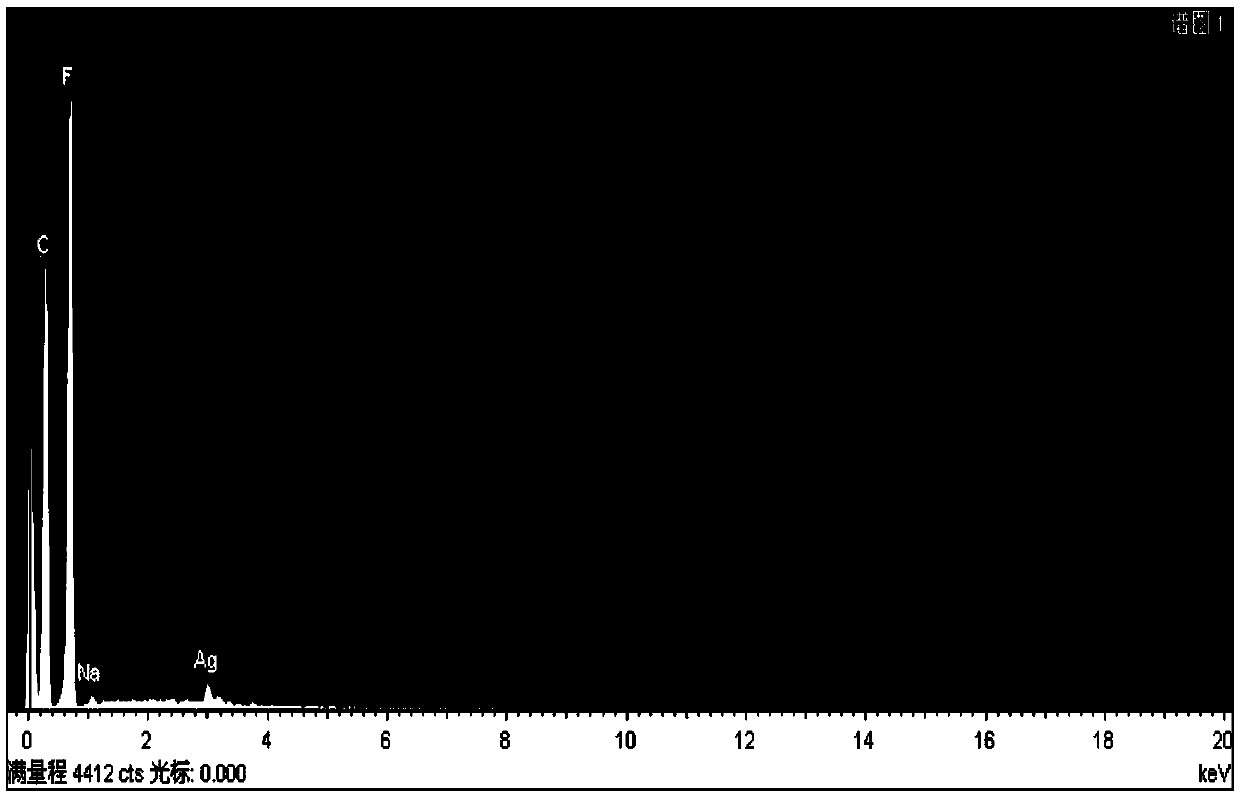

Preparation method of Ag@C-modified fluorinated carbon electrode material

An electrode material, carbon fluoride technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unsatisfactory results, achieve significant effects, improve discharge performance, and improve voltage hysteresis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

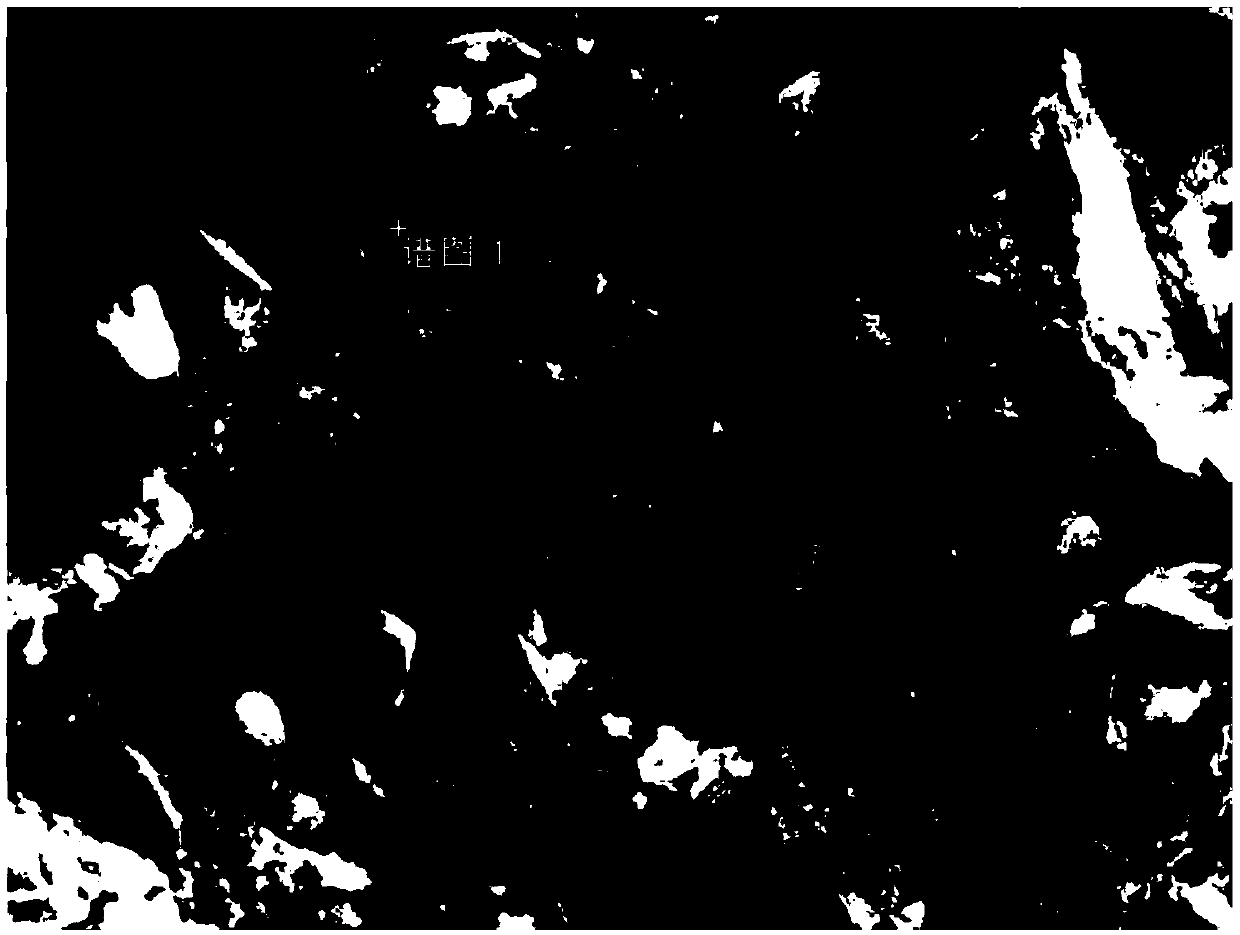

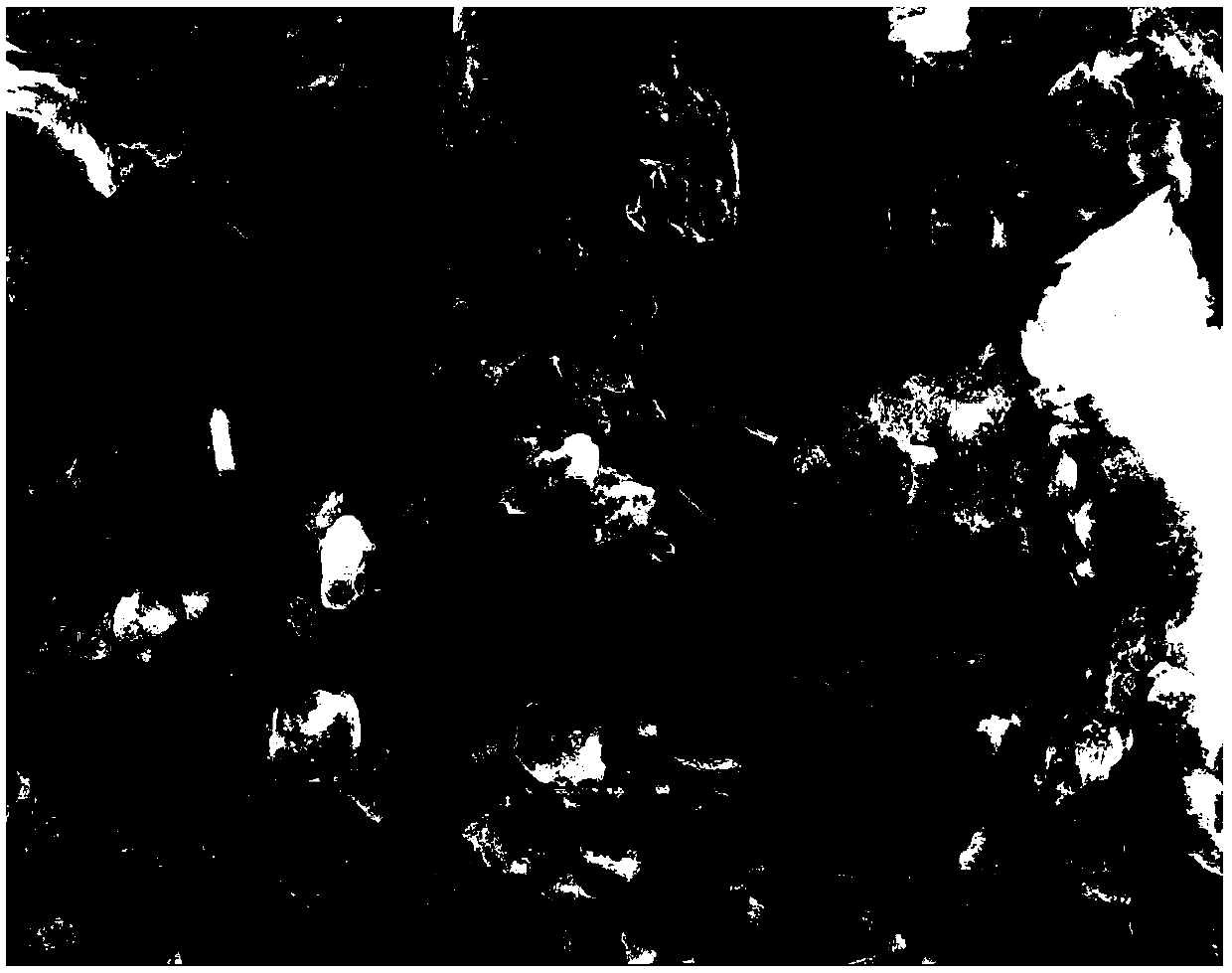

[0044] A preparation method of Ag@C modified carbon fluoride electrode material, the method is chemical reduction, comprising the following steps:

[0045] Step a, add the Ag compound and the solvent into the reactor according to the mass ratio=0.5:500, control the stirring speed of the reactor to 300r / min, and the stirring time is 30min; the solvent is composed of absolute ethanol and water according to the mass ratio=2.5 : 1 mix uniformly and make; Described Ag compound is silver nitrate;

[0046] Step b, adding carbon fluoride to the above-mentioned reactor, controlling the stirring speed of the reactor to 650r / min, and the stirring time is 1.6h to obtain a uniformly mixed mixed solution; the mass ratio of the carbon fluoride to the Ag compound=100 :0.5;

[0047] Step c, controlling the stirring speed of the reactor to 200r / min, adding NaOH or KOH aqueous solution with a mass fraction of 20% to the above mixed solution to obtain an alkaline solution with a pH value of 13; ...

Embodiment 2

[0058] A preparation method of Ag@C modified carbon fluoride electrode material, the method is chemical reduction, comprising the following steps:

[0059] Step a, Ag compound and solvent are added in the reactor according to mass ratio=5:500, and the stirring speed of control reactor is 400r / min, and stirring time is 40min; Described Ag compound is silver nitrate; Described solvent is made of anhydrous Ethanol and water are prepared by mixing uniformly according to the mass ratio = 3:1;

[0060] Step b, adding carbon fluoride to the above-mentioned reactor, the stirring speed of the control reactor is 800r / min, and the stirring time is 2h to obtain a uniform mixed solution; the mass ratio of the carbon fluoride and the Ag compound=100: 5;

[0061] Step c, controlling the stirring speed of the reactor to 300r / min, adding NaOH or KOH aqueous solution with a mass fraction of 25% to the above mixed solution to obtain an alkaline solution with a pH value of 14;

[0062] Step d, ...

Embodiment 3

[0071] A preparation method of Ag@C modified carbon fluoride electrode material, the method is chemical reduction, comprising the following steps:

[0072] Step a, Ag compound and solvent are added in the reactor according to mass ratio=1:500, and the stirring speed of control reactor is 200r / min, and stirring time is 20min; Described Ag compound is silver nitrate; Described solvent is made of anhydrous Ethanol and water are prepared by mixing uniformly according to the mass ratio = 2:1;

[0073] Step b, adding carbon fluoride to the above-mentioned reactor, controlling the stirring speed of the reactor to be 500r / min, and the stirring time is 1h to obtain a uniform mixed solution; the mass ratio of the carbon fluoride to the Ag compound=100: 4.5;

[0074] Step c, controlling the stirring speed of the reactor to 100r / min, adding NaOH or KOH aqueous solution with a mass fraction of 15% to the above mixed solution to obtain an alkaline solution with a pH value of 12;

[0075] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com