Lithium ion battery negative material and preparation method thereof

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as the unfavorable factors of battery capacity improvement, and achieve the effects of superior electrochemical performance, easy operation, and reduction of irreversible loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] First, 7g of metallic lithium powder was gradually dissolved in a Dewar flask containing 1L of liquid ammonia to form a 1mol / L dark blue lithium solution; secondly, 58.1g of propylene oxide was added to the above lithium solution under magnetic stirring conditions, Stir evenly to obtain a white sol solution; then, gradually add 120 g of natural graphite to the above sol solution while stirring, and stir for 1 hour to obtain a uniformly dispersed suspension; then, evaporate the above suspension to dryness at 60°C to obtain a precursor powder Grind the powder evenly and place it in a vacuum drying oven for 10 hours at 120°C for vacuum drying; finally, put the vacuum-dried powder into a corundum boat, and heat it at 600°C for 5 hours in an atmosphere furnace with nitrogen to obtain the pre-embedded Lithium's natural graphite material.

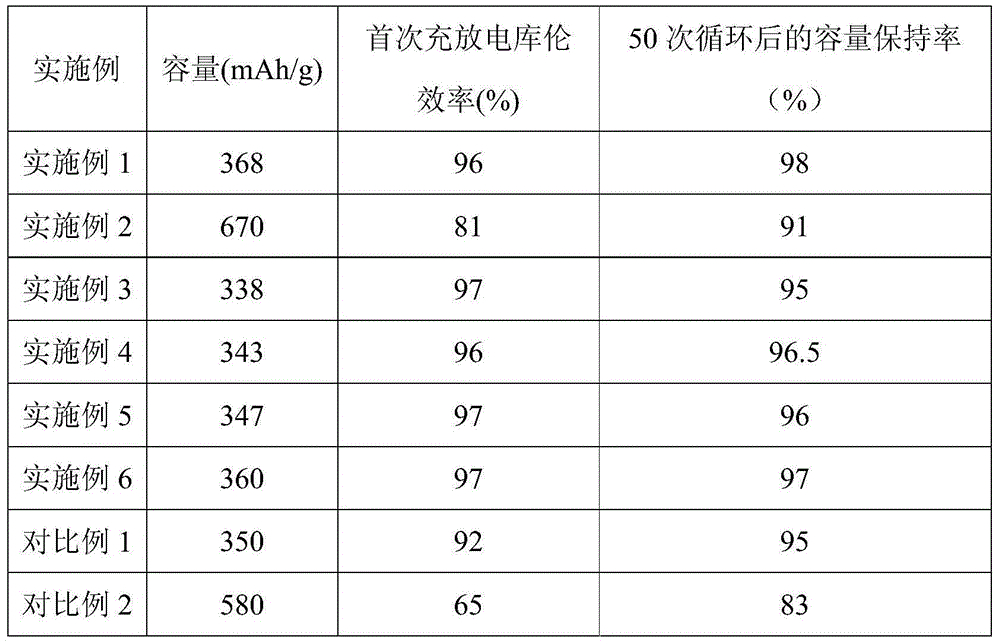

[0036] Electrochemical performance test: The above-mentioned pre-lithiated graphite, binder (PVDF) and conductive agent acetylene black ar...

Embodiment 2

[0038] Dissolve 7g of lithium metal powder successively in a Dewar flask containing 1L of liquid ammonia to form a 1mol / L dark blue lithium solution; add 58.1g of propylene oxide to the above lithium solution under magnetic stirring conditions, and stir evenly to obtain A white sol solution; gradually add 120g of graphene to the above sol solution while stirring, and stir for 0.5h to obtain a uniformly dispersed suspension; evaporate the above suspension to dryness at 60°C to obtain a precursor powder, and grind the powder evenly Put it in a vacuum drying oven at 120°C for 10 hours; put the vacuum-dried powder into an atmosphere furnace with nitrogen, and heat it at 600°C for 5 hours to obtain a graphene material with embedded lithium.

[0039] The electrochemical performance testing method and conditions are the same as those in Example 1 above.

Embodiment 3

[0041]Dissolve 7g of lithium metal powder successively in a Dewar flask containing 1L of liquid ammonia to form a 1mol / L dark blue lithium solution; add 58.1g of propylene oxide to the above lithium solution under magnetic stirring conditions, and stir evenly to obtain A white sol solution; gradually add 60g of mesocarbon microspheres to the above sol solution while stirring, stir for 0.5h to obtain a uniformly dispersed suspension, evaporate the above suspension to dryness at 60°C to obtain a precursor powder; powder After grinding evenly, place it in a vacuum drying oven for 10 hours at 120°C for vacuum drying; put the vacuum-dried powder into an atmosphere furnace with nitrogen, and heat it at 600°C for 5 hours to obtain the lithium-embedded mesophase carbon microsphere material.

[0042] The electrochemical performance testing method and conditions are the same as those in Example 1 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com