Thermoplastic elastomer composition and molded article thereof

A technology of thermoplastic elastomer and composition, which is applied in the field of dynamic cross-linked thermoplastic elastomer composition and its molded products, which can solve the problems of poor molding appearance, insufficient sliding property, bad appearance, etc., and achieve excellent durable sliding property , Injection molding hot melt excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

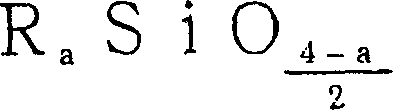

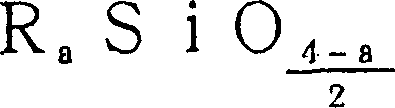

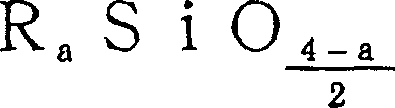

Method used

Image

Examples

preparation example Construction

[0125] Process for the preparation of thermoplastic elastomer compositions

[0126] As described above, the thermoplastic elastomer composition of the present invention can be obtained by adding at least (A1) or (X) component and (B) component, usually adding (A1) to (E1) component or (X) to (E1) component , supplied to a continuous or closed melt kneader, and obtained by dynamic heat treatment in the presence of a crosslinking agent.

[0127] Here, the above-mentioned "dynamic heat treatment" means that both application of shearing force and heating are performed. This dynamic heat treatment can be performed by, for example, a melting and kneading device, and the treatment by the melting and kneading device may be continuous or batch.

[0128] Among them, examples of devices capable of melt-kneading include open mixing rolls, non-open Banbury kneaders, single-screw extruders, twin-screw extruders, continuous kneaders, pressurized kneaders, etc. machines and other devices. ...

Embodiment 1~7

[0174] Examples 1-7, Comparative Examples 1-4 (preparation of thermoplastic elastomer composition)

[0175] The following EAO-based copolymer (A) or oil-extended rubber (X), olefin-based thermoplastic resin (B), unmodified polyorganosiloxane (C), vinyl group-containing polyorganosiloxane ( D), mineral oil-based softener (E) and other additives are put into a pressurized kneader (capacity 10 liters, manufactured by Moriyama Co., Ltd.) heated to 150 ° C in advance according to the compounding ratio shown in Table 1. Speed 200 / sec) kneading for 15 minutes until the olefin resin is melted and the ingredients are uniformly dispersed.

[0176] The obtained molten composition was made into pellets using Fi-Da-Lu-Da (manufactured by Moriyama Corporation).

[0177]Add the following crosslinking agent in the ratio shown in Table 1 to the obtained granules, mix it with a Henschel mixer for 30 seconds, and then use a twin-screw extruder (completely intermeshing screw in the same direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com