Magnetron sputtering source, sputter coating system and method for coating a substrate

A magnetron sputtering and coating equipment technology, applied in sputtering coating, coating, discharge tube and other directions, can solve problems such as power density limitation and temperature reduction, and achieve the effect of reducing cost and shortening coating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

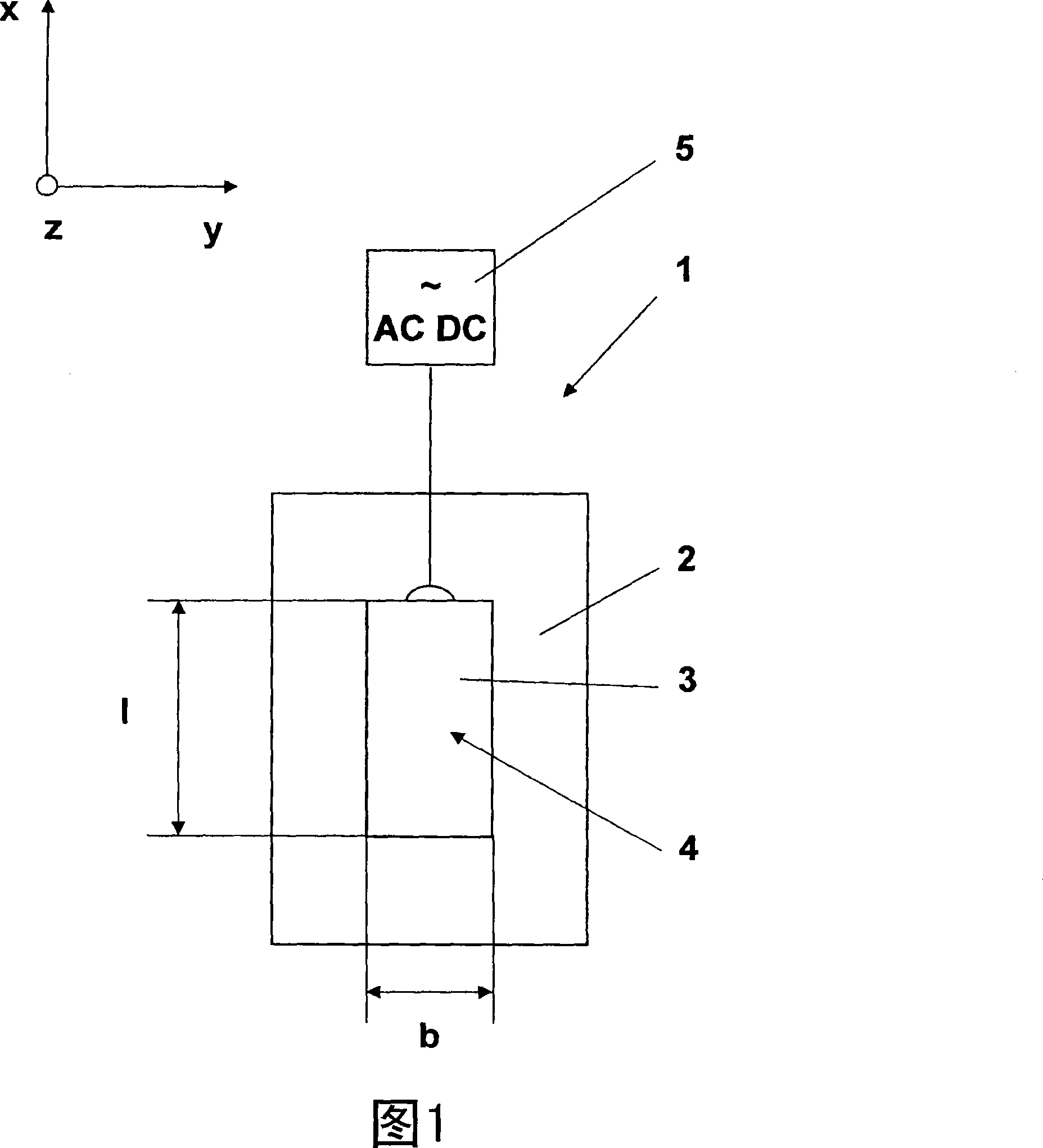

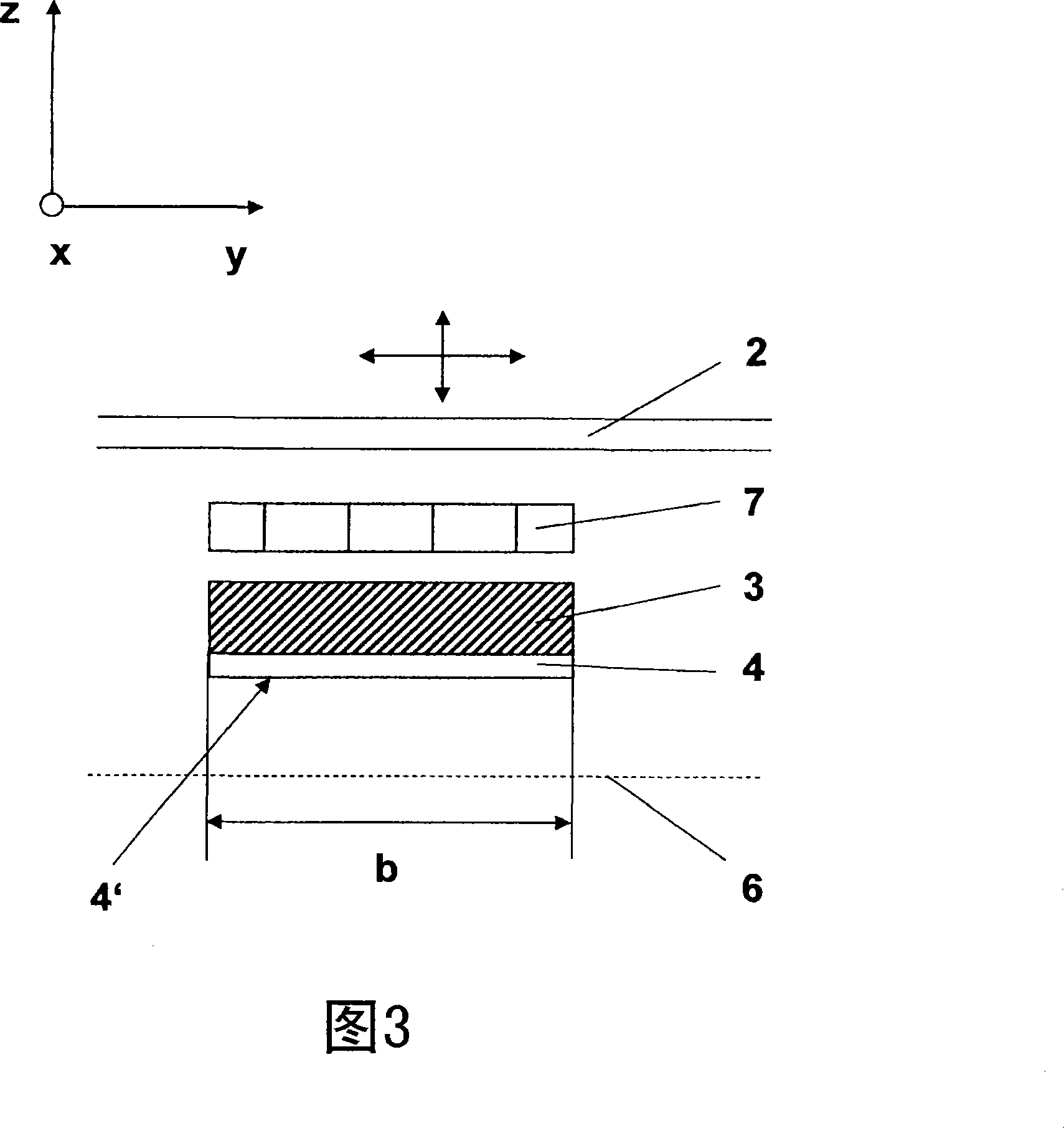

[0081] FIG. 1 shows a coating device 1 according to the invention in a sectional view. In the coating chamber 2 , an oblong cathode 3 with a length of 1 and a width of b is arranged, and a target 4 is installed on the cathode 3 . In this view, the cathode 3 is located below the target 4 within the page. However, within the scope of the invention, the cathode 3 and the target 4 can also be formed as an integral part, ie the cathode 3 can be formed from the target material 4 itself.

[0082] The cathode 3 is connected to a power source 5 by a connecting cable. Electrical energy can be coupled into the coating system 1 in the form of direct current, alternating current, unipolar pulsed current, bipolar pulsed current or RF (radio frequency) voltage.

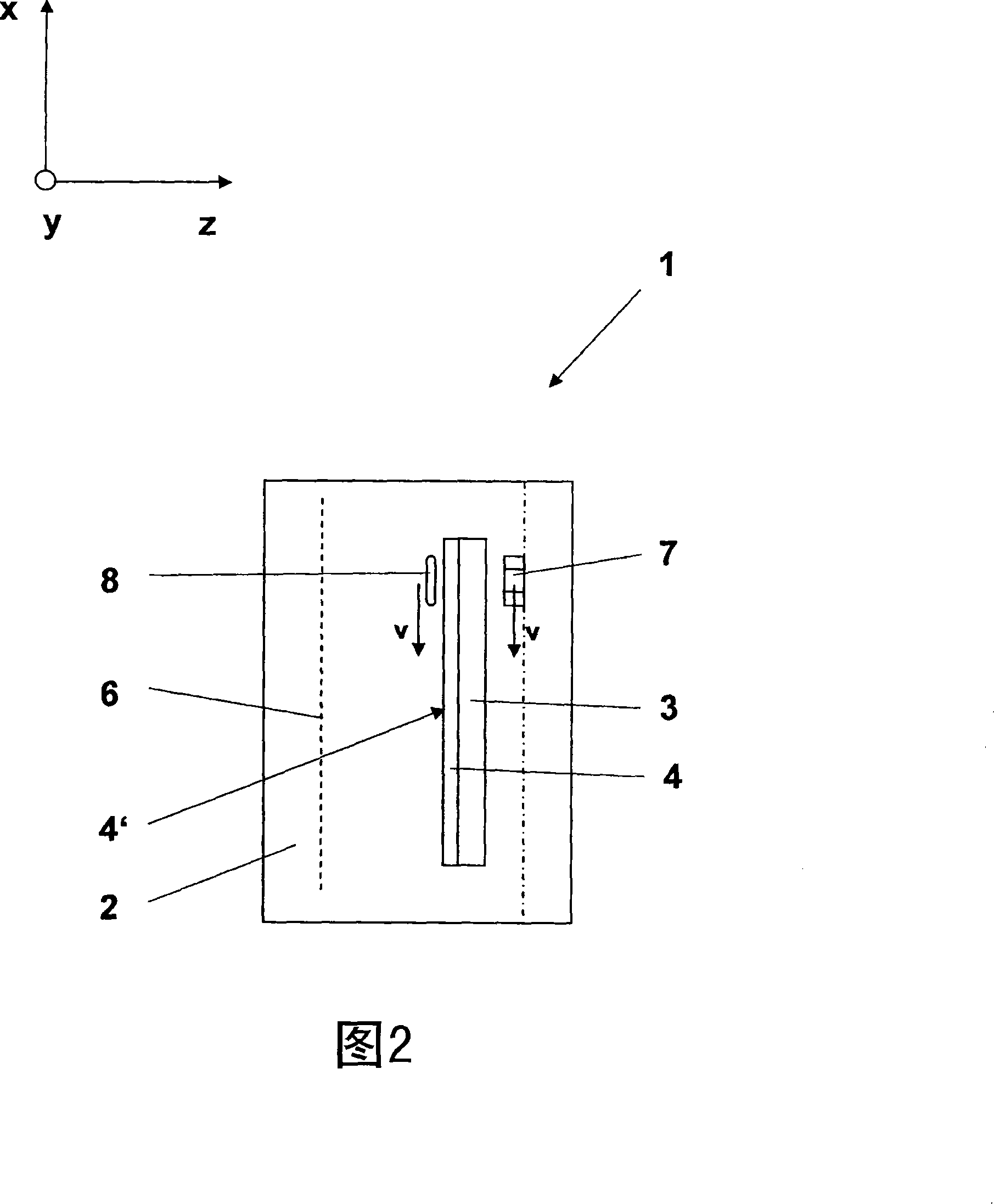

[0083] FIG. 2 shows a side view of the coating device 1 as indicated by the coordinate system in its upper left corner. In the coating chamber 2 delimited by walls, a cathode 3 and a target 4 mounted to the cathode 3 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com