Preparation method of high-power soft-package ferrous disulfide battery

A technology for iron disulfide batteries and flexible packaging batteries, which is applied in the direction of primary batteries, battery electrodes, non-aqueous electrolyte batteries, etc., and can solve the problems of affecting battery energy, large polarization, and large thickness of lithium in the negative electrode, so as to improve discharge capacity and operate Convenience, improve the effect of voltage hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

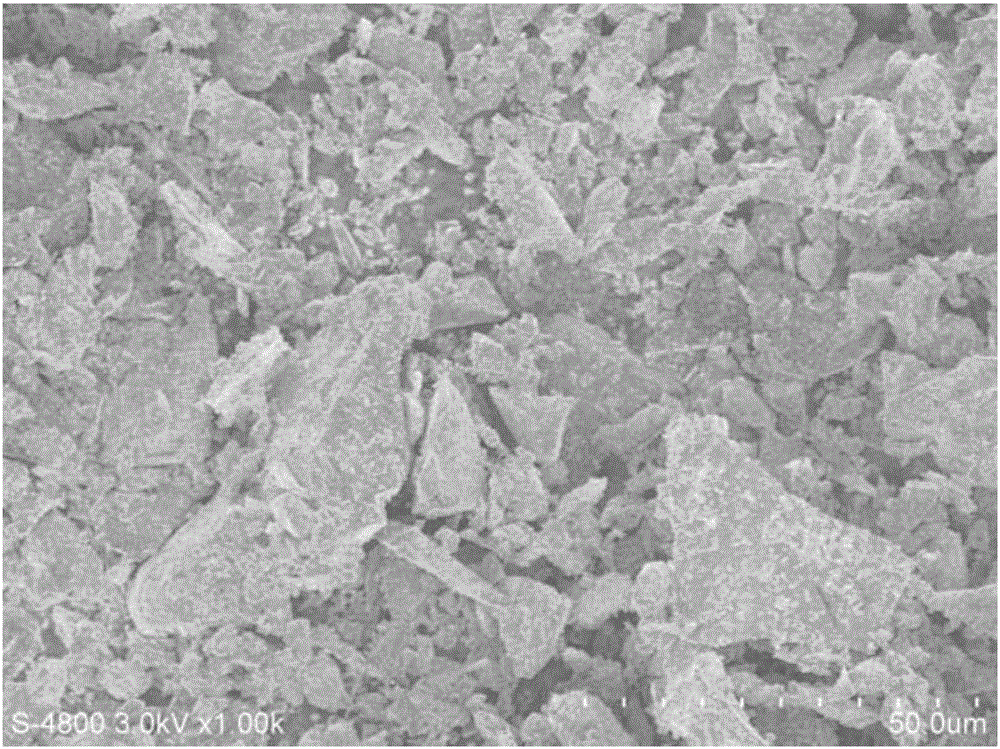

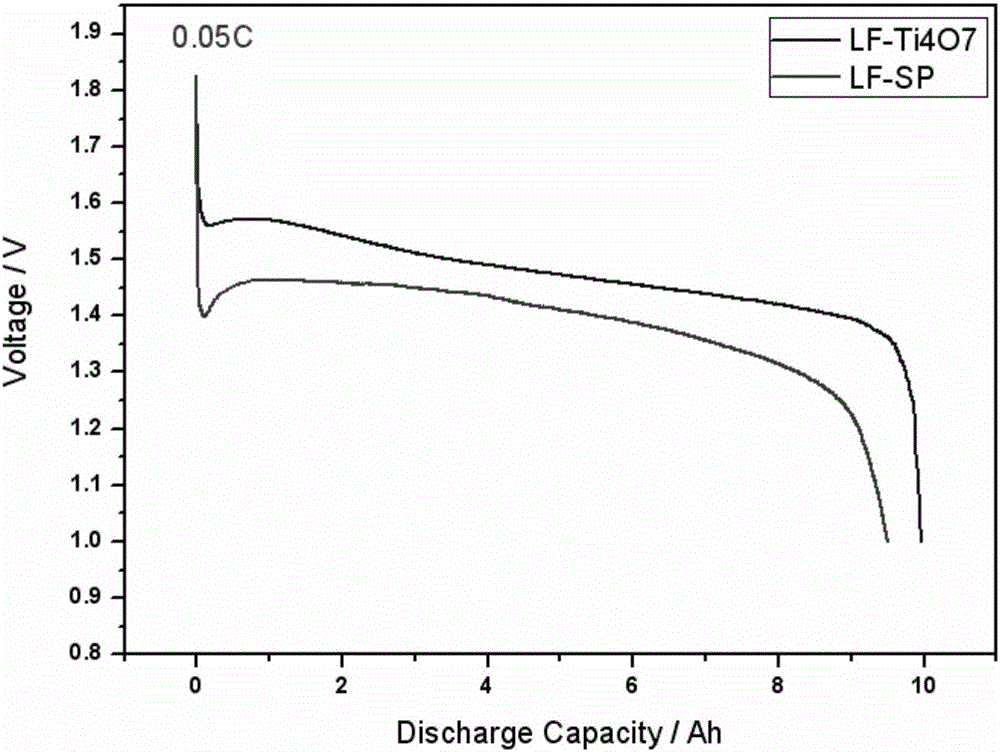

[0024] A preparation method for a high-power flexible packaging lithium iron disulfide battery, which prepares a high-power flexible packaging lithium iron disulfide battery, including Li / FeS 2 The preparation process of the positive and negative electrodes of flexible packaging batteries, the positive electrode uses the active material FeS 2 , The conductive agent contains Ti 4 o 7 , the positive electrode is prepared by coating method, and the Li / FeS 2 The power characteristics of the battery. The conductive agent is Ti 4 o 7 , or Ti 4 o 7 It is mixed with one or more of conductive carbon black, conductive graphite, vapor-phase grown carbon fiber, Ketjen black, carbon nanotubes, and graphene. When preparing the positive electrode by coating method, the coating amount should not exceed 30mg / cm 2 .

[0025] The concrete implementation process of this embodiment:

[0026] Step 1 Manufacturing process of flexible packaging positive electrode plate

[0027] Weigh 90wt%...

Embodiment 2

[0033] A preparation method for a high-power flexible packaging lithium iron disulfide battery, which prepares a high-power flexible packaging lithium iron disulfide battery, including Li / FeS 2 The preparation process of the positive and negative electrodes of flexible packaging batteries, the positive electrode uses the active material FeS 2 , The conductive agent contains Ti 4 o 7 , the positive electrode is prepared by coating method, and the Li / FeS 2 The power characteristics of the battery. The conductive agent is Ti 4 o 7 , or Ti 4 o 7 It is mixed with one or more of conductive carbon black, conductive graphite, vapor-phase grown carbon fiber, Ketjen black, carbon nanotubes, and graphene. When preparing the positive electrode by coating method, the coating amount should not exceed 30mg / cm 2 .

[0034] The specific implementation steps of this embodiment:

[0035] Step 1 Manufacturing process of flexible packaging positive electrode plate

[0036] Weigh 85wt% FeS...

Embodiment 3

[0042] A preparation method for a high-power flexible packaging lithium iron disulfide battery, which prepares a high-power flexible packaging lithium iron disulfide battery, including Li / FeS 2 The preparation process of the positive and negative electrodes of flexible packaging batteries, the positive electrode uses the active material FeS 2 , The conductive agent contains Ti 4 o 7 , the positive electrode is prepared by coating method, and the Li / FeS 2 The power characteristics of the battery. The conductive agent is Ti 4 o 7 , or Ti 4 o 7 It is mixed with one or more of conductive carbon black, conductive graphite, vapor-phase grown carbon fiber, Ketjen black, carbon nanotubes, and graphene. When preparing the positive electrode by coating method, the coating amount should not exceed 30mg / cm 2 .

[0043] The specific implementation steps of this embodiment:

[0044] Step 1 Manufacturing process of flexible packaging positive electrode plate

[0045] Weigh 91wt% F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com