Graphene-bismuth oxide composite material as well as preparation method thereof, lead carbon battery cathode diachylon as well as preparation method thereof and lead carbon battery cathode plate

A technology of composite materials and lead-carbon batteries, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problem of severe hydrogen evolution on the negative plate of lead-carbon batteries, prevent battery dehydration, ensure service life, and have simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] In addition, the present invention also provides a kind of preparation method of graphene-bismuth oxide composite material, comprises the following steps:

[0061] (1) Add graphene to water, and sonicate for 0.5 to 1 hour to form a graphene suspension with a concentration of 1 to 10 mg / mL;

[0062] (2) Add bismuth oxide to the graphene suspension at a mass ratio of bismuth oxide to graphene of 0.005-0.25:1, stir vigorously for 0.5-2 hours, and stand at 20-50°C after stirring completely 12 to 24 hours;

[0063] (3) Filtration, filtering and drying the filter residue to obtain a graphene-bismuth oxide composite material.

[0064] The bismuth oxide is added according to the mass ratio of bismuth oxide to graphene of 0.05-0.25:1.

[0065] The vigorous stirring is mechanical stirring, and the rotating speed of the stirrer is 200~800r / min.

[0066] The drying is vacuum drying, the drying temperature is 60-80° C., and the drying time is 1-2 hours.

[0067] In the preparati...

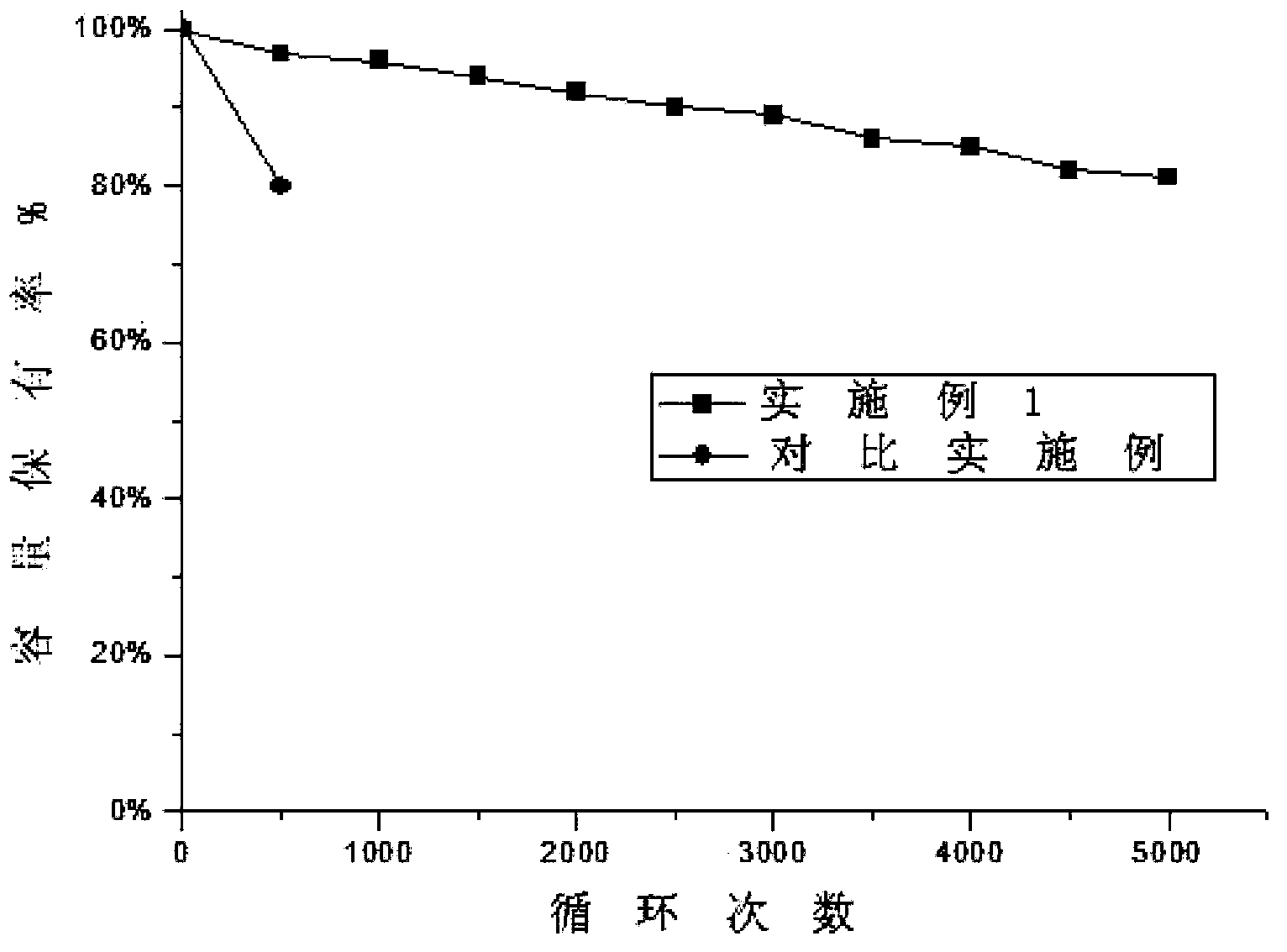

Embodiment 1

[0121] A kind of preparation method of graphene-bismuth oxide composite material, comprises the following steps:

[0122] (1) Take 100 parts of graphene and add it to deionized water, and sonicate for 0.5 hours to form a graphene suspension with a concentration of 1 mg / mL;

[0123] (2) Add 25 parts of bismuth oxide to the above-mentioned graphene suspension, stir vigorously at a speed of 500r / min for 0.5 hours, and stand at 50°C for 24 hours after the stirring is completed;

[0124] (3) Filtration, filter the filter residue into a vacuum drying oven, and dry at 60° C. for 2 hours to obtain a graphene-bismuth oxide composite material.

[0125] The graphene-bismuth oxide composite material includes graphene and bismuth oxide supported on graphene sheets, and the mass ratio of bismuth oxide to graphene is 0.25:1.

[0126] A preparation method of lead-carbon battery negative electrode paste, comprising the following steps:

[0127] (4) Take 100 parts of lead powder, 0.1 part of ...

Embodiment 2

[0137] A kind of preparation method of graphene-bismuth oxide composite material, comprises the following steps:

[0138] (1) Take 100 parts of graphene and add it to deionized water, and sonicate for 1 hour to form a graphene suspension with a concentration of 5 mg / mL;

[0139] (2) Add 20 parts of bismuth oxide to the above-mentioned graphene suspension, stir vigorously at a speed of 200r / min for 2 hours, and let stand at 20°C for 12 hours after stirring;

[0140] (3) Filtration, filter the filter residue into a vacuum drying oven, and dry at 80° C. for 1 hour to obtain a graphene-bismuth oxide composite material.

[0141] The graphene-bismuth oxide composite material includes graphene and bismuth oxide loaded on graphene sheets, and the mass ratio of bismuth oxide to graphene is 0.2:1.

[0142] A preparation method of lead-carbon battery negative electrode paste, comprising the following steps:

[0143] (4) Take 100 parts of lead powder, 0.3 parts of barium sulfate, 2 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com