 and the cover plate 4 are made of metal, preferably iron-nickel alloy.

[0049]The thickness of the LTCC substrate 2 is not less than 2 mm, the height of the frame 3 is not less than 3 mm, and the contact width between each edge of the frame 3 and the LTCC substrate 2 is 2 mm.

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com