Method for preparing nitrogen-enriched porous carbon material for supercapacitor by taking lignite as raw material

A technology for supercapacitors and porous carbons is applied in the field of preparing nitrogen-rich porous carbon materials for supercapacitors. Large specific capacity and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

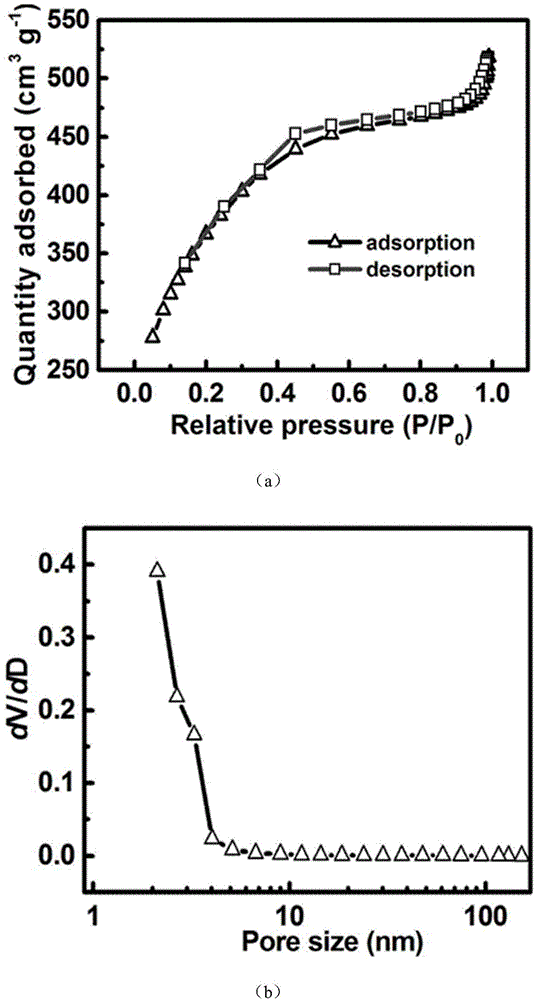

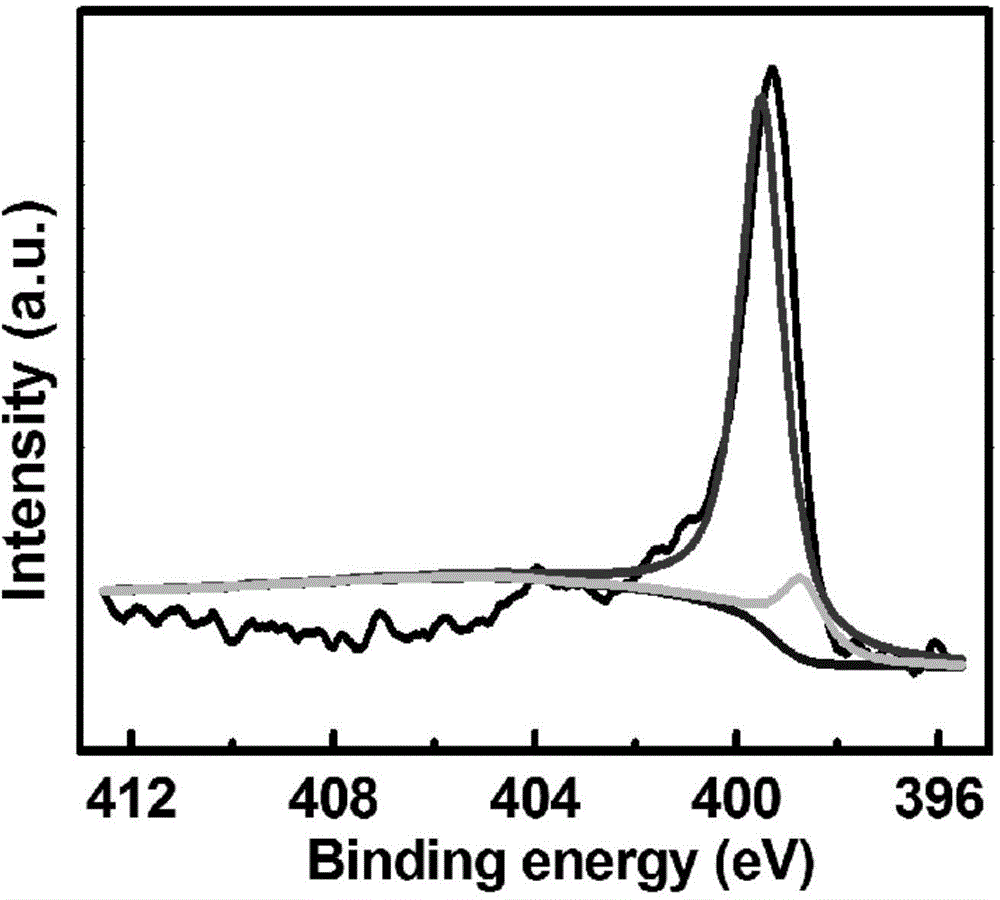

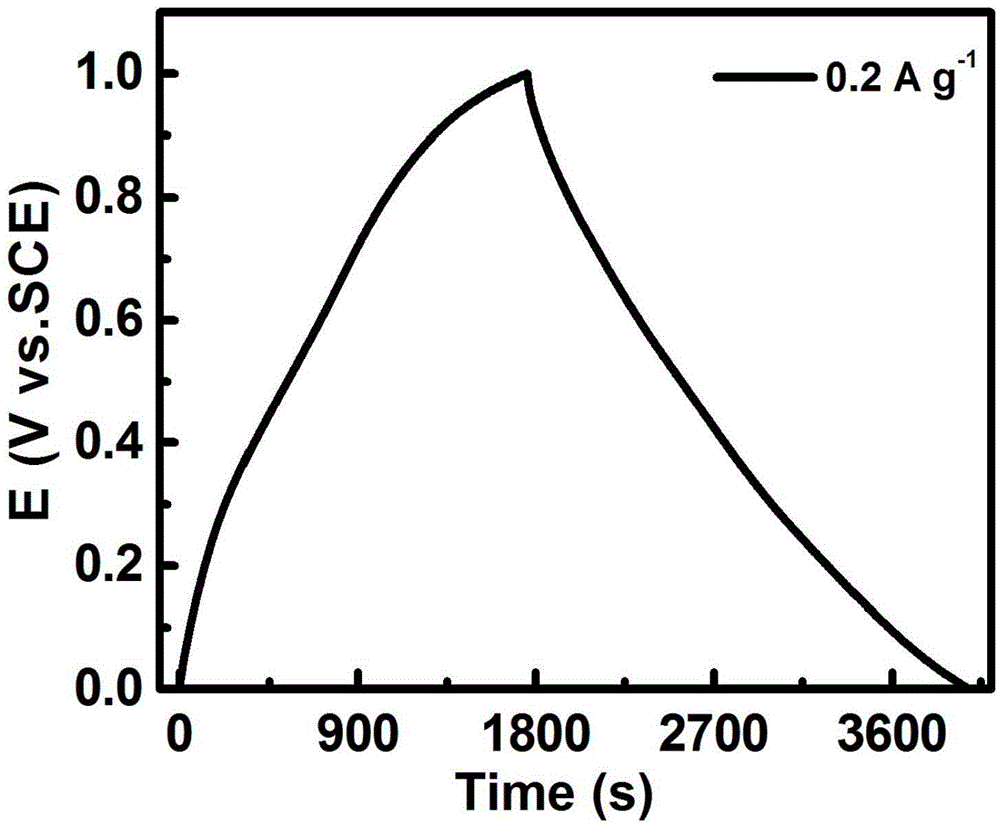

[0034] In conjunction with the accompanying drawings, a method for preparing a nitrogen-rich porous carbon material for a supercapacitor using lignite as a raw material in this embodiment collects the Shengli lignite produced in Xilinhot, Inner Mongolia, washes it with deionized water after crushing, and puts the cleaned lignite in Dry it in a vacuum oven at 60°C and place it in a quartz tube, raise the temperature to 500°C at a rate of 5°C / min in a tube furnace filled with nitrogen, and keep it warm for 2 hours. Then fully mix the lignite obtained by the above pre-carbonization with the activator potassium hydroxide at a mass ratio of 1:3, and activate it at a rate of 5°C / min to 800°C under a nitrogen atmosphere for 2 hours. The above-mentioned activated product was washed with 0.1M dilute hydrochloric acid, and then washed with deionized water until neutral, and then dried to obtain a nitrogen-rich porous carbon material.

[0035] In this embodiment, low-cost lignite is used...

Embodiment 2

[0041] A method of preparing a nitrogen-rich porous carbon material for a supercapacitor using lignite as a raw material in this embodiment, collects the Shengli lignite produced in Xilinhot, Inner Mongolia, washes it with deionized water after crushing, and puts the cleaned lignite in a vacuum drying box Dry at 60°C, place in a quartz tube, raise the temperature to 350°C at a rate of 1°C / min in a tube furnace with argon, and keep it warm for 2 hours. Then fully mix the lignite obtained by the above pre-carbonization with the activator at a mass ratio of 1:2. The activator is potassium hydroxide, and then activate it at a heating rate of 1°C / min to 700°C under an argon atmosphere. , The activation time is 1h. The above-mentioned activated product was washed with 0.1M dilute sulfuric acid, and then deionized water until neutral, and then dried to obtain a nitrogen-rich porous carbon material.

[0042] The electrochemical testing method of the nitrogen-rich porous carbon materi...

Embodiment 3

[0044] A method of preparing a nitrogen-rich porous carbon material for a supercapacitor using lignite as a raw material in this embodiment, collects the Shengli lignite produced in Xilinhot, Inner Mongolia, washes it with deionized water after crushing, and puts the cleaned lignite in a vacuum drying box Dry at 60°C, place in a quartz tube, raise the temperature to 450°C at a rate of 3°C / min in a tube furnace with argon gas, and keep it warm for 2 hours. Then fully mix the lignite obtained by the above pre-carbonization with the activator at a mass ratio of 1:4. The activator is sodium hydroxide, and then activate it at a heating rate of 3°C / min to 800°C under an argon atmosphere. , The activation time is 5h. The above-mentioned activated product was washed with 0.1 M dilute nitric acid, and then washed with deionized water until neutral, and then dried to obtain a nitrogen-rich porous carbon material.

[0045] The electrochemical testing method of the nitrogen-rich porous c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com