Modified polyvinyl butyral (PVB) resin with high plasticizer absorption rate, and sound reduction PVB film containing modified PVB resin

A plasticizer and resin technology, applied in the field of PVB resin modified with high plasticizer absorption rate and sound-reducing PVB film containing it, can solve the problem of no plasticizer absorption and sound-reducing performance modified PVB resin, no Issues such as patents and literature reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

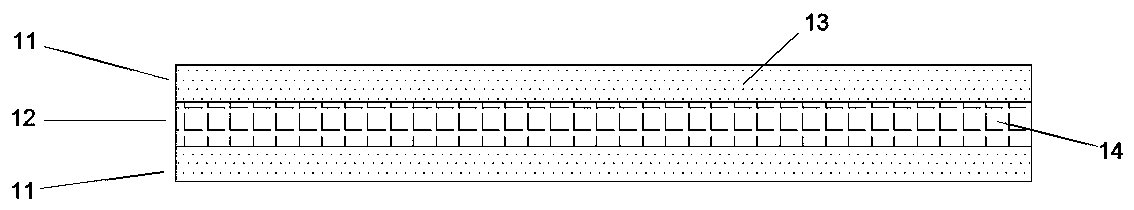

[0043] Synthesis of PVB resin modified with high plasticizer absorption rate and using it to manufacture rectangular sound-reducing PVB film

[0044] ⑴Add modifier before PVB resin synthesis to make PVB resin modified with high plasticizer absorption rate:

[0045] Add 200kg of PVA granules with 12% acetyl content and 3000kg of pure water into a dissolution tank, stir and heat to 95°C. After the PVA is completely dissolved, introduce it into a reaction kettle and start to lower the temperature. At 45°C, add 150 kg of n-butyraldehyde. After stirring for 0.5 hours, it becomes milky white. When the temperature drops to 10°C, add 400 kg of dilute hydrochloric acid with a concentration of 6mol / L. Start the acetal reaction to synthesize PVB with 50 kg of modifier rosin resin. After reacting at a low temperature of 10°C for 2 hours, the temperature is slowly raised to 65°C at a rate of 20°C / h, and kept at 65°C for 2 hours. The reaction is over . All the materials in the reaction ke...

Embodiment 2

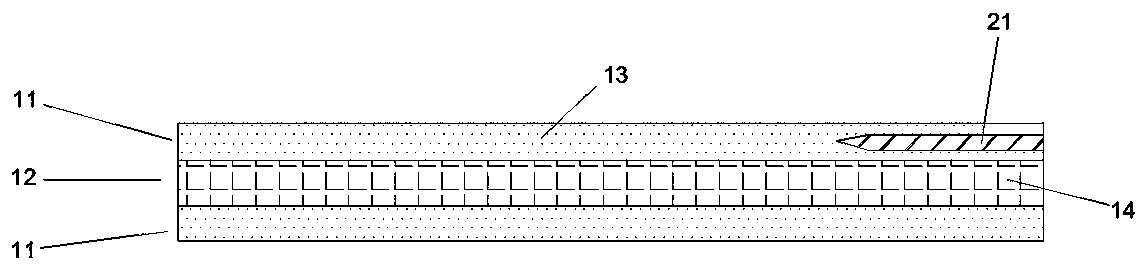

[0063] Synthesize PVB resin modified with high plasticizer absorption rate and use it to make rectangular sound-reducing PVB film with ribbon on top

[0064] (1) Modification is carried out in the synthesis of PVB resin to manufacture modified PVB resin with high plasticizer absorption rate:

[0065] Add 180kg of PVA granules with 10% acetyl content and 2500kg of pure water into a dissolution tank, stir and heat to 90°C. After the dissolution is complete, introduce it into a reaction kettle and start to lower the temperature. Add 120 kg of n-butyraldehyde at 40 ° C, and it will become milky white after stirring for 0.5 hours. When the temperature drops to 10 ° C, add 350 kg of dilute hydrochloric acid with a concentration of 6mol / L to start For the acetal reaction of PVB synthesis, after reacting at a low temperature of 10°C for 2 hours, add 25 kg of modifier maleic acid modified rosin ester, slowly raise the temperature to 65°C at a rate of 20°C / h, and keep it warm at 65°C A...

Embodiment 3

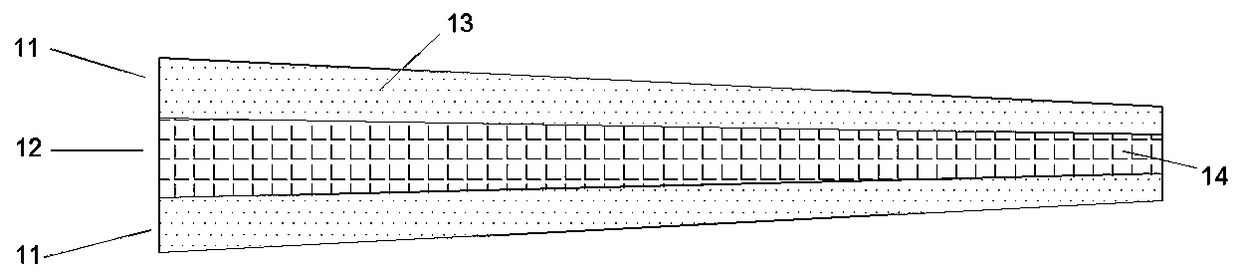

[0079] Synthesis of PVB resin modified with high plasticizer absorption rate and using it to manufacture wedge-shaped sound-reducing PVB film

[0080] ⑴PVB resin is modified after synthesis to produce modified PVB resin with high plasticizer absorption rate:

[0081] Add 300kg of PVA granules with 8% acetyl content and 3000kg of pure water into a dissolution tank, stir and heat to 90°C. After the dissolution is complete, introduce it into a reaction kettle and start to lower the temperature. At 50°C, add 150 kg of n-butyraldehyde, and stir for 0.5 hours to become milky. When the temperature drops to 15°C, add 360 kg of dilute hydrochloric acid with a concentration of 6mol / L. Start the acetal reaction for the synthesis of PVB, react at a low temperature of 15°C for 2 hours, then slowly raise the temperature to 65°C at a rate of 20°C / h, and keep it at 65°C for 2 hours. After the acetal reaction is over, add 30 kg of modifier bis (Methylbenylene)sorbitol. All the materials in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Degree of acetalization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com