Method for producing alkali-free glass

An alkali-free glass, glass technology, applied in glass production and other directions, can solve problems such as strain point reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

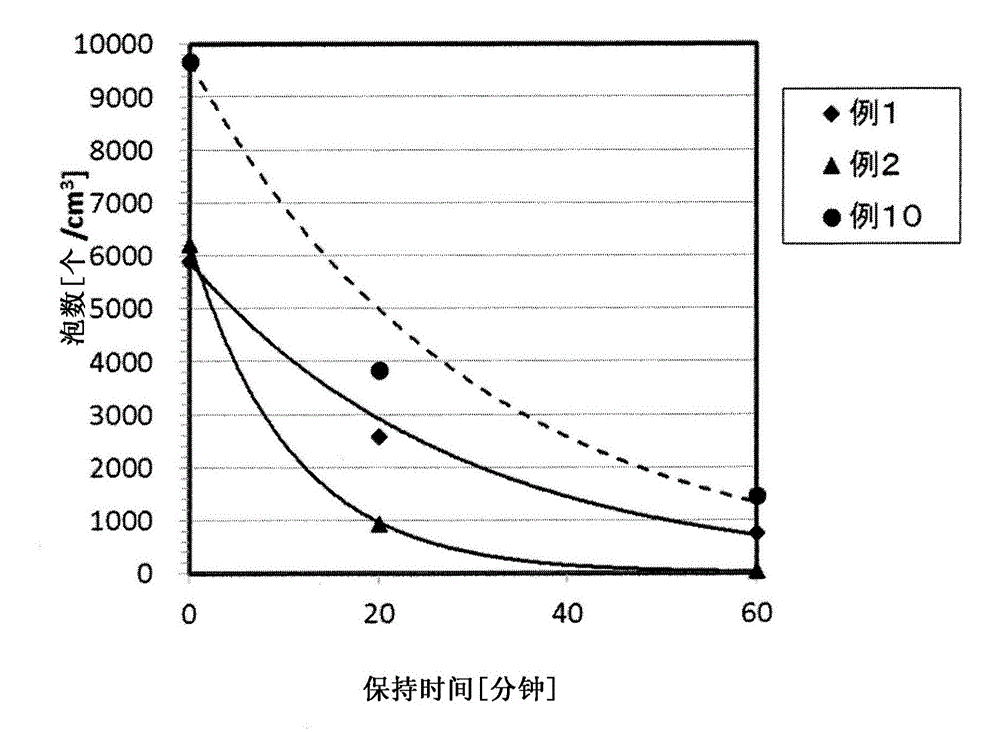

[0110] Raw materials were prepared to form glasses in Tables 1, 2, 4, and 5, and melted at a temperature of 1650° C. using a platinum crucible. At the time of melting, stirring was performed using a platinum stirrer to homogenize the glass. Next, the molten glass is poured out, shaped into a plate, and cooled slowly.

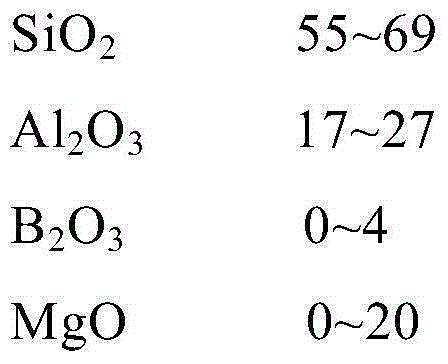

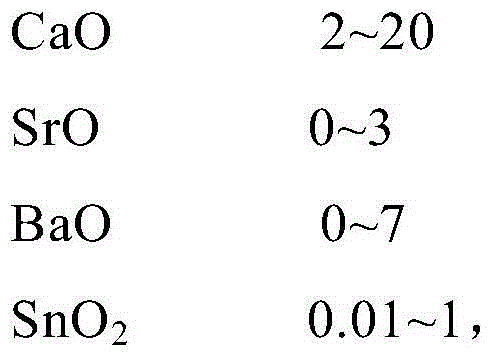

[0111] Tables 1, 2, 4, and 5 show the glass composition (unit: mass %), strain point (unit: °C) (measured by the fiber method described in JIS R3103), and glass transition of Examples 1 to 17. Temperature Tg (unit: °C), average coefficient of thermal expansion from 50 °C to 350 °C (unit: ×10 -7 / ℃), specific gravity (unit: g / cm 3 ) (measured by Archimedes method), Young's modulus (unit: GPa) (measured by ultrasonic method), specific modulus (unit: GPa·cm 3 / g), the temperature T that becomes the reference value of solubility as the high-temperature viscosity value 2 (glass viscosity η becomes 10 2 Poise temperature, unit: °C), and temperature T which become...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com