Pitch carbon coated fluorocarbon cathode material and preparation method thereof

A carbon fluoride-coated, positive electrode material technology, applied to battery electrodes, organic electrolyte batteries, electrical components, etc., can solve problems such as uneven mixing, environmental pollution of organic solvents, and large amount of modifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

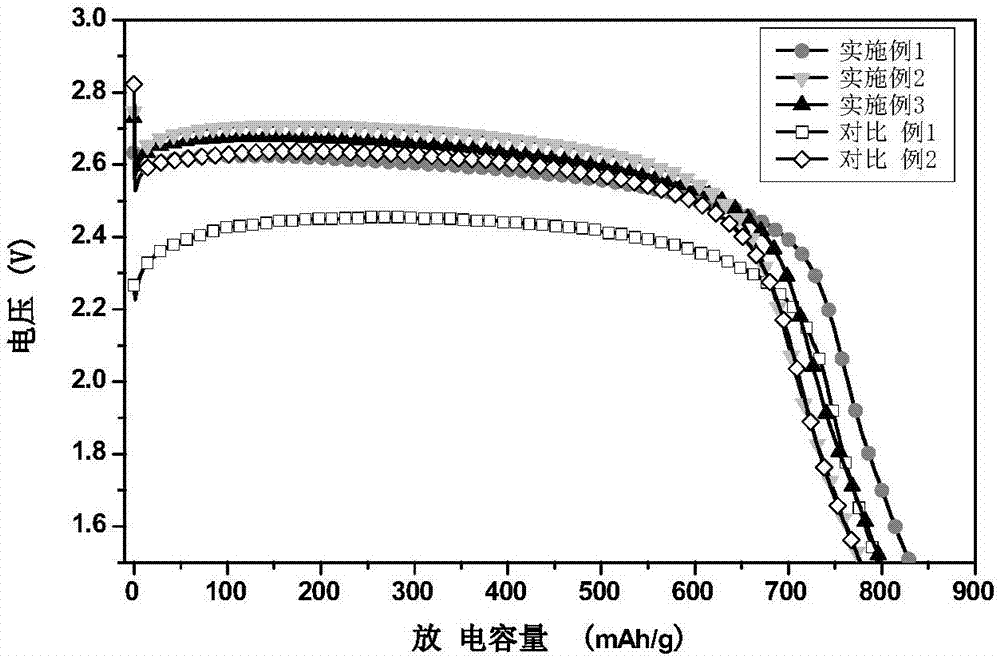

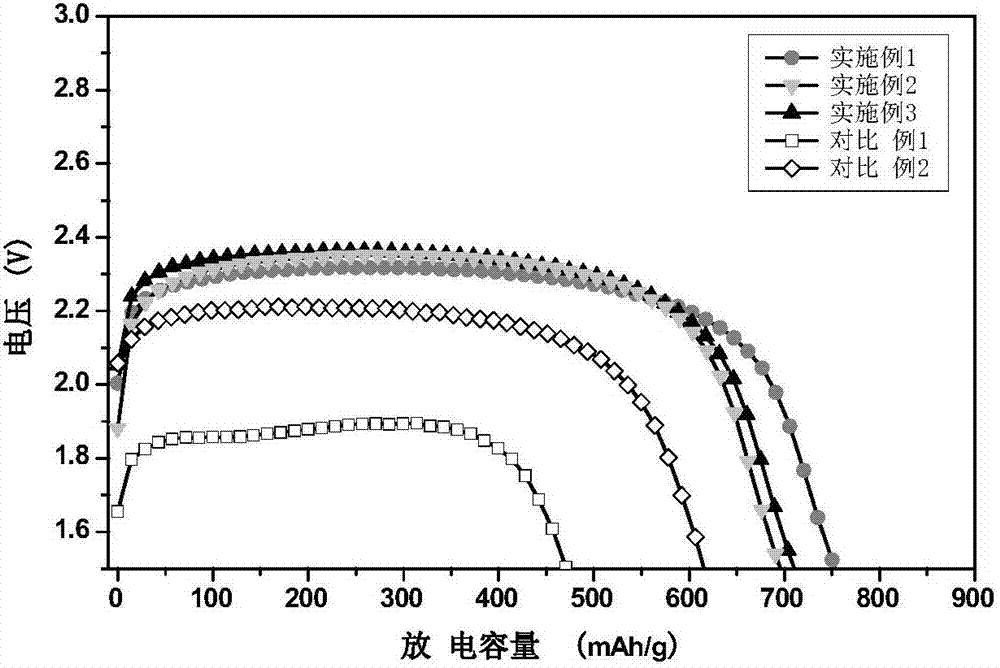

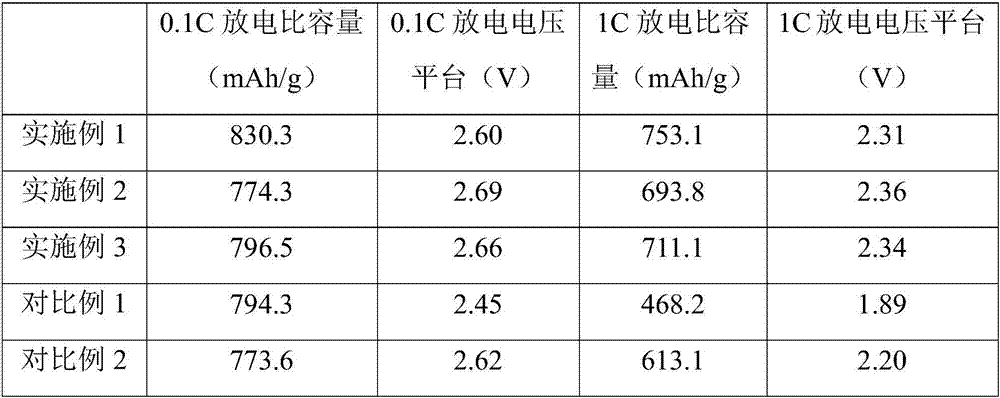

Embodiment 1

[0022] Weigh pitch and carbon fluoride according to the mass of carbon in pitch accounting for 1% of the mass of carbon fluoride, mix the two, and then heat-treat at 500°C for 2 hours in a nitrogen atmosphere; cool and sieve to obtain pitch carbon-coated fluoride carbon cathode material.

[0023] Test the discharge performance of the pitch carbon-coated carbon fluoride cathode material obtained in this embodiment in a 2032-type button cell;

[0024] The composition of the electrode material is: the weight ratio of pitch carbon-coated carbon fluoride positive electrode material to conductive agent SP and binder PVDF is 90:5:5; the counter electrode is metal lithium; the electrolyte is 1mol / L LiPF 6 EC / DMC (1:1 by volume) solution; the membrane is Cellgard 2400 microporous membrane. The current density of the battery test is 0.1C and 1C, and the discharge voltage range is 3-1.5V.

Embodiment 2

[0026] Weigh pitch and carbon fluoride according to the mass of carbon in pitch accounting for 5% of the mass of carbon fluoride, mix the two, and then heat-treat at 400°C for 5 hours in an argon atmosphere; cool and sieve to obtain pitch carbon-coated fluorine carbonized cathode material.

[0027] According to the method in Example 1, the discharge performance of the pitch carbon-coated carbon fluoride positive electrode material obtained in this example in a 2032-type button battery was tested.

Embodiment 3

[0029] Weigh pitch and carbon fluoride according to the mass of carbon in pitch accounting for 2% of the mass of carbon fluoride, mix the two, and then heat-treat at 400°C for 8 hours in a nitrogen atmosphere; cool and sieve to obtain pitch carbon-coated fluoride carbon cathode material.

[0030] According to the method in Example 1, the discharge performance of the pitch carbon-coated carbon fluoride positive electrode material obtained in this example in a 2032-type button battery was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com