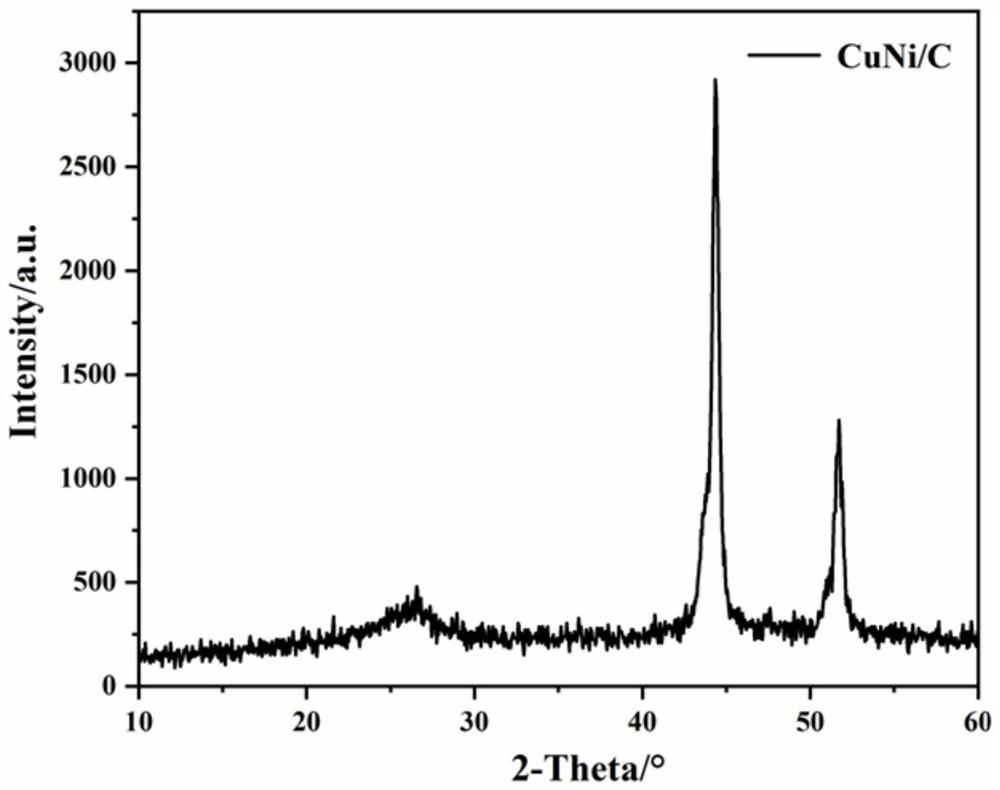

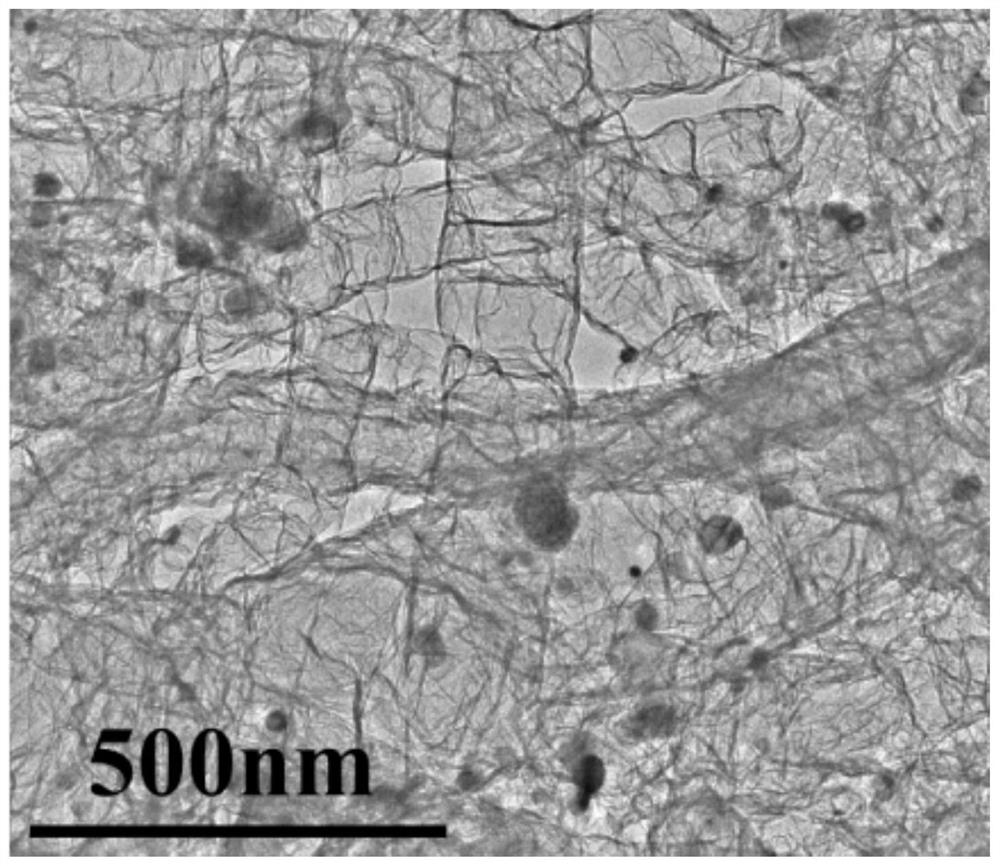

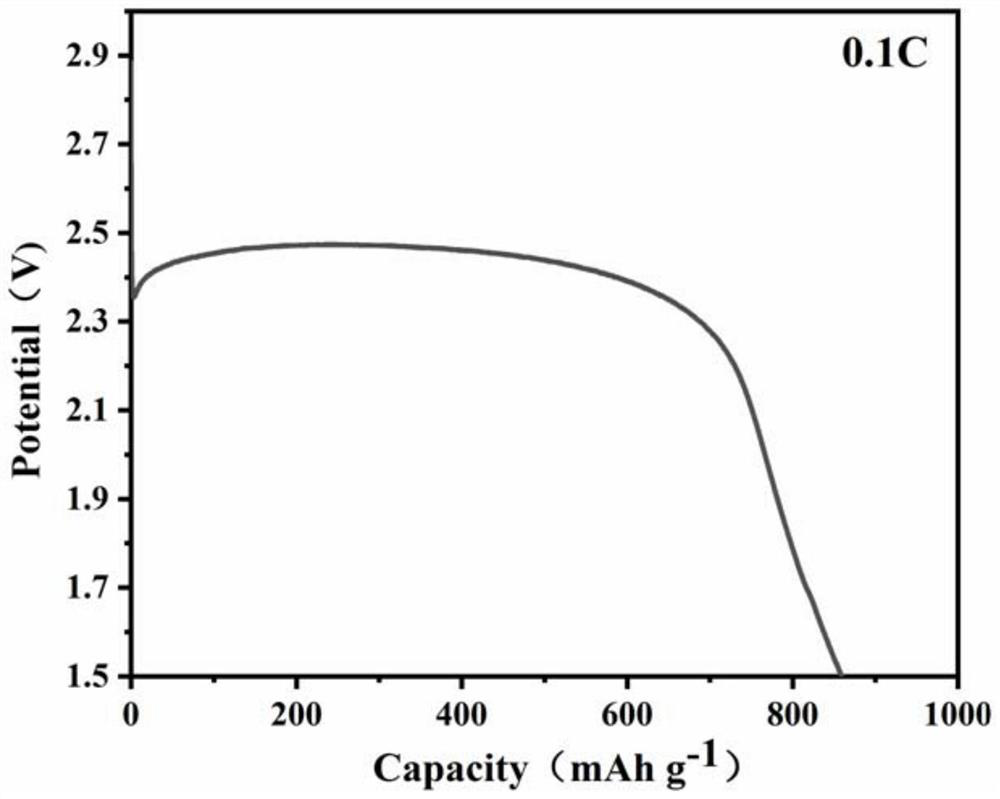

CuNi/C composite catalytic material modified lithium carbon fluoride battery positive plate and preparation method thereof

A lithium carbon fluoride battery and catalytic material technology, which is applied in the direction of primary battery electrodes, battery electrodes, active material electrodes, etc., can solve the problems of hindering the balance of power density and energy density, low conductivity, and low reaction kinetics of batteries , to achieve the effect of improving voltage hysteresis, improving battery performance, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Weigh copper nitrate, nickel sulfate and urea according to the molar ratio of copper, nickel and carbon atoms at 1:8:21 and mix them, add them to the high-speed centrifugal dispersion tank, and put the materials in the high-speed centrifugal dispersion tank at 1500r / min The rotation speed was dispersed for 5 minutes, and then the mixture A was obtained by taking it out;

[0032] Step 2: Put the mixture A in a high-temperature tube furnace, and in a flowing argon atmosphere of 100 sccm, first rapidly raise the temperature from room temperature to 160°C at a rate of 10°C / min, keep it warm for 0.5h, and cool it down naturally After reaching room temperature, take out to obtain product B;

[0033] Step 3: Grind the product B with a mortar for 20 minutes, then put the ground solid powder into a sealed glove box, place it in a crucible under a flowing argon atmosphere of 100 sccm, and in an induction alternating magnetic field environment, the material in the crucible...

Embodiment 2

[0036] Step 1: Weigh copper sulfate, nickel nitrate and melamine according to the molar ratio of copper, nickel and carbon atoms at 1:10:30 and mix them, add them to the high-speed centrifugal dispersion tank, and put the materials in the high-speed centrifugal dispersion tank at 2000r / min Disperse at a rotating speed of 10 minutes, and then take out to obtain the mixture A;

[0037] Step 2: Put the mixture A in a high-temperature tube furnace, and in a flowing nitrogen atmosphere of 100 sccm, first rapidly raise the temperature from room temperature to 200 °C at a rate of 15 °C / min, keep it warm for 1 hour, and cool it naturally to room temperature after the heat preservation is over. After taking out to obtain product B;

[0038] Step 3: Grind product B with a mortar for 25 minutes, then put the ground solid powder into a sealed glove box, place it in a crucible under a flowing nitrogen atmosphere of 100 sccm, and cut the material in the crucible under an induction alternati...

Embodiment 3

[0041] Step 1: Weigh copper sulfate, nickel bromide and glucose according to the molar ratio of copper, nickel and carbon atoms at 1:20:20 and mix them, add them to the high-speed centrifugal dispersion tank, and place the materials in the high-speed centrifugal dispersion tank at 2500r / The rotation speed of min was dispersed for 15 minutes, and then taken out to obtain mixture A;

[0042] Step 2: Put the mixture A in a high-temperature tube furnace, and in a flowing argon atmosphere of 100 sccm, first rapidly raise the temperature from room temperature to 250°C at a rate of 20°C / min, keep it warm for 0.8h, and then cool it down naturally After reaching room temperature, take out to obtain product B;

[0043] Step 3: Grind product B with a mortar for 30 minutes, then put the ground solid powder into a sealed glove box, place it in a crucible under a flowing hydrogen atmosphere of 100 sccm, and cut the material in the crucible under an induction alternating magnetic field envi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com