Polytetrafluoroethylene (PTFE) outer lining butterfly plate making method

A technology of polytetrafluoroethylene and butterfly plate, which is applied in the field of chemistry and chemical industry, can solve the problems of low molding rate of molding and sintering and low density of butterfly plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] a. Place the polytetrafluoroethylene suspension powder and the metal plate core in the mold, and the metal plate core is located on the axis of the mold;

[0014] b. Put the mold into the press, pressurize to 19Mpa, hold the pressure for 100 minutes, and then demould to obtain the semi-finished butterfly plate;

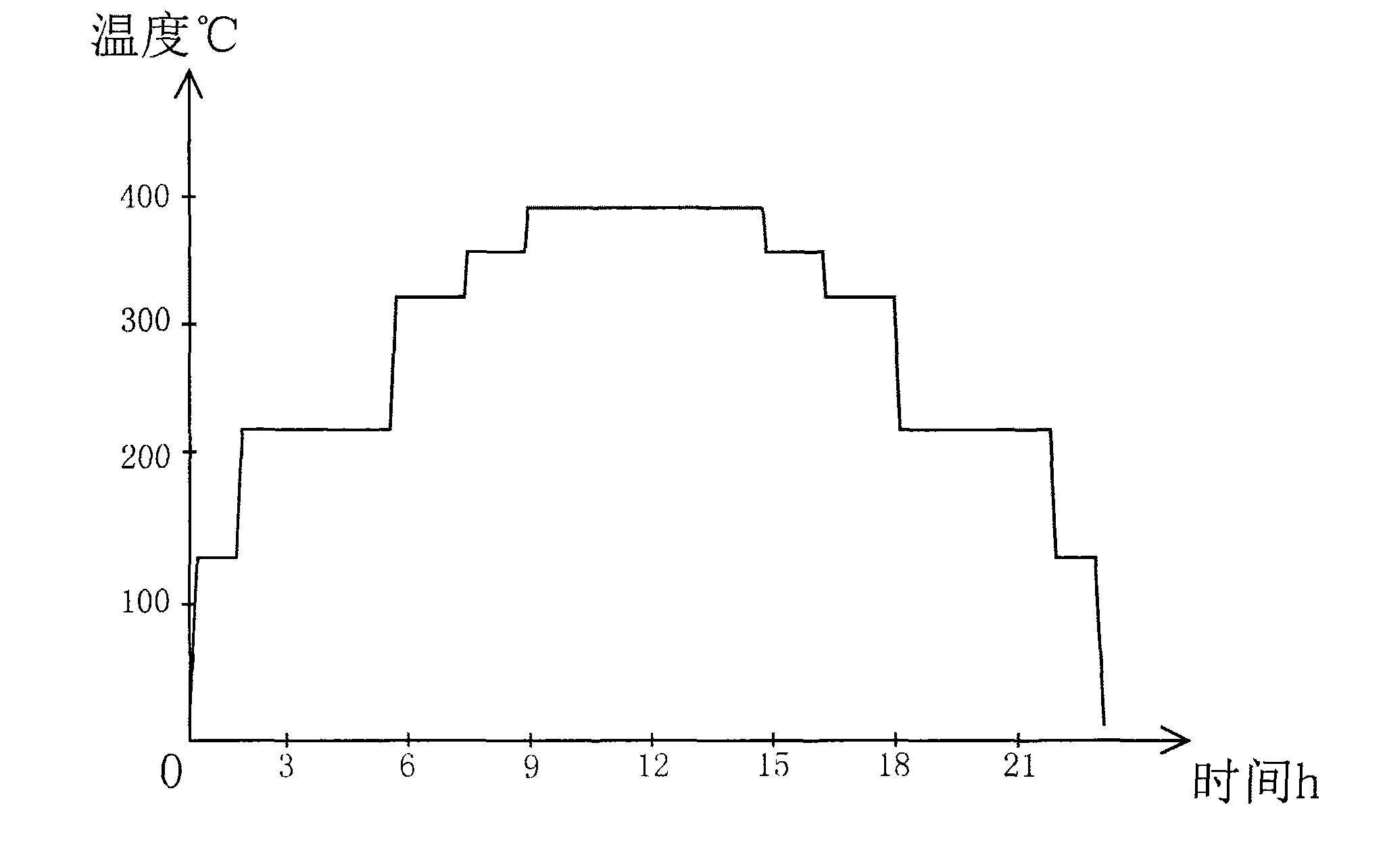

[0015] c. Put the semi-finished butterfly plate above into the sintering furnace, raise the sintering temperature from room temperature to 130°C, keep it warm for 85 minutes, then raise the temperature to 220°C, keep it warm for 240 minutes, then raise the temperature to 330°C, keep it warm for 110 minutes, and then raise the temperature to 360°C, hold for 130 minutes, then raise the temperature to 375°C, hold for 430 minutes, cool down to 360°C, hold for 130 minutes, then cool down to 330°C, hold for 110 minutes, then cool down to 220°C, hold for 240 minutes, then cool down to 130°C ℃, heat preservation for 85 minutes, and then cooled to room temperature to ob...

Embodiment 2

[0017] a. Place the polytetrafluoroethylene suspension powder and the metal plate core in the mold, and the metal plate core is located on the axis of the mold;

[0018] b. Put the mold into the press, pressurize to 20Mpa, hold the pressure for 70 minutes, and then demould to obtain the semi-finished butterfly plate;

[0019] c. Put the semi-finished butterfly plate above into the sintering furnace, raise the sintering temperature from room temperature to 138°C, keep it for 78 minutes, then raise the temperature to 235°C, keep it for 245 minutes, then raise the temperature to 340°C, keep it for 95 minutes, and then raise the temperature to 364°C, hold for 127 minutes, then raise the temperature to 386°C, hold for 460 minutes, cool down to 364°C, hold for 127 minutes, then cool down to 340°C, hold for 95 minutes, then cool down to 235°C, hold for 245 minutes, then cool down to 138 ℃, heat preservation for 78 minutes, and then cooled to room temperature to obtain the finished bu...

Embodiment 3

[0021] a. Place the polytetrafluoroethylene suspension powder and the metal plate core in the mold, and the metal plate core is located on the axis of the mold;

[0022] b. Put the mold into the press, pressurize to 21Mpa, hold the pressure for 60 minutes, and then demould to obtain the semi-finished butterfly plate;

[0023] c. Put the semi-finished butterfly plate above into the sintering furnace, raise the sintering temperature from room temperature to 150°C, keep it warm for 75 minutes, then raise the temperature to 250°C, keep it warm for 255 minutes, then raise the temperature to 345°C, keep it warm for 106 minutes, and then raise the temperature to 370°C, hold for 120 minutes, then raise the temperature to 390°C, hold for 440 minutes, cool down to 370°C, hold for 130 minutes, then cool down to 345°C, hold for 106 minutes, then cool down to 250°C, hold for 255 minutes, then cool down to 150 ℃, heat preservation for 75 minutes, and then cooled to room temperature to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com