A self-cleaning super weather-resistant powder coating and its preparation method

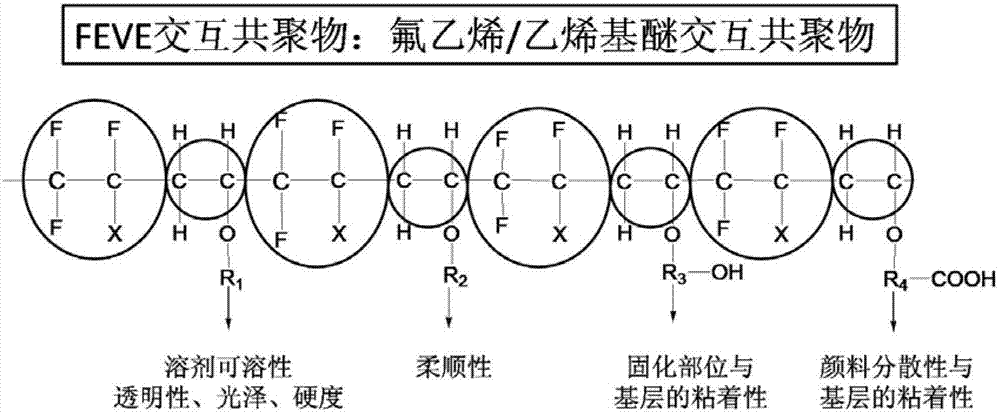

A powder coating, super weather-resistant technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of complex fluorocarbon resin treatment process, poor adhesion of substrate materials, etc., to shorten the pretreatment process, protect and anti-aging , Not easy to crack and peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The self-cleaning super-weather-resistant powder coating described in this example is obtained by dry mixing a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system at a weight-to-number ratio of 1:1.

[0059] The carboxyl-terminated polyester particle system includes the following components by weight:

[0060] Carboxyl-terminated polyester and its suitable curing agent A60 parts; among them, the carboxyl-terminated polyester is UralacP2400, 55.8 parts, and the corresponding curing agent is triglycidyl isocyanurate TGIC (purchased from Ningbo Nanhai Chemical Co., Ltd.), 4.2 share;

[0061] 39.9 parts of pigments and fillers;

[0062] Among them, carbon black pigment FW200 is 0.8 parts, barium sulfate W-44HB is 38.9 parts;

[0063] Auxiliary A is 0.1 part;

[0064] Auxiliary A is a flow aid AluC.

[0065] The fluorocarbon resin particle system consists of the following components by weight:

[0066] Fluorocarbon resin and its matc...

Embodiment 2

[0078] The self-cleaning super-weather-resistant powder coating described in this example is obtained by dry mixing a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system at a weight-to-number ratio of 1:1.

[0079] The carboxyl-terminated polyester particle system includes the following components by weight:

[0080] Carboxyl-terminated polyester and its suitable curing agent A63 parts; wherein the selected carboxyl-terminated polyester is UralacP780, 60 parts, and the carboxyl-terminated polyester curing agent is hydroxyalkylamide XL552, for 3 servings.

[0081] 36.7 parts of pigments and fillers, including 26 parts of titanium dioxide CR826 and 10.7 parts of barium sulfate W-44HB;

[0082] Auxiliary A is 0.3 part;

[0083] Auxiliary A is a flow aid AluC, 0.3 phr.

[0084] The fluorocarbon resin particle system consists of the following components by weight:

[0085] Fluorocarbon resin and its matching curing agent B50.7 parts;

[00...

Embodiment 3

[0097] The self-cleaning super-weather-resistant powder coating described in this example is obtained by dry mixing a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system at a ratio of parts by weight of 4:1.

[0098] The carboxyl-terminated polyester particle system includes the following components by weight:

[0099] Carboxyl-terminated polyester and its suitable curing agent A40 parts, wherein the selected carboxyl-terminated polyester is Crylcoat TM E04131, 36 parts, the corresponding curing agent is triglycidyl isocyanurate TGIC (purchased from Ningbo Nanhai Chemical Co., Ltd.), 4 parts.

[0100] 50 parts of pigments and fillers, iron red For 36 parts, aluminum hydroxide such as for 14 copies;

[0101] Additive A is 10 parts, wherein, corner coverage modifier parts, curing accelerator BASF2-MI2 parts, wetting and dispersing agent share.

[0102] The fluorocarbon resin particle system consists of the following components by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com