Carbon fluoride composite positive active material for lithium-carbon fluoride battery as well as preparation method and application of carbon fluoride composite positive active material

A carbon fluoride battery, the technology of using carbon fluoride, applied in the direction of carbon fluoride, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of high rate performance voltage lag, difficult to take into account high specific capacity and other problems, and achieve polarization phenomenon The effect of reducing and improving battery rate performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

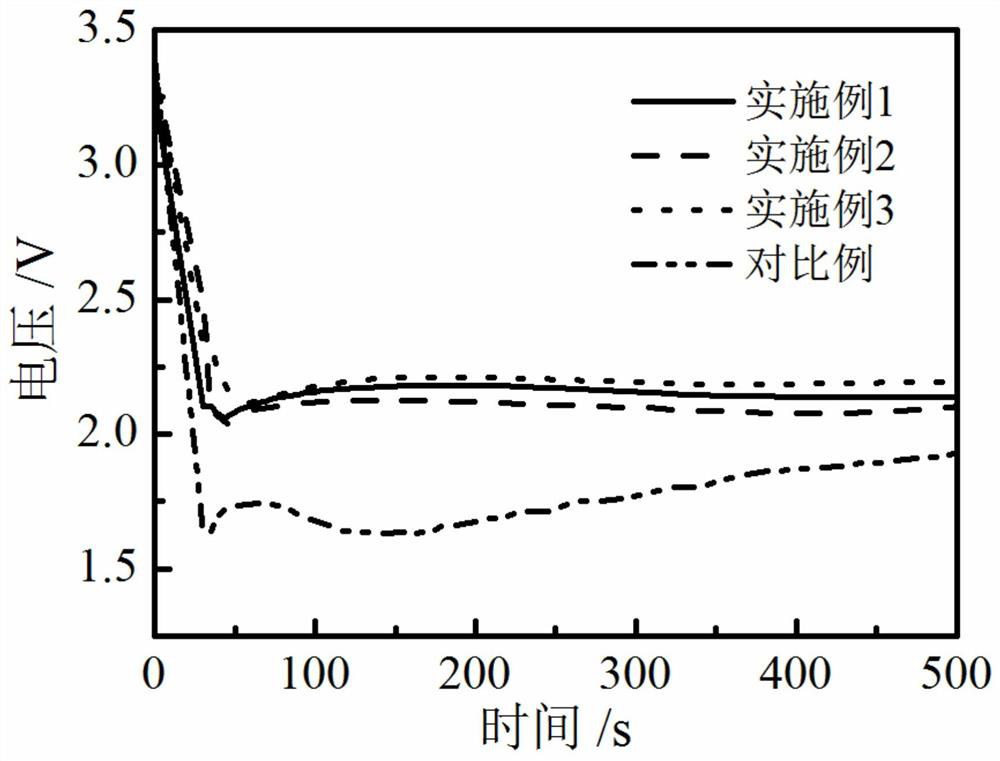

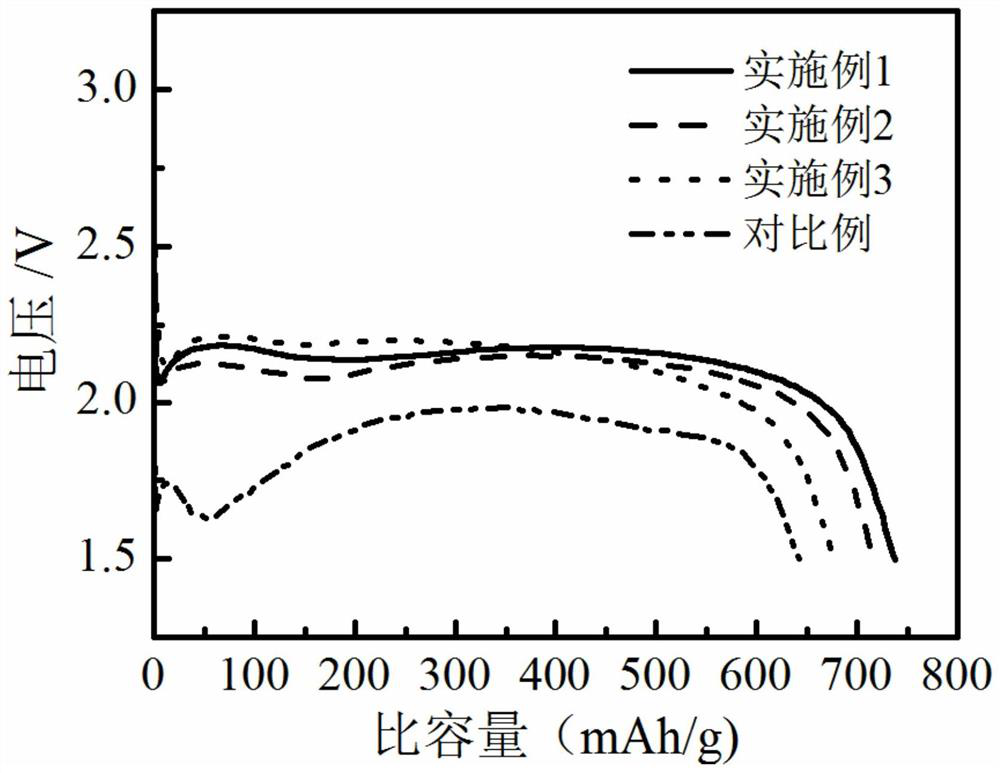

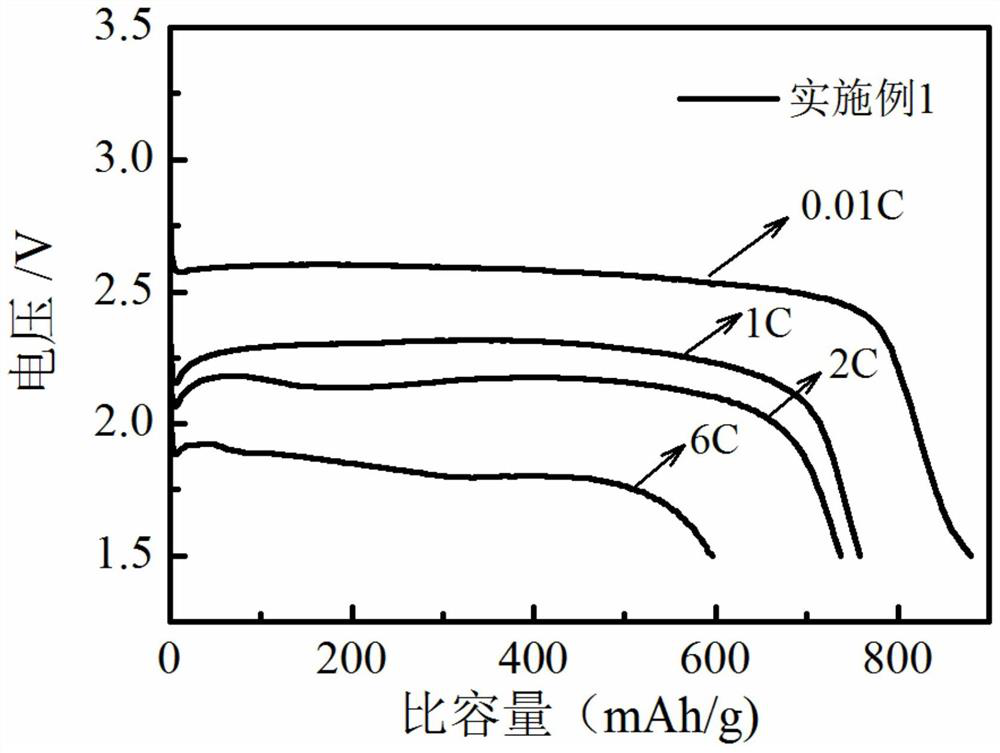

Embodiment 1

[0038] 1.1) Place 10.0 g of the pretreated graphite powder in an airtight container, and pour a fluorinated reagent into the airtight container, and the fluorinated reagent is 100% NF 3 gas; the material of the heated part of the airtight container is pure nickel, and the material of the rest of the container is stainless steel;

[0039] 1.2) Keep the pressure in the airtight container at 120Kpa and 500℃, and heat for 8h;

[0040] 1.3) After the reaction, the temperature in the airtight container is lowered to room temperature, and the product is taken out and vacuum-dried at 200° C. for 6 hours to obtain carbon fluoride;

[0041] 2) put carbon fluoride and ketjen black into a ball mill tank according to the mixing mass ratio of 1:0.02 and carry out ball milling mixing, the ball milling time is 24h, and the ball mill rotating speed is 100 rev / min, to obtain a well-mixed mixture of ketjen black. Fluorocarbon composites.

Embodiment 2

[0043] 1.1) Place 10.0 g of the pretreated graphite powder in an airtight container, and pass a fluorinating reagent into the airtight container, and the fluorinating reagent is 90% NF 3 gas; the material of the heated part of the airtight container is pure nickel, and the material of the rest of the container is stainless steel;

[0044] 1.2) Keep the pressure in the airtight container at 140Kpa and 500℃, and heat for 10h;

[0045] 1.3) After the reaction, the temperature in the airtight container is lowered to room temperature, and the product is taken out and vacuum-dried at 200° C. for 6 hours to obtain carbon fluoride;

[0046] 2) put carbon fluoride and ketjen black into the ball mill tank according to the mixing mass ratio of 1:0.05 and carry out ball milling mixing, the ball milling time is 12h, and the ball mill rotating speed is 300 rev / min, to obtain uniformly mixed with Ketjen black. Fluorocarbon composites.

Embodiment 3

[0048] 1.1) Place 10.0 g of the pretreated graphite powder in an airtight container, and pass a fluorinating reagent into the airtight container, and the fluorinating reagent is 80% NF 3 gas; the material of the heated part of the airtight container is pure nickel, and the material of the rest of the container is stainless steel;

[0049] 1.2) Keep the pressure in the airtight container at 140Kpa and 500℃, and heat for 8h;

[0050] 1.3) After the reaction, the temperature in the airtight container is lowered to room temperature, and the product is taken out and vacuum-dried at 200° C. for 6 hours to obtain carbon fluoride;

[0051] 2) put carbon fluoride and ketjen black into the ball mill tank according to the mixing mass ratio of 1:0.03 and carry out ball milling mixing, the ball milling time is 24h, and the ball mill rotating speed is 200 rev / min, to obtain the homogeneous mixture mixed with ketjen black. Fluorocarbon composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com