Preparation method of composite material bipolar plate of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, applied in fuel cells, fuel cell parts, battery electrodes, etc., can solve the problem of high cost, improve performance and life, reduce cost, corrosion resistance and conductivity are not affected effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

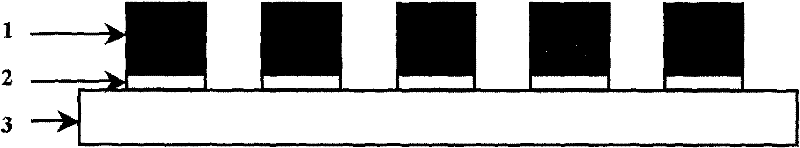

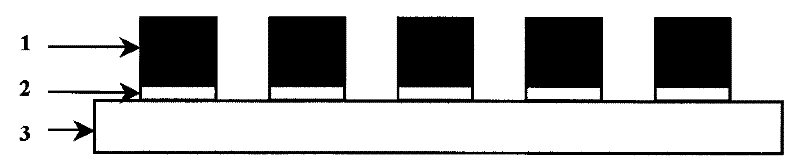

[0018] Paste the polyimide film with flow field-shaped through holes on the surface of the 904L stainless steel bipolar plate. The flow field is strip-shaped, the flow channel width is 2.0mm, and the flow field width is 2.0mm.

[0019] First, the stainless steel plate is activated cathodically, the activation solution is 200ml / L sulfuric acid (98%), and it is treated at 20°C for 3min, and the current density is 0.5A / dm 2 .

[0020] Copper plating after DI water cleaning. The copper plating solution is composed of CuSO 4 200g / L, H 2 SO 4 80g / L; temperature 25℃, current density 2.0A / dm 2 , time 5min.

[0021] Electroless silver plating after cleaning with deionized water, the composition of the electroless silver plating solution is Na 2 SO 3 150g / L, AgNO 3 1.0g / L; the electroless plating temperature is 25°C, and the time is 30s.

[0022] Electroformed silver / carbon composite layer after deionized water cleaning. The composite plating solution group includes nicoti...

Embodiment 2

[0025] Paste the polyimide film with flow field-shaped through holes on the surface of the 316L stainless steel bipolar plate, the flow field is serpentine, the flow channel width is 1.0 mm, and the flow field width is 1.0 mm.

[0026] First, the stainless steel plate is activated cathodically, the activation solution is 200ml / L sulfuric acid (98%), and it is treated at 20°C for 3min, and the current density is 0.5A / dm 2 .

[0027] Copper plating after DI water cleaning. The copper plating solution is composed of CuSO 4 200g / L, H 2 SO 4 80g / L; temperature 25℃, current density 2.0A / dm 2 , time 5min.

[0028] Electroless silver plating after cleaning with deionized water, the composition of the electroless silver plating solution is Na 2 SO 3 150g / L, AgNO 3 1.0g / L; the electroless plating temperature is 25°C, and the time is 30s.

[0029] Electroformed silver / carbon composite layer after deionized water cleaning. The composite plating solution group includes nicoti...

Embodiment 3

[0032] Paste the polycarbonate film with flow field-shaped through holes on the surface of the titanium alloy (TC4) bipolar plate, the flow field is strip-shaped, the flow channel width is 2.0 mm, and the flow field width is 2.0 mm.

[0033] First, the stainless steel plate is activated cathodically, the activation solution is 200ml / L sulfuric acid (98%), and it is treated at 20°C for 3min, and the current density is 0.5A / dm 2 .

[0034] Copper plating after DI water cleaning. The copper plating solution is composed of CuSO 4 200g / L, H 2 SO 4 80g / L; temperature 25℃, current density 2.0A / dm 2 , time 5min.

[0035] Electroless silver plating after cleaning with deionized water, the composition of the electroless silver plating solution is Na 2 SO 3 150g / L, AgNO 3 1.0g / L; the electroless plating temperature is 25°C, and the time is 30s.

[0036] Electroformed silver / carbon composite layer after deionized water cleaning. The composite plating solution group includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com