Lithium-thionyl chloride button cell anode carrier and preparation method thereof

A lithium thionyl chloride button and battery positive electrode technology, which is applied to the electrodes of primary batteries, electrode carriers/collectors, etc., can solve the problems of positive electrode activity, low battery capacity, poor high-current discharge performance, and battery micro-short circuit, etc., to achieve Improved battery reliability and assembly efficiency, improved high-current discharge conditions, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment.

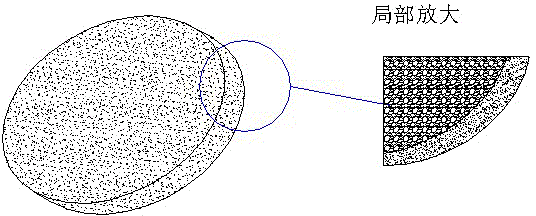

[0027] as attached figure 1 As shown, the present invention has micropores on the positive electrode carrier, the positive electrode carrier is a film-like, porous electrode, the film thickness is: 0.2-3mm, and the number of micropores is 1-3 / mm 2 .

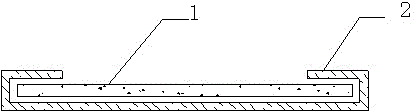

[0028] as attached figure 2 As shown, there is a film 2 on the positive carrier of the present invention, and the adhesive sticks the film on one side of the positive carrier, and the edge of the film wraps the positive carrier 1, and there are micropores on the positive carrier. The positive carrier is mechanically punched with copper needles to punch multiple micropores. The positive carrier is a film-like, porous electrode with a film thickness of 0.2-3mm and the number of micropores is 1-3 / mm 2 .

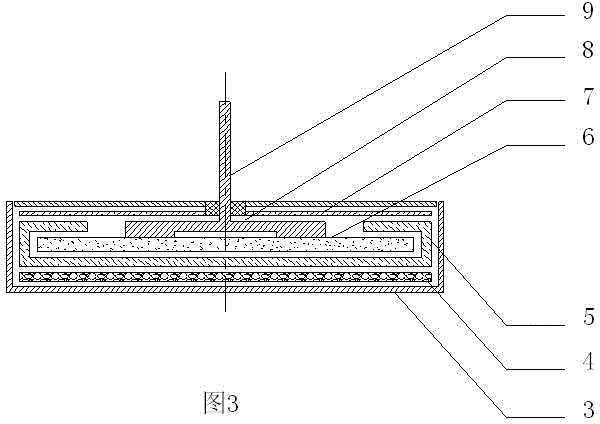

[0029] as attached image 3 As shown, the positive electrode button cell of the present invention is made of stainless steel case ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com