Patents

Literature

43results about How to "Improve voltage hysteresis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

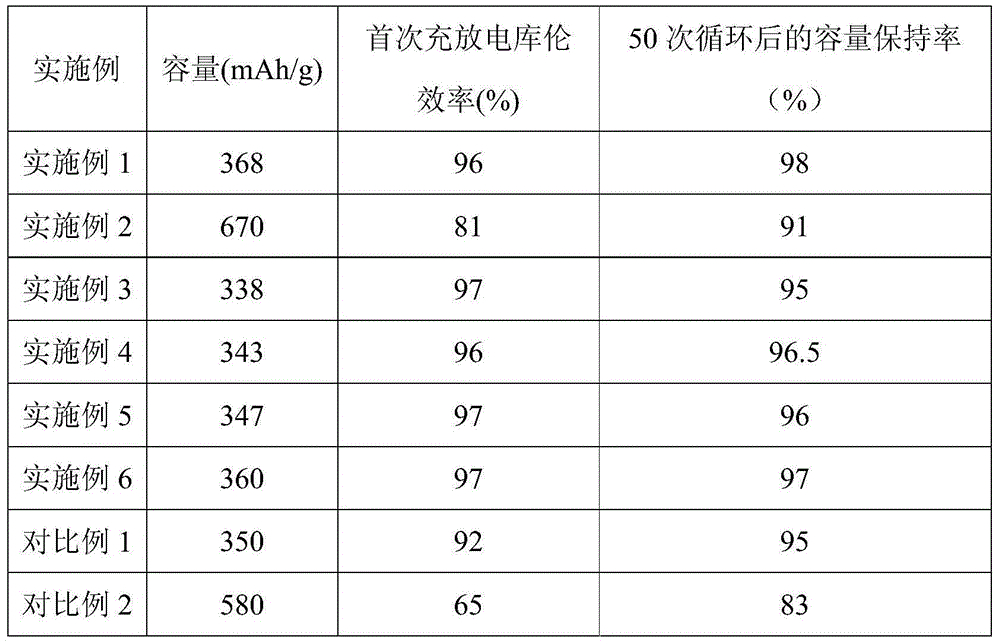

Lithium ion battery anode material and preparation method thereof

InactiveCN101859886ARegular shapeUniform particle size distributionNon-aqueous electrolyte accumulator electrodesCarbon coatingCarbon composites

The invention discloses a lithium ion battery anode material, which is characterized in that a carbon coating layer is coated on a silicon / carbon composite material. The invention also discloses a preparation method of the lithium ion battery anode material. The carbon shell layer of the carbon-coated silicon / carbon composite material prevents exposed silicon on the surface of the composite material from directly contacting with electrolyte, and a stable SEI film is formed on the surface of the carbon-coated silicon / carbon composite material, thereby improving the initial charge-discharge efficiency and the cycle stability.

Owner:HUBEI SANJUN BATTERY

Surface finish method of carbon fluoride material

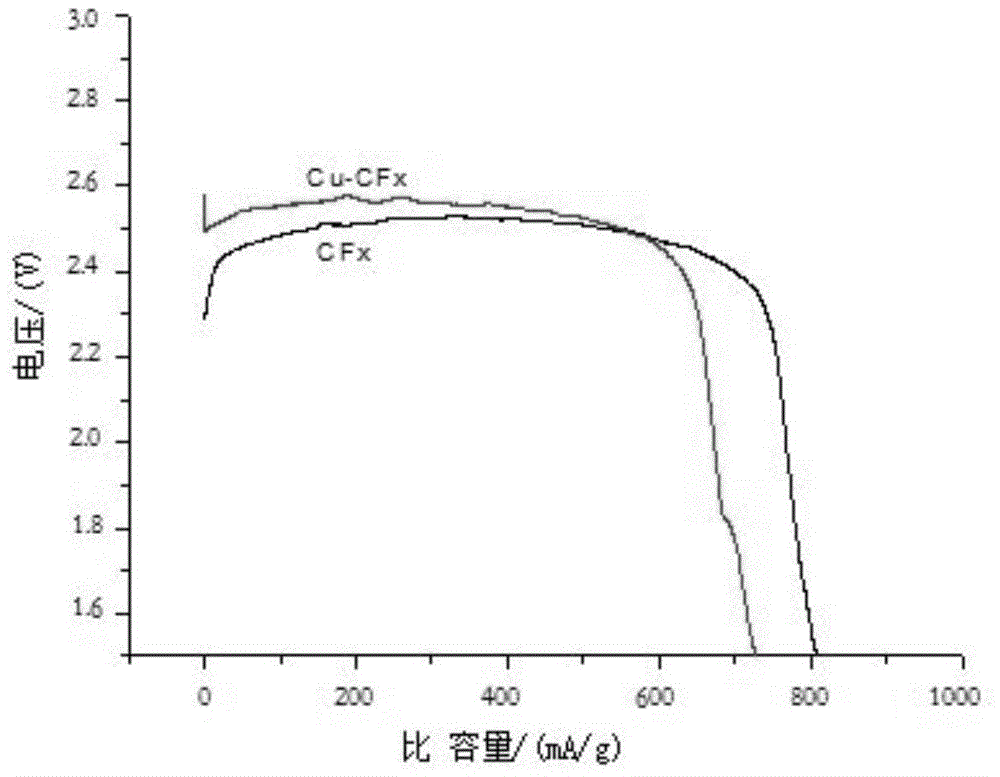

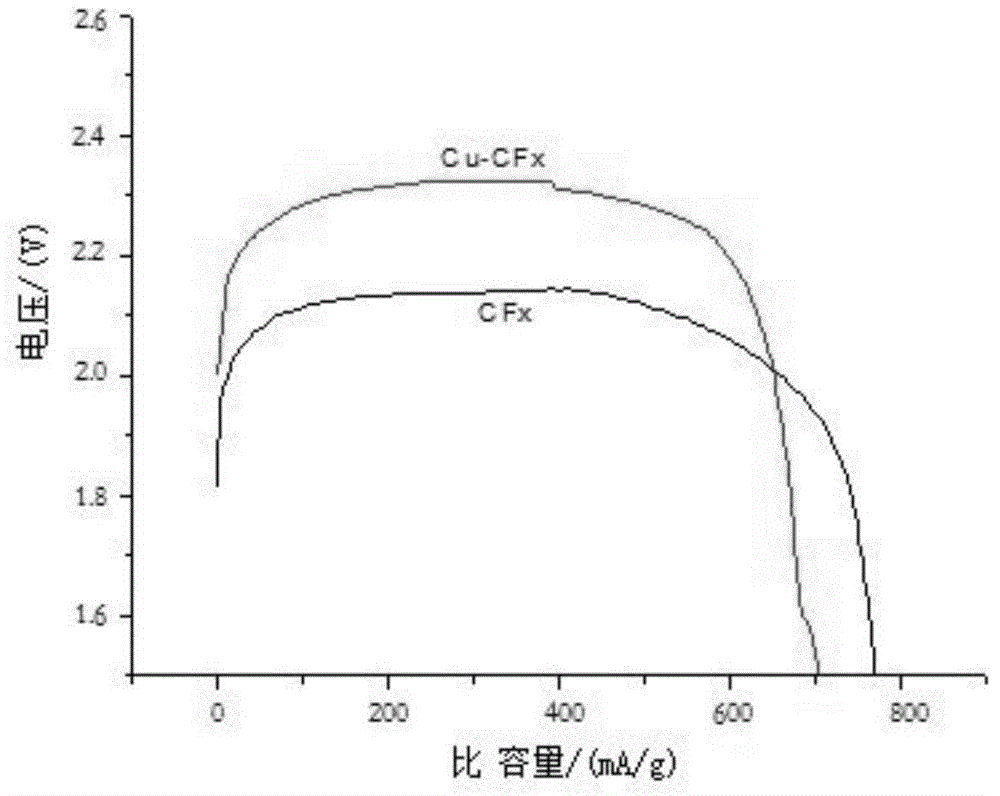

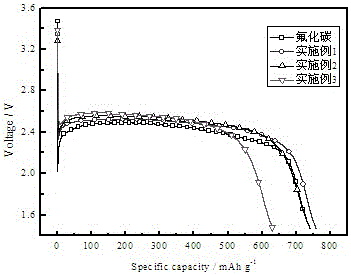

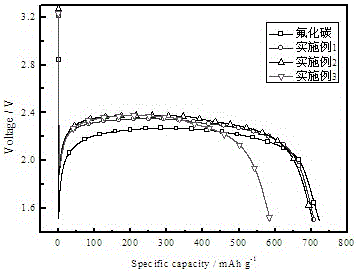

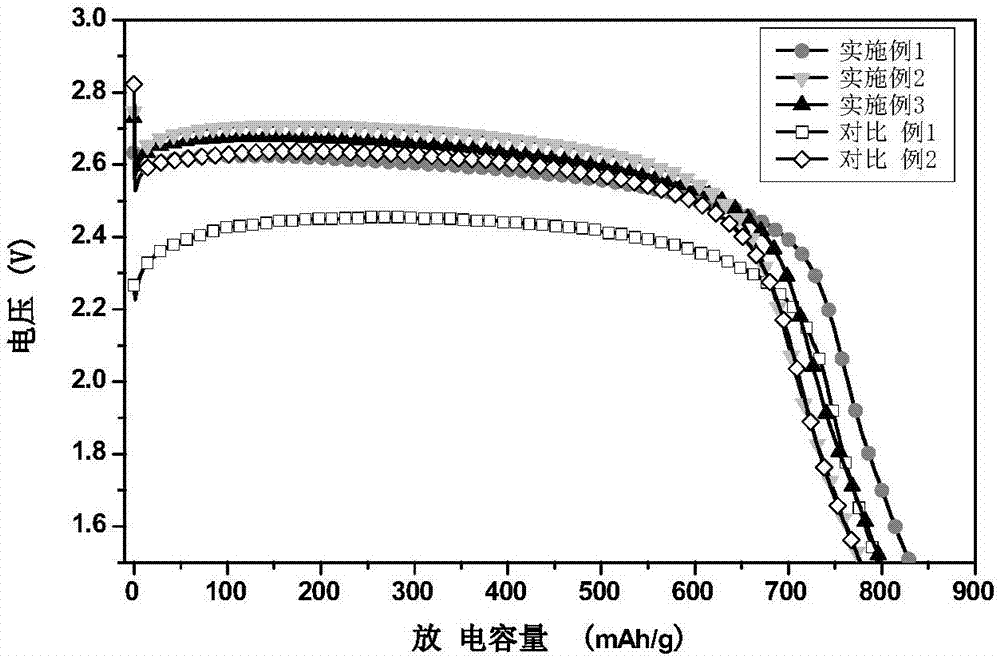

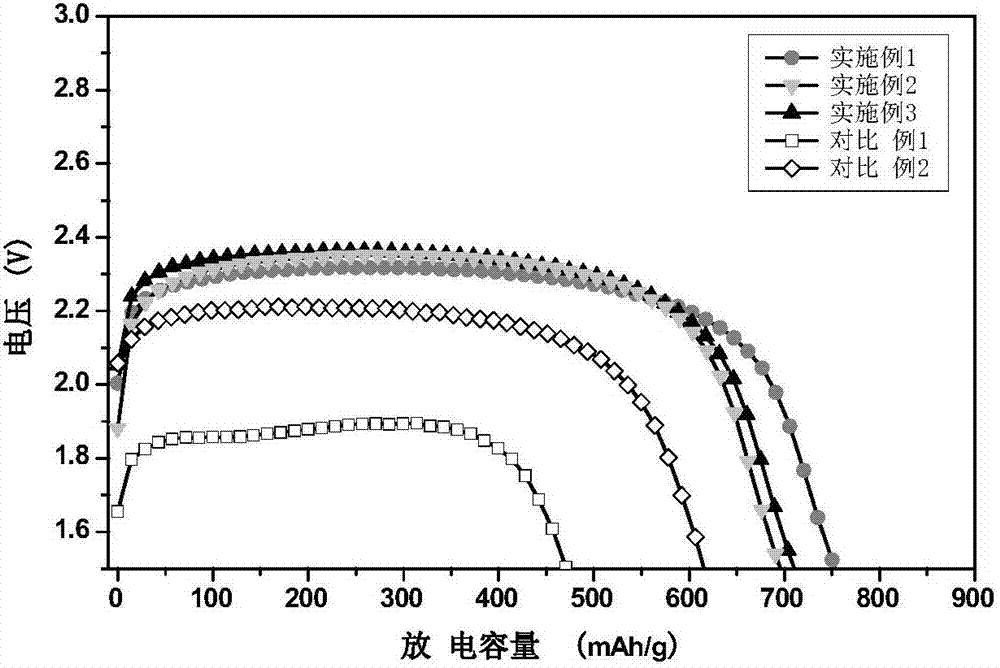

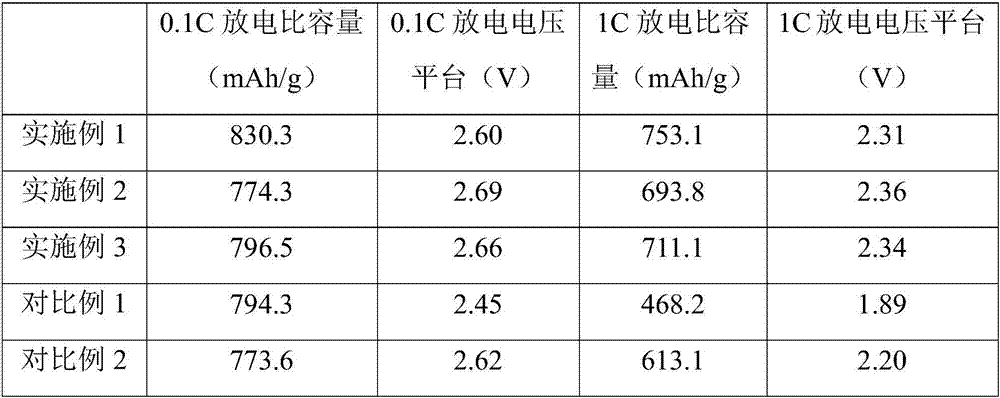

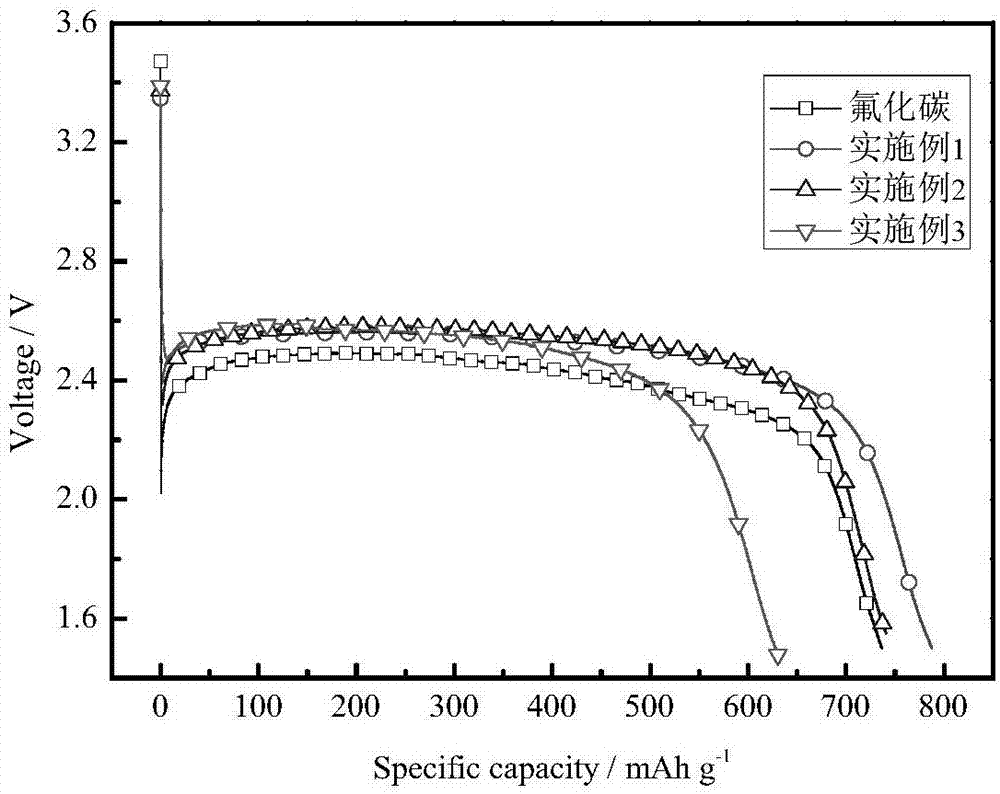

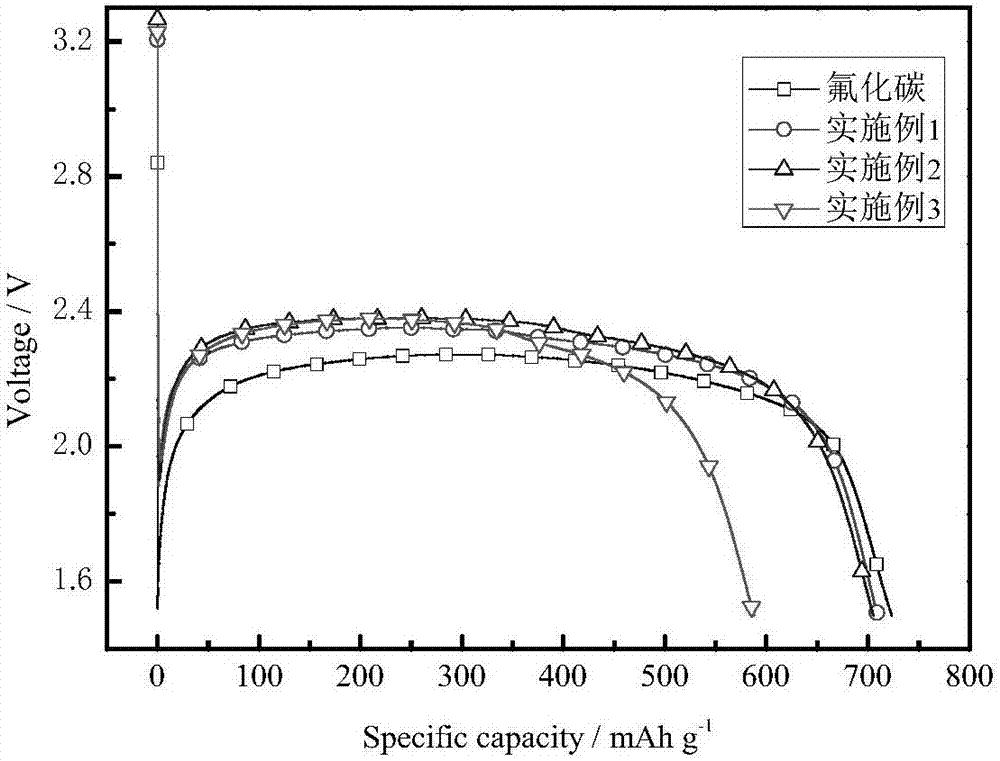

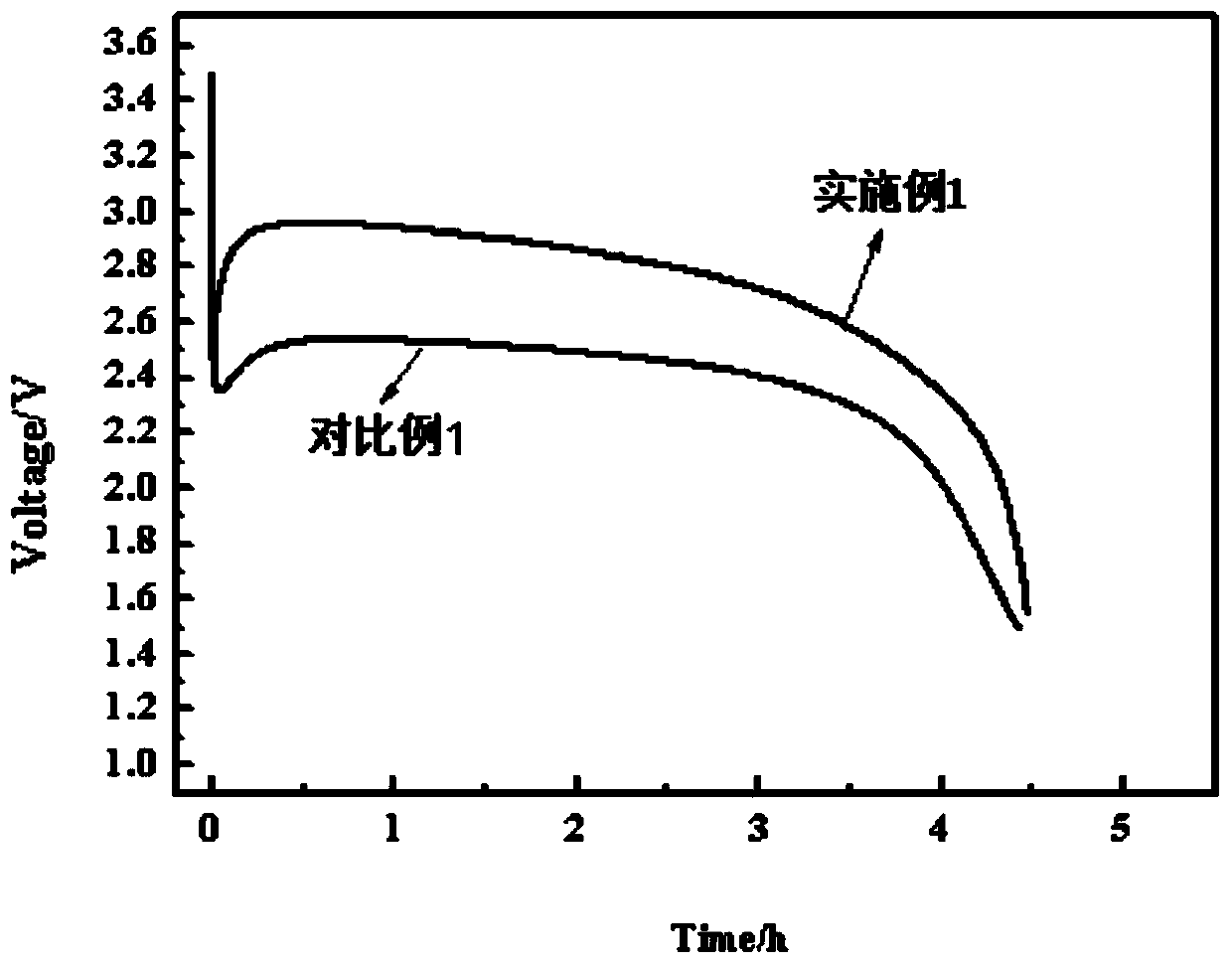

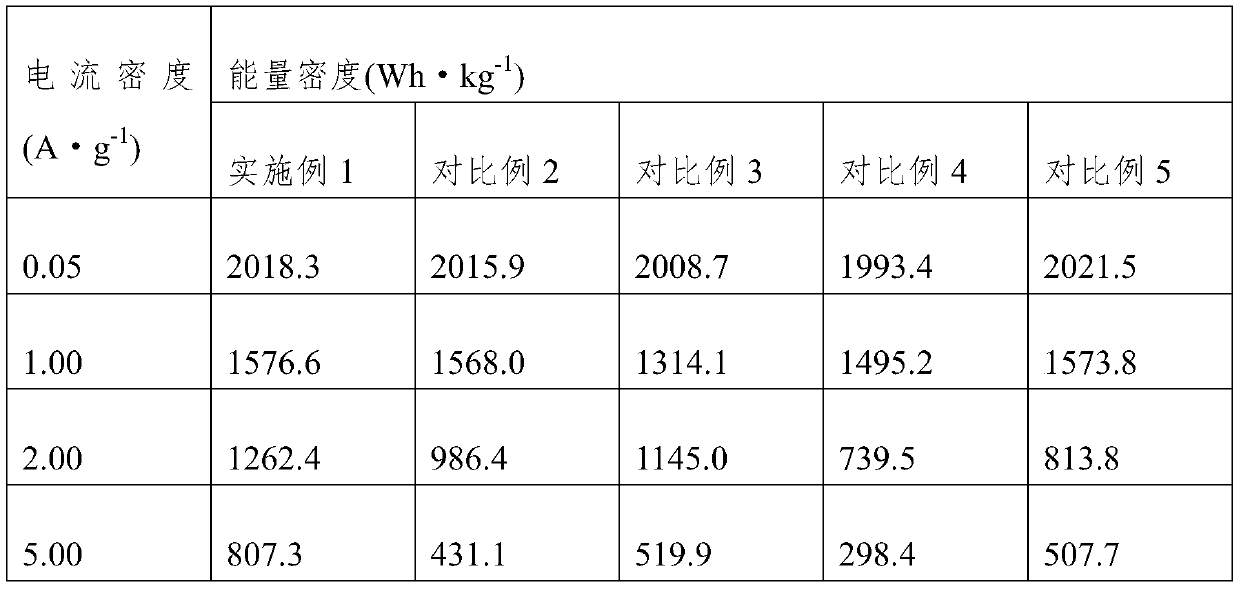

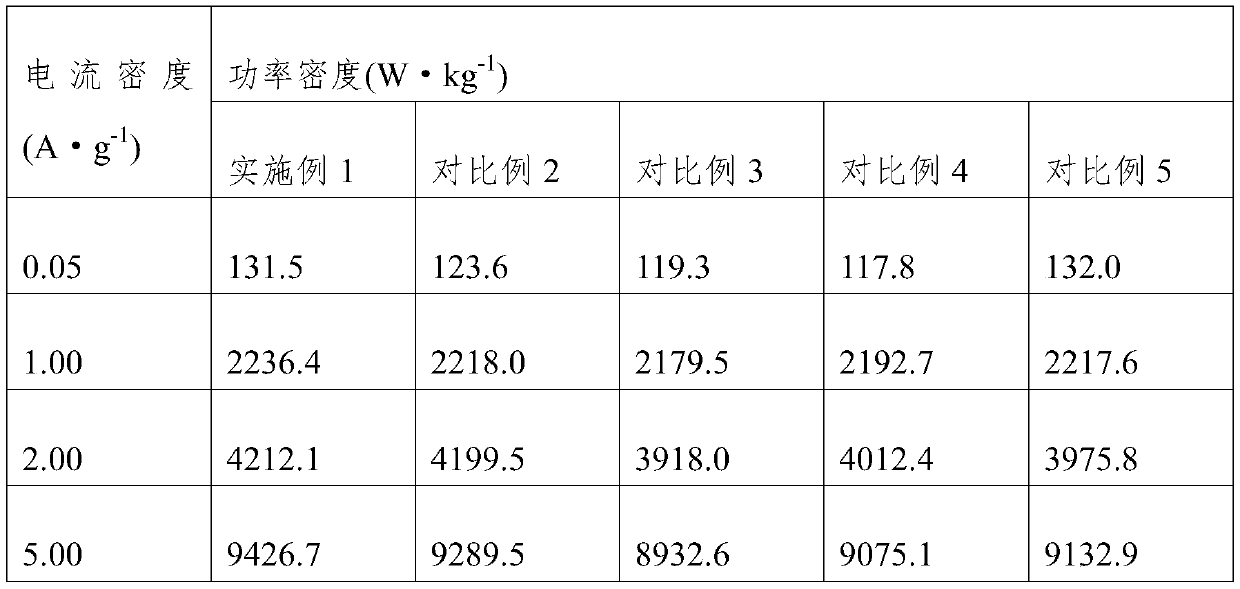

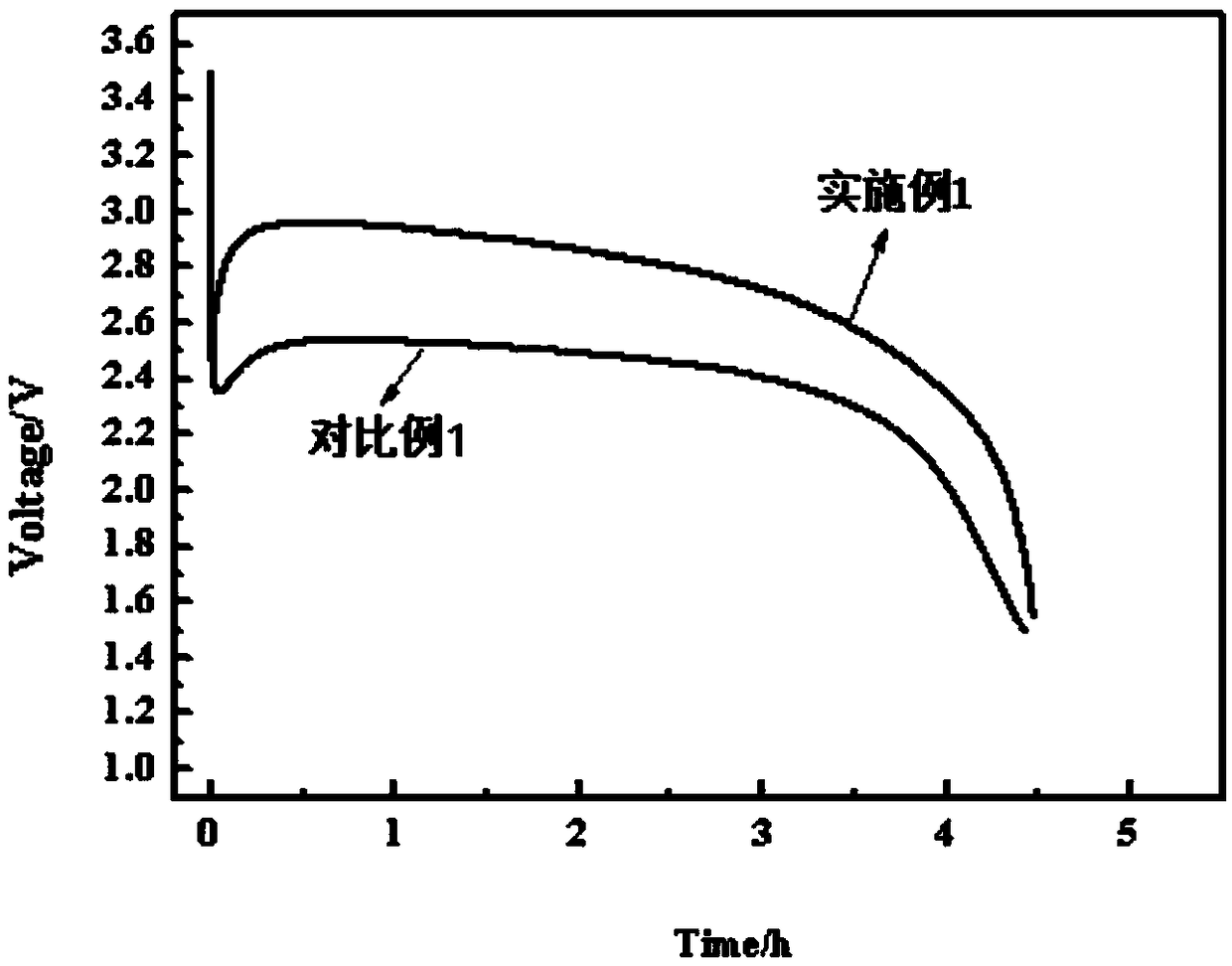

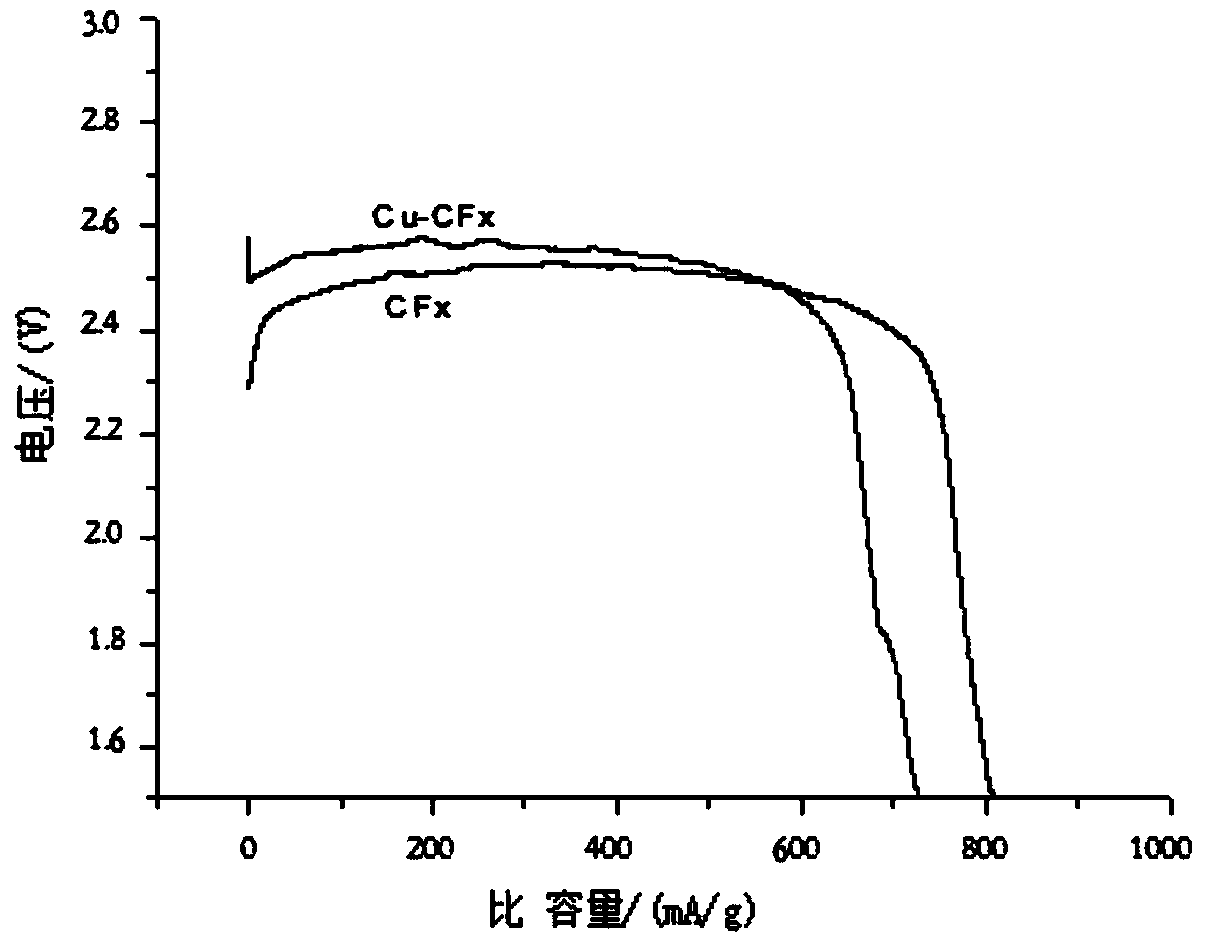

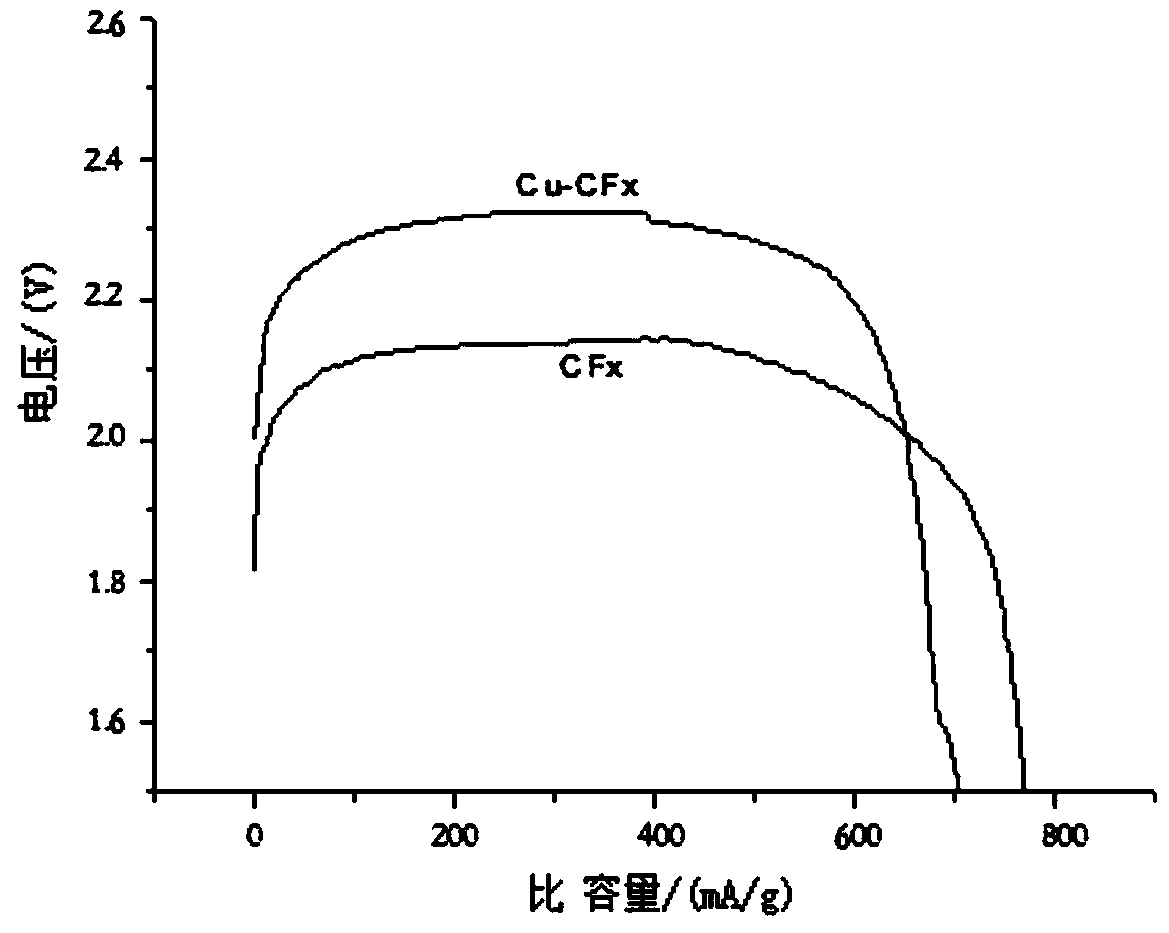

ActiveCN104577107AImprove voltage hysteresisHigh rate discharge and low temperature performance improvementNanotechnologyPrimary cell electrodesSolventPowder mixture

The invention relates to a surface finish method of a carbon fluoride material. The method comprises the following steps: (1) mixing nanometer copper and carbon fluoride, then adding a solvent for ball milling so as to form a combined pulp; (2) drying the mixed pulp so as to form a mixture; (3) screening the mixture so as to obtain the powder mixture; (4) putting the powder mixture into an atmosphere oven so as to be calcined; (5) taking out the calcined powder mixture, lowering the temperature of the calcined powder mixture to the room temperature, and then screening the calcined powder mixture of which the temperature is lowered so as to form the carbon fluoride material modifies by the nanometer copper. According to the invention, the carbon fluoride and the nanometer copper with good conductivity are mixed, and after the mixture is calcined at a high temperature in an inert atmosphere, the nanometer copper reacts on the surface of the carbon fluoride, so that the phenomenon that the voltage of carbon fluoride is delayed is obviously improved, and high-ratio discharge and low temperature performance are greatly improved. The carbon fluoride with a finished surface, prepared by the method, is used as a positive material to be made into a lithium-carbon fluoride battery system, wherein the lithium-carbon fluoride battery system has the properties of high-ratio discharge and low temperature high-current discharge, so that the application range of the lithium-carbon fluoride battery system is extended.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Lithium cell utilizing foamed nickel material as current-collecting body and producing method thereof

InactiveCN1707831AImprove electron conduction pathwaysImproved ability to work with heavy loadsElectrode carriers/collectorsNickel electrodeHeavy load

The present invention is lithium cell with foamed nickel material as current collector and its making process. This kind of lithium cell is obtained through the process including ultrasonic wave treatment, coating, and rolling or negative pressure adsorption to fill active matter, copper powder, PTFE emulsion, distilled water and alcohol into foamed nickel electrode. The lithium cell making process includes main steps of compounding material, filling, drying, pressurizing, etc. The present invention has obviously lowered electrochemical polarization of lithium cell, improved electron conducting path of electrode, improved heavy load work capacity, low temperature performance, lagging characteristic, etc of cell, and raised safety performance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Lithium ion battery negative material and preparation method thereof

ActiveCN104538630ASimple and fast operationEasy to operateCell electrodesSecondary cellsMetallic lithiumCharge discharge

The invention discloses a lithium ion battery negative material and a preparation method thereof. The preparation method comprises the following steps: firstly adding metallic lithium to a non-aqueous solvent to dissolve to form a lithium solution; then adding a complexing agent of which the weight is 1-1.2 times more than the molar weight of the metallic lithium to the lithium solution to obtain a sol solution; then adding a negative material, stirring to obtain suspension liquid; then evaporating the suspension liquid to dryness at the temperature of 30-80 DEG C to obtain a precursor, uniformly grinding, then placing into a vacuum drying box, drying at 120 DEG C for 8-12 hours, and cooling with a furnace; and finally loading the powder obtained by grinding and drying into a corundum boat, placing the corundum boat into a cavity of an inert atmosphere furnace, and sintering at the temperature of 400-800 DEG C for 2-6 hours. According to the preparation method disclosed by the invention, previous lithiation treatment is carried out on the negative material by adopting the lithium sol solution, lithium ions are provided for the formation of an SEI film in a first-time charge-discharge process, the loss of positive lithium ions is reduced and the first-time charge-discharge coulomb efficiency, capacity and circulating property of the negative material are greatly improved.

Owner:李震祺 +1

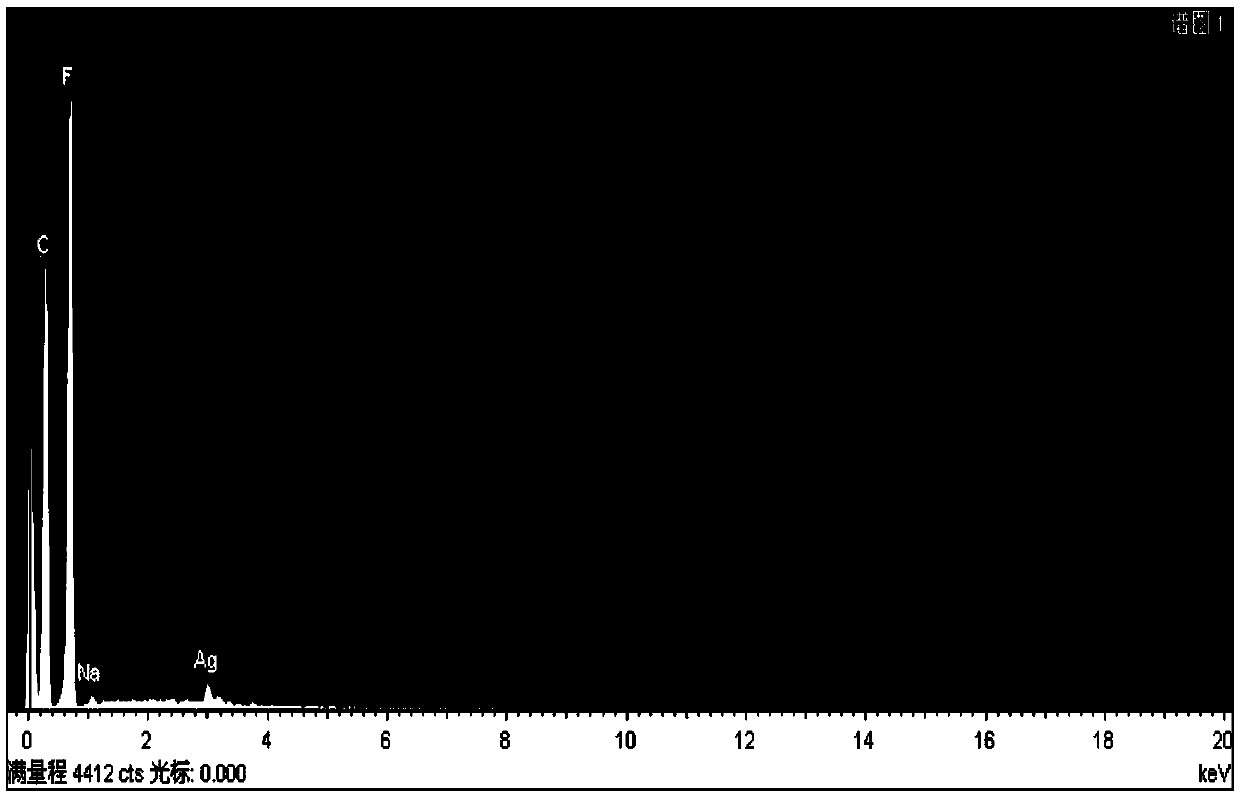

Preparation method of Ag@C-modified fluorinated carbon electrode material

InactiveCN109659515AImprove conductivityImprove voltage hysteresisNon-aqueous electrolyte cellsCell electrodesLithiumHysteresis

The invention discloses a preparation method of an Ag@C-modified fluorinated carbon electrode material. The method comprises the following steps of: mixing an Ag compound and a solvent, adding carbonfluoride, 15-25 parts of NaOH or KOH aqueous solution, parts by mass fraction, adding reducing agent for action after temperature rise, performing filtering, washing, drying and grinding, and performing 100-200mesh screening to prepare an Ag@C-modified fluorinated carbon electrode material. Part of fluorinated carbon material is restored to C while restoring the Ag compound to Ag by employing thechemical reduction method. The Ag@C is employed to perform modification of the fluorinated carbon material, and the surface of the fluorinated carbon material is uniformly coated with the Ag@C to increase the conductivity of the fluorinated carbon material, effectively improve the problems of the voltage hysteresis and low-temperature performance of the fluorinated carbon material and improve therate performance of the lithium fluorocarbon battery.

Preparation method of modified carbon fluoride positive electrode material

InactiveCN106159268AImprove electronic conductivityLower internal resistanceCell electrodesNon-aqueous electrolyte cellsReduction treatmentPolarization phenomenon

The invention discloses a method for preparing a modified carbon fluoride positive electrode material, which comprises the following preparation steps: (1) selecting raw materials: including carbon fluoride, additional carbon source, and binder; (2) modifying the carbon fluoride positive electrode Material preparation: Mix fluorocarbons, additional carbon sources and binders according to a certain proportion, put them into a sintering furnace under a nitrogen atmosphere, control the reaction temperature in the furnace, carry out carbothermal reduction treatment on the materials for a certain period of time, and then cool down to obtain The material is the modified carbon fluoride cathode material in the present invention. The present invention utilizes carbothermal reduction method to process fluorinated carbon, improves the electronic conductivity of the material, reduces the internal resistance and polarization phenomenon of the lithium / carbon battery during discharge, and improves the initial voltage hysteresis of the lithium / carbon fluorinated battery. Rate discharge performance.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Pitch carbon coated fluorocarbon cathode material and preparation method thereof

ActiveCN107482187AHigh specific capacityHigh magnificationCell electrodesOrganic electrolyte cellsCarbon sourceFluorocarbon

The invention discloses a pitch carbon coated fluorocarbon cathode material and a preparation method thereof. The preparation method comprises the following steps: mixing fluorocarbon with pitch, performing heat treatment on the obtained mixture and sieving the mixture to obtain the pitch carbon coated fluorocarbon cathode material. According to the method, fluorocarbon is coated with pitch carbon, and by improving binding force between the fluorocarbon surface and a carbon source, the electric conductivity of the material is improved to a greater extent, so that the discharge voltage plateau, specific capacity and high-current discharge performance of the material are improved substantially. The method has the advantages of low cost, simple equipment, simple and easily controllable process conditions, high yield and the like and is quite suitable for large-scale industrial production.

Owner:TIANJIN B&M SCI & TECH

Method of modifying carbon fluoride cathode material through chemical reduction process

InactiveCN107968205AImprove electronic conductivityLower internal resistancePrimary cell electrodesModified carbonInternal resistance

The invention discloses a method of modifying a carbon fluoride cathode material through a chemical reduction process. The method includes the steps of: (1) raw material selection: preparing carbon fluoride, a chemical reducing agent and a solvent; (2) preparation of the modified carbon fluoride cathode material: according to certain ratio, mixing the carbon fluoride, the chemical reducing agent and the solvent, and performing chemical reduction treatment for a certain time under a heating and stirring condition, and cooling and filtering the product to obtain the modified carbon fluoride cathode material. In the invention, the carbon fluoride is treated through the chemical reduction method, thus increasing the electronic conductivity of the material. During discharge, a lithium / carbon fluoride battery is reduced in internal resistance and polarization phenomenon, thus reducing a problem of voltage delay during initial stage of discharge and improving rate discharge performance of thelithium / carbon fluoride battery.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Preparing method of electrolyte for lithium thionyl chloride cell

InactiveCN1622383AHigh purityLess side effectsFinal product manufactureOrganic electrolyte cellsEnvironmental chemistryVoltage

The present invention is improved preparation process of electrolyte for lithium thionyl chloride. The SOCl2 solution is first rectified, then added with LiAlCl4 and metal lithium and heated and reflux purified for at least 12 hr, SO2 gas is injected into the solution, and in dry environment, the solution is filtered to prepare the electrolyte. The electrolyte has raised purity and can improve the voltage lag state of the lithium cell effectively.

Owner:武汉孚特电子科技有限公司

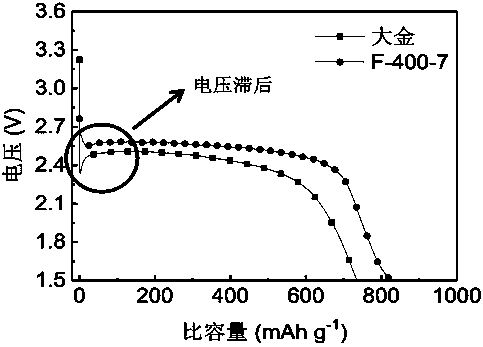

A preparation method of a fluorinated nanometer graphite as cathode material of lithium fluoride carbon battery

ActiveCN109216698AImproved magnification performanceFacilitated DiffusionCell electrodesHysteresisHigh voltage

The invention relates to a preparation method of a fluorinated nanometer graphite as a cathode material of a lithium fluoride carbon battery, belonging to the technical field of the cathode material of the lithium battery. Nano-graphite was prepared by magnetic stirring milling method as precursor. Fluorine gas and nano-graphite intercalated into carbon and fluorine at high temperature by direct fluorination method to obtain fluorinated nano-graphite. Compared with commercial graphite fluoride, the method has higher voltage plateau and higher specific capacity, and overcomes the problem of voltage hysteresis when the fluorocarbon material starts to discharge. Fluorinated graphite nanoparticles are excellent cathode materials for lithium fluoride batteries.

Owner:SHANDONG UNIV OF TECH

Nano-material modified carbon fluoride electrode material manufacturing method

ActiveCN110783522AImprove conductivityImprove voltage hysteresisMaterial nanotechnologyPrimary cell electrodesCarbon monofluorideModified carbon

The invention discloses a nano-material modified carbon fluoride electrode material manufacturing method. The method comprises the following steps of mixing a medium and carbon fluoride, adding a ferro-nickel alloy and mixing; adding a nano material, reacting, airing, carrying out vacuum drying, grinding, calcining in an argon atmosphere, and cooling to a room temperature; and grinding, and screening with a 100-200-mesh sieve to obtain a nano-material modified carbon fluoride electrode material. A mass ratio of the nano material to the carbon fluoride is (0.5-5):100. In the invention, a carbonfluoride material is modified by adopting the nano material, and the nano material is uniformly distributed on a surface of the carbon fluoride material so that conductivity of the carbon fluoride material is improved, problems of voltage lag and low-temperature performance of the carbon fluoride material are effectively solved, and a rate capability of a lithium carbon fluoride battery is improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Lithium/thionyl dichloride battery

InactiveCN102208675AImprove performanceImprove discharge capacityCell electrodesLi-accumulatorsLithiumHigh rate

The invention relates to a lithium / thionyl dichloride battery, which is characterized in that lithium is taken as an anode, carbon is taken as a cathode carrier, a thionyl dichloride solution of anhydrous lithium aluminum tetrachloride is taken as an electrolyte, and an active material of the battery contains calcium metal halides. The lithium / thionyl dichloride battery can improve voltage hysteretic properties and be used under the condition of intermediate-rate and high-rate discharge at a low temperature.

Owner:SUZHOU JINKEFA LITHIUM BATTERY

Preparation method of nanometer material modified carbon fluoride electrode material

InactiveCN109390551AImprove conductivityImprove voltage hysteresisMaterial nanotechnologyPrimary cell electrodesVoltageLithium

The invention discloses a preparation method of a nanometer material modified carbon fluoride electrode material. The method comprises the following steps: mixing a medium and carbon fluoride, addinga nanometer material, performing reaction, drying, vacuum drying and grinding, performing calcination in argon atmosphere, cooling down the medium and carbon fluoride to room temperature, grinding, and sieving the medium and carbon fluoride through a 100 to 200-mesh sieve, so as to obtained the nanometer material modified carbon fluoride electrode material; the mass ratio of the nanometer materialto the carbon fluoride is equal to (0.5-5): 100. The method has the advantages that the carbon fluoride material is modified through the nanometer material, the nanometer material is uniformly coatedon the surface of the carbon fluoride material, the conductivity of the carbon fluoride material is improved, the problems of voltage hysteresis and poor low-temperature performance of the carbon fluoride material are effectively improved, and the rate capability of a lithium carbon fluoride battery is improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

V2O5-carbon fluoride mixed positive electrode material and preparation method thereof

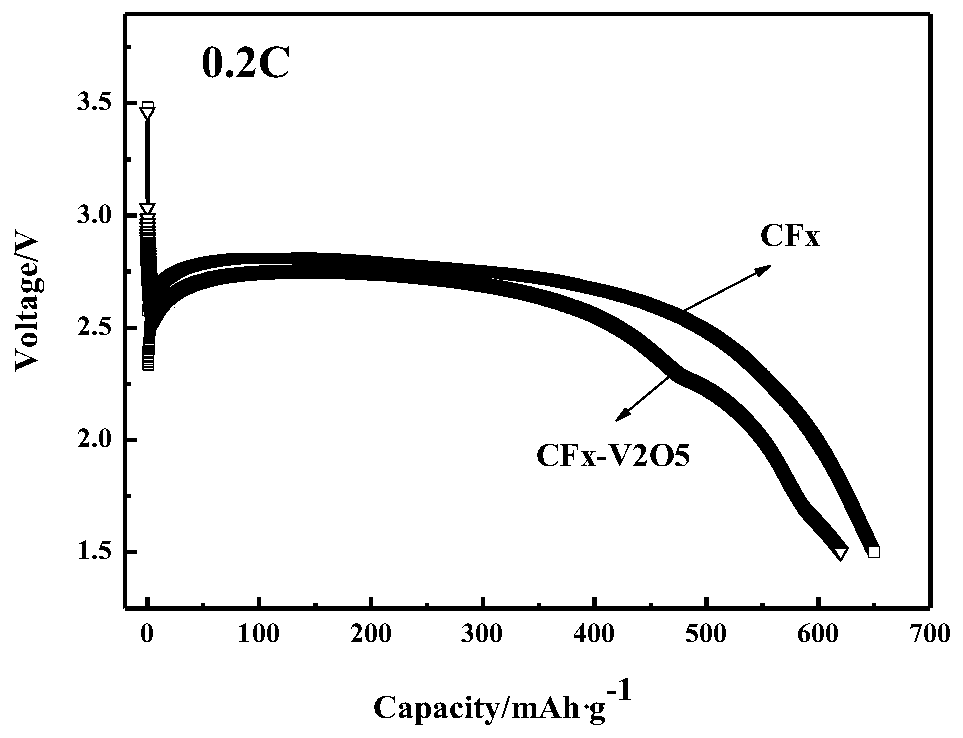

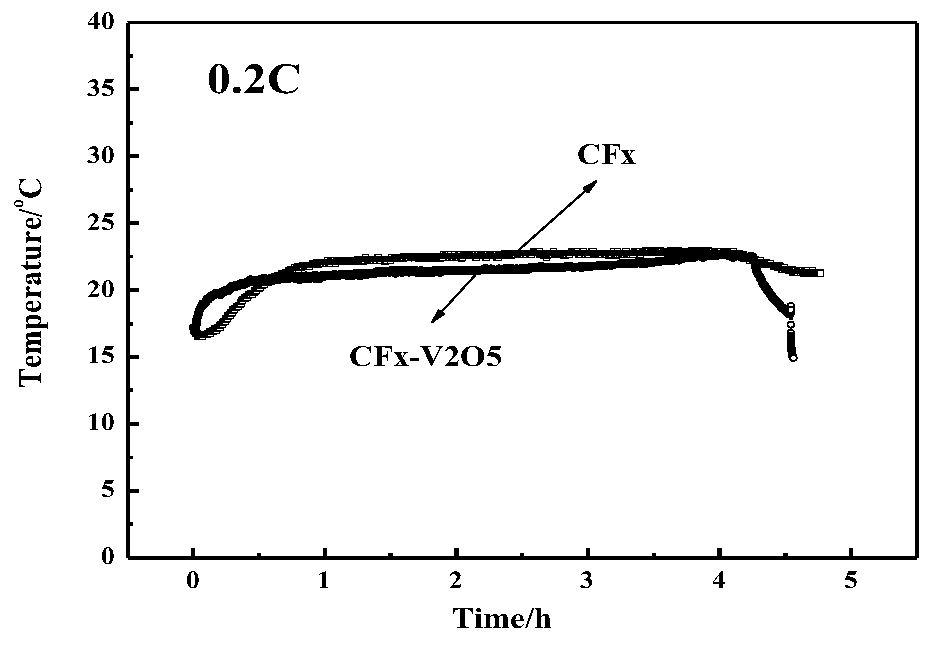

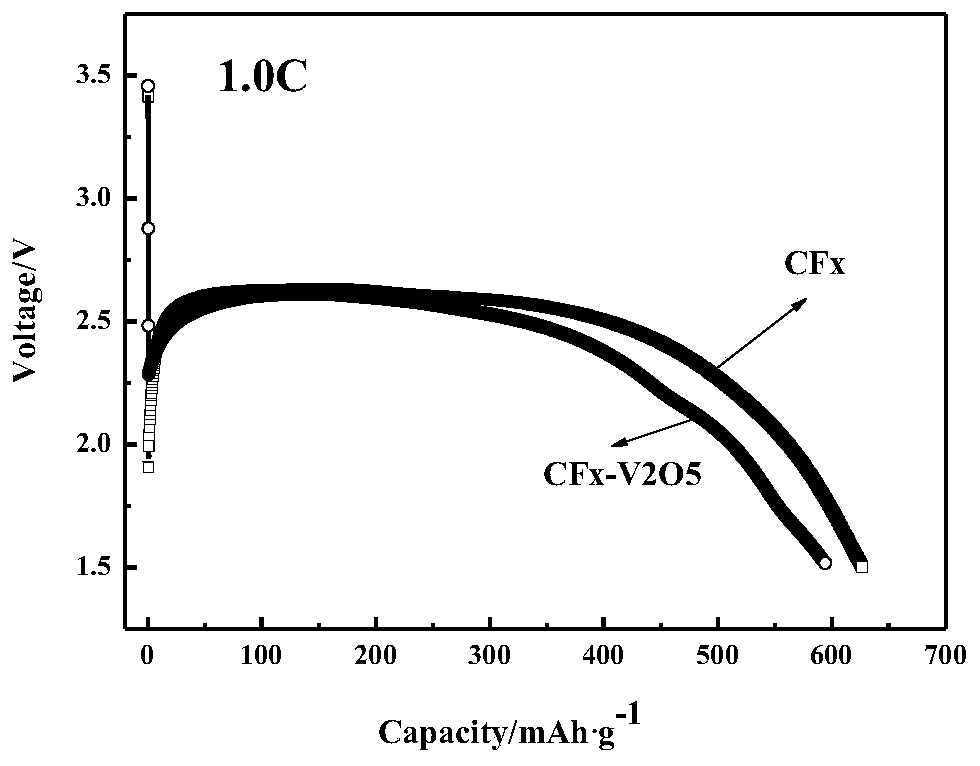

ActiveCN110707313AMake up for the voltage lag problemHigh voltageCell electrodesPhysical chemistryBattery cell

The invention relates to the technical field of lithium battery materials, in particular to a V2O5-carbon fluoride mixed positive electrode material and a preparation method thereof. According to theinvention, a V2O5 material is doped in a carbon fluoride positive electrode material, so that the advantages that the V2O5 material has higher discharge platform voltage, good high-current discharge capacity, very small heat generation during the discharge process and the like are fully utilized, the problem of voltage lag at the initial discharge stage of the carbon fluoride positive electrode material is solved, the large-current discharge capacity of the carbon fluoride positive electrode material is effectively improved, the rate capability of the lithium carbon fluoride battery is greatlyimproved, the temperature rise during the discharge process of the lithium carbon fluoride battery is reduced, and the application range of the lithium carbon fluoride battery is expanded. Under theaction of a dispersing agent, the two materials are mixed in a high-energy ball milling manner, so that the problem of voltage lag at the initial discharge stage of the carbon fluoride positive electrode material and the problem of high heat productivity under a high-current discharge condition are further solved. According to the present invention, the zirconium oxide balls are added during the high-energy ball milling process, so that the uniformity of the mixed materials is further improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Lithium-thionyl chloride button cell anode carrier and preparation method thereof

ActiveCN102751506AImprove reliabilityImprove assembly efficiencyElectrode carriers/collectorsPrimary cell electrodesHysteresisLithium

The invention discloses a lithium-thionyl chloride button cell anode carrier and a preparation method thereof, and belongs to the field of button cells. The preparation method comprises the following steps of mixing anode powder, drying by a drying box at a constant drying oven temperature of 180 DEG C for about 15 hours, cooling the fully dried anode powder to a temperature of 90 to 100 DEG C, maintaining the temperature, heating alcohol to a temperature of 55 to 65 DEG C by hot water, rolling an anode carrier 3-5 times by a rolling mill to obtain a thin sheet, coating a binder layer on the rolled anode carrier, carrying out punching and perforation, carrying out sintering at a high temperature of 240 DEG C for 10 to 30 minutes, and carrying out cooling and sealing for next use. The preparation method has simple processes. The lithium-thionyl chloride button cell anode carrier obtained by the preparation method greatly improves cell reliability and assembly efficiency and effectively improves voltage hysteresis and large current discharging of a lithium-thionyl chloride button cell.

Owner:安徽里亚电池有限公司

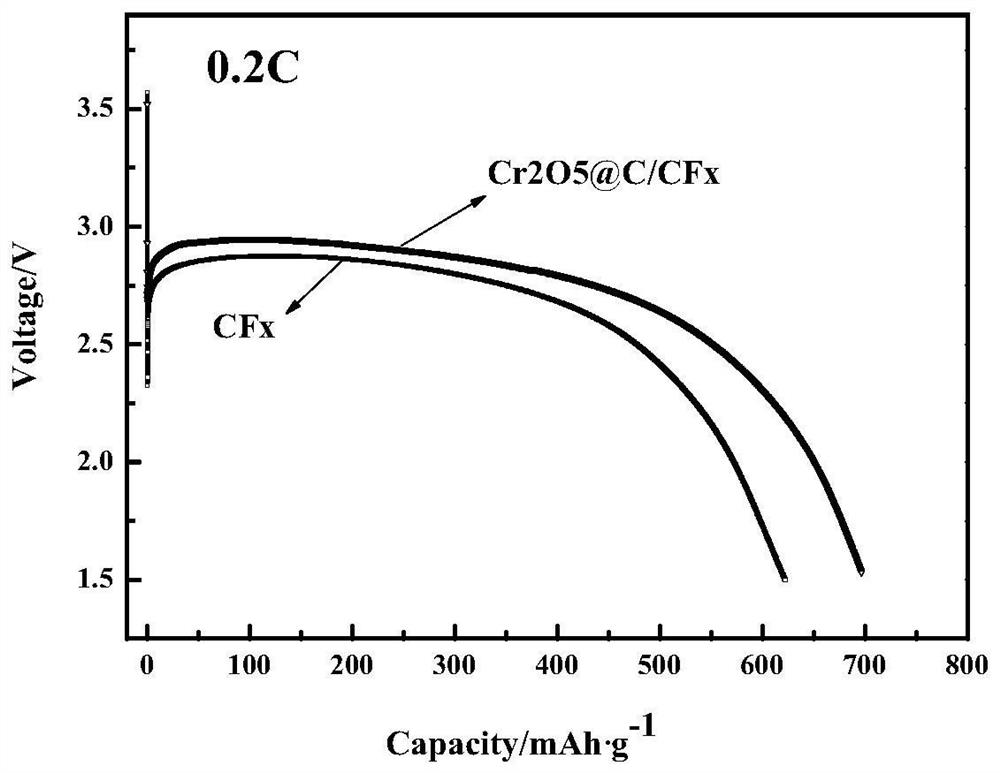

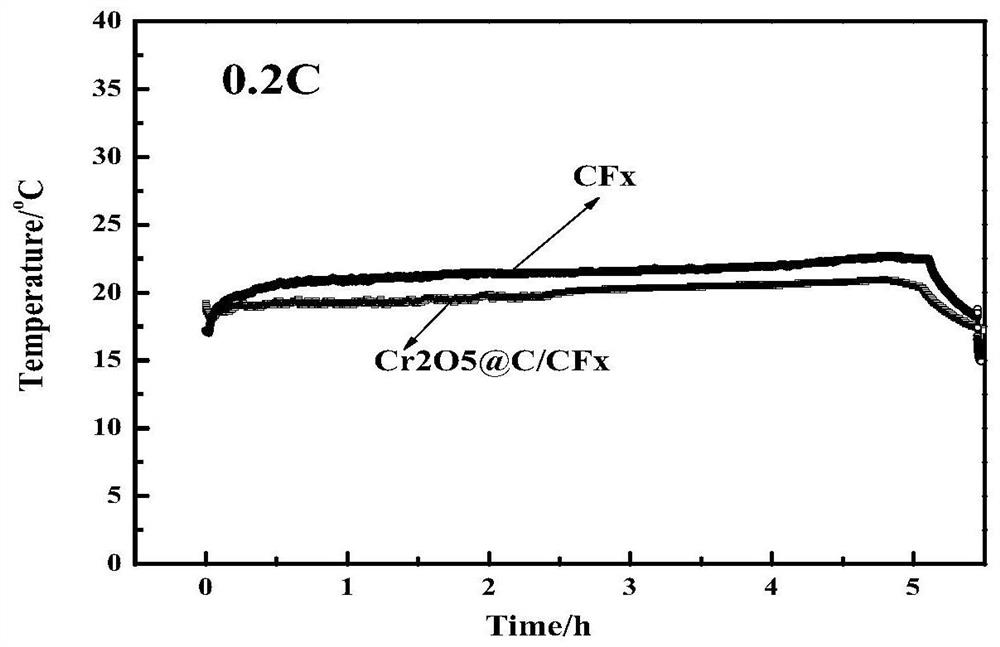

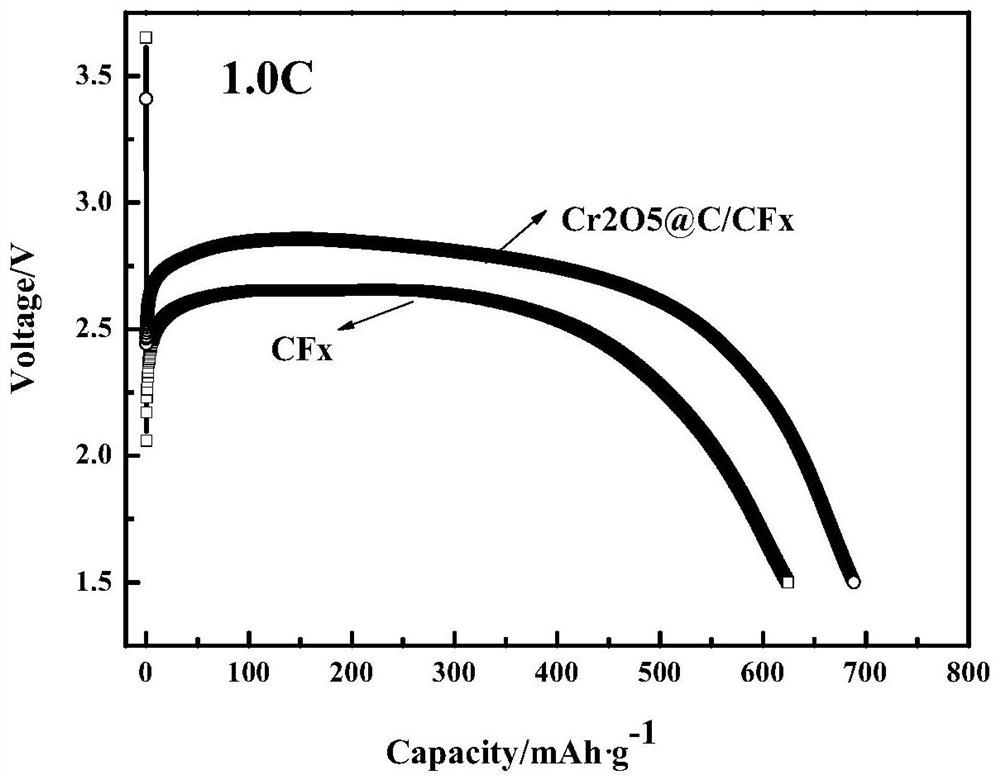

Method for modifying carbon fluoride positive electrode material by using chromium oxide or chromium oxide compound

InactiveCN113363494AImprove voltage hysteresisImproved magnification performanceNon-aqueous electrolyte cellsPositive electrodesMolten stateCarbon monofluoride

The invention discloses a method for modifying a carbon fluoride positive electrode material by using a chromium oxide or a chromium oxide compound, which comprises the following steps of: (1) adding CrO3 and carbon fluoride into absolute ethyl alcohol, and performing high-energy ball milling to form mixed slurry; (2) drying the mixed slurry and sieving the dried mixed slurry with a 100-200-mesh sieve to obtain mixed powder; (3) putting the mixed powder in an air atmosphere furnace, and heating the mixed powder to 196-240 DEG C to obtain a molten-state mixture; and (4) stirring the molten-state mixture for 2 hours to fully and uniformly mix the carbon fluoride and the molten-state CrO3, heating and calcining the mixture, taking out a product, cooling and grinding the product, and sieving with a 100-200-mesh sieve to obtain the carbon fluoride positive electrode material modified by the chromium oxide or the chromium oxide compound. According to the obtained material, the problem of voltage lag at the initial stage of discharge is effectively solved, the rate capability and platform voltage of a lithium carbon fluoride battery are improved, the temperature rise of the lithium carbon fluoride battery in the discharge process is reduced, and the preparation method is simple and low in cost.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Manufacturing method of lithium/thionyl chloride battery electrolyte material

InactiveCN102709599AImprove performanceImprove discharge capacityFinal product manufactureElectrolyte accumulators manufactureHigh rateTetrachloride

The invention relates to a manufacturing method of a lithium / thionyl chloride battery electrolyte material, which comprises the following steps: proportioning and metering thionyl chloride, lithium aluminum tetrachloride, calcium metal halide, and metal lithium foil according to a mass ratio of 1:0.09-0.19:0.013-0.20:0.001-0.002 in dry environment with a relative humidity of not more than 1%; orderly adding the metered thionyl chloride, lithium aluminum tetrachloride, calcium metal halide, and metal lithium foil into a preparation container, wherein the calcium metal halide is added to reach saturation in the lithium / thionyl chloride battery electrolyte, stirring the materials for 4-8 hours, and filtering residual lithium foil and reaction residues to obtain the finished product. The invention provides the manufacturing method of a lithium / thionyl chloride battery electrolyte material which can improve the voltage delay performance of lithium / thionyl chloride batteries and can be used under conditions with a low temperature and medium-high rate discharge.

Owner:SUZHOU JINKEFA LITHIUM BATTERY

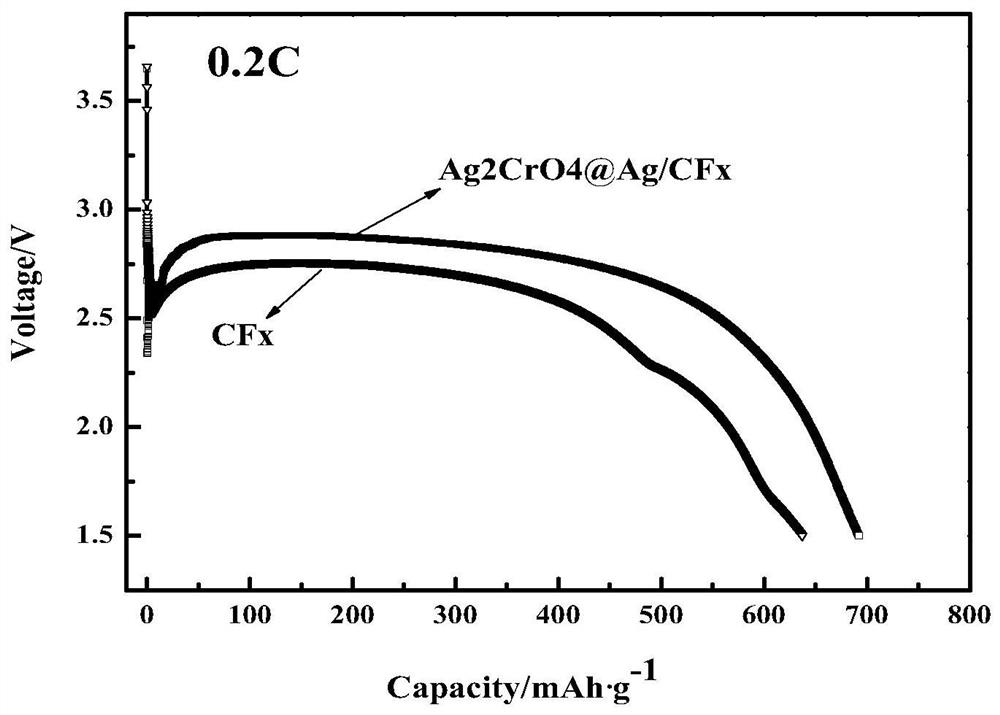

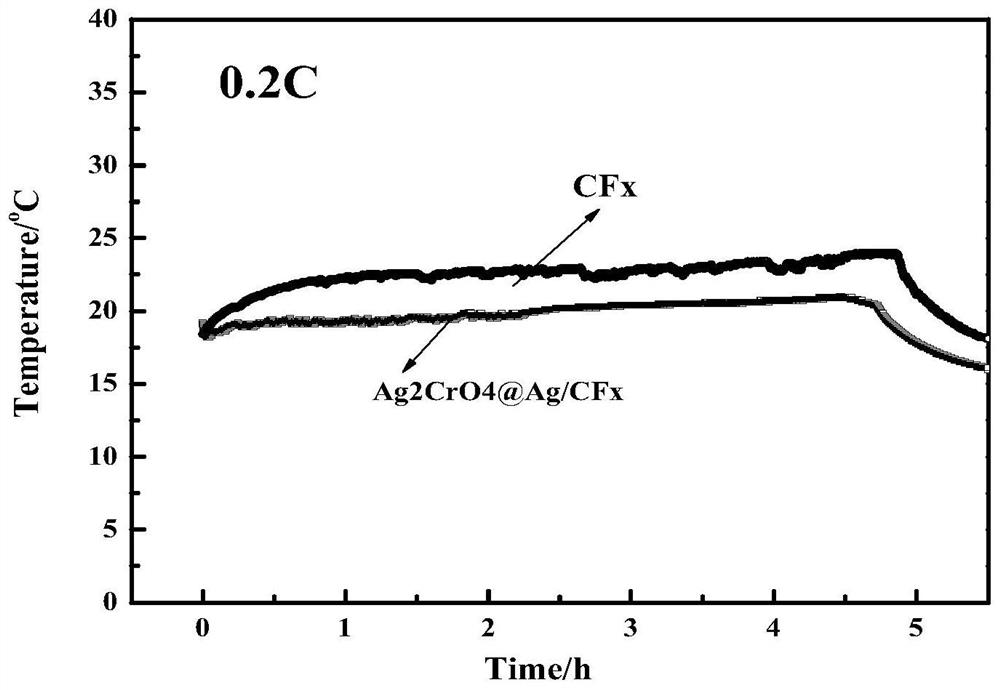

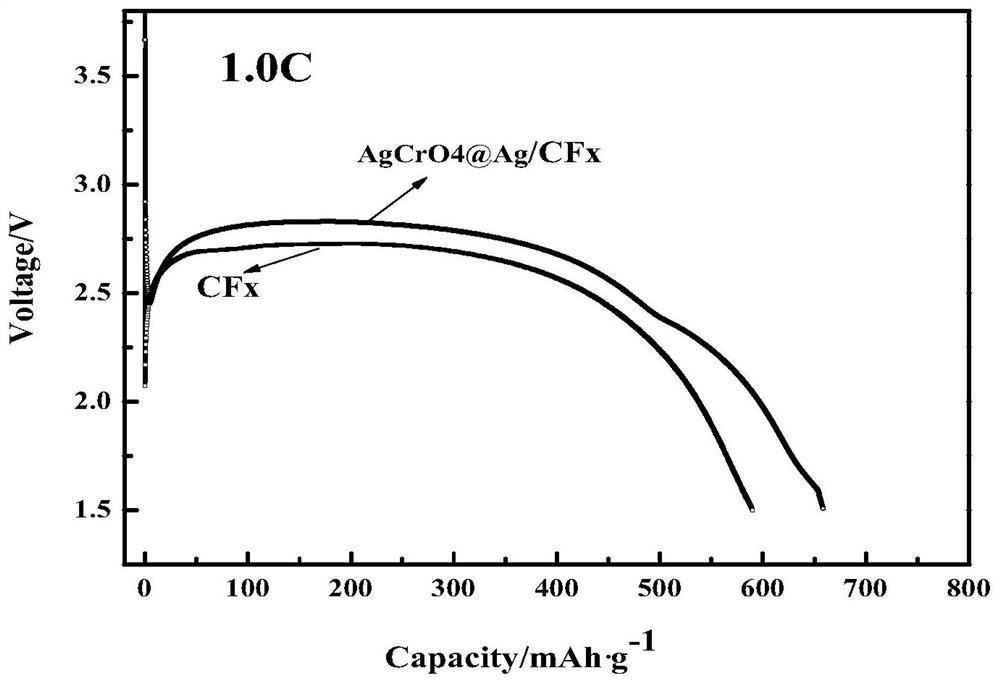

Preparation method of Ag2CrO4@Ag modified carbon fluoride positive electrode material

ActiveCN113363495AMake up for the voltage lag problemGood high current discharge performanceNon-aqueous electrolyte cellsPositive electrodesModified carbonElectrical battery

The invention relates to the technical field of carbon fluoride positive electrode material modification, in particular to a preparation method of an Ag2CrO4@Ag modified carbon fluoride positive electrode material, which comprises the following steps of: (1) preparing a potassium chromate solution; (2) preparing a carbon fluoride dispersion liquid; (3) preparing a mixed solution: well stirring the potassium chromate solution and the carbon fluoride dispersion liquid to obtain the mixed solution; (4) preparing a silver nitrate solution; (5) preparing mixed slurry: slowly adding the silver nitrate solution into the mixed solution, continuing reaction after the silver nitrate solution is completely added to obtain a mixed reaction solution, and performing high-energy ball milling to obtain the mixed slurry; (6) drying and sieving the mixed slurry to obtain mixed powder; and (7) calcining: calcining the mixed powder. The problem of voltage lag at the initial discharge stage of the carbon fluoride battery is effectively solved, the rate capability and platform voltage are improved, the temperature rise in the discharge process of the lithium carbon fluoride battery is reduced, and the preparation method is simple and low in cost.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD +1

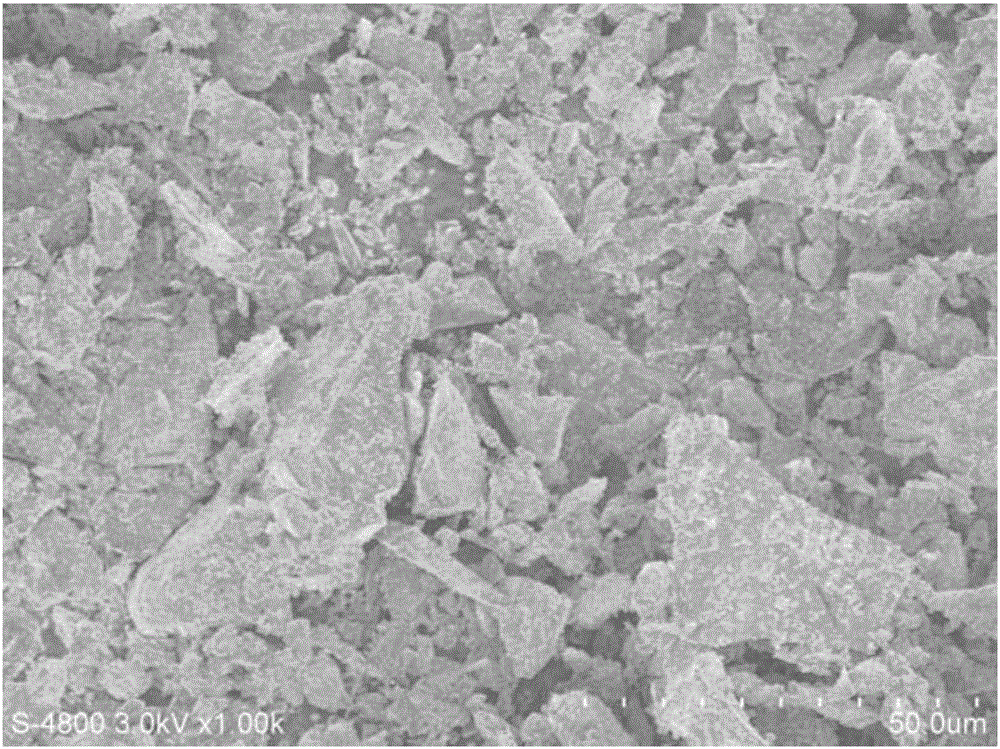

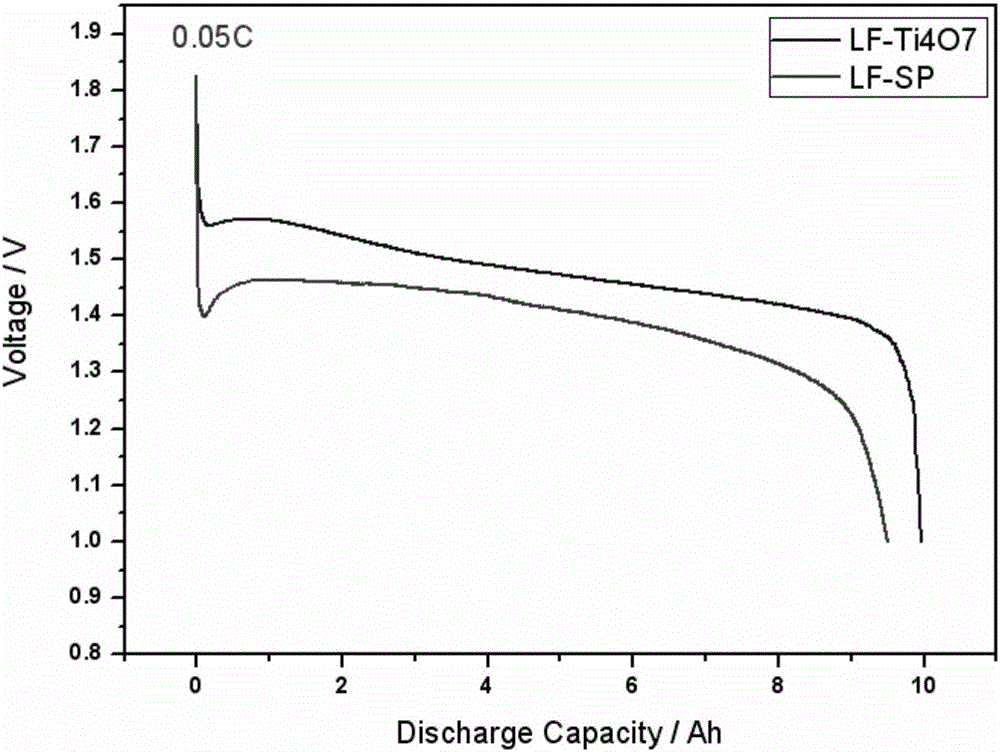

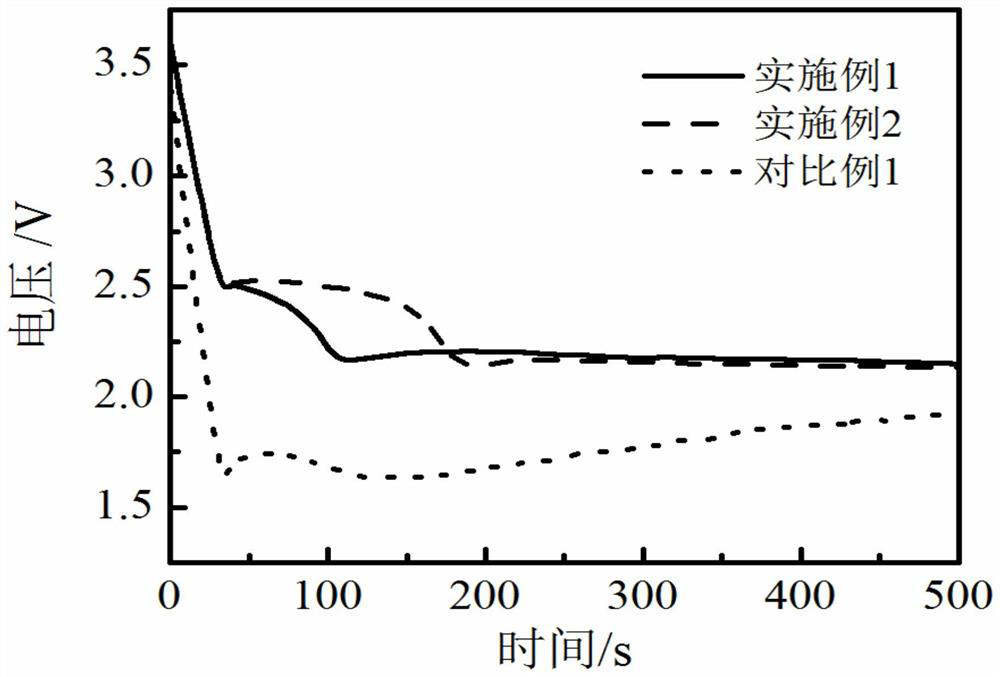

Preparation method of high-power soft-package ferrous disulfide battery

InactiveCN106784818AImprove power characteristicsImprove voltage hysteresisCell electrodesNon-aqueous electrolyte cellsVoltageChemistry

The invention relates to a preparation method of a high-power soft-package ferrous disulfide battery. The invention belongs to the technical field of lithium primary batteries. The preparation method of the high-power soft-package ferrous disulfide battery has the characteristics that preparation of the high-power soft-package ferrous disulfide battery comprises the preparation process of a positive electrode and a negative electrode of a Li / FeS2 soft package battery; the positive electrode adopts an active substance FeS2; a conductive agent contains Ti4O7; the positive electrode is prepared by a coating mode; the power characteristic of the Li / FeS2 battery is improved. The preparation method of the high-power soft-package ferrous disulfide battery has the advantages of simple process, scientific formula, convenience in operation, capabilities of improving the power characteristic of the soft package battery, improving voltage delay of the Li / FeS2 battery, and improving the discharge capacity.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

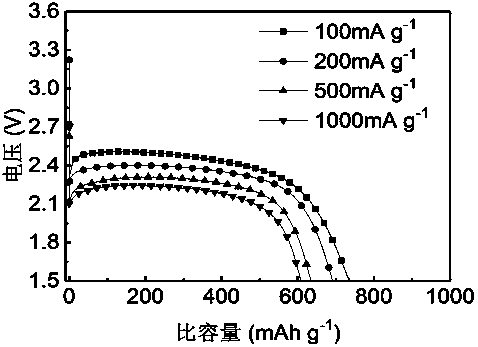

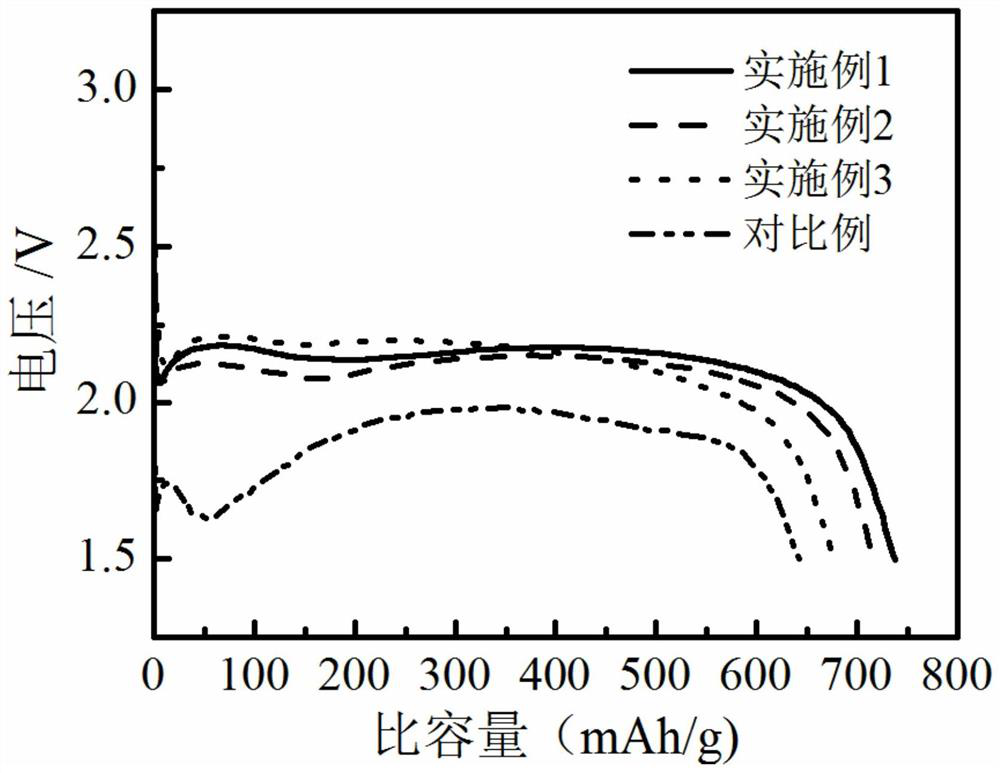

Positive electrode composite material for lithium primary battery and preparation method thereof

ActiveCN113285067AHigh specific capacityImprove conductivityCell electrodesOrganic electrolyte cellsElectrical batteryGraphite

The invention belongs to the technical field of lithium primary battery positive electrode materials, and provides a positive electrode composite material for a lithium primary battery and a preparation method. The positive electrode composite material provided by the invention comprises a carbon fluoride material with high graphitization degree and a fluorinated ketjen black material; the positive electrode composite material is prepared by ball-milling and mixing a high-graphitization-degree carbon fluoride material and a fluorinated ketjen black material; the ball milling time is 8-48 hours, and the mass ratio range is (1: 0.01)-(1: 0.3). The positive electrode composite material obtained by mixing and ball-milling the fluorinated carbon material with high graphitization degree and the fluorinated ketjen black material combines the advantages of the two materials, so that the conductivity of the positive electrode material is improved, and the impedance of charge transfer is effectively reduced. According to the lithium primary battery prepared from the positive electrode composite material, the preparation process of the positive electrode material of the battery is simple, the discharge rate performance of the battery is improved, the voltage hysteresis phenomenon in the discharge process of the battery is effectively improved, and the overall discharge performance of the material is improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

Manufacturing method for lithium thionyl chloride battery electrolyte

The invention discloses a manufacturing method for a lithium thionyl chloride battery electrolyte. The manufacturing method specifically comprises the following steps of putting LiAlCl<4> into a dry container, and rectifying and purifying SOCl<2>; pumping SO<2> gas into the LiAlCl<4>, and then standing for 15-20h after the SO<2> is completely pumped; pumping a proper amount of water vapor to BrCL, and performing a complete reaction to obtain HCl and HBrO; adding the rectified and purified SOCl<2>, HCl and HBrO into a lithium salt product after the SO<2> is completely pumped; and then adding a lithium sheet, and maintaining a humidity dew-point temperature value of the container to be lower than minus 35 DEG C to obtain the electrolyte. According to the manufacturing method for the lithium thionyl chloride battery electrolyte, a proper amount of halogen or halogen compounds is added to the electrolyte; based on a principle that BrCl plus H<2>O is equal to HCl plus HBrO, the content of the halogen or halogen compounds in the electrolyte is increased; and the voltage delay condition of the battery is effectively reduced.

Owner:湖北艾超特新能源有限公司

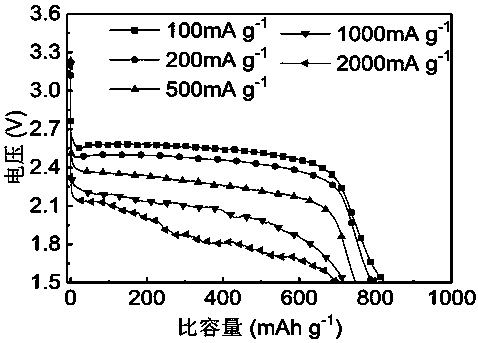

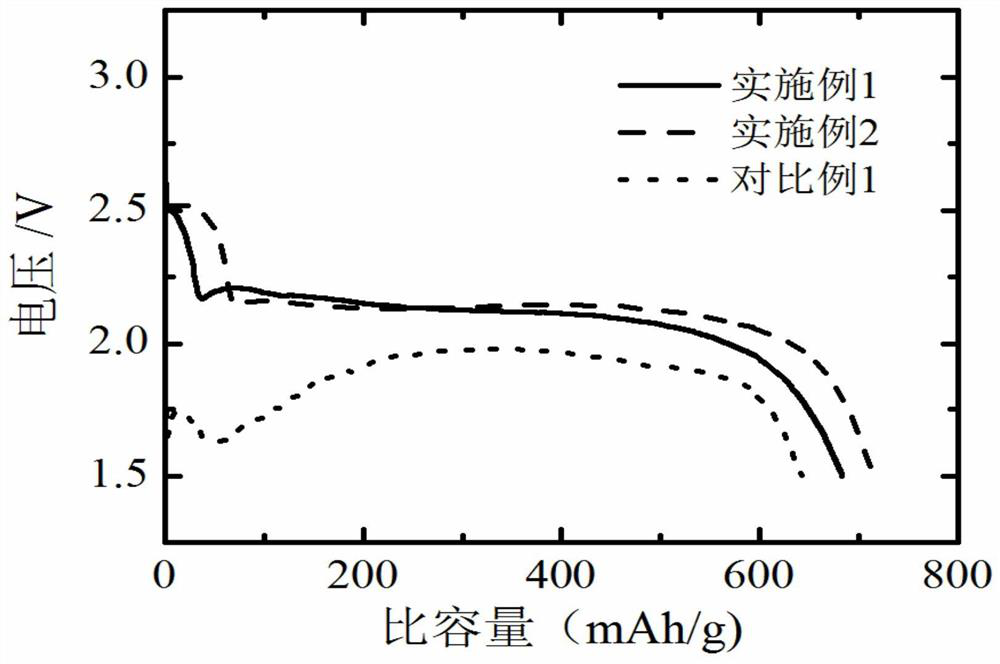

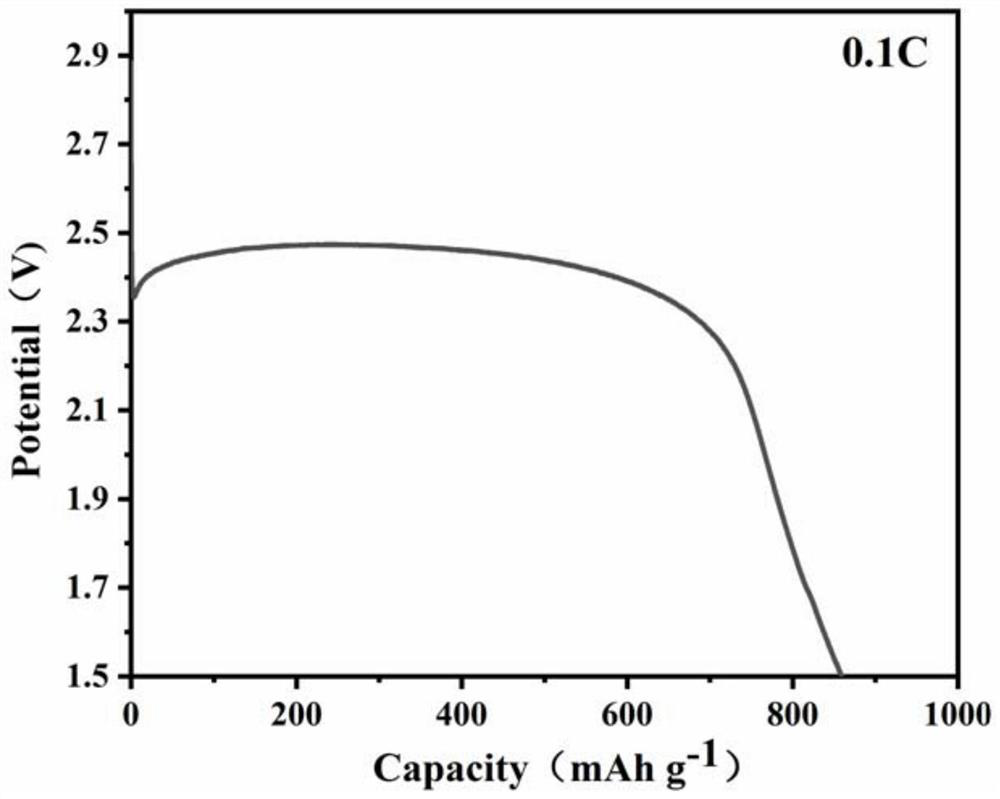

Carbon fluoride composite positive active material for lithium-carbon fluoride battery as well as preparation method and application of carbon fluoride composite positive active material

PendingCN113299912AImprove voltage hysteresisHigh specific capacityCell electrodesOrganic electrolyte cellsBattery cellMaterials science

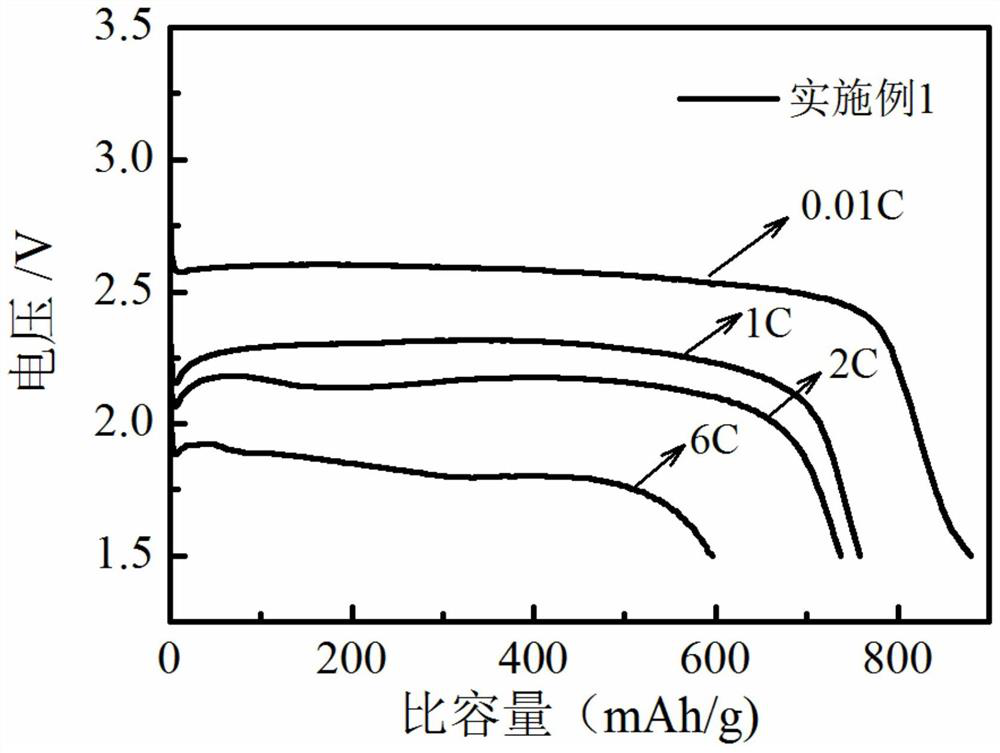

The invention relates to a carbon fluoride composite positive active material for a lithium-carbon fluoride battery as well as a preparation method and application of the carbon fluoride composite positive active material. The invention aims to solve the technical problem that it is difficult for an existing carbon fluoride composite positive electrode active material for the lithium-carbon fluoride battery to simultaneously consider high specific capacity, high rate capability and improvement of voltage hysteresis phenomenon. The material is prepared by ball-milling and mixing carbon fluoride and ketjen black, and the mixing mass ratio of the carbon fluoride to the ketjen black is (1: 0.01)-(1: 0.1). The preparation method comprises the following steps: 1) preparing carbon fluoride by adopting a gas phase fluorination method; and 2) mixing the carbon fluoride and the ketjen black through ball milling to obtain the uniformly mixed carbon fluoride composite material mixed with the ketjen black. When the carbon fluoride composite positive electrode active material is applied to the carbon fluoride composite positive electrode active material for the lithium-carbon fluoride battery, relatively high specific capacity can be reserved, the rate capability can be improved, the discharge rate can reach 6C, and the voltage hysteresis phenomenon at the initial stage of discharge can be improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

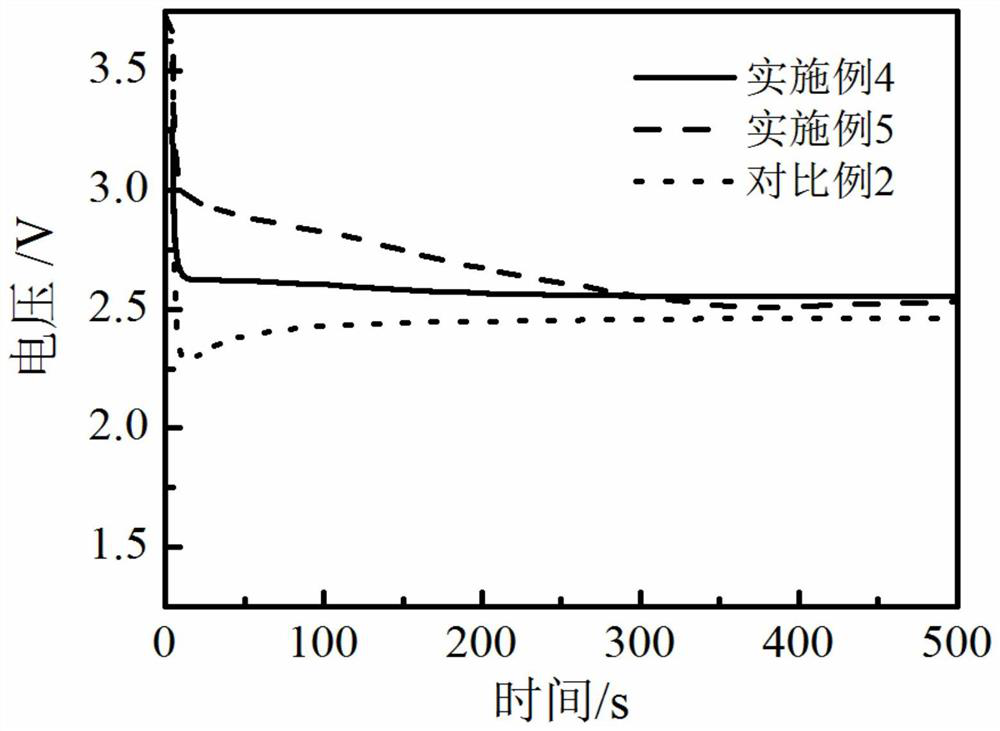

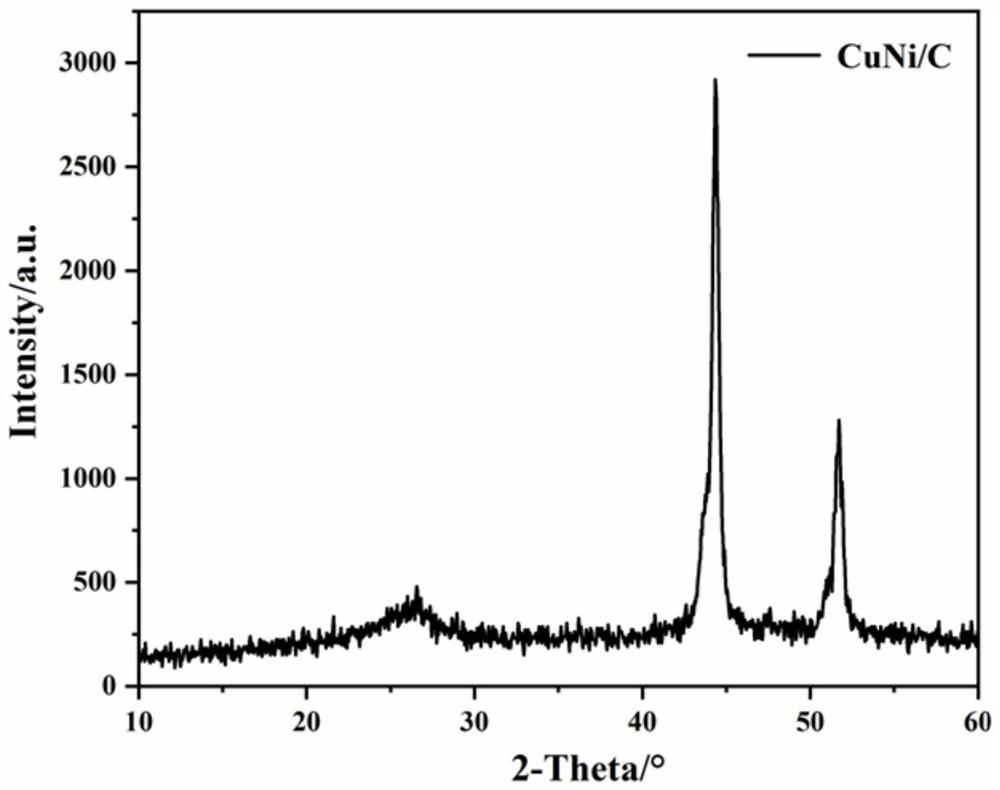

CuNi/C composite catalytic material modified lithium carbon fluoride battery positive plate and preparation method thereof

PendingCN113991051AImprove voltage hysteresisImprove conductivityOrganic electrolyte cellsPositive electrodesCarbon monofluoridePtru catalyst

The invention discloses a CuNi / C composite catalytic material modified lithium carbon fluoride battery positive plate, and the positive plate comprises a current collector and an active substance coating coated on the current collector, and the active substance coating comprises the following components in percentage by mass: 70-90% of carbon fluoride powder, 5-20% of catalyst powder and 5-10% of binder; the catalyst is a CuNi / C composite catalytic material. According to the invention, a compound containing a copper source, a nickel source and a carbon source is used for preparing a CuNi / C composite catalytic material serving as a catalyst, and then a current collector is coated with carbon fluoride and the catalyst, so that the required positive plate is obtained. According to the positive plate, the performance of a lithium carbon fluoride battery is improved, the specific energy and storage performance of the battery are improved, the conductivity of a positive electrode material and the rate capability of the battery are improved, and the preparation method has important practical significance.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of surface modification method of carbon fluoride material

ActiveCN104577107BImprove voltage hysteresisHigh rate dischargeNanotechnologyPrimary cell electrodesPowder mixtureSolvent

The invention relates to a surface finish method of a carbon fluoride material. The method comprises the following steps: (1) mixing nanometer copper and carbon fluoride, then adding a solvent for ball milling so as to form a combined pulp; (2) drying the mixed pulp so as to form a mixture; (3) screening the mixture so as to obtain the powder mixture; (4) putting the powder mixture into an atmosphere oven so as to be calcined; (5) taking out the calcined powder mixture, lowering the temperature of the calcined powder mixture to the room temperature, and then screening the calcined powder mixture of which the temperature is lowered so as to form the carbon fluoride material modifies by the nanometer copper. According to the invention, the carbon fluoride and the nanometer copper with good conductivity are mixed, and after the mixture is calcined at a high temperature in an inert atmosphere, the nanometer copper reacts on the surface of the carbon fluoride, so that the phenomenon that the voltage of carbon fluoride is delayed is obviously improved, and high-ratio discharge and low temperature performance are greatly improved. The carbon fluoride with a finished surface, prepared by the method, is used as a positive material to be made into a lithium-carbon fluoride battery system, wherein the lithium-carbon fluoride battery system has the properties of high-ratio discharge and low temperature high-current discharge, so that the application range of the lithium-carbon fluoride battery system is extended.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Manufacturing method for lithium/thionyl chloride battery

InactiveCN106229546AImprove performanceGood discharge voltageFinal product manufactureElectrolyte accumulators manufactureGlass fiberAir blower

The invention relates to a manufacturing method for a lithium / thionyl chloride battery. The method comprises the following steps: adding calcium chloride at mass ratio of 0.02-0.05 in a production process of a cathode material, thereby obtaining the cathode material of the lithium / thionyl chloride battery containing calcium chloride; adding calcium chloride till calcium chloride is saturated in an electrolyte material in the production process of the electrolyte material, thus obtaining the electrolyte material of the lithium / thionyl chloride battery containing calcium chloride; winding the cathode material of the lithium / thionyl chloride battery containing calcium chloride, the glass fiber diaphragm and the metal lithium anode into a battery core under a dry environment at relative humidity less than or equal to 1%; packaging into a battery shell; performing girth welding on the battery, injecting the electrolyte material of the lithium / thionyl chloride battery containing calcium chloride into the battery, plugging the hole and welding according to the present technique; at last, storing the lithium / thionyl chloride battery containing calcium chloride into a hot air blower box with the temperature of 54 DEG C for 48h and thus obtaining the end product.

Owner:SUZHOU JINKEFA LITHIUM BATTERY

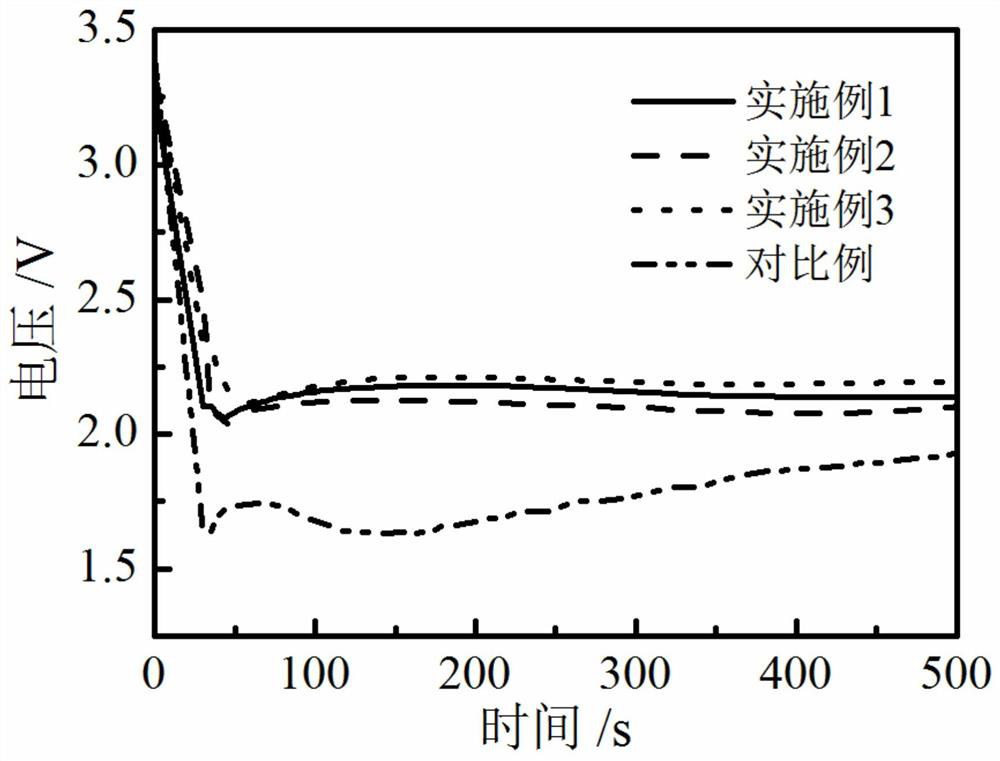

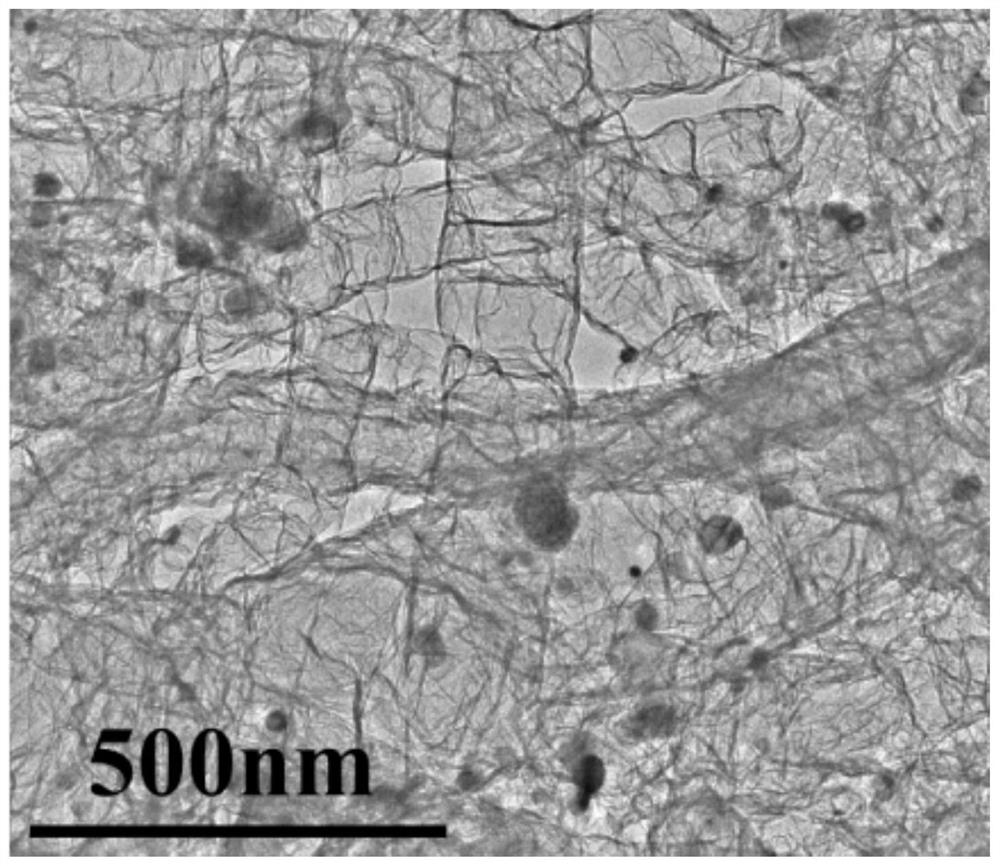

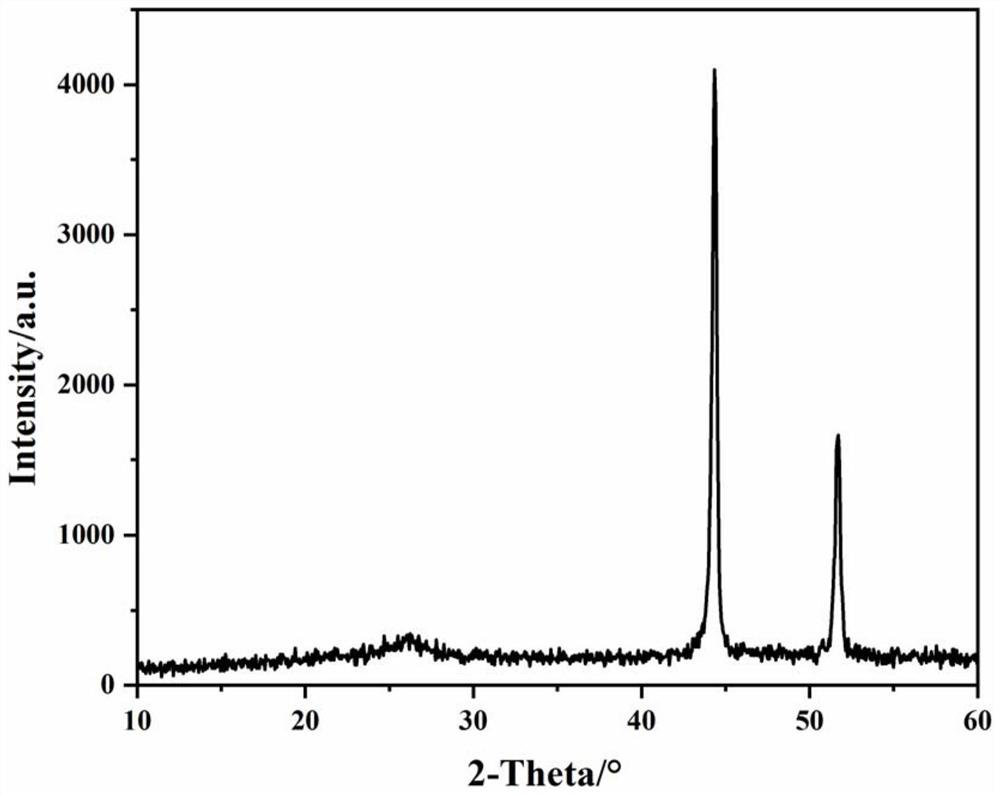

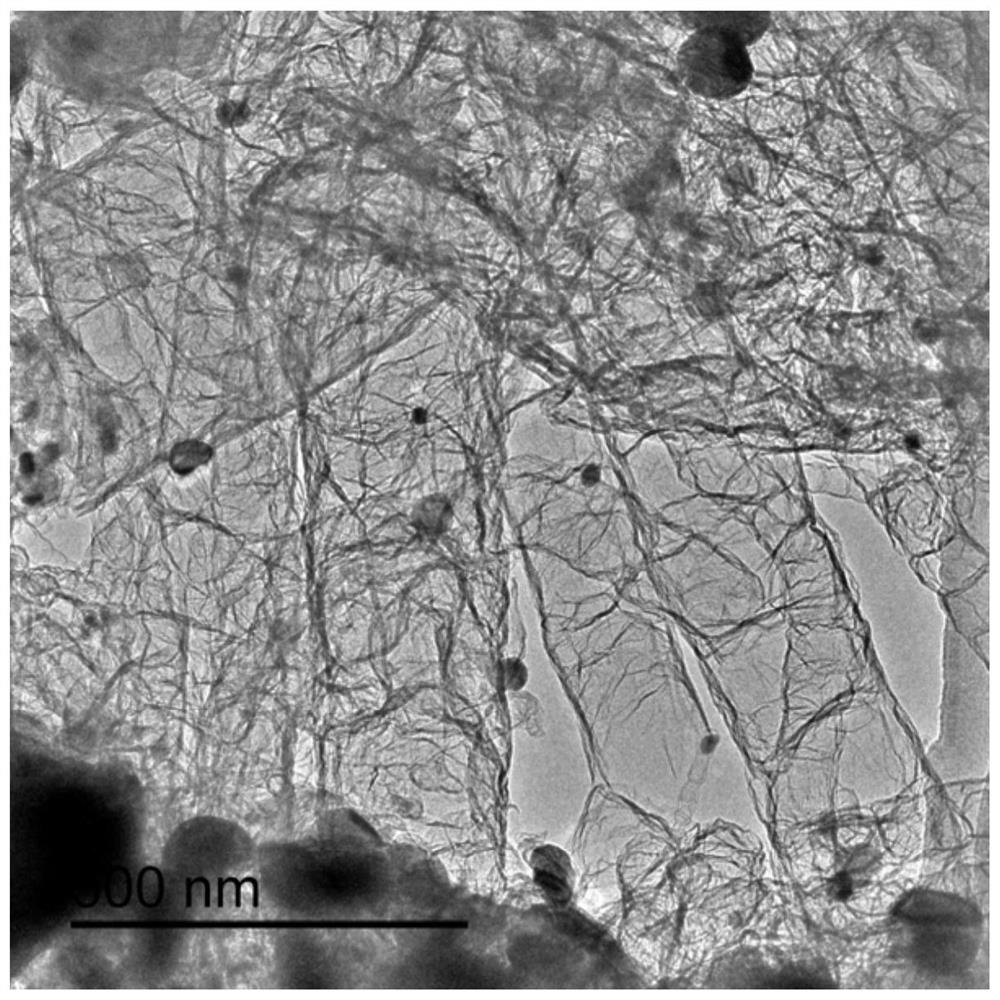

Nickel-based high-entropy alloy/carbon nanotube modified lithium carbon fluoride battery positive electrode plate and preparation method thereof

PendingCN113972377AImprove conductivityIncrease capacityPositive electrodesNon-aqueous electrolyte accumulator electrodesPtru catalystHigh entropy alloys

The invention discloses a nickel-based high-entropy alloy / carbon nanotube modified lithium carbon fluoride battery positive electrode plate. The nickel-based high-entropy alloy / carbon nanotube modified lithium carbon fluoride battery positive electrode plate comprises a current collector and an active substance coating applied onto the current collector; the active substance coating comprises the following components in percentage by mass: 70-90% of carbon fluoride powder, 5-20% of catalyst powder and 5-10% of binder, wherein the catalyst is a nickel-based high-entropy alloy / carbon nanotube composite material. According to the method, the nickel-based high-entropy alloy / carbon nanotube composite material is prepared from a compound containing an iron source, a cobalt source, a copper source, a zinc source, a nickel source and a carbon source to serve as the catalyst, and then the current collector is coated with the carbon fluoride and the catalyst; after the carbon fluoride and the nickel-based high-entropy alloy / carbon nanotubes are mixed, the conductivity of the battery positive electrode material is improved, the carbon fluoride voltage hysteresis phenomenon is improved, the capacity, the storage performance, the rate capability and the platform stability of a lithium carbon fluoride high-voltage plateau are improved, and the performance improvement of a lithium carbon fluoride battery is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of fluorinated nano-graphite as cathode material for lithium fluoride battery

The invention discloses a preparation method of fluorinated nano-graphite, which is a positive electrode material of a lithium fluoride carbon battery, and belongs to the technical field of lithium battery positive electrode materials. Using magnetic stirring and grinding method to prepare nano-graphite as a precursor, using direct fluorination method, fluorine gas and nano-graphite material to generate intercalation compounds of two elements of carbon and fluorine at high temperature to obtain fluorinated nano-graphite material. The preparation process of the method is simple, the process conditions are relatively mild, and the prepared fluorinated nano-graphite has a stable structure. voltage lag problem. Fluorinated nano-graphite material is a kind of cathode material for lithium carbon fluoride battery with excellent performance.

Owner:SHANDONG UNIV OF TECH

Lithium cell utilizing foamed nickel material as current-collecting body and producing method thereof

InactiveCN1321473CImprove electron conduction pathwaysImproved ability to work with heavy loadsElectrode manufacturing processesElectrode carriers/collectorsNickel electrodeHeavy load

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Lithium/thionyl chloride battery electrolyte and preparation method thereof

ActiveCN109742446AImprove discharge capacityImprove voltage hysteresisLi-accumulatorsSecondary cells servicing/maintenancePhysical chemistryBattery electrolyte

The invention discloses a lithium / thionyl chloride battery electrolyte and a preparation method thereof. The lithium / thionyl chloride battery electrolyte comprises thionyl chloride, electrolyte saltsand additives, wherein the additives comprise a first additive and a second additive. The preparation method comprises the following steps that the thionyl chloride is distilled, and cut fraction is collected; the electrolyte salt is weighed and dissolved in the thionyl chloride cut fraction; purification of the first additive is carried out; purification of the second additive is carried out; andthe purified first additive and the purified second additive are weighed and added into a thionyl chloride solution of the electrolyte salt to obtain the lithium / thionyl chloride battery electrolyte.The first additive and the second additive in the lithium / thionyl chloride battery electrolyte act synergistically so as to enable a lithium / thionyl chloride battery to obtain good discharge voltageand discharge capacity, the voltage hysteresis phenomenon of the lithium / thionyl chloride battery is obviously avoided, and the lithium / thionyl chloride battery prepared from the electrolyte has better cycle performance and higher safety.

Owner:江苏中禄满新材料科技有限公司

Lithium/thionyl chloride battery electrolyte

PendingCN112072178AImprove discharge capacityImprove voltage hysteresisSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentPhysical chemistry

The invention discloses a lithium / thionyl chloride battery electrolyte which comprises thionyl chloride, electrolyte salt and additives, the additives comprise a first additive and a second additive,and the preparation method comprises the following steps: distilling thionyl chloride, collecting fractions, weighing electrolyte salt, dissolving the electrolyte salt in the thionyl chloride fraction, purifying the first additive, purifying the second additive, weighing the purified first additive and the purified second additive, and adding the first additive and the second additive into the thionyl chloride solution of the electrolyte salt to obtain the lithium thionyl chloride battery electrolyte. The first additive and the second additive in the lithium thionyl chloride battery electrolyte have a synergistic effect, so that the lithium / thionyl chloride battery obtains good discharge voltage and discharge capacity, and the voltage lag phenomenon of the lithium / thionyl chloride batteryis remarkably improved, and the lithium thionyl chloride battery prepared from the electrolyte has relatively good cycle performance and relatively high safety.

Owner:裴广华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com