Nanodiamondene-containing electricity-conducting and heat-conducting electronic paste and preparation method thereof

A nanodiamondene, electrical and thermal conduction technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, heat exchange materials, chemical instruments and methods, etc., can solve the problem of inability to meet the heat conduction requirements of electronic components and low thermal conductivity , conductivity decline and other issues, to achieve the effect of high hardness, good thermal conductivity and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of conductive and thermally conductive electronic paste containing nano-diamantene, prepared by adding glass powder in the slurry matrix, the slurry matrix is composed of silver-plated copper powder and nano-diamantene, when the amount of silver-plated copper powder is 70g , the amount of nanodiamondene is 1g, and the amount of glass powder added is 5% of the weight of the slurry matrix.

[0034] Its preparation method comprises the following steps:

[0035] 1) Stir and mix the nanodiamondene and silver-plated copper powder, the stirring speed is 40rpm, and the stirring time is 10min; the nanodiamondene is selected from four different particle sizes of 50nm, 100nm, 200nm, and 250nm, and its mass ratio is controlled is 1:2:3:4;

[0036]2) Pour the mixed nanodiamondene and silver-plated copper powder into a dilute sulfuric acid solution with a mass concentration of 5%, and ultrasonically clean it for 25 minutes at an ultrasonic frequency of 30KHz; after ultrason...

Embodiment 2

[0046] A kind of conductive and thermally conductive electronic paste containing nano-diamantene, made by adding glass powder in the slurry matrix, the slurry matrix is composed of silver-plated copper powder and nano-diamantene, when the amount of silver-plated copper powder is 80g , the amount of nanodiamondene is 10g, and the amount of glass powder added is 10% of the weight of the slurry matrix.

[0047] The preparation method of the described conductive and thermally conductive electronic paste containing nano-diamondene comprises the following steps:

[0048] 1) Stir and mix the nanodiamondene and silver-plated copper powder, the stirring speed is 60rpm, and the stirring time is 10min; the nanodiamondene is selected from four different particle sizes of 50nm, 100nm, 200nm, and 250nm, and its mass ratio is controlled is 2:3:4:5;

[0049] 2) Pour the mixed nanodiamondene and silver-plated copper powder into a dilute sulfuric acid solution with a mass concentration of 10...

Embodiment 3

[0059] A kind of conductive and thermally conductive electronic paste containing nano-diamantene, made by adding glass powder in the slurry matrix, the slurry matrix is composed of silver-plated copper powder and nano-diamantene, when the amount of silver-plated copper powder is 80g , the amount of nanodiamondene is 5g, and the amount of glass powder added is 6% of the weight of the slurry matrix.

[0060] The preparation method of the described conductive and thermally conductive electronic paste containing nano-diamondene comprises the following steps:

[0061] 1) Stir and mix the nanodiamondene and silver-plated copper powder, the stirring speed is 50rpm, and the stirring time is 8min; the nanodiamondene is selected from four different particle sizes of 50nm, 100nm, 200nm, and 250nm, and its mass ratio is controlled is 2:2:4:5;

[0062] 2) Pour the mixed nanodiamondene and silver-plated copper powder into a dilute sulfuric acid solution with a mass concentration of 8%, a...

PUM

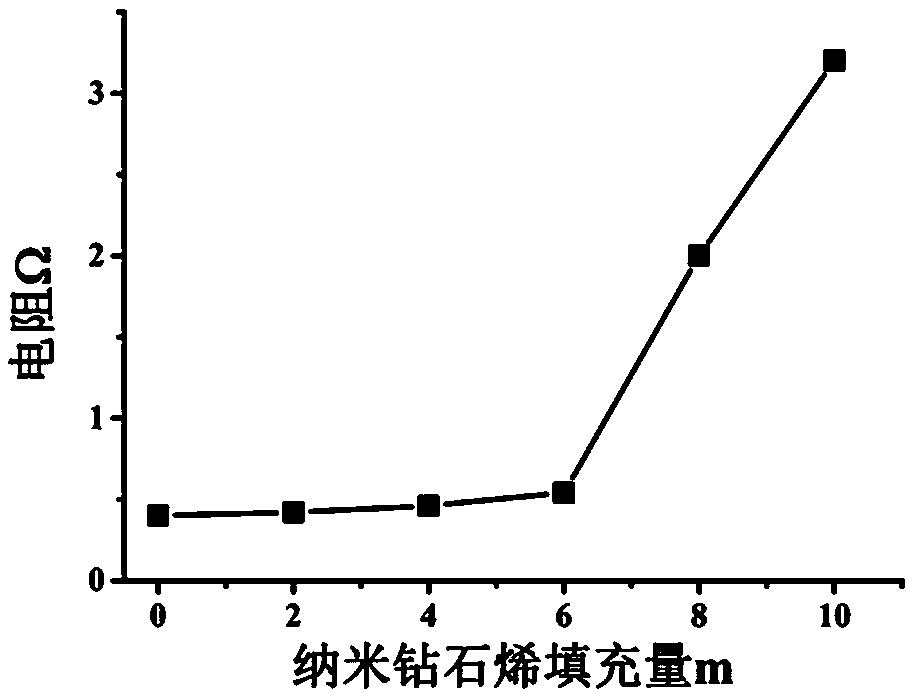

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com