PP antibacterial plastic and preparation method thereof

An antibacterial plastic and plasticizer technology, applied in the polymer field, can solve the problems of short service life, poor heat resistance, poor safety, etc., and achieve the effects of simple and convenient operation, super antibacterial properties, and low requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

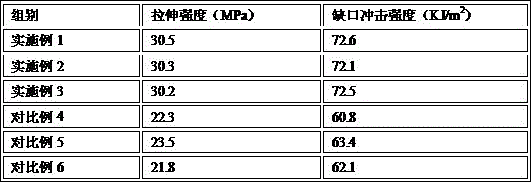

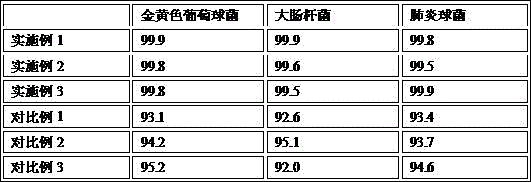

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of a kind of PP antibacterial plastic

[0029] Ingredients: 120 parts of polypropylene, 4 parts of dodecyltrimethylammonium chloride, 3 parts of chitosan, 4 parts of betaine, 3 parts of nano-zinc oxide powder, 4 parts of nano-calcium oxide, 1 part of zinc stearate , 1.5 parts of white oil, 2 parts of coupling agent, 1 part of nonylphenol polyoxyethylene ether, 0.5 parts of ethylene-octene copolymer, 0.7 parts of antioxidant, 2 parts of random copolymer of styrene and maleic anhydride , 1 part of plasticizer; coupling agent is a combination of titanate coupling agent and silane coupling agent, the ratio of the two is 2:1; plasticizer is triethyl citrate; antioxidant is 4 , a combination of 4′-thiobis(6-tert-butyl-3-methylphenol) and sodium tripolyphosphate, the ratio of the two is 1:1;

[0030] Preparation includes the following steps:

[0031] (1) Premixing dodecyltrimethylammonium chloride, chitosan, betaine and antioxidant to obtain a p...

Embodiment 2

[0034] Embodiment 2: the preparation of a kind of PP antibacterial plastic

[0035] Ingredients: 100 parts of polypropylene, 3 parts of lauryltrimethylammonium chloride, 2 parts of chitosan, 2 parts of betaine, 2 parts of nano-zinc oxide powder, 3 parts of nano-calcium oxide, 0.5 part of zinc stearate , 0.5 parts of white oil, 0.5 parts of coupling agent, 0.5 parts of nonylphenol polyoxyethylene ether, 0.1 parts of ethylene-octene copolymer, 0.5 parts of antioxidant, 0.1 part of random copolymer of styrene and maleic anhydride , 0.5 parts of plasticizer; coupling agent is a combination of titanate coupling agent and silane coupling agent, the ratio of the two is 2:1; plasticizer is triethyl citrate; antioxidant is 4 , a combination of 4′-thiobis(6-tert-butyl-3-methylphenol) and sodium tripolyphosphate, the ratio of the two is 1:1;

[0036] Preparation includes the following steps:

[0037] (1) Premixing dodecyltrimethylammonium chloride, chitosan, betaine and antioxidant to ...

Embodiment 3

[0040] Embodiment 3: the preparation of a kind of PP antibacterial plastic

[0041] Ingredients: 150 parts of polypropylene, 5 parts of lauryltrimethylammonium chloride, 5 parts of chitosan, 5 parts of betaine, 5 parts of nano zinc oxide powder, 5 parts of nano calcium oxide, 2 parts of zinc stearate , 2 parts of white oil, 5 parts of coupling agent, 2 parts of nonylphenol polyoxyethylene ether, 1 part of ethylene-octene copolymer, 1 part of antioxidant, 3 parts of random copolymer of styrene and maleic anhydride , plasticizer 2 parts; coupling agent is a combination of titanate coupling agent and silane coupling agent, the ratio of the two is 2:1; plasticizer is triethyl citrate; antioxidant is 4 , a combination of 4′-thiobis(6-tert-butyl-3-methylphenol) and sodium tripolyphosphate, the ratio of the two is 1:1;

[0042] Preparation includes the following steps:

[0043] (1) Premixing dodecyltrimethylammonium chloride, chitosan, betaine and antioxidant to obtain a premixed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com