Adhesive applying device for medical accessory assembly machine

A technology of gluing device and assembling machine, which is applied in the direction of device, coating, etc. for applying liquid to the surface, so as to prevent excessive gluing and firmly bond.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

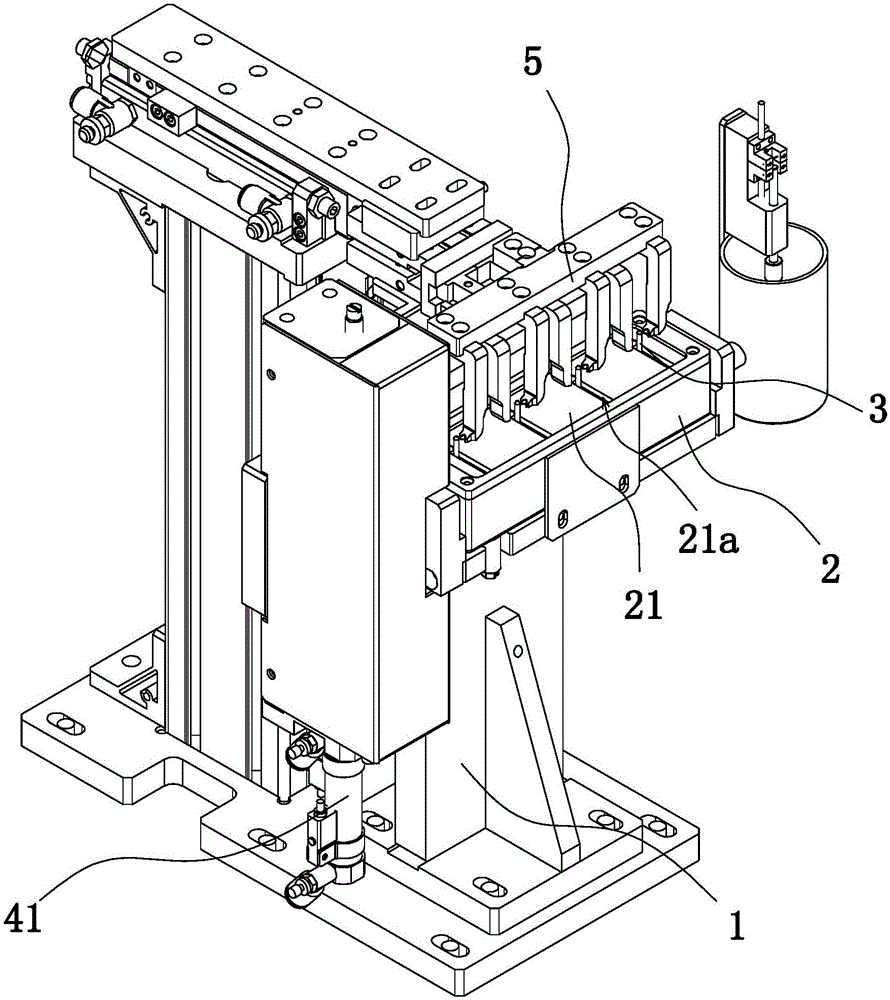

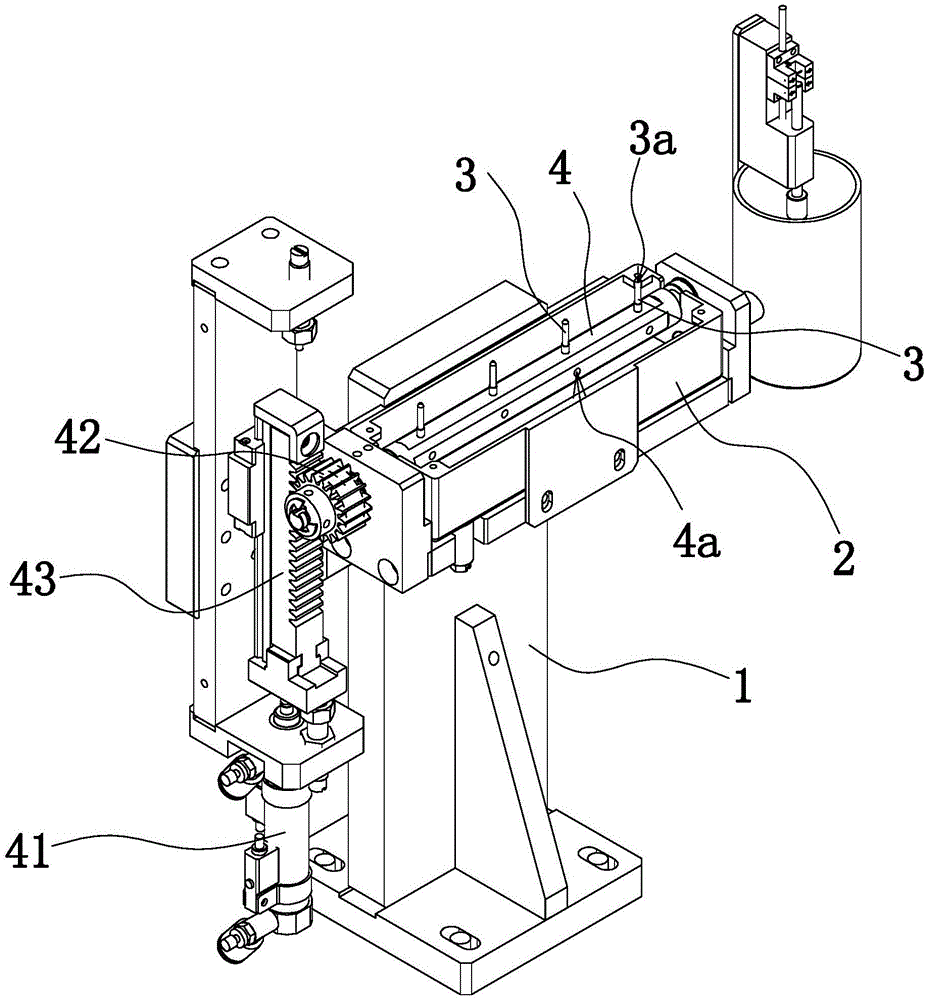

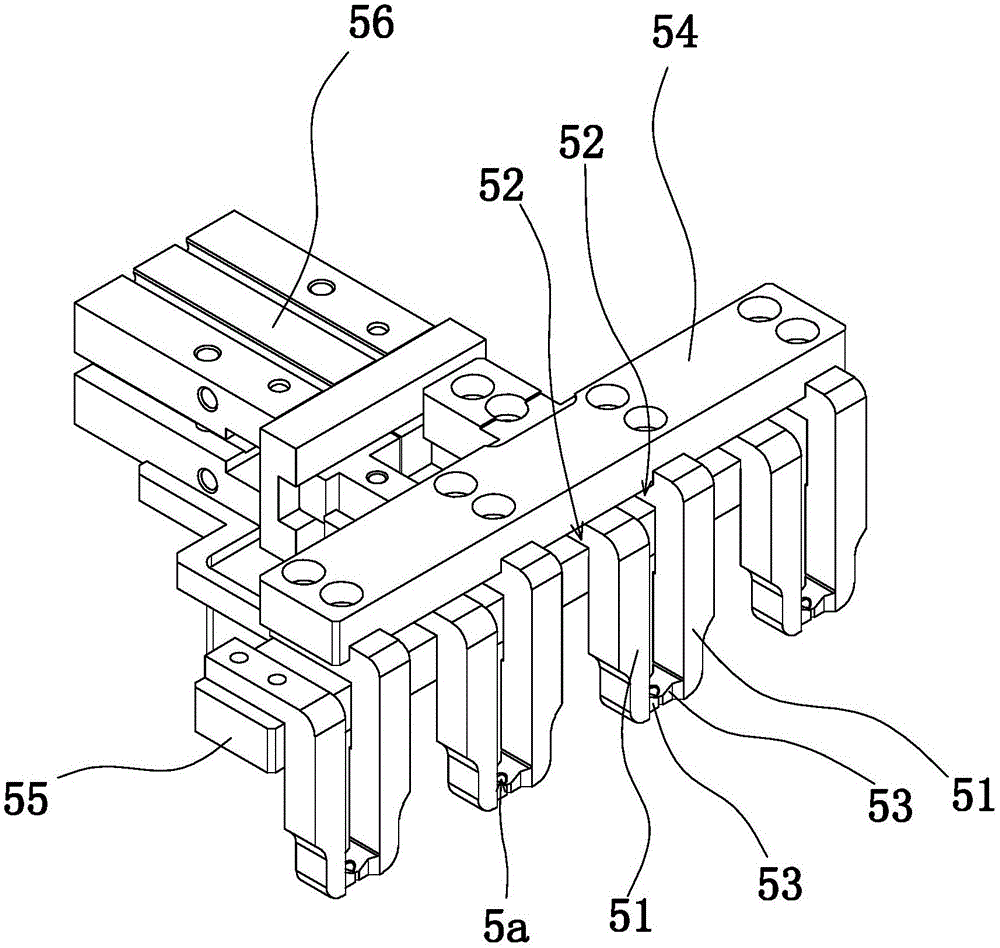

[0027] A gluing device of a medical accessories assembly machine, such as figure 1 , image 3 with Figure 4 As shown, it includes a plastic box 2 for storing glue on the frame 1 and a glue coating claw 5. A cover plate 21 is fixed in the mouth of the glue box 2, and four glue-taking holes 21a are opened on the cover plate 21. The gluing claw 5 is arranged on the top of the cover plate 21. The gluing claw 5 can be opened or closed. The gluing claw 5 forms a gluing hole 5a when it is closed. There are four gluing claws. The glue application hole 5a corresponds to the glue take hole 21a one by one and the glue application hole 5a is located directly above the corresponding glue take hole 21a, the glue box 2 is provided with a glue taker 3, and the glue taker 3 has a glue taker end 3a , the glue box 2 is provided with a driving positioning structure that can drive the glue-taking rod 3 to rotate. This driving and positioning structure can make the dipping end 3a of the glue-tak...

Embodiment 2

[0035] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference lies in that the driving positioning structure includes a rotating shaft and a motor. Above, the motor and the shaft are connected by a synchronous belt.

[0036] In other embodiments, the number of glue-taking holes 21a provided on the cover plate 21 can be 1, 2, 3, or even more; the number of gluing claws 5 can be 1, 2, 3 1, or even more; the number of glue rods 3 can be 1, 2, 3, or even more. In a preferred embodiment, there is a one-to-one correspondence between the number of glue-taking holes, glue-applying claws, and glue-taking rods; Take the glue through the glue hole.

[0037] In other embodiments, the glue-taking hole can be a strip hole or a hole of other shapes, as long as the glue on the glue-taking rod can be easily transported to the glue-applying claw through the glue-taking hole, in a preferred embodiment , take the glue rod in strip shape. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com