PU protective film adhesive tape capable of automatically changing color and preparation method of adhesive tape

A protective film, discoloration technology, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc., can solve the problem that the protective film tape cannot be discolored, and achieves vision protection, excellent bubble removal effect, Small effect over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also discloses a preparation method of the PU protective film tape that can automatically change color, including the following steps:

[0024] (1) Glue preparation: the curing additives are diluted and dispersed with a solvent in a ratio of 1:1, then added to the polyurethane adhesive for stirring, and finally the coloring additives are added to stir and let it stand for 25-35min. Before adding the coloring additives, an antistatic agent is also added for stirring, and the polyurethane adhesive: solvent: curing additive: antistatic agent: coloring additive = (10-30): (0.1-0.5): (0.1-0.5): (0.5- 1): (1-5). The solvent is ETAC or butanone.

[0025] (2) Coating operation: The direct coating method is used to coat the surface of the transparent base film. The initial drying and curing treatment is carried out in an oven at 95℃-105℃ to form a color-changing polyurethane adhesive layer. The surface of the polyurethane adhesive layer is covered with a singl...

Embodiment 1

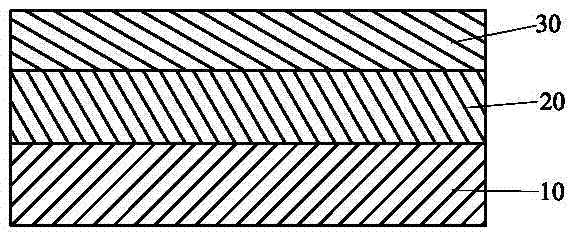

[0028] A specific structure of a PU protective film tape capable of changing colors automatically includes a transparent base film 10, a color changeable polyurethane adhesive layer 20, and a single-sided release film 30.

[0029] The color changeable polyurethane glue layer 20 is coated on the surface of the transparent base film 10, and the single-sided release film 30 is laminated on the surface of the color changeable polyurethane glue layer 20. Moreover, the transparent base film 10 is made of PET. The color changeable polyurethane adhesive layer 20 includes the following components by weight percentage: 80% polyurethane adhesive, 8% curing additive, and 12% coloring additive. The thickness of the color changeable polyurethane adhesive layer 20 is 10 μm. The single-sided release film 30 is made of PET.

[0030] The present invention also discloses a preparation method of the PU protective film tape that can automatically change color, including the following steps:

[0031] (1...

Embodiment 2

[0034] A specific structure of a PU protective film tape capable of changing colors automatically includes a transparent base film 10, a color changeable polyurethane adhesive layer 20, and a single-sided release film 30.

[0035] The color changeable polyurethane glue layer 20 is coated on the surface of the transparent base film 10, and the single-sided release film 30 is laminated on the surface of the color changeable polyurethane glue layer 20. Moreover, the transparent base film 10 is made of PET. The color-changing polyurethane adhesive layer 20 includes the following components by weight percentage: 93% polyurethane adhesive, 2% curing additives and 5% coloring additives, and the thickness of the color-changing polyurethane adhesive layer 20 is 5 μm. The single-sided release film 30 is made of PET.

[0036] The present invention also discloses a preparation method of the PU protective film tape that can automatically change color, including the following steps:

[0037] (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com