Optical adhesive, optical adhesive tape, and layered body

A technology of adhesive layer and adhesive, applied in the direction of adhesive type, ester copolymer adhesive, film/sheet adhesive, etc., which can solve the problems of transparent electrode degradation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~3

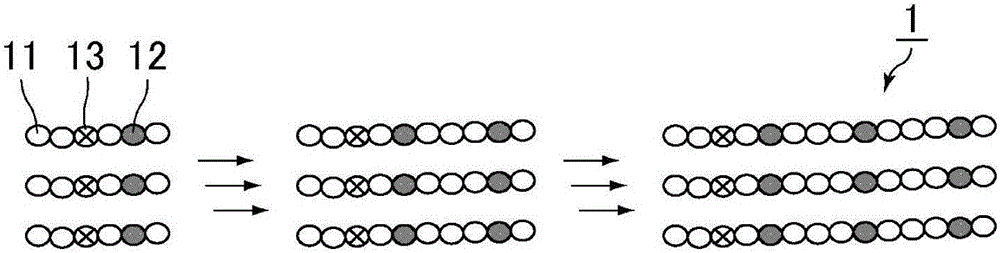

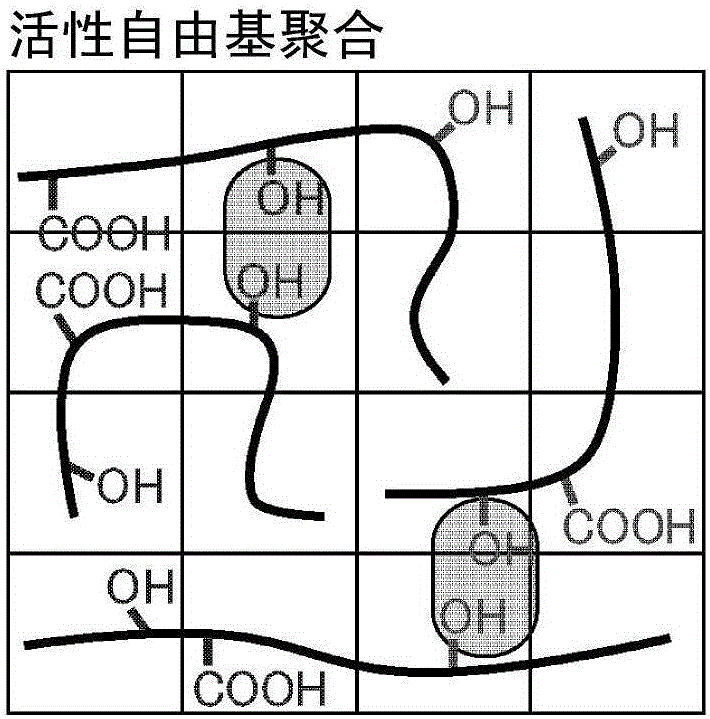

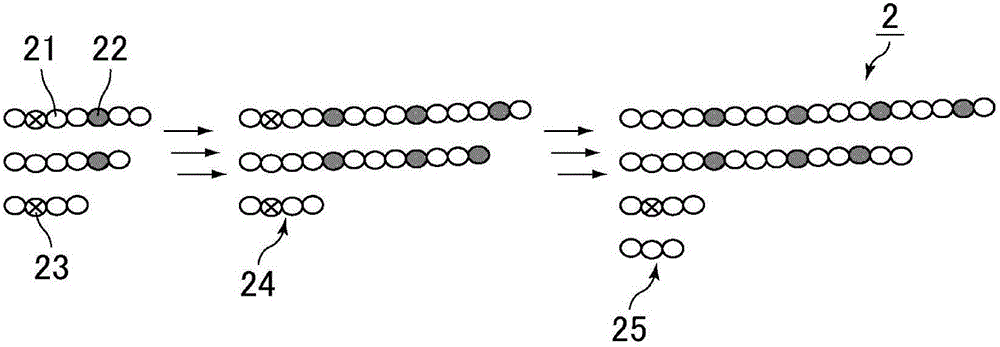

[0091] (1) Synthesis of Living Radical Polymerization (LRP)

[0092] 6.38 g (50 mmol) of Tellurium (40 mesh, metal tellurium, manufactured by Aldrich) was suspended in 50 mL of tetrahydrofuran (THF), and 1.6 mol / L of n-butyllithium / hexane was slowly dropped thereinto at room temperature. 34.4 mL (55 mmol) of alkane solution (manufactured by Aldrich). The reaction solution was stirred until the tellurium metal disappeared completely. To this reaction solution was added 10.7 g (55 mmol) of ethyl 2-bromo-isobutyrate at room temperature, followed by stirring for 2 hours. After the reaction, the solvent was concentrated under reduced pressure, followed by distillation under reduced pressure to obtain ethyl 2-methyl-2-n-butylhydrotelluryl-propionate as a yellow oil.

[0093] In a glove box replaced with argon, 38 μL of 2-methyl-2-n-butylhydrotelluryl-propionic acid ethyl ester, V-60 (2,2'- After 2.8 mg of azodiisobutyronitrile (manufactured by Wako Pure Chemical Industries, Ltd.)...

Embodiment 4

[0098] After preparing a solution containing a living radical polymerization polymer (LRP) in the same manner as in Example 1, 1.5 parts by weight of MITECNY260A (manufactured by Mitsubishi Gas Chemical Co., Ltd.) was added as a crosslinking agent with respect to 100 parts by weight of the copolymer solid content, After stirring, apply on the release-treated surface of a release polyethylene terephthalate (PET) film, and dry at 110°C for 10 minutes to remove ethyl acetate and form an adhesive layer with a thickness of 50 μm . In addition, the release film for protecting an adhesive layer was laminated|stacked on the surface of both sides of an adhesive layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com