Alkaline zinc-manganese dioxide cell

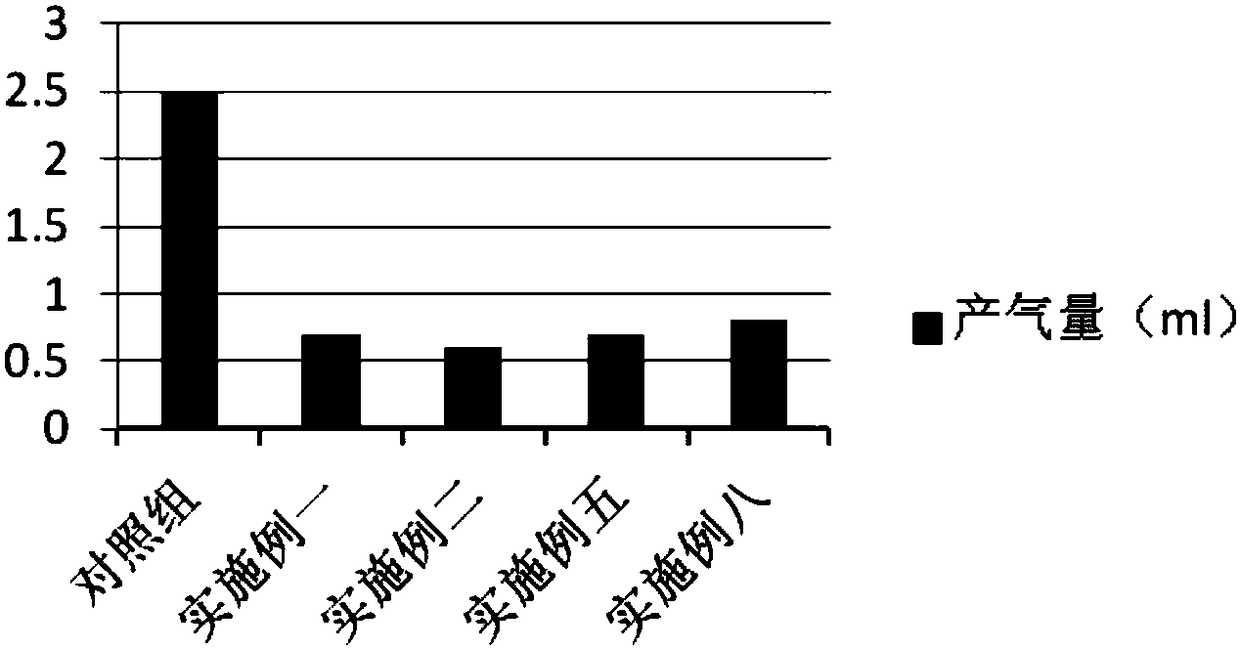

A zinc-manganese battery, alkaline technology, applied in the field of alkaline zinc-manganese batteries, can solve the problems of shortening battery life, large hydrogen evolution of zinc paste, easy expansion, etc., to extend storage life, reduce hydrogen evolution, and improve discharge performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

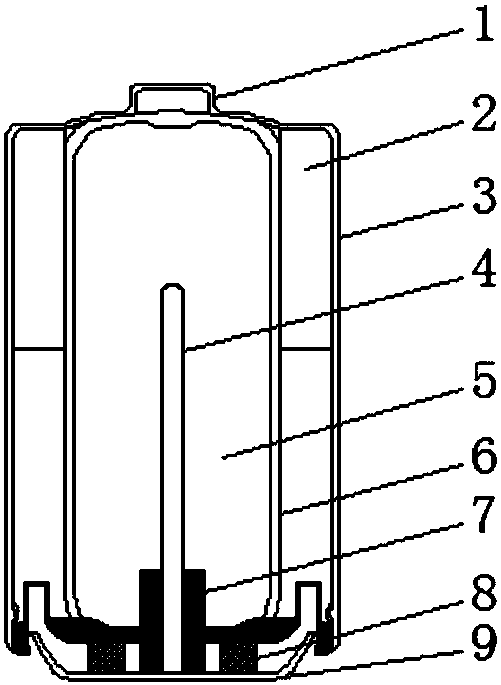

Image

Examples

Embodiment 1

[0040] Preparation of alkaline manganese battery containing multifunctional additives:

[0041] (1) A negative electrode zinc paste was prepared according to the above-mentioned method for preparing a negative electrode formulation containing the additive polyethylene glycol 2000 (PEG2000). At this time, the added amount of the new multifunctional additive is 0.05% wt of the anode zinc paste.

[0042] (2) Prepare the battery parts and accessories according to the normal production process, and the production process remains unchanged.

[0043] (3) The positive electrode of the battery, the electrolyte formula is consistent with the control group.

[0044] (4) Assemble and produce finished batteries on the LR06 alkaline manganese battery production line.

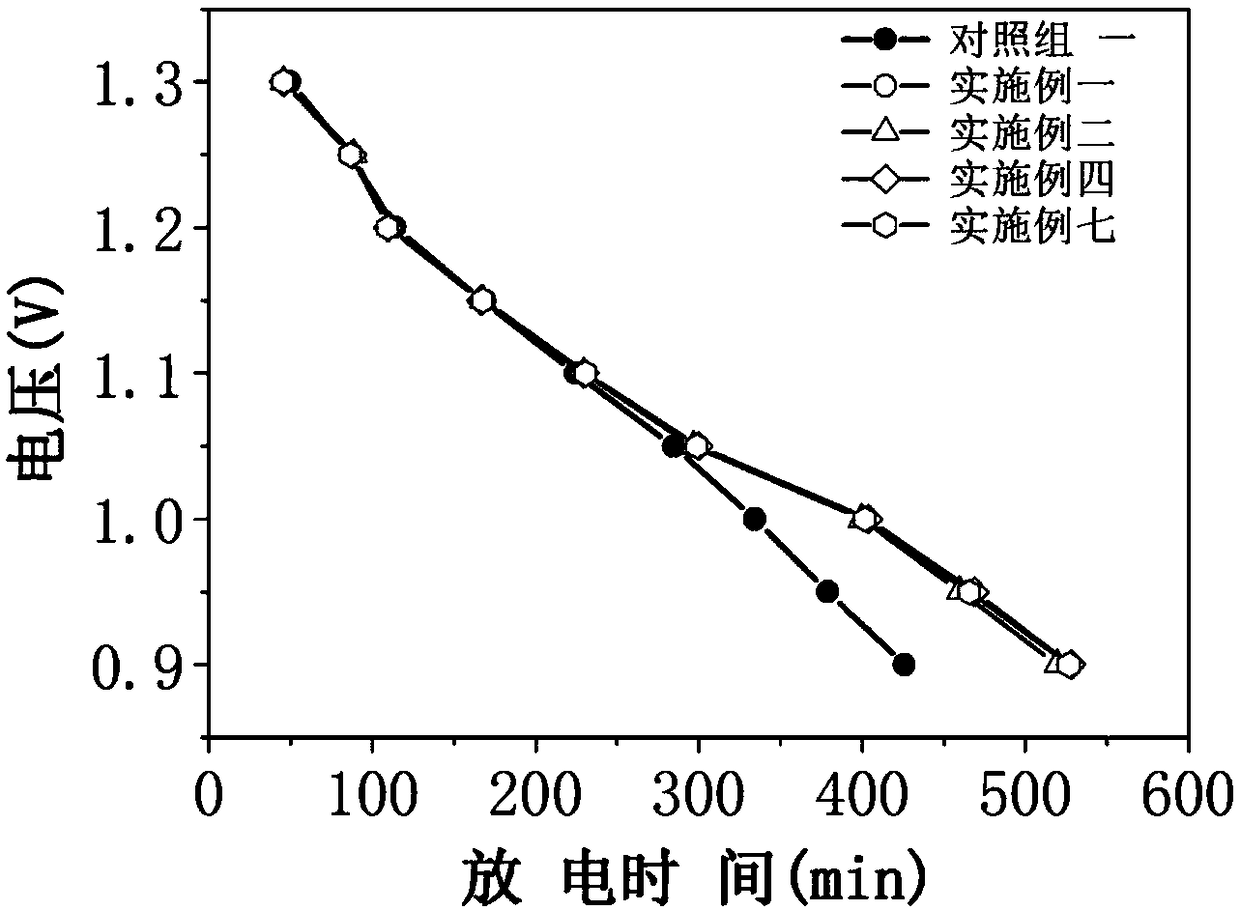

[0045] The following tests are carried out with LR06 batteries. It should be noted that the present invention is not limited to LR06 alkaline manganese batteries. The positive effects consistent with the present invention can be obta...

Embodiment 2

[0059] The negative electrode zinc paste containing the novel multifunctional additive of the present invention is prepared by the same method as the first embodiment. The production process is the same as that of the first embodiment, and the battery gas production test is the same as that of the first embodiment. The difference is that the added amount of the new multifunctional additive polyethylene glycol 2000 of the present invention is 0.5% wt. The battery is discharged for gas production experiment.

Embodiment 3

[0061] The negative electrode zinc paste containing the novel multifunctional additive of the present invention is prepared by the same method as in Example 1. The production process is the same as that of Example 1. The difference is that the added amount of the novel multifunctional additive of the present invention polyethylene glycol 2000 is 0.5% wt. And discharge in 3.9Ω, 24h / d discharge mode. Record data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com