Long-acting broad-spectrum antibiotic polypropylene plastic and method for preparing the same

An antibacterial polypropylene and polypropylene technology, applied in the field of long-acting broad-spectrum antibacterial polypropylene plastics and its preparation, can solve the problems of long time consumption, high possibility of decomposition, difficulty in large-scale production, etc., and achieve good finish and easy operation Simple, convenient and low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] a. 0.5g zinc pyrithione (particle diameter 50nm) and 0.5g antioxidant 1010 are premixed;

[0044] b. blend the premix obtained in a with 100g polypropylene on a high-speed mixer (rotating speed is 3000r / min), add 1g dispersant liquid paraffin during the blending process, and mix for 3 minutes at normal temperature;

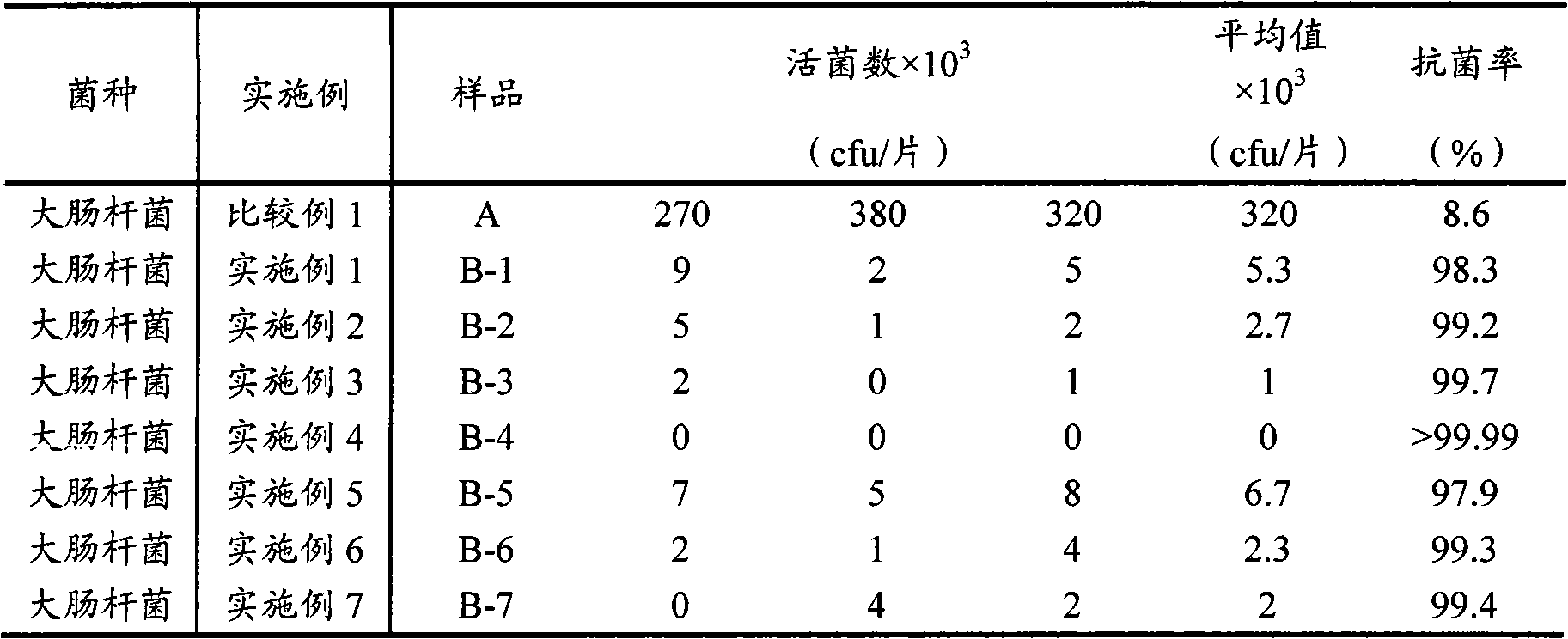

[0045] c. Extrude and granulate the mixture obtained in b through parallel twin-screws, the processing temperature is 200°C, the screw speed is 400r / min, and then the pellets are baked at 80°C for 12 hours to obtain a compound with high-efficiency broad-spectrum antibacterial properties Polypropylene plastic, see Table 1 for antibacterial properties.

Embodiment 2

[0047] a. Premix 1g zinc pyrithione (50nm particle size) with 0.5g antioxidant 1010;

[0048] b. blend the premix obtained in a with 100g polypropylene on a high-speed mixer (rotating speed is 3000r / min), add 1g dispersant liquid paraffin during the blending process, and mix for 3 minutes at normal temperature;

[0049] c. The mixture obtained in b is extruded and granulated through parallel twin-screws, the processing temperature is 180°C, the screw speed is 400r / min, and the pellets are dried at 80°C for 12 hours to obtain a compound with high-efficiency broad-spectrum antibacterial properties Polypropylene plastic, see Table 1 for antibacterial properties.

Embodiment 3

[0051] a. Premix 1.5g zinc pyrithione (50nm particle size) with 0.5g antioxidant 1010;

[0052] b. blend the premix obtained in a with 100g polypropylene on a high-speed mixer (rotating speed is 3000r / min), add 1g dispersant liquid paraffin during the blending process, and mix for 3 minutes at normal temperature;

[0053] c. Extrude and granulate the mixture obtained in b through parallel twin-screws, the processing temperature is 200°C, the screw speed is 400r / min, and then the pellets are baked at 80°C for 12 hours to obtain a compound with high-efficiency broad-spectrum antibacterial properties Polypropylene plastic, see Table 1 for antibacterial properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com