Electric connector for high-voltage electric equipment

An electrical connector and high-voltage electrical technology, which is applied in the direction of connection, electrical components, and two-component connection devices, can solve the problems that the interface cannot adapt to the electrical connection structure and is inconvenient to install, and meets the requirements of use, superior impact resistance, Effect of High Withstand Voltage Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

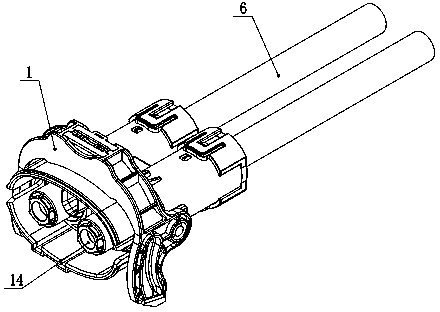

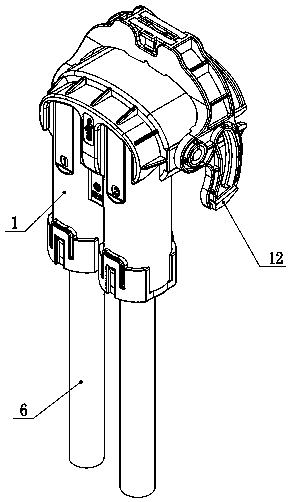

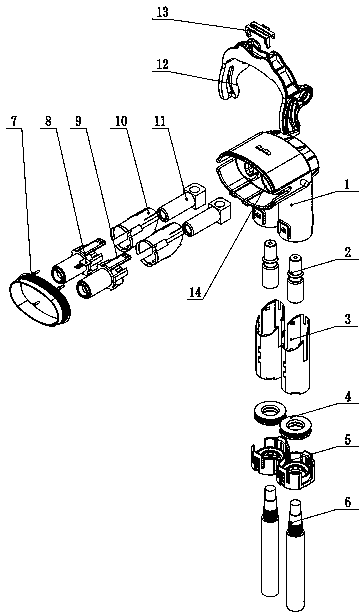

[0022] Electrical connectors for high-voltage electrical applications, including plugs and sockets. Such as figure 2 and image 3 As shown, the present invention discloses a plug for a high-voltage electrical connector. The plug includes a plug body 1 , and at least two through holes 14 are formed through the plug body 1 . Same as the prior art, the function of the two through holes 14 is to set the metal conductors and electrically connect the positive and negative poles with the socket.

[0023] One end of the through hole 14 is provided with a socket 11 for electrical connection with the pin of the socket, and the other end of the through hole 14 is provided with a transfer terminal 2 electrically connected with the connecting cable 6, so The plug body 1 described above is a curved structure, and the curvature of the through hole 14 is equal to the curvature of the plug body 1 . Specifically, preferably, the bending angles of the plug body 1 and the through hole 14 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com