ZIF-L-based epoxy resin composite coating, preparation method and coating product

An epoxy resin coating, ZIF-L technology, applied in the field of coatings and surface coatings, can solve the problems of two-dimensional metal organic framework material ZIF-L layer cracking, weakening interaction, short timeliness, etc., and achieve excellent anti-corrosion performance , prevent biofouling, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] On the other hand, the embodiment of the present invention also proposes a method for preparing the above-mentioned ZIF-L-based epoxy resin composite coating, which mainly includes the following steps:

[0064] Step 1) Mix two-dimensional metal-organic framework material ZIF-L nanoparticles, 8-hydroxyquinoline-terminated aniline trimer, and a first solvent, perform ultrasonic treatment, and then wash and filter to obtain a filter cake.

[0065] This step is specifically: disperse the two-dimensional metal-organic framework material ZIF-L nanoparticles in the first solvent, then add 8-hydroxyquinoline-terminated aniline trimer to it, perform ultrasonic treatment, and wash with deionized water for several times After centrifugation and removal of the first solvent, a filter cake is obtained.

[0066] The first solvent is selected from one or a combination of N,N-dimethylformamide and N,N-dimethylacetamide.

[0067] In this step, the two-dimensional metal organic framewor...

Embodiment 1

[0083] The present embodiment prepares a kind of epoxy resin composite coating based on ZIF-L, mainly comprises the following steps:

[0084] 1) Preparation of two-dimensional metal organic framework material ZIF-L nanoparticles:

[0085] 0.4g Zn(NO 3 ) 2 ·6H 2 O and 1.1 g of 2-methylimidazole were respectively dissolved in 10 mL of deionized water; then an aqueous solution of zinc nitrate was added to an aqueous solution of 2-methylimidazole to obtain a mixture; the mixture was vigorously stirred at room temperature for 2 hours. The resulting white precipitate was collected by repeated centrifugation at 8000 rpm for 30 min, washed three times with water and methanol, and dried overnight in an oven at 65 °C to obtain white powder two-dimensional metal organic framework material ZIF-L nanoparticles.

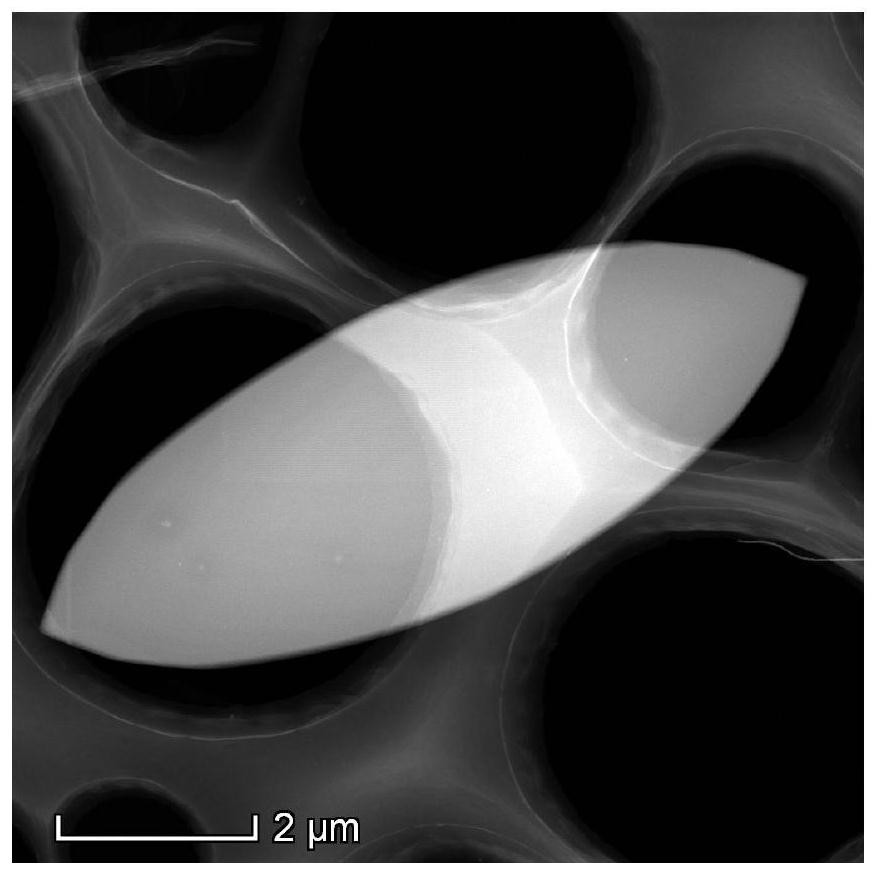

[0086] Such as figure 1 As shown, the two-dimensional metal organic framework material ZIF-L nanoparticles prepared in this example are in the shape of two-dimensional leaves....

Embodiment 2

[0096] The present embodiment prepares a kind of epoxy resin composite coating based on ZIF-L, mainly comprises the following steps:

[0097] 1) Preparation of two-dimensional metal organic framework material ZIF-L nanoparticles:

[0098] This step is completely consistent with step 1) of Example 1.

[0099] 2) Preparation of 8-hydroxyquinoline-terminated aniline trimer (QAAT):

[0100] This step is completely consistent with step 2) of Example 1.

[0101] 3) prepare the epoxy resin composite coating based on ZIF-L:

[0102] Disperse 0.5g of two-dimensional metal-organic framework material ZIF-L nanoparticles in 20mL of N,N-dimethylformamide, and add 0.25g of 8-hydroxyquinoline-terminated aniline trimer (QAAT) to it, Ultrasonic disperse for 10 minutes, wash and centrifuge with 50 mL deionized water to obtain a filter cake. The filter cake was ultrasonically dispersed in 20 mL of ethanol for 10 minutes to form a dispersion. Add the prepared dispersion to 72.93g of epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com