Preparation method of nanometer material modified carbon fluoride electrode material

A technology of nanomaterials and electrode materials, applied in the field of preparation of carbon fluoride electrode materials, can solve problems such as unsatisfactory effects, and achieve the effects of significant effects, solving voltage hysteresis, and improving voltage hysteresis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

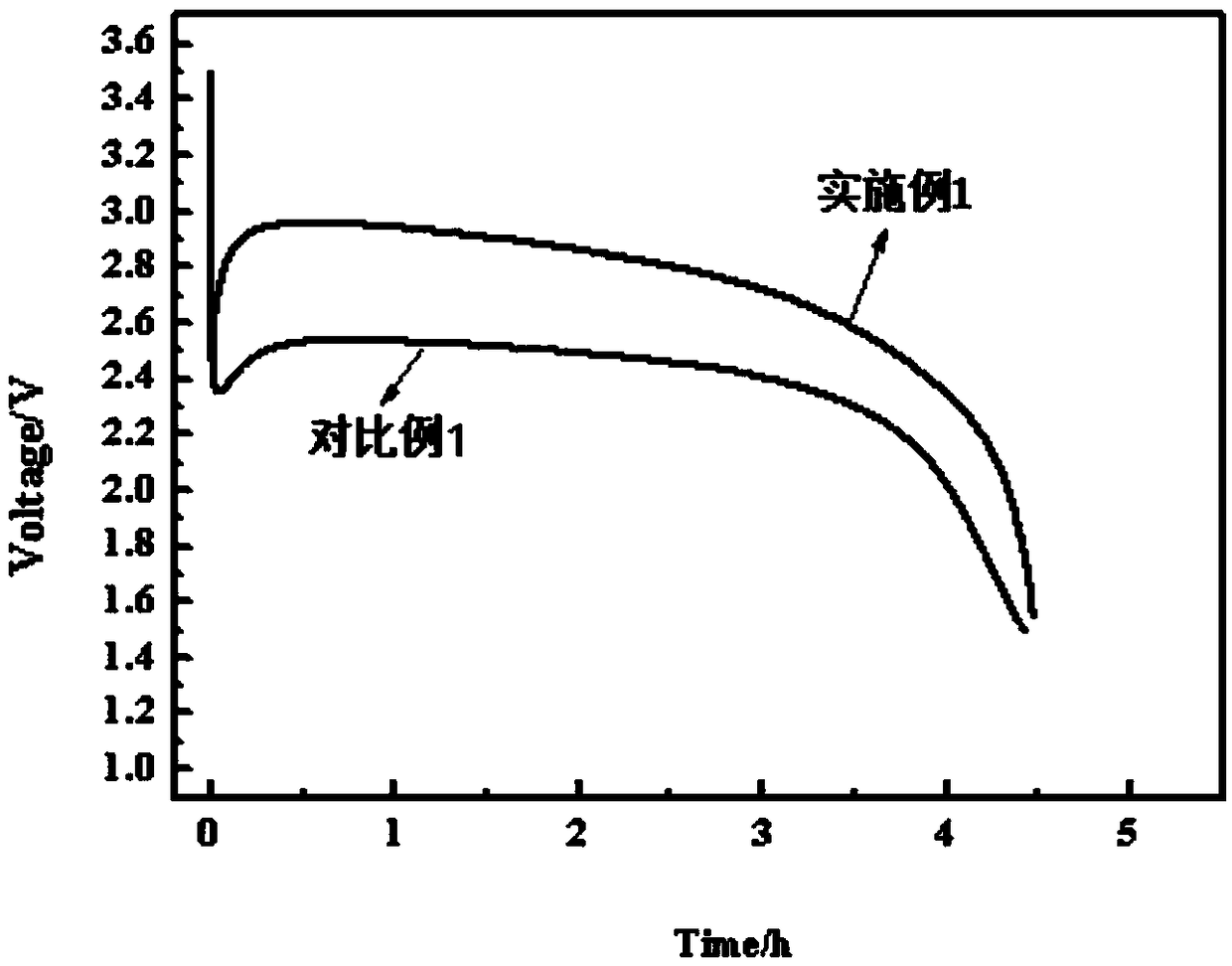

Examples

Embodiment 1

[0037] A preparation method of a carbon fluoride electrode material modified by a nanometer material, the method is a dispersion-calcination method, comprising the following steps:

[0038] Step 1: Add the medium and carbon fluoride into the high-speed centrifugal dispersion tank according to the ratio of mass ratio = 2:1, and let the material disperse in the high-speed centrifugal dispersion tank at a speed of 2500r / min for 20min; the medium is ethanol and acetone;

[0039] Step 2: Add nanomaterials to the high-speed centrifugal dispersion tank, and allow the material to disperse for 1.5 hours at a speed of 3000r / min in the high-speed centrifugal dispersion tank to obtain a slurry; the nanomaterials are nano-silver; the nanomaterials and fluorinated The mass ratio of carbon material=0.5:100; the diameter of the nanomaterial is 50nm;

[0040] Step 3: Dry the slurry obtained in Step 2 at room temperature, and then vacuum-dry it for 10 hours in a vacuum environment at 35°C to ob...

Embodiment 2

[0050] A preparation method of a carbon fluoride electrode material modified by a nanometer material, the method is a dispersion-calcination method, comprising the following steps:

[0051] Step 1: Add the medium and carbon fluoride into the high-speed centrifugal dispersion tank according to the ratio of mass ratio = 3:1, and let the material disperse in the high-speed centrifugal dispersion tank at a speed of 3000r / min for 30min; the medium is ethanol and acetone;

[0052] Step 2: Adding nanomaterials to the high-speed centrifugal dispersion tank, allowing the material to disperse in the high-speed centrifugal dispersion tank at a speed of 3500r / min for 2 hours to obtain a slurry; the nanomaterials are nano-silver; the nanomaterials and carbon fluoride The mass ratio of materials=5:100; the diameter of the nanomaterial is 100nm;

[0053] Step 3: Dry the slurry obtained in Step 2 at room temperature, and then vacuum-dry it in a vacuum environment of 30-40°C for 12 hours to ob...

Embodiment 3

[0059] A preparation method of a carbon fluoride electrode material modified by a nanometer material, the method is a dispersion-calcination method, comprising the following steps:

[0060] Step 1: Add the medium and carbon fluoride into the high-speed centrifugal dispersion tank according to the ratio of mass ratio = 2:1, and let the material disperse in the high-speed centrifugal dispersion tank at a speed of 2000r / min for 10 minutes; the medium is ethanol and acetone;

[0061] Step 2: Adding nanomaterials to the high-speed centrifugal dispersion tank, allowing the material to disperse for 1 hour at a speed of 3000r / min in the high-speed centrifugal dispersion tank to obtain a slurry; the nanomaterials are nano-silver; the nanomaterials and carbon fluoride The mass ratio of materials=0.5:100; the diameter of the nanomaterial is 10nm;

[0062] Step 3: Dry the slurry obtained in Step 2 at room temperature, and then vacuum-dry it in a vacuum environment at 30°C for 8 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com