Foamed glass material for purifying water, and preparation method thereof

A technology for foaming glass and purifying water, which is applied in glass manufacturing equipment, chemical instruments and methods, and glass molding, etc. It can solve the problems of economic constraints and high cost of activated carbon, and achieve high performance and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] S1, 8.4 kg of glass powder with a particle size of 500 μm, 0.042 kg of activated carbon with a particle size of 400 μm, 0.033 kg of shell powder with a particle size of 2 to 4 mm, and 0.05 kg of shell powder with a particle size of less than 1 mm were mixed and stirred to prepare a foaming mixture.

[0046] S2, spread the foam mixture prepared above in a heating furnace with a height of 20 mm, and the foam mixture goes through three stages of preheating, foaming and sintering in the heating furnace, and then naturally cools to normal temperature after taking it out from the heating furnace to obtain Foamed microporous sillicite for water purification; the preheating temperature is 830°C, the preheating time is 15 minutes; the foaming temperature is 920°C, the foaming time is 10 minutes, the sintering temperature is 850°C, and the sintering time is 10 minutes minute.

[0047]S3, taking the sintered and foamed heating material out of the heating furnace and then cooling i...

Embodiment 2

[0049] S1, mixing and stirring 9.5 kg of glass powder with a particle size of 900 μm, 0.047 kg of activated carbon with a particle size of 300 μm, 0.038 kg of shell powder with a particle size of 2 to 4 mm, and 0.057 kg of shell powder with a particle size of less than 1 mm to prepare a foaming mixture;

[0050] S2, spread the foam mixture prepared above in a heating furnace with a height of 20 mm, and the foam mixture goes through three stages of preheating, foaming and sintering in the heating furnace, and then it is taken out from the heating furnace and naturally cooled to normal temperature to obtain Foamed microporous silica pumice for water purification; the preheating temperature is 880°C and the preheating time is 30 minutes; the foaming temperature is 950°C and the foaming time is 20 minutes; the sintering temperature is 900°C and the sintering time is 15 minutes .

[0051] S3, take the sintered and foamed heating material out of the heating furnace and cool it down ...

Embodiment 3

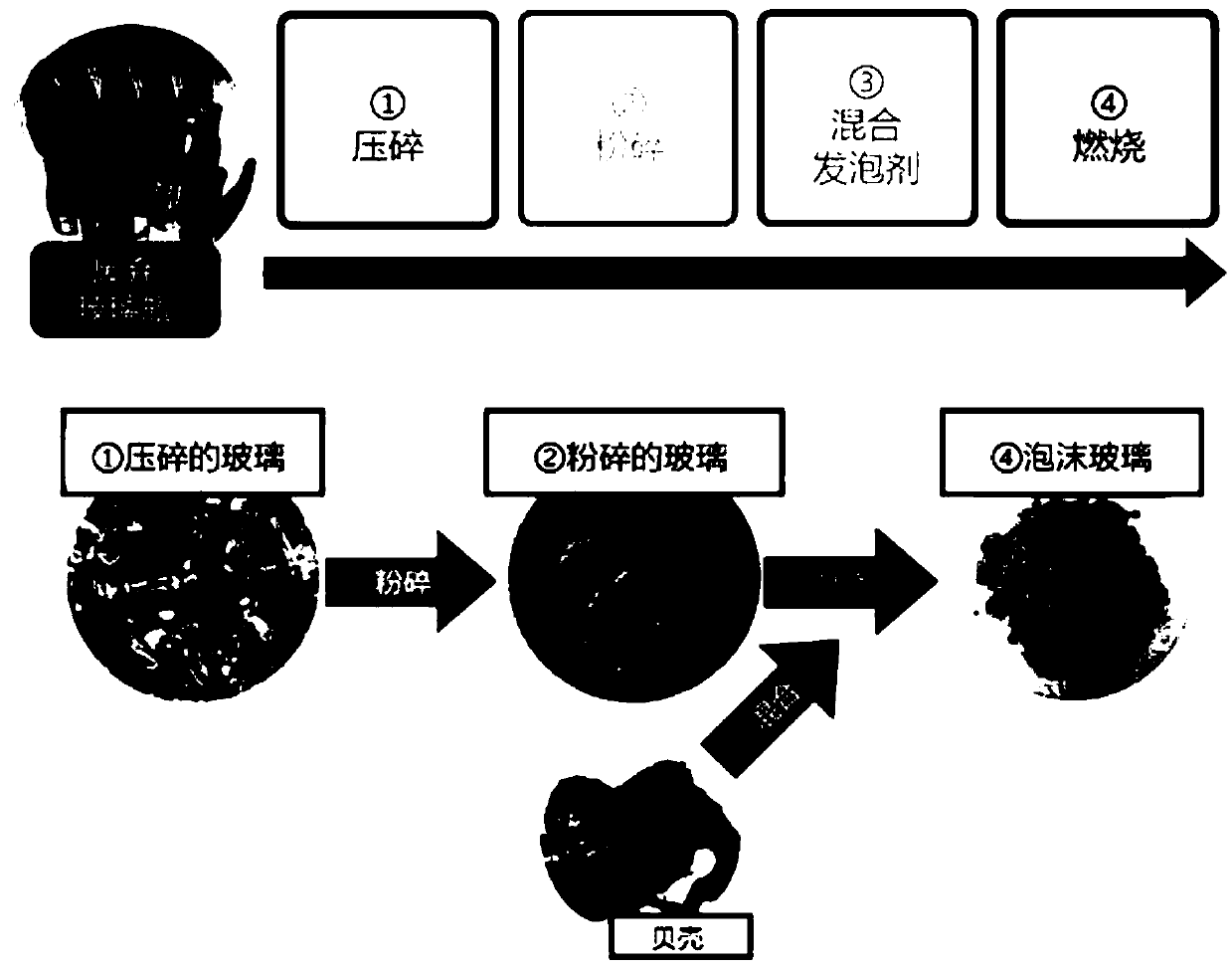

[0053] This embodiment combines the attached figure 1 , 2 The preparation method and the principle of water purification of the present invention are described.

[0054] Such as figure 1 Shown, preparation method of the present invention comprises:

[0055] Select a discarded glass bottle, rinse it clean and do:

[0056] Step 1: crushing to obtain crushed glass;

[0057] Step 2: crushing, further crushing the crushed glass to obtain glass powder, the particle size of the glass powder should be below 1mm.

[0058] Step 3: Mix glass powder, shell powder with a particle size of 2-4 mm, shell powder with a particle size of less than 1 mm, and activated carbon with a particle size of less than 500 μm according to the formula ratio.

[0059] Process 4: After three stages of preheating, foaming and sintering, it is taken out from the heating furnace and then cooled naturally to room temperature to obtain a water-purified foamed glass material: foamed microporous silica pumice. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com