Fluid-containing cooling plate for an electronic component

A technology of fluids and components, applied in the field of cooling components, which can solve the problem of a large amount of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

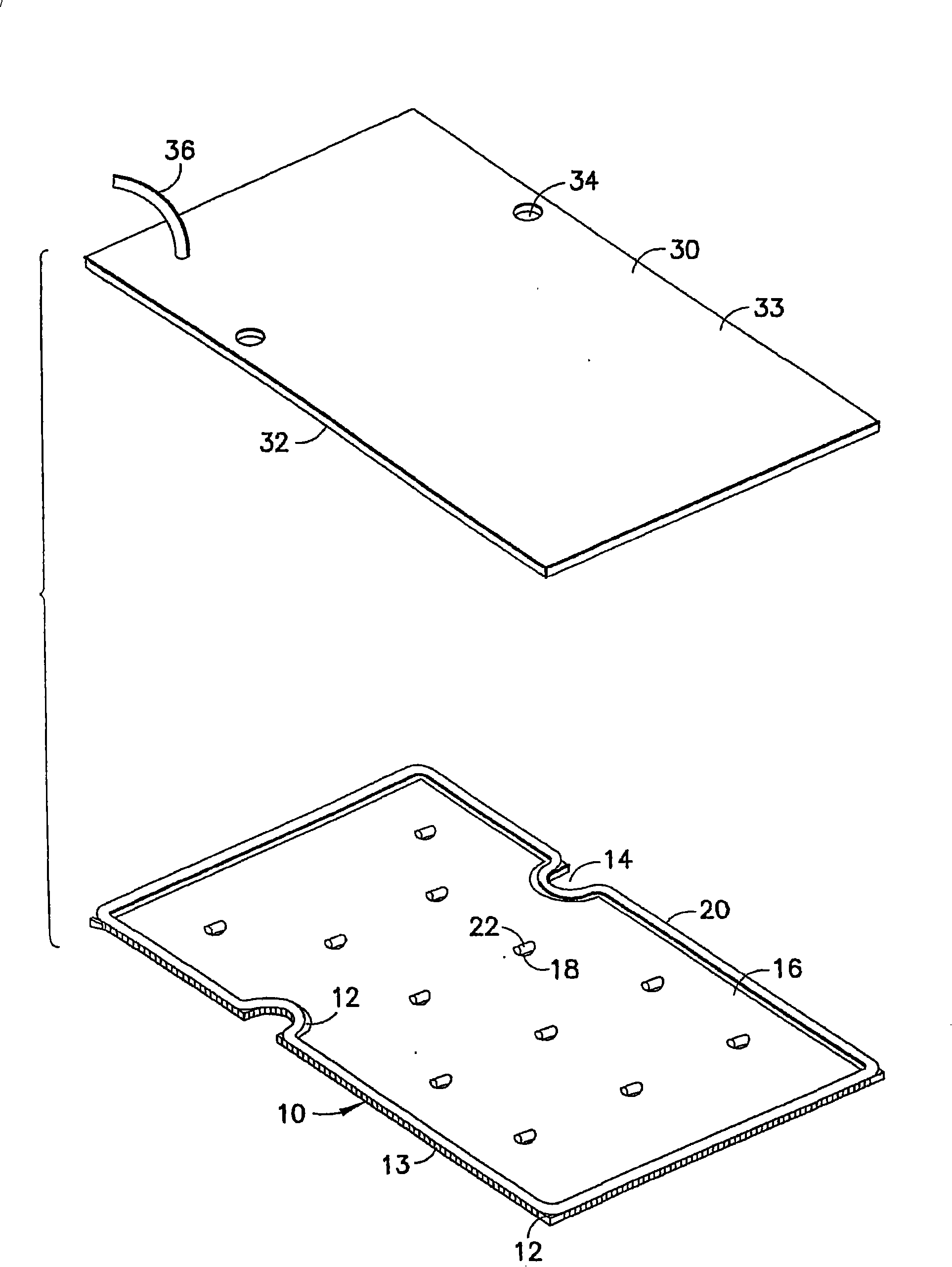

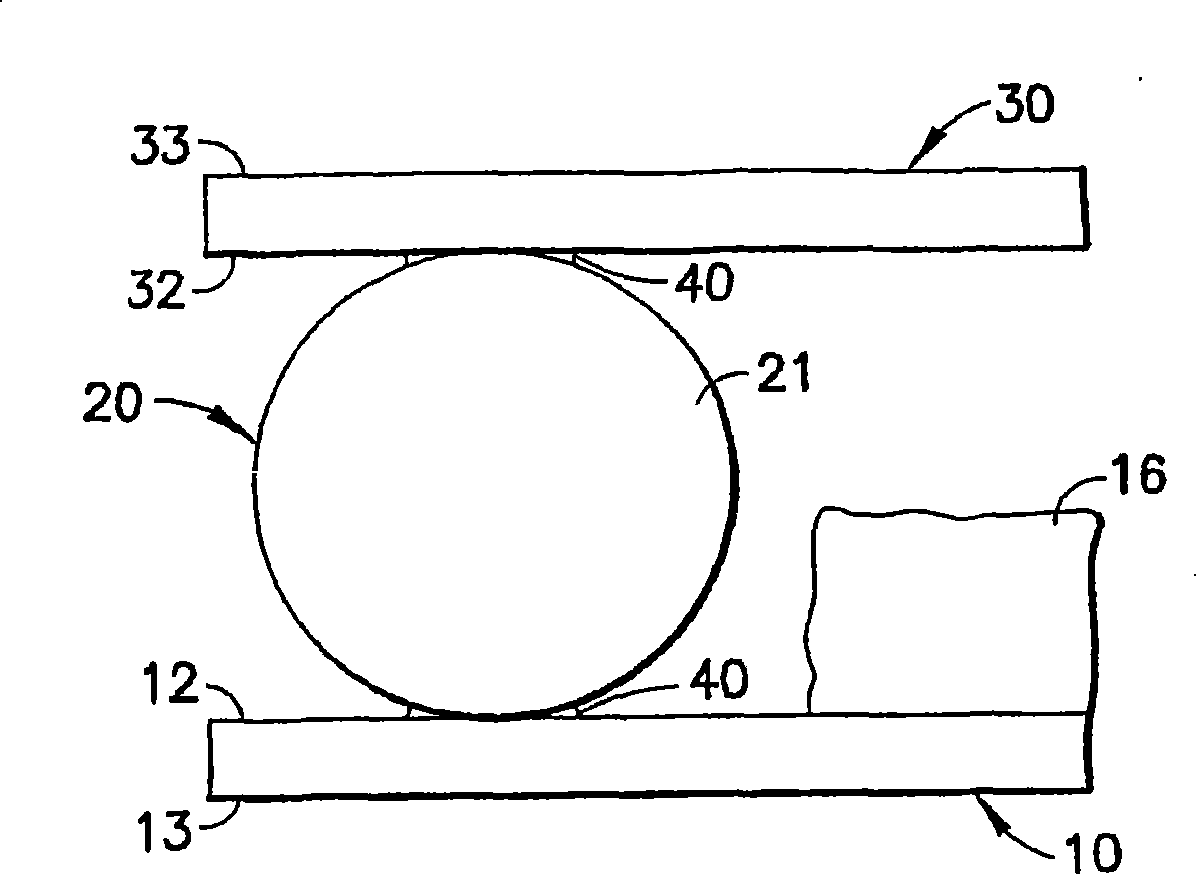

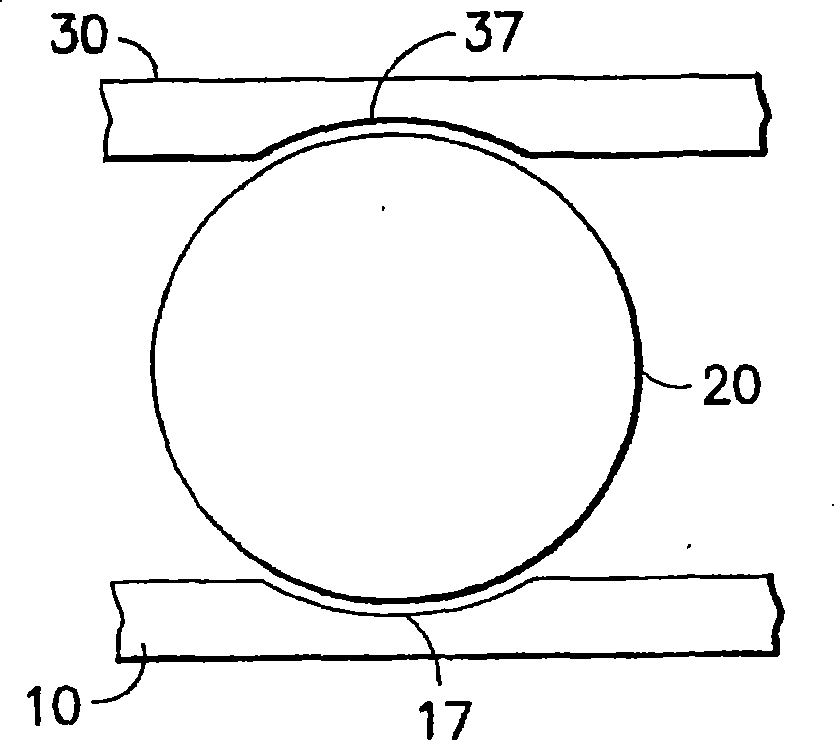

[0020] figure 1 Shown is a base plate 10 having: an inner surface 12 to which a wicking structure 16 of openpore copper foam is diffusion bonded; an opposing surface 13; A pair of laterally opposite notches 14. The wire 20 is formed as a circuit that is disposed against the inner surface 12 closest to the outer periphery of the base plate 10, the structure 16 being spaced from the wire wall 20 to form a gap so that the brazing alloy does not penetrate. capillary structure. The wire can have any external cross-section, such as circular, elliptical, square, rectangular, triangular, trapezoidal or rhombus, as long as it has consistent dimensions transversely to the inner surface 12 . From the viewpoint of commercial availability as wire rods, circular cross-section wire rods are preferable, which are easy to bend into any desired shape and keep the spacing of the plates. A tubular material having one of a variety of outer cross-sections may also be used instead of a solid core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com