Manufacture method of sisal fiber wet nonwoven fabric

A sisal fiber, wet non-woven technology, applied in the direction of synthetic cellulose fiber, non-woody plant/crop pulp, etc., can solve the problems of complex process, breakage of hemp fiber, reducing the strength of non-woven fabric, etc., and achieve a simple process. , excellent performance, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail in conjunction with embodiment:

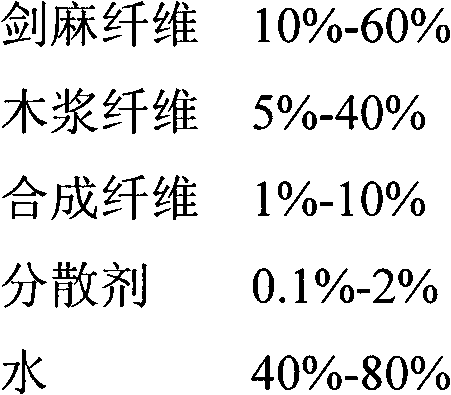

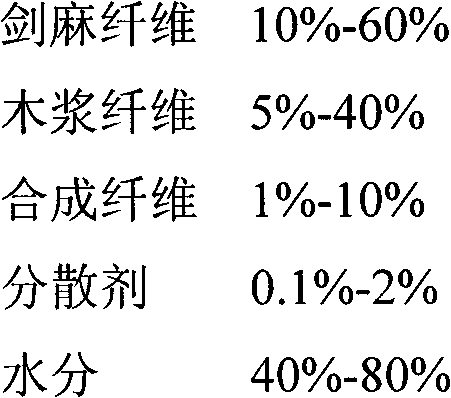

[0019] 1. Cut commercially available raw sisal fiber raw materials into sections about 1 to 10 cm in length, soak them in water for 10 hours, heat them for 3 times to form a mechanical pulp, then take 50 parts (by weight, the same below) of sisal fiber and 35 parts Bleached softwood kraft pulp fibers are mixed and put into a beater for beating to 30°SR.

[0020] 2. For ingredients, take 10 parts of polyvinyl alcohol fiber and 1 part of carboxymethyl cellulose to mix, fully decompose on the decomposer, and mix evenly;

[0021] 3. Put the mixed slurry on the wet-laid machine and form it on the net, the forming concentration is 0.03%, and dry it to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com