Elemental sulfur composite material containing graphene and preparation method thereof

A composite material and elemental sulfur technology, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of complex preparation process and uneven compounding, and achieve the effect of simple synthesis method and adjustable and controllable material shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

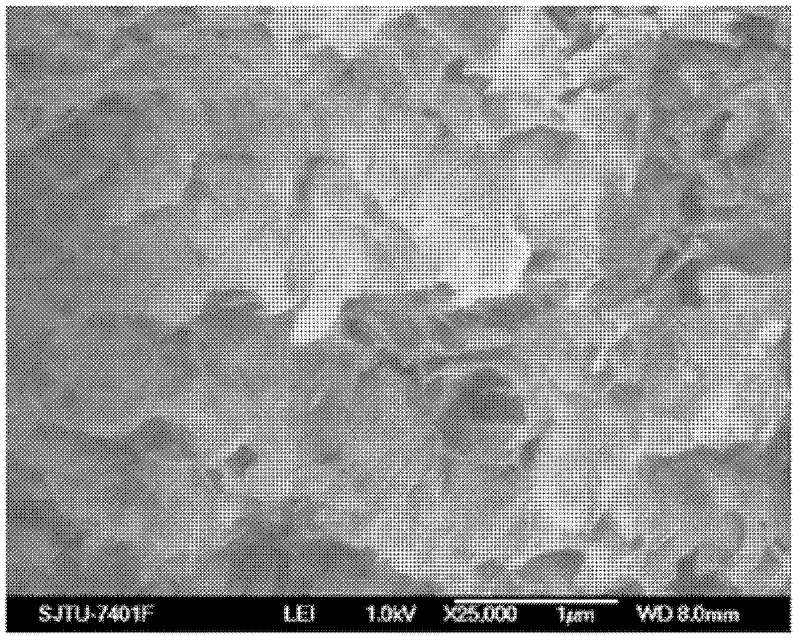

[0030] This embodiment provides a graphene-containing elemental sulfur composite material, which is a binary composite material A x B y , wherein, A is graphene, B is elemental sulfur, and B is uniformly dispersed on the surface of A in a nanometer state, wherein, 1%≤x≤90%, 10%≤y≤99%, and x+y=100%.

[0031] The following examples are examples of the preparation method of the graphene-containing elemental sulfur composite material provided in Example 1.

Embodiment 2

[0033] This embodiment provides a method for preparing the graphene-containing elemental sulfur composite material provided in Example 1, comprising the following steps:

[0034] Step 1, adding graphene oxide into deionized water to obtain a graphene oxide dispersion; specifically, adding 1 mass part of graphene oxide to 1 mass part of deionized water to obtain a graphene oxide dispersion;

[0035] Step 2, adding elemental sulfur to obtain a mixture slurry of graphene oxide and elemental sulfur; specifically, adding 1 mass part of elemental sulfur to obtain a mixture slurry of graphene oxide and elemental sulfur;

[0036] Step 3, after heat-treating the mixture slurry, washing and filtering with water to obtain a graphene-containing elemental sulfur composite material; specifically, heat-treating the mixture slurry in a polytetrafluoroethylene sealed tank at 200°C for 24 hours, washing and filtering with water to obtain a graphene-containing elemental sulfur composite material;...

Embodiment 3

[0038] Embodiment 3 is a variation example of embodiment 2, specifically:

[0039] Step 1, adding 1 mass part of graphene oxide into 10 mass parts of deionized water to obtain a dispersion of graphene oxide;

[0040] Step 2, adding 3 parts by mass of elemental sulfur to obtain a mixture slurry of graphene oxide and elemental sulfur;

[0041] Step 3, after heat-treating the mixture slurry in a polytetrafluoroethylene sealed tank at 155°C for 48 hours, washing and filtering with water to obtain a graphene-containing elemental sulfur composite material, wherein the mass content of graphene is 20%, and the mass content of elemental sulfur is 80% %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com