Novel sisal fiber extraction method and device

An extraction method, the technology of sisal, is applied in the field of new equipment suitable for sisal fiber extraction, which can solve the problems of high labor intensity and unsafeness of the reverse pull type, huge structure of the horizontal feed type production line, and low quality of direct feed type fibers, etc., to achieve Increased productivity per person, light weight, small structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

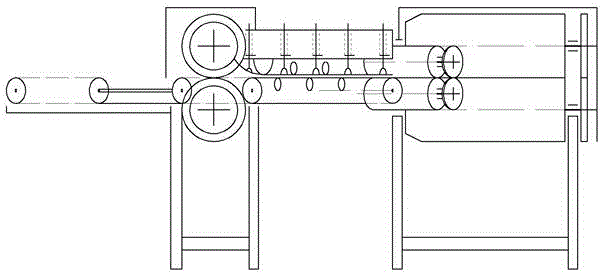

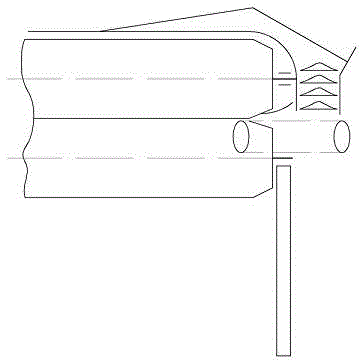

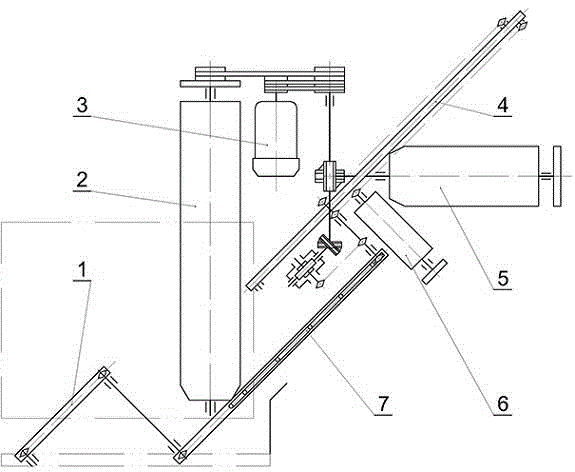

[0030] figure 1 It shows the schematic layout and working principle of the whole machine used for sisal fiber extraction equipment, including the feeding mechanism (1) composed of the feeding port and the transfer chain, the two left and right dehemping mechanisms composed of double drums (2) and (5), the crushing mechanism at the base of the hemp leaf (6), and the chain belt clamping and conveying mechanism (4) and (7).

[0031] The feeding chain, clamping chain, clamping belt and denumbing mechanism are arranged at an inclination of 45°, the conveying speed is about 0.3 m / s, and the speed of axial feeding and tangential pulling is about 0.21 m / s. The left and right desemping mechanisms are perpendicular to each other, the diameter of the drum is 200-300 mm, the linear speed is about 15 m / s, the length of the left demashing drum is twice the length of the right demashing drum, the crushing drum and the demashing drum are inclined at 45°, crushing The rolling speed is 1.4 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com