Electrodeposition preparation method for biomedical titanium base hydroxyapatite composite material

A technology of hydroxyapatite and electrodeposition, which is applied in the field of biomedical composite materials, can solve the problems of loose structure, poor bonding strength, and reduced concentration of electrodeposited hydroxyapatite coating, and achieves low price, easy control, and low concentration. The effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Pretreatment of the substrate: ①Mechanical polishing: wire-cut the pure titanium sheet into a rectangular strip of 10.0cm×1.0cm×0.8cm, and pass through 100 # 、200 # , 800 # 、1000 # Water abrasive paper is mechanically polished in the same direction until the surface is even and bright, and rinsed with deionized water. ② Degreasing: In a beaker filled with 500mL deionized water, add 12g of anhydrous Na 2 CO 3 , 2g anhydrous Na 2 SiO 3 , 12gNa 3 PO 4 12H 2O, after stirring and dissolving, it is prepared as a degreasing liquid. Pour about 100mL into a beaker, use polished and bright pure titanium substrate as anode, and platinum-plated titanium mesh as cathode, current density 10mA·cm -2 Next, electrolytically degrease for 30s, take out the pure titanium substrate and rinse it with distilled water. ③Acid etching: In two 200mL beakers, first add a certain amount of deionized water, then add 3mL H 2 SO 4 and 1.5mL HNO 3 Prepare a strong infusion, then add 1...

Embodiment 2

[0030] (1) Pretreatment of substrate: same as embodiment 1.

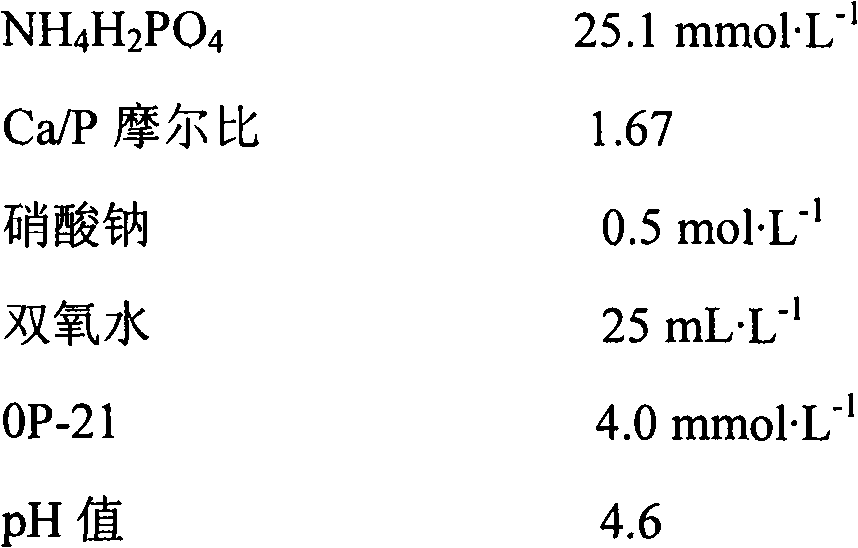

[0031] (2) Preparation of electroplating solution:

[0032] (3) With the pure titanium sheet pretreated in the above step (1) as the cathode, and the platinum-plated titanium mesh as the anode, the electroplating solution prepared in the step (2) is heated to a constant temperature of 60° C. Electrodeposition is carried out on the surface of the substrate in the potential mode, wherein the deposition potential is 4.0V.

[0033] (4) After 1 hour of electrodeposition, take out the sample, rinse it with distilled water, and dry the sample in a vacuum oven at a constant temperature of 80°C for 1 hour, forming a well-bonded hydroxyapatite coating on the surface of the substrate .

Embodiment 3

[0035] (1) Pretreatment of the substrate: the substrate in Examples 1 and 2 was replaced with titanium alloy (Ti6Al4V), and the pretreatment method remained unchanged.

[0036] (2) Preparation of electroplating solution:

[0037]

[0038] (3) With the titanium alloy (Ti6Al4V) pretreated by the above step (1) as the cathode, and the platinum-plated titanium mesh as the anode, the electroplating solution prepared in the step (2) is heated to a constant temperature of 80 ° C, and under magnetic stirring conditions, Electrodeposition is carried out on the surface of the substrate by constant current method, in which the current density is 5.0mA·cm -2 .

[0039] (4) After 1 hour of electrodeposition, take out the sample, rinse it with distilled water, and dry the sample in a vacuum oven at a constant temperature of 80°C for 1 hour, forming a well-bonded hydroxyapatite coating on the surface of the substrate .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com