Preparation method of zinc oxide nanometer fiber cathode material for lithium ion battery

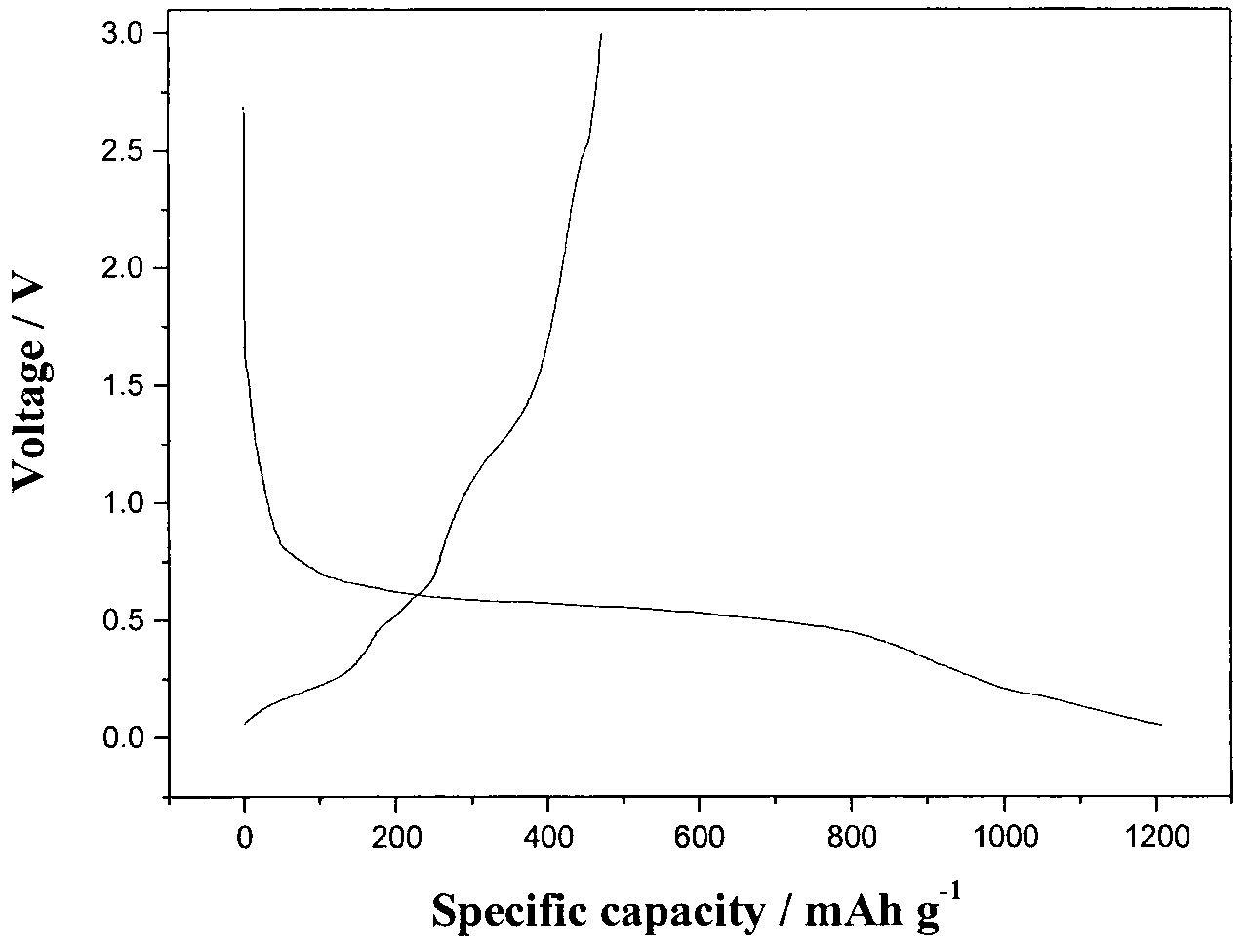

A zinc oxide nanometer, lithium-ion battery technology, applied in the fields of polymer materials and chemical power sources, can solve the problems of poor cycle stability, rapid charge and discharge ability, low first cycle efficiency, etc., and achieves simple and easy-to-control preparation process, high initial Effects of discharge capacity and cycle stability, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

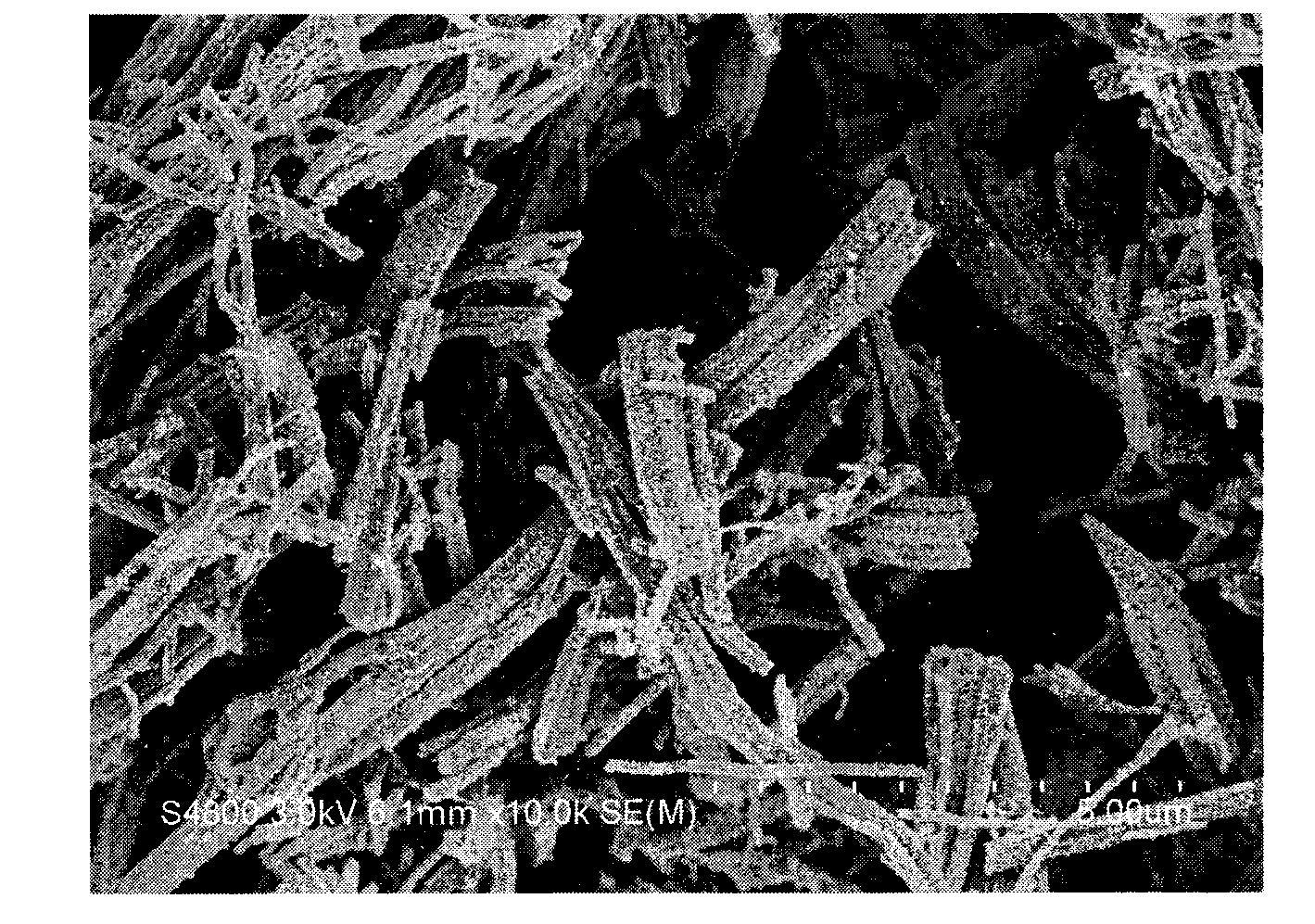

Embodiment 1

[0018] Weigh PAN 1.4g, PVP 0.6g (PAN / PVP=7:3), (CH 3 COO) 2 Zn 1.0g, then added to 23ml of DMF solution, stirred with a glass rod for about 20min until completely uniform swelling. Then the mixed solution was transferred to a 50ml Erlenmeyer flask, put into a magnetic rotor, adjusted to an appropriate rotational speed, and stirred at room temperature for 24 hours. The above-mentioned spinning solution prepared is put into self-made spinning equipment, under the process conditions of spinning voltage 10kV, collecting distance 8cm, solution extrusion speed 0.3ml / h, spinning for 10 hours, then drying in a vacuum oven for 2 hour, get PAN / PVP / (CH 3 COO) 2 Zn composite nanofibrous membrane. The above PAN / PVP / (CH 3 COO) 2 The Zn composite nanofiber membrane was transferred to a high-temperature tube furnace, heated from room temperature to 600 °C in an air atmosphere at a heating rate of 0.5 °C / min, and naturally cooled to room temperature after calcination.

Embodiment 2

[0020] Weigh PAN 1.4g, PVP 0.6g (PAN / PVP=7:3), (CH 3 COO) 2 Zn 1.0g, then added to 23ml of DMF solution, stirred with a glass rod for about 20min until completely uniform swelling. Then the mixed solution was transferred to a 50ml Erlenmeyer flask, put into a magnetic rotor, adjusted to an appropriate rotational speed, and stirred at room temperature for 24 hours. The above-mentioned spinning solution prepared is put into self-made spinning equipment, under the process conditions of spinning voltage 10kV, collecting distance 12cm, solution extrusion speed 0.5ml / h, spinning for 10 hours, then drying in a vacuum oven for 2 hour, get PAN / PVP / (CH 3 COO) 2 Zn composite nanofibrous membrane. The above PAN / PVP / (CH 3 COO) 2 The Zn composite nanofiber membrane was transferred to a high-temperature tube furnace, heated from room temperature to 600 °C in an air atmosphere at a heating rate of 1.5 °C / min, and naturally cooled to room temperature after calcination.

Embodiment 3

[0022] Weigh PAN 1.4g, PVP 0.6g (PAN / PVP=7:3), (CH 3 COO) 2 Zn 1.0g, then added to 23ml of DMF solution, stirred with a glass rod for about 20min until completely uniform swelling. Then the mixed solution was transferred to a 50ml Erlenmeyer flask, put into a magnetic rotor, adjusted to an appropriate rotational speed, and stirred at room temperature for 24 hours. The above-mentioned spinning solution prepared is put into self-made spinning equipment, under the process conditions of spinning voltage 12kV, collection distance 15cm, solution extrusion speed 1.0ml / h, spinning for 10 hours, then drying in a vacuum oven for 2 hour, get PAN / PVP / (CH 3 COO) 2 Zn composite nanofibrous membrane. The above PAN / PVP / (CH 3 COO) 2 The Zn composite nanofiber membrane was transferred to a high-temperature tube furnace, heated from room temperature to 700 °C in an air atmosphere, and the heating rate was 0.5 °C / min, and naturally cooled to room temperature after calcination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com