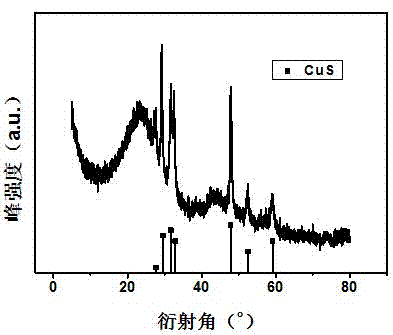

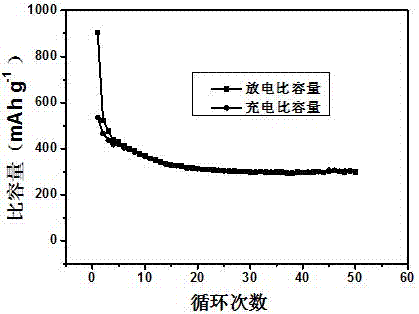

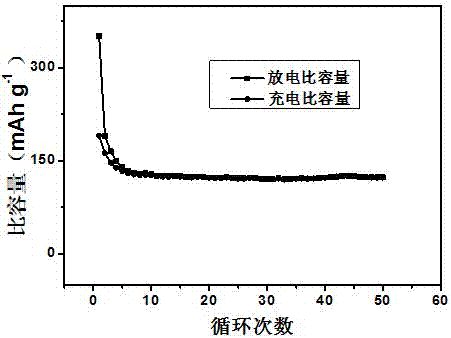

Submicron copper sulfide/sisal fiber carbon anode material for lithium ion battery and preparation method thereof

A lithium-ion battery and sisal fiber technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that have not been reported in the preparation, and achieve the effects of low cost, simple production, and increased specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] (1) Carbonize the sisal fiber for 0.5h in a nitrogen atmosphere with a gas flow rate of 40mL / min, the carbonization temperature is 900°C, and the heating rate is 3°C / min. After natural cooling to room temperature, the sisal fiber carbon is obtained. After mechanical ball milling at a rotating speed of 1 / min, sisal fiber carbon powder was obtained by passing through a 200-mesh sieve.

[0016] (2) Add 0.4g of copper nitrate to 76ml of deionized water, stir with a magnetic stirrer until completely dissolved, add 0.64g of sisal fiber charcoal powder prepared in step (1) under continuous stirring, and continue to add 0.48g of thiourea , sealed and continued to stir overnight, then transferred the mixed solution to a stainless steel reactor lined with polytetrafluoroethylene, controlled the filling amount of the solution in the reactor to 75%, and then placed the reactor in an oven at 180°C for 12 hours , naturally cooled to room temperature, then filtered, washed the filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com