Welding wheel mounting mechanism of narrow lap seam welder

An installation mechanism and lap joint technology, applied in welding equipment, resistance welding equipment, roller electrode welding, etc., can solve the problems of unusable, broken thread, damaged mandrel and welding wheel, etc., to improve the overall installation strength , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, specific embodiment of the present invention is elaborated:

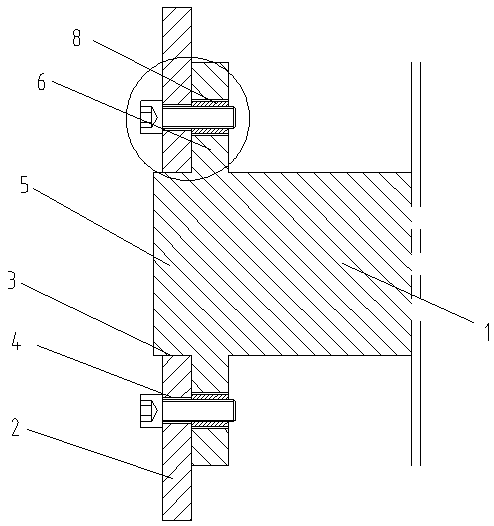

[0015] Such as figure 1 As shown, the welding wheel installation mechanism of a narrow lap seam welding machine disclosed by the present invention includes a mandrel 1 and a welding wheel body 2 installed on the mandrel 1 .

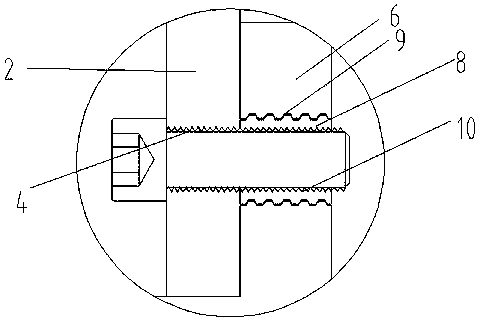

[0016] Specifically, the welding wheel body 2 has a central axis hole 3, and a plurality of fixed threaded holes 4 are distributed in the circumferential direction of the disk surface of the welding wheel body 2, and there are toothed internal threads in the threaded fixing holes, and the mandrel includes The shaft head 5 and the mounting flange surface 6, the welding wheel body 2 is set on the shaft head 5 through the central shaft hole 3, and the side is attached to the mounting flange surface 6, and the position of the fixed threaded hole corresponding to the circumferential direction of the mounting flange surface is the same A fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com