PA/ABS composite material and preparation method thereof

A technology of composite materials and maleic anhydride, applied in the field of PA/ABS composite materials and its preparation, to achieve good thermal and electrical conductivity, excellent application prospects, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

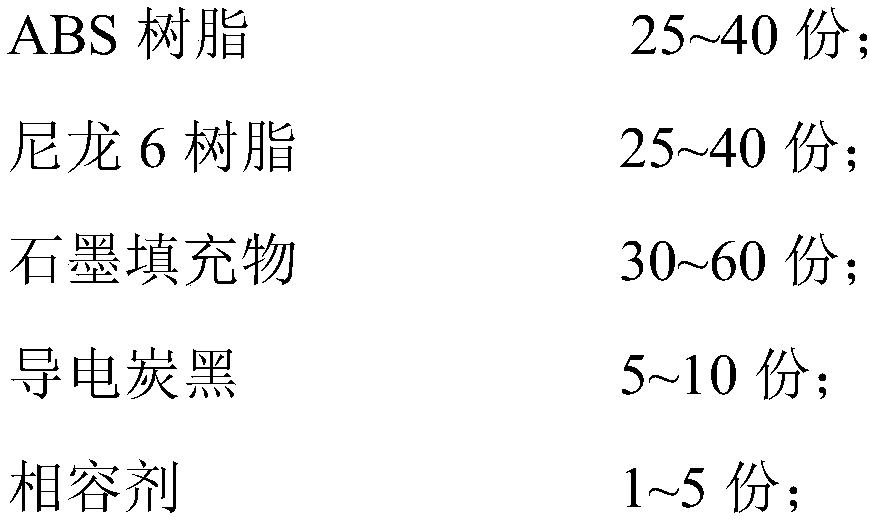

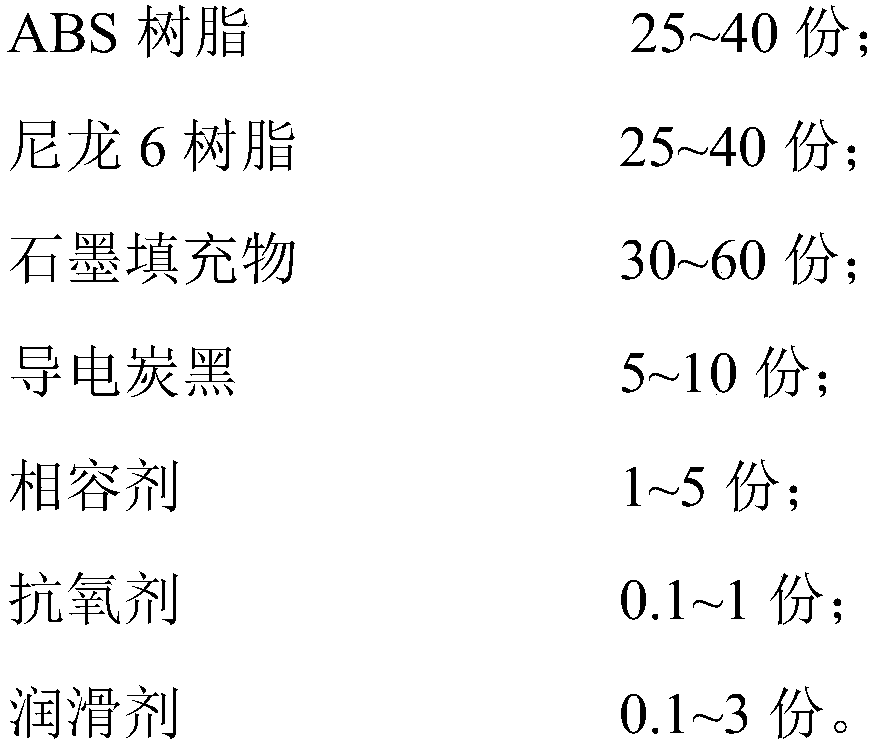

[0047] Correspondingly, an embodiment of the present invention provides a method for preparing a PA / ABS composite material, comprising the following steps:

[0048] According to the formula of the PA / ABS composite material described in the embodiment of the present invention, each component is weighed; an internal mixer with a sealed structure and a twin-screw extruder provided with forced side feeding equipment are provided;

[0049] Mixing the ABS resin, PA resin, graphite filler, compatibilizer, antioxidant, lubricant, and toner to obtain a mixture;

[0050] Put the above mixture into the internal mixer for melting and banburying, until the materials are completely mixed and uniform, and then take out the semi-finished composite material;

[0051] Putting the conductive carbon black into the forced side feeding device of the twin-screw extruder;

[0052] While putting the semi-finished composite material into the twin-screw extruder for melt extrusion, the conductive carbo...

Embodiment 1-6

[0080] A kind of PA / ABS composite material, comprises each component of content shown in Table 1 embodiment 1-6.

[0081] The preparation method of the PA / ABS composite material is as follows: after weighing the ingredients, mix the formula components except the conductive carbon black for 3 minutes with a high mixer to obtain a uniform mixture; put the above mixture into the internal mixer for melting and kneading , and then melted and extruded together with conductive carbon black in a twin-screw extruder, and pelletized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com