Antibacterial HDPE plastic

A technology of plastics and antibacterial agents, which is applied in the field of antibacterial HDPE plastics and its preparation, can solve problems such as environmental pollution, unstable quality, and low antibacterial activity, and achieve broad application prospects, simple preparation methods, and improved antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

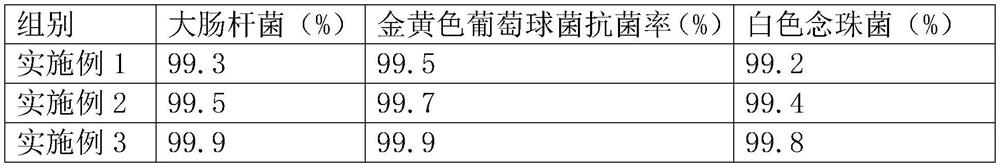

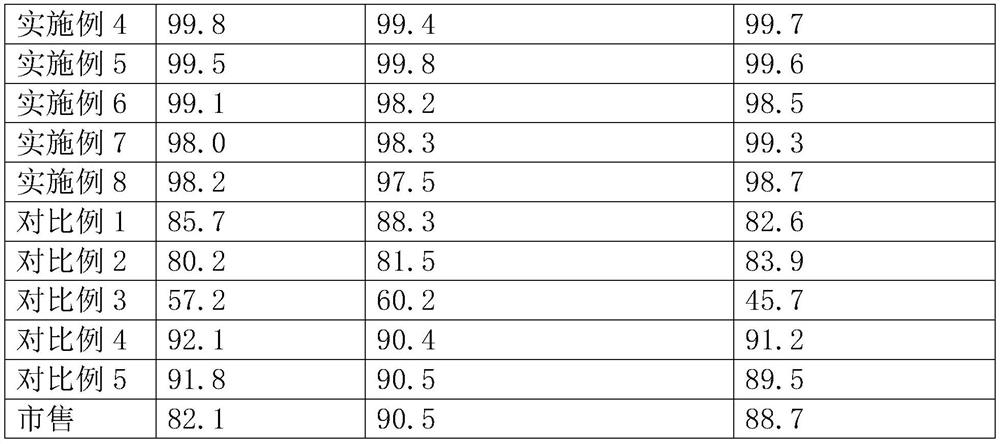

Examples

preparation example 1

[0037] Antibacterial agent enhanced HDPE is prepared by the following methods:

[0038] Dissolve 10g of PVC in 250mL of DMF solvent, raise the temperature to 100°C and drop into 50mL of DMF solution containing 1g of triisopropanolamine, reflux reaction in nitrogen atmosphere for 2h, after the reaction is over, add 100g of HDPE and stir to dissolve, stir After reacting for 0.5h, the mixed solution was poured into 10 times the volume of distilled water to precipitate the product. After suction filtration and drying, the product was sent to the twin-screw extrusion granulation through the feeding funnel, and then extruded by parallel twin-screws to form The particle temperature is 180°C, the screw speed is 400r / min, and finally water-cooled and shaped to obtain antibacterial agent-enhanced HDPE.

preparation example 2

[0040] Antibacterial agent enhanced HDPE is prepared by the following methods:

[0041] Dissolve 10g of PVC in 250mL of DMF solvent, raise the temperature to 150°C, drop into 50mL of DMF solution containing 5g of tributylphosphine, and reflux for 5 hours in a nitrogen atmosphere. After the reaction, add 100g of HDPE and stir to dissolve. After 1h, the mixed solution was poured into 10 times the volume of distilled water to precipitate the product. After suction filtration and drying, the product was sent into the twin-screw extrusion granulation through the feeding funnel, and then extruded by parallel twin-screw. The temperature is 200°C, the screw speed is 500r / min, and finally water-cooled and shaped to obtain antibacterial agent-enhanced HDPE.

preparation example 3

[0043] Antibacterial agent enhanced HDPE is prepared by the following methods:

[0044] Dissolve 10g of PVC in 250mL of DMF solvent, raise the temperature to 125°C and drop into 50mL of DMF solution containing 3g of tri-n-butylamine, reflux reaction in nitrogen atmosphere for 3.5h, after the reaction, add 100g of HDPE and stir to dissolve, stir After reacting for 0.75h, the mixed solution was poured into 10 times the volume of distilled water to precipitate the product. After suction filtration and drying, the product was sent into the twin-screw extrusion granulation through the feeding funnel, and then extruded by parallel twin-screws to form The particle temperature is 190°C, the screw speed is 450r / min, and finally water-cooled and shaped to obtain antibacterial agent-enhanced HDPE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com