Imide polypropylene beta crystalline form nucleating agent and preparation method thereof

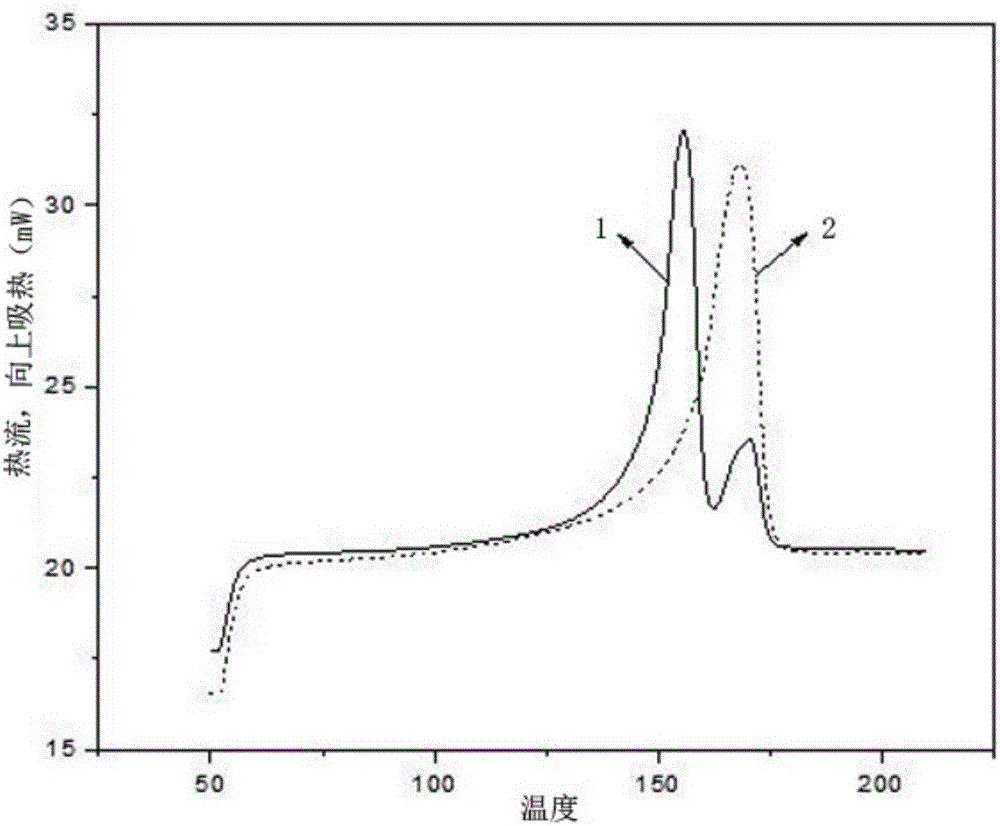

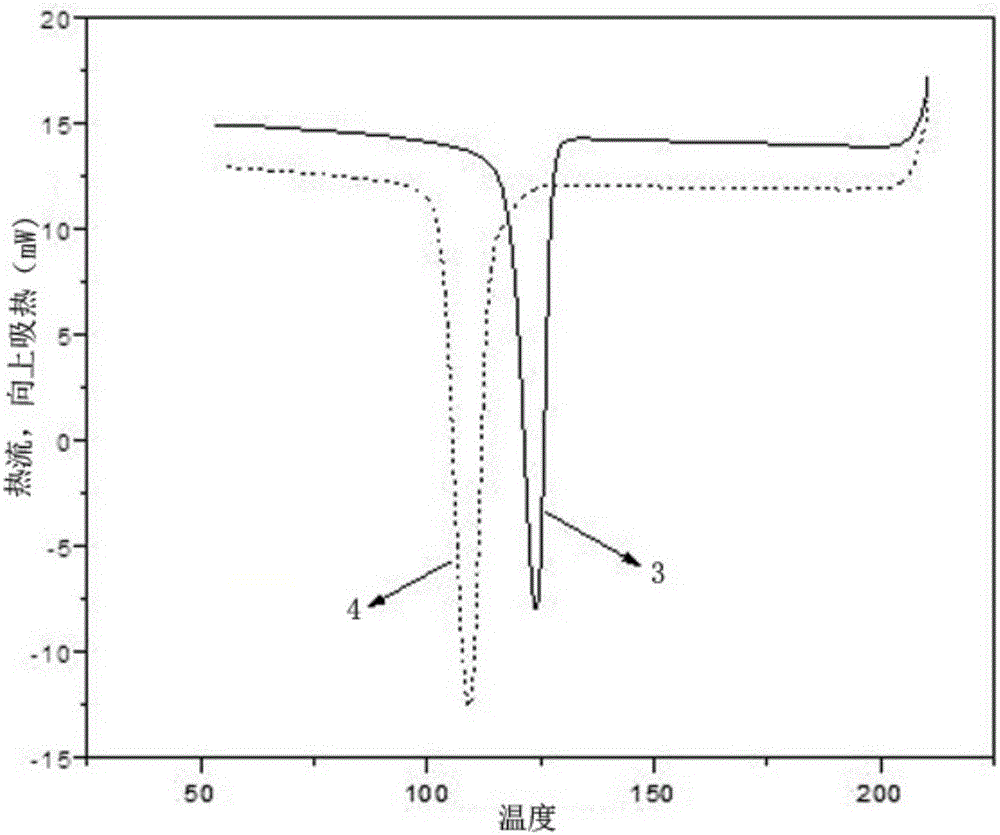

A polypropylene, beta crystal technology, applied in the direction of organic chemistry, etc., can solve problems such as unfavorable production and application, complex synthesis process, etc., and achieve the effects of improving impact strength, simple synthesis steps, and easy dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

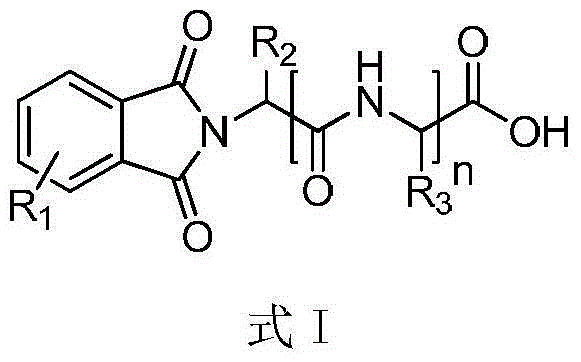

[0031] After melting 0.06 mol of commercially available phthalic anhydride, add 2 mL of ethylenediamine, then add 0.05 mol of α-amino β-imidazolylpropionic acid, stir for 4 hours and recrystallize, then add 120 mL of ethyl acetate, Place the flask in an ice-water bath at -10-10°C, add 0.15mL of triethylamine, and slowly add 20.0g of isobutyl chloroformate, after reacting for 2 hours, add 0.15mol of glycine that has been cooled to -10-10°C in advance and 20mL aqueous sodium hydroxide solution, stirred for a period of time under ice-water bath conditions, then removed the ice-water bath, reacted at room temperature for 2 hours, the reaction solution was allowed to stand and separated, the water layer was acidified with concentrated hydrochloric acid, and the precipitated solid was recrystallized with ethanol-water solution to obtain The imide polypropylene beta crystal nucleating agent of the following structural formula:

[0032]

Embodiment 2

[0034] After melting 0.06mol of commercially available phthalic anhydride, add 2mL of ethylenediamine, then add 0.05mol of aminoacetic acid, stir and react for 8 hours, then recrystallize, then add 120mL of ethyl acetate, and place the flask at -10~ In an ice-water bath at 10°C, add 0.15mL triethylamine, and slowly add 20.0g isobutyl chloroformate. After 10 hours of reaction, add 0.15mol glycine that has been cooled to -10-10°C and 180mL aqueous sodium hydroxide solution. After stirring in an ice-water bath for a period of time, remove the ice-water bath and react at room temperature for 24 hours. The reaction solution is allowed to stand and separate into layers, the water layer is acidified with acetic acid, and the precipitated solid is directly filtered with water to obtain the imide polypropylene β crystal form with the following structural formula Nucleating agent:

[0035]

Embodiment 3

[0037] After melting 0.06 mol of commercially available phthalic anhydride, add 2 mL of ethylenediamine, then add 0.05 mol of phenylalanine, stir and react for 6 hours, then recrystallize, then add 120 mL of ethyl acetate, and place the flask in - In an ice-water bath at 10-10°C, add 0.15mL triethylamine, and slowly add 20.0g isobutyl chloroformate. After 5 hours of reaction, add 0.15mol glycine that has been cooled to -10-10°C in advance and 100mL sodium hydroxide Aqueous solution, after stirring for a period of time under the condition of ice-water bath, then remove the ice-water bath, react at room temperature for 10 hours, the reaction solution is allowed to stand for stratification, the water layer is acidified with concentrated hydrochloric acid, and the precipitated solid is recrystallized with ethanol-water solution to obtain the imide of the following structural formula Polypropylene-like β-crystal nucleating agent:

[0038] Hereinafter, for convenience of descripti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com