Lithium battery electrode and dry preparation method and application thereof

A lithium battery, dry process technology, applied in the field of materials, can solve problems such as poor applicability, high requirements for hot pressing process, and it is difficult for ordinary equipment to meet the requirements of process pressure, so as to achieve unaffected conductivity and good cycle stability. The effect of stability and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

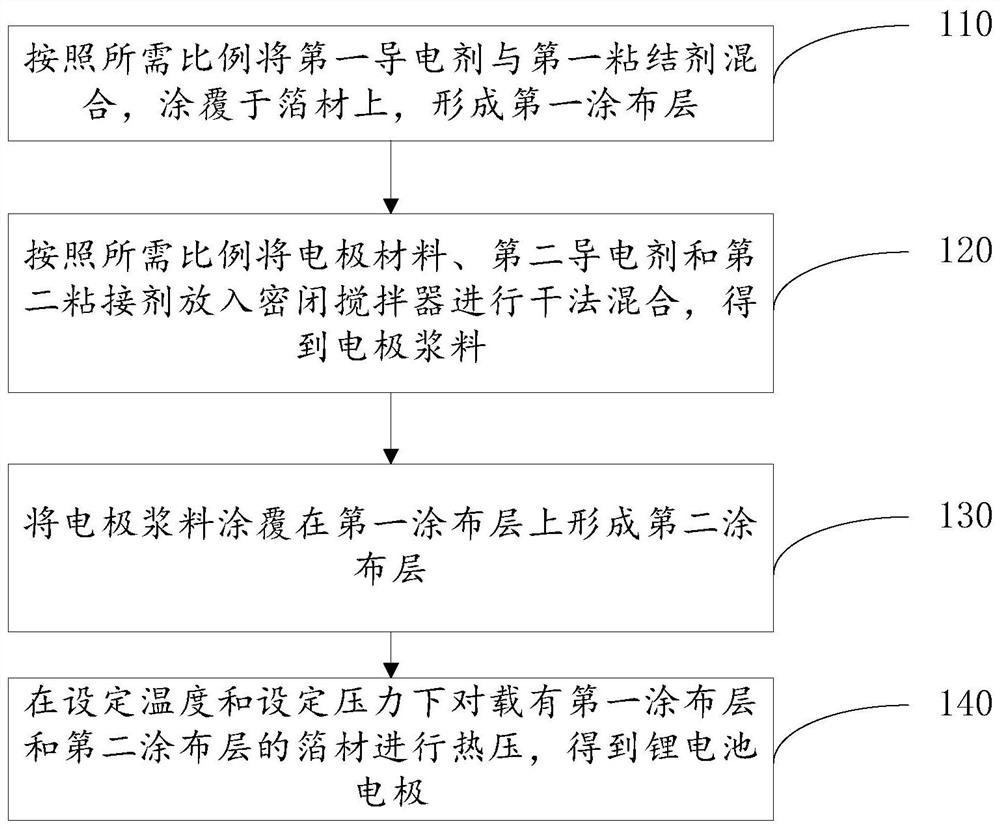

[0039] The embodiment of the present invention provides a dry method for preparing lithium battery electrodes, the main method steps are as follows: figure 1 shown, including:

[0040] Step 110, mixing the first conductive agent and the first binder according to the required ratio, and coating on the foil to form a first coating layer;

[0041] Wherein, the electrode material includes any one of positive electrode material or negative electrode material;

[0042] The positive electrode material includes one or a combination of lithium nickel cobalt manganese oxide, lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, and lithium nickel oxide;

[0043] Negative electrode materials include one or a combination of nano-silicon, silicon-oxygen, silicon-carbon, graphite, soft carbon, and hard carbon;

[0044] The foil material can be selected from conventionally used aluminum foil, copper foil, and the like.

[0045] The first conductive agent includes one or a...

Embodiment 1

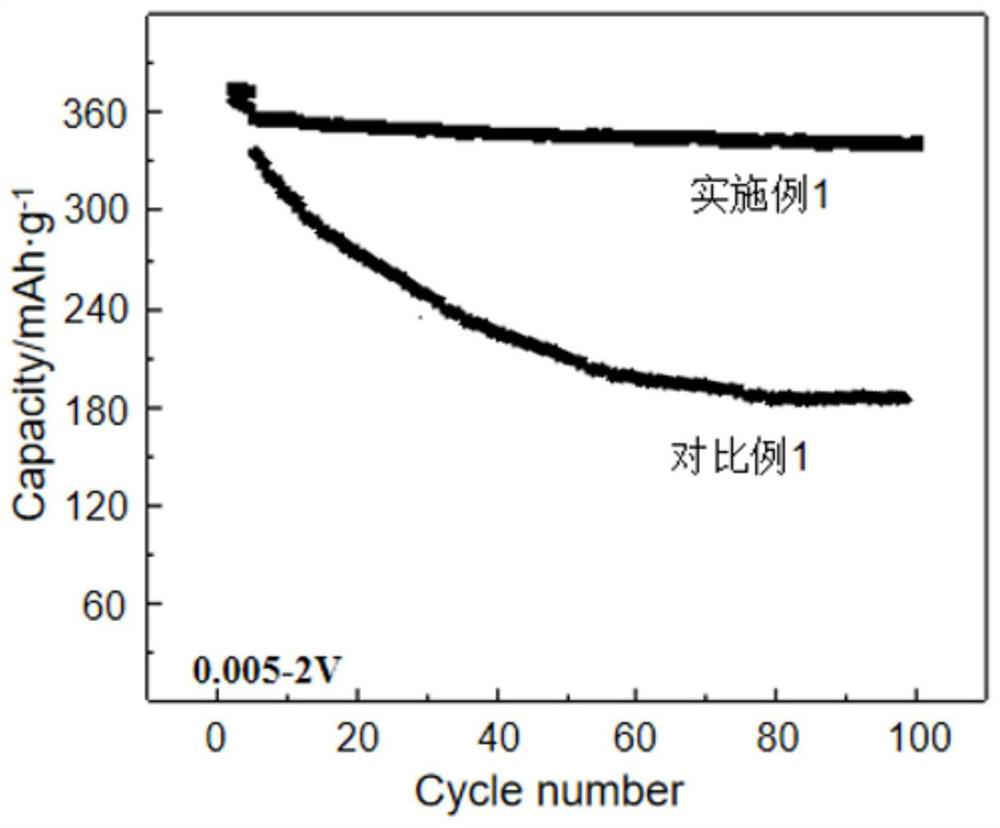

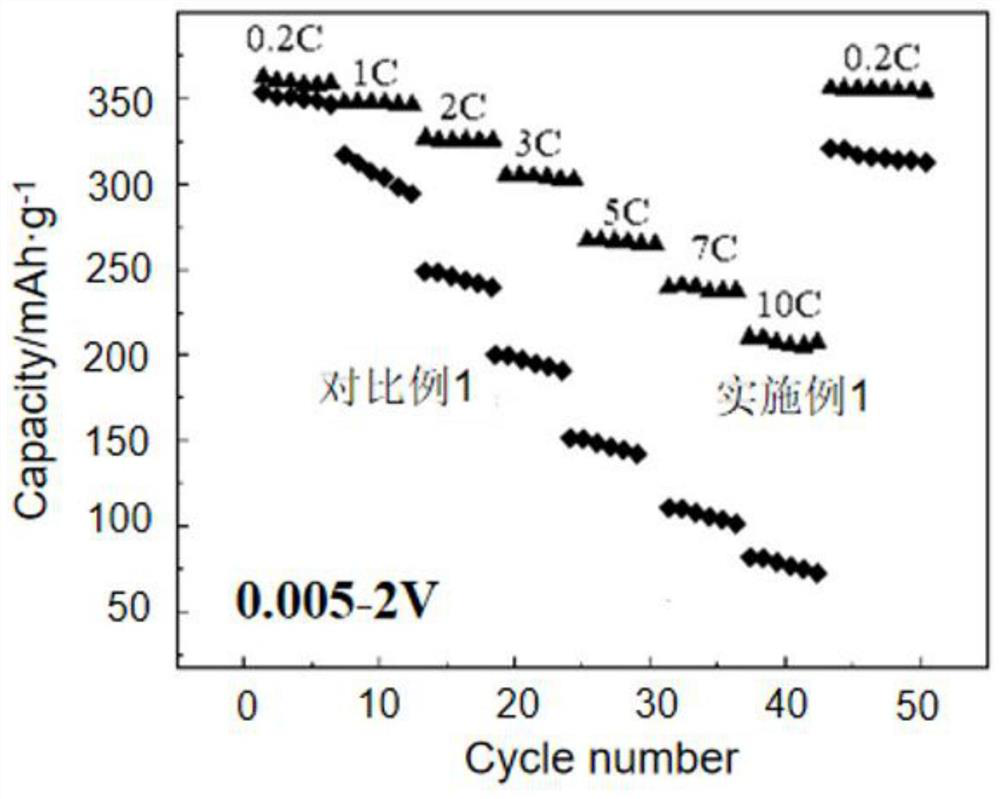

[0067] This embodiment provides a dry electrode preparation method for a lithium battery electrode, comprising the following steps:

[0068] Dispersing carbon nanotubes (CNTs) in a polyvinylidene fluoride (PVDF) solution, wherein CNTs accounts for 5wt% of the dispersion, and coating the dispersion on the surface of the copper foil;

[0069] According to the mass ratio of 90:5:2.5:2.5, graphite negative electrode material, conductive agent conductive carbon black (SP), binder styrene-butadiene rubber and sodium carboxymethyl cellulose (CMC) were placed in a closed mixer for dry process Mixing, the stirring rate is 2000rpm, and the stirring state is kept for 1 hour. After the completion, the mixed slurry is coated on the copper foil coated with the dispersion liquid, and hot-pressed. The hot-pressing temperature is 150°C and the hot-pressing pressure is 1MPa. Negative pole piece. The mass ratio of the first coating layer composed of the dispersion liquid applied in the first la...

Embodiment 2

[0081] This embodiment provides a dry method for preparing lithium battery electrodes, comprising the following steps:

[0082] Dispersing carbon nanotubes (CNTs) in a polyvinylidene fluoride (PVDF) solution, wherein CNTs accounts for 25wt% of the dispersion, and coating the dispersion on the surface of the copper foil;

[0083] According to the mass ratio of 88:6:3:3, the silica negative electrode material, the conductive agent conductive carbon black (SP), the binder styrene-butadiene rubber and sodium carboxymethyl cellulose (CMC) were placed in a closed mixer for drying. Method mixing, the stirring rate is 1600rpm, and the stirring state is kept for 1 hour. After the completion, the mixed slurry is coated on the copper foil coated with the dispersion liquid, and hot-pressed. The hot-pressing temperature is 120°C, and the hot-pressing pressure is 3MPa. Obtain the negative pole piece. The mass ratio of the first coating layer composed of the dispersion liquid applied in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com