LDPE (low-density polyethylene) antibacterial plastic and preparation method therefor

A technology of antibacterial plastics and plasticizers, applied in the field of polymers, can solve problems such as short service life, poor heat resistance, and poor safety, and achieve excellent processing performance, super antibacterial properties, and undemanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

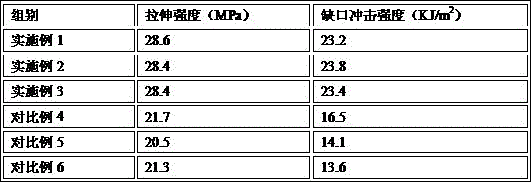

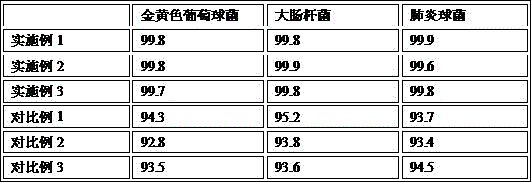

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of a kind of LDPE antibacterial plastic

[0029] Ingredients: 120 parts of low-density polyethylene, 4 parts of isothiazolinone, 3 parts of polyhexamethyleneguanidine, 4 parts of betaine, 3 parts of nano-zinc oxide powder, 4 parts of nano-titanium dioxide, 1 part of zinc stearate, white 1.5 parts of oil, 2 parts of coupling agent, 1 part of oleic acid amide, 0.5 parts of ethylene-octene copolymer, 0.7 parts of antioxidant, 2 parts of random copolymer of styrene and maleic anhydride, 1 part of plasticizer The coupling agent is a combination of titanate coupling agent and silane coupling agent, the ratio of the two is 2:1; the plasticizer is triethyl citrate; the antioxidant is 4,4'-thio Combination of bis(6-tert-butyl-3-methylphenol) and sodium tripolyphosphate, the ratio of the two is 1:1;

[0030] Preparation includes the following steps:

[0031] (1) Premixing isothiazolinone, polyhexamethyleneguanidine, betaine and antioxidant to obtai...

Embodiment 2

[0034] Embodiment 2: the preparation of a kind of LDPE antibacterial plastic

[0035] Ingredients: 100 parts of low-density polyethylene, 3 parts of isothiazolinone, 2 parts of polyhexamethyleneguanidine, 2 parts of betaine, 2 parts of nano-zinc oxide powder, 3 parts of nano-titanium dioxide, 0.5 parts of zinc stearate, white 0.5 parts of oil, 0.5 parts of coupling agent, 0.5 parts of oleic acid amide, 0.1 parts of ethylene-octene copolymer, 0.5 parts of antioxidant, 0.1 parts of random copolymer of styrene and maleic anhydride, 0.5 parts of plasticizer The coupling agent is a combination of titanate coupling agent and silane coupling agent, the ratio of the two is 2:1; the plasticizer is triethyl citrate; the antioxidant is 4,4'-thio Combination of bis(6-tert-butyl-3-methylphenol) and sodium tripolyphosphate, the ratio of the two is 1:1;

[0036] Preparation includes the following steps:

[0037] (1) Premixing isothiazolinone, polyhexamethyleneguanidine, betaine and antioxi...

Embodiment 3

[0040] Embodiment 3: the preparation of a kind of LDPE antibacterial plastic

[0041] Ingredients: 150 parts of low-density polyethylene, 5 parts of isothiazolinone, 5 parts of polyhexamethyleneguanidine, 5 parts of betaine, 5 parts of nano-zinc oxide powder, 5 parts of nano-titanium dioxide, 2 parts of zinc stearate, white 2 parts of oil, 5 parts of coupling agent, 2 parts of oleic acid amide, 1 part of ethylene-octene copolymer, 1 part of antioxidant, 3 parts of random copolymer of styrene and maleic anhydride, 2 parts of plasticizer The coupling agent is a combination of titanate coupling agent and silane coupling agent, the ratio of the two is 2:1; the plasticizer is triethyl citrate; the antioxidant is 4,4'-thio Combination of bis(6-tert-butyl-3-methylphenol) and sodium tripolyphosphate, the ratio of the two is 1:1;

[0042] Preparation includes the following steps:

[0043] (1) Premixing isothiazolinone, polyhexamethyleneguanidine, betaine and antioxidant to obtain a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com