Preparation method of modified carbon fluoride positive electrode material

A technology of positive electrode material and carbon fluoride, applied in battery electrodes, electrical components, non-aqueous electrolyte batteries, etc., can solve problems such as restricting the use of lithium/carbon fluoride batteries, affecting battery discharge performance, and increasing battery internal resistance. Achieve the effect of improving rate discharge performance, improving voltage hysteresis at the initial stage of discharge, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A method for preparing a modified carbon fluoride positive electrode material, comprising the following preparation steps:

[0020] (1) Selection of raw materials: including fluorocarbons, additional carbon sources, and binders;

[0021] (2) Preparation of modified carbon fluoride cathode material: After mixing fluoride carbon, additional carbon source and binder according to a certain proportion, the material is subjected to carbothermal reduction treatment under nitrogen atmosphere for a certain period of time, and the obtained material after cooling is The modified carbon fluoride cathode material in the present invention.

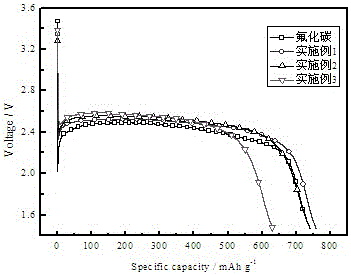

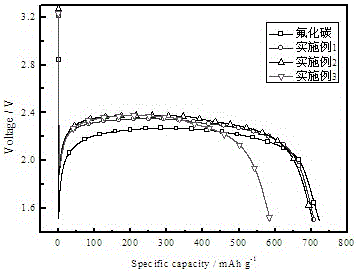

Embodiment 1

[0022] Embodiment 1: fluorinated graphite with a mass ratio of 9:0.7:0.3, carbon source and binder are subjected to carbothermal reduction treatment, the reaction temperature is 450°C, and the reaction time is 4h. After the treatment is completed, it is prepared by the present invention Modified fluorocarbon materials. The modified fluorinated carbon material prepared in the present invention is selected to be bonded to an aluminum current collector and coated with a conductive agent to form a positive electrode. The content of modified fluorocarbon material is 88%. The conductive agent can be conductive carbon black and carbon nanotubes, and the total content of the conductive agent is 5%. The type of binder is styrene-butadiene rubber and sodium carboxymethyl cellulose, and the content is 7%. The positive electrode sheet is paired with the metal lithium sheet to form a lithium / carbon fluoride battery.

Embodiment 2

[0023] Embodiment 2: fluorinated graphite with a mass ratio of 8.5:1:0.5, carbon source and binder are subjected to carbothermal reduction treatment, the reaction temperature is 450°C, and the reaction time is 4h. After the treatment is completed, it is prepared by the present invention Modified fluorocarbon materials. The modified fluorinated carbon material prepared in the present invention is selected to be bonded to an aluminum current collector and coated with a conductive agent to form a positive electrode. The content of modified fluorocarbon material is 88%. The conductive agent can be conductive carbon black and carbon nanotubes, and the total content of the conductive agent is 5%. The type of binder is styrene-butadiene rubber and sodium carboxymethyl cellulose, and the content is 7%. The positive electrode sheet is paired with the metal lithium sheet to form a lithium / carbon fluoride battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com