Apparatus and technology for controlling and improving plating solution PH value on fingerprint resistant production chain

A fingerprint-resistant, PH-value technology, applied in cells, electrolytic processes, electrolytic components, etc., can solve the problems of increasing the sediment in the bath, unsuitable use, and small effect, so as to reduce power consumption, increase overpotential, and refine the coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

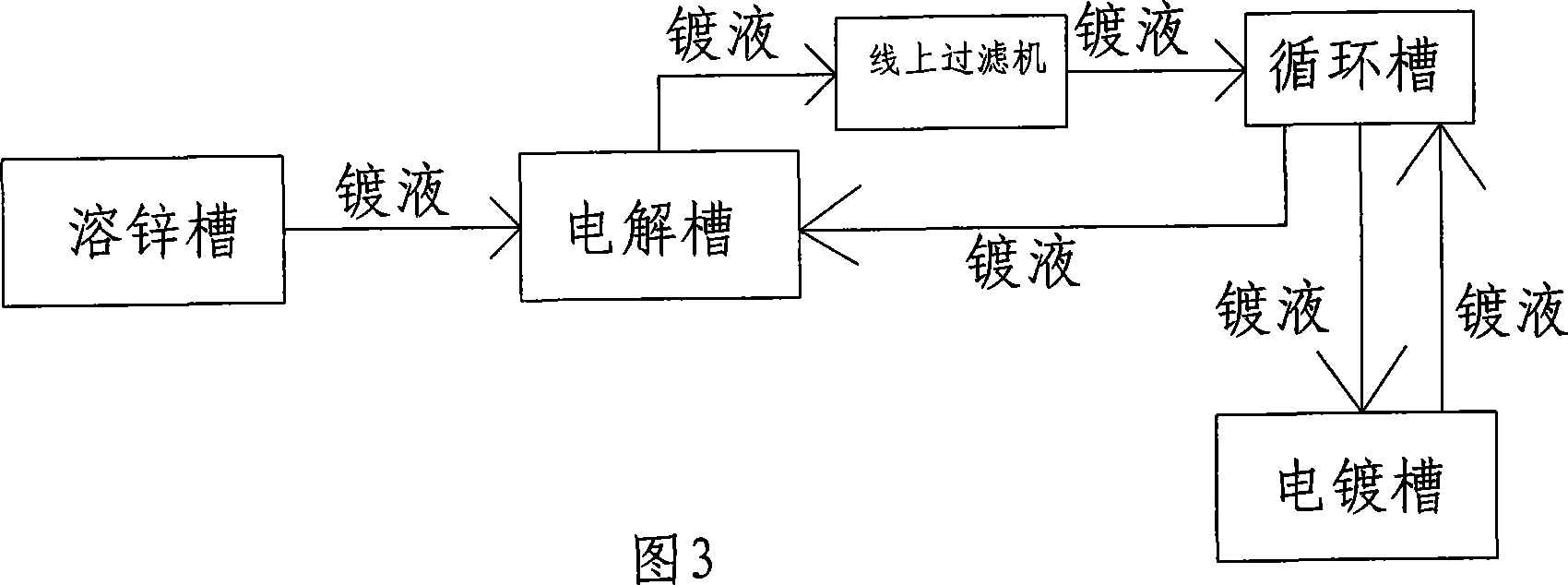

[0025] As shown in Figure 3, the process of controlling and improving the pH value of the plating solution on the fingerprint-resistant board production line of the present invention is that before the plating solution enters the electroplating tank from the zinc-dissolving tank, the plating solution is first pumped or overflowed from the zinc-dissolving tank The method enters the electrolytic tank, and the plating solution is electrolyzed in the electrolytic tank with a current density of 0.1-0.3A / dm2. After the electrolytic treatment, the plating solution is filtered by an online filter and then enters the circulation tank, and then enters the electroplating tank from the circulation tank. The plating solution in the electroplating tank returns to the electrolytic tank through the circulation tank.

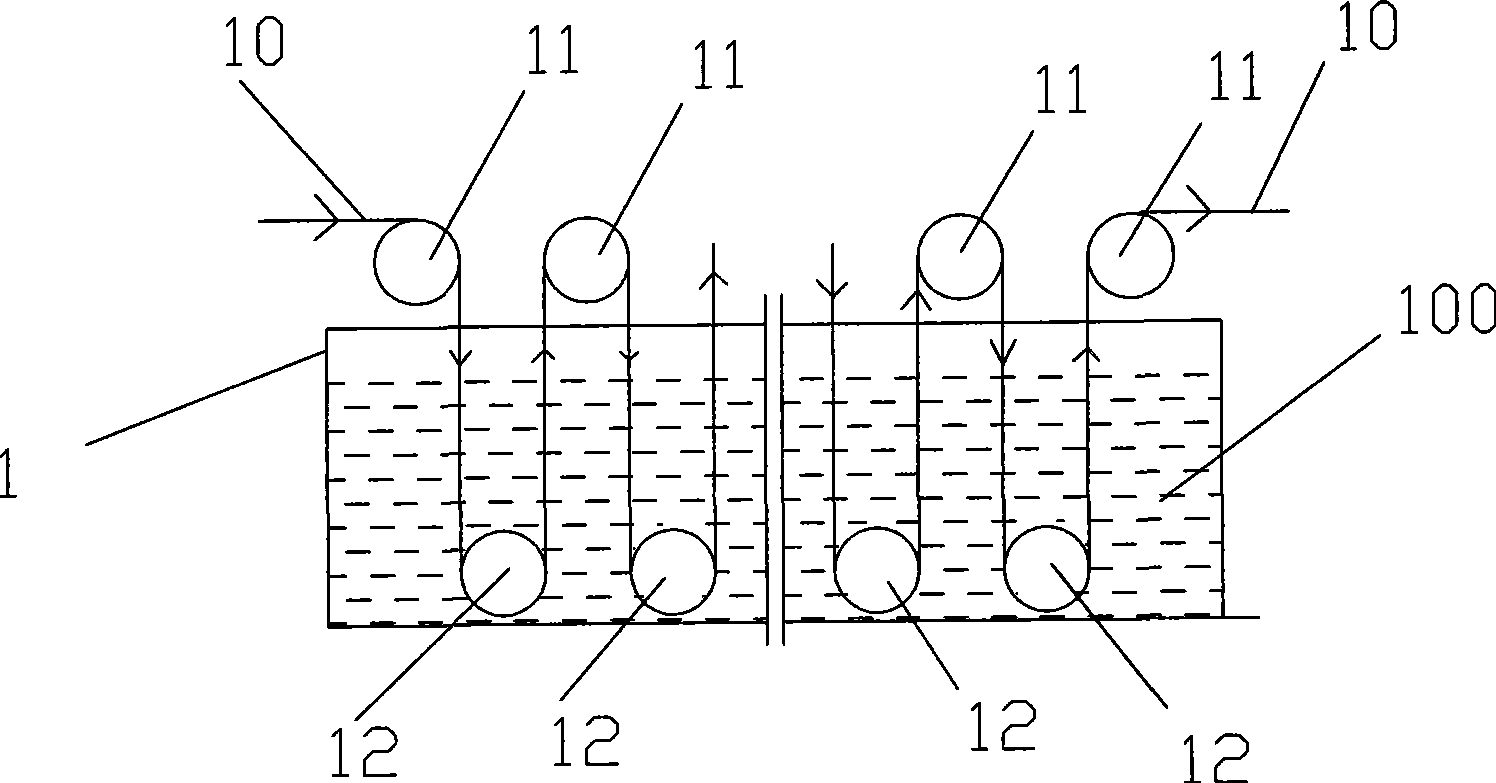

[0026] Such as Figure 4 Shown is the device for realizing the above-mentioned process method, which has an electrolytic tank 4, and the size of the electrolytic tank 4 is 1 / 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com