Preparation method of sisal fiber surface sizing agent and sisal fiber composite material

A technology of sisal fiber and sizing agent, which is applied in the field of material surface modification and composite material processing and molding, can solve the problems of poor bonding performance, long production cycle of finished products, and inability to continue production, so as to improve bonding strength, Improve compatibility and reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

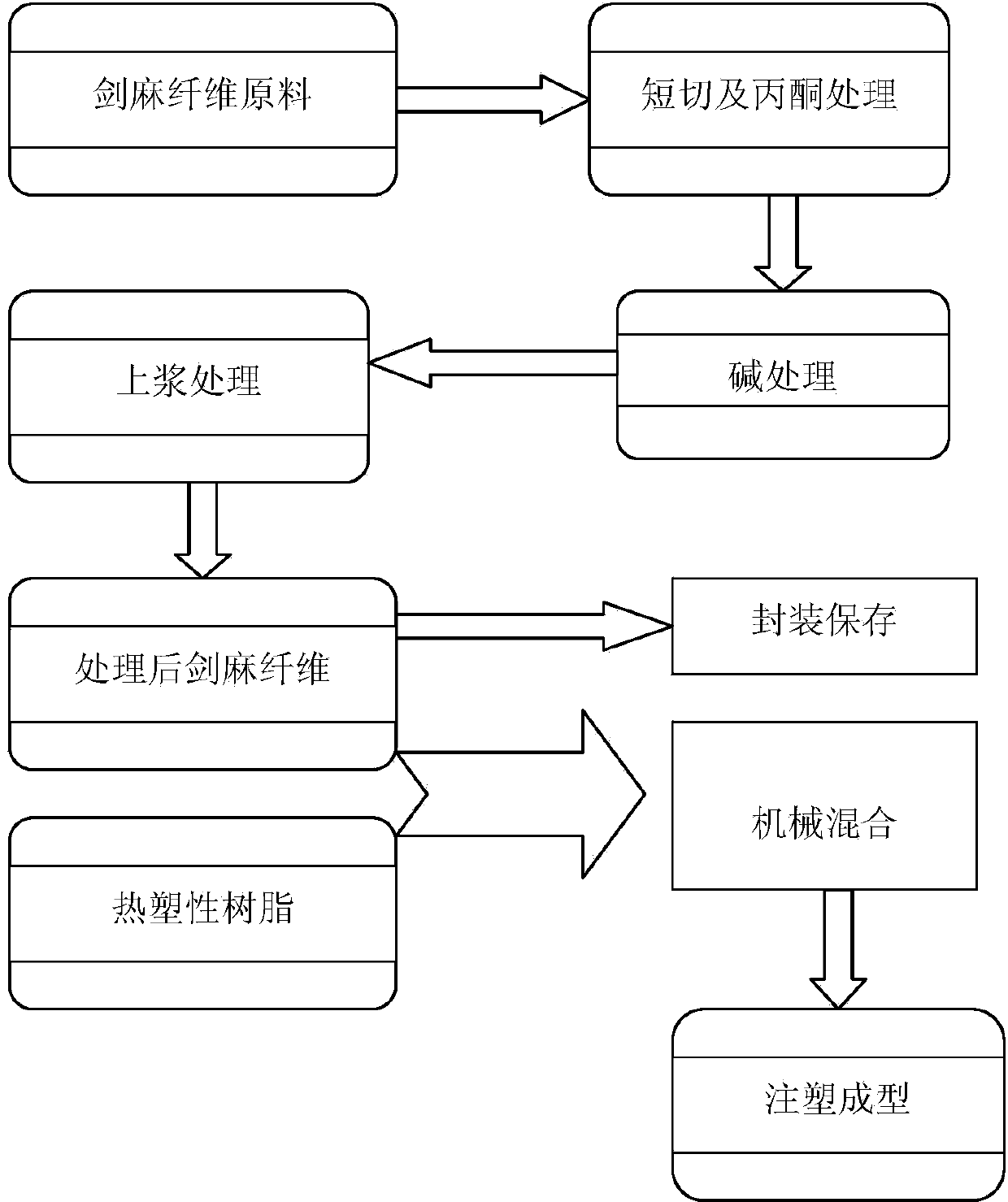

[0020] A kind of preparation method of sisal fiber composite material of the present invention is as figure 1 As shown, the main process is: after the sisal fiber raw material is dried and cut short - acetone treatment - alkali treatment - fiber surface sizing treatment - encapsulation for standby or mechanical mixing with thermoplastic resin, one-step injection molding injection molding, specific steps as follows:

[0021] Step 1. Surface pretreatment of sisal fibers: drying the sisal fibers at 50-80°C; cutting the dried sisal fibers into short fibers with a length of 4-5 mm, immersing them in acetone and boiling for 30-50 minutes , cleaned with deionized water, dried again, immersed in a 10% sodium hydroxide solution by weight, soaked for 4 hours, filtered to obtain fibers, rinsed with deionized water until neutral, and dried;

[0022] Step 2, sizing the sisal fiber after surface pretreatment: immersing the sisal fiber treated in step 1 in the sisal fiber surface sizing age...

Embodiment 1

[0026] In Example 1, sisal fiber polylactic acid composite material, the raw material used is sisal fiber, the sizing agent for surface treatment of sisal fiber and the thermoplastic resin and treatment agent in the process of preparing the composite material include acetone (AR), hydroxide Sodium (AR), isocyanate-modified bisphenol F type epoxy resin aqueous emulsion (nonionic surfactant), γ-(2,3-glycidoxy)propyltrimethoxysilane coupling agent, polylactic acid. Using one-step injection molding method, the specific steps are as follows:

[0027] Step 1. Pretreatment of the sisal fiber surface: put the sisal fiber in an oven at 50°C and dry for 3 hours; cut the dried sisal fiber into short fibers with a length of 4-5 mm, and immerse in acetone (Acetone should not pass through the fiber), boil for 30min, take out the sisal fiber and clean it with deionized water, dry it at 50°C for 3h, then immerse the sisal fiber in a sodium hydroxide solution with a concentration of 10wt%, soa...

Embodiment 2

[0033] In Example 2, sisal fiber polylactic acid composite material, the raw material includes sisal fiber, the treatment agent includes acetone (AR) and sodium hydroxide (AR), and the composition and weight percentage of the sizing agent are: isocyanate modified bisphenol A Mixed aqueous emulsion of type epoxy resin and epoxy-terminated polyurethane resin (the weight ratio between the two is 2:1), bis(dioctyloxypyrophosphate) ethylene titanate coupling agent, γ -(2,3-Glycidoxy)propyltrimethoxysilane coupling agent, the thermoplastic resin is polylactic acid. Among them, the concentration of sizing agent is 60wt%, the concentration of bis(dioctyloxypyrophosphate) ethylene titanate coupling agent is 2wt%, and γ-(2,3-glycidyloxy)propyltrimethoxysilane The coupling agent concentration is 4wt%, the polyether-modified polysiloxane copolymer is 1wt%, the fatty acid sorbitan is 5wt%, and the rest is water. The preparation steps of the sisal fiber polylactic acid composite material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com