Cholesterol modified amphiphilic pH response pennicuius copolymer as well as preparation and micelle of copolymer

An amphiphilic and copolymer technology, which is applied in the direction of drug combination, emulsion delivery, organic active ingredients, etc., can solve problems such as difficult to obtain effects, and achieve the effect of enhancing loading performance, enhancing stability, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

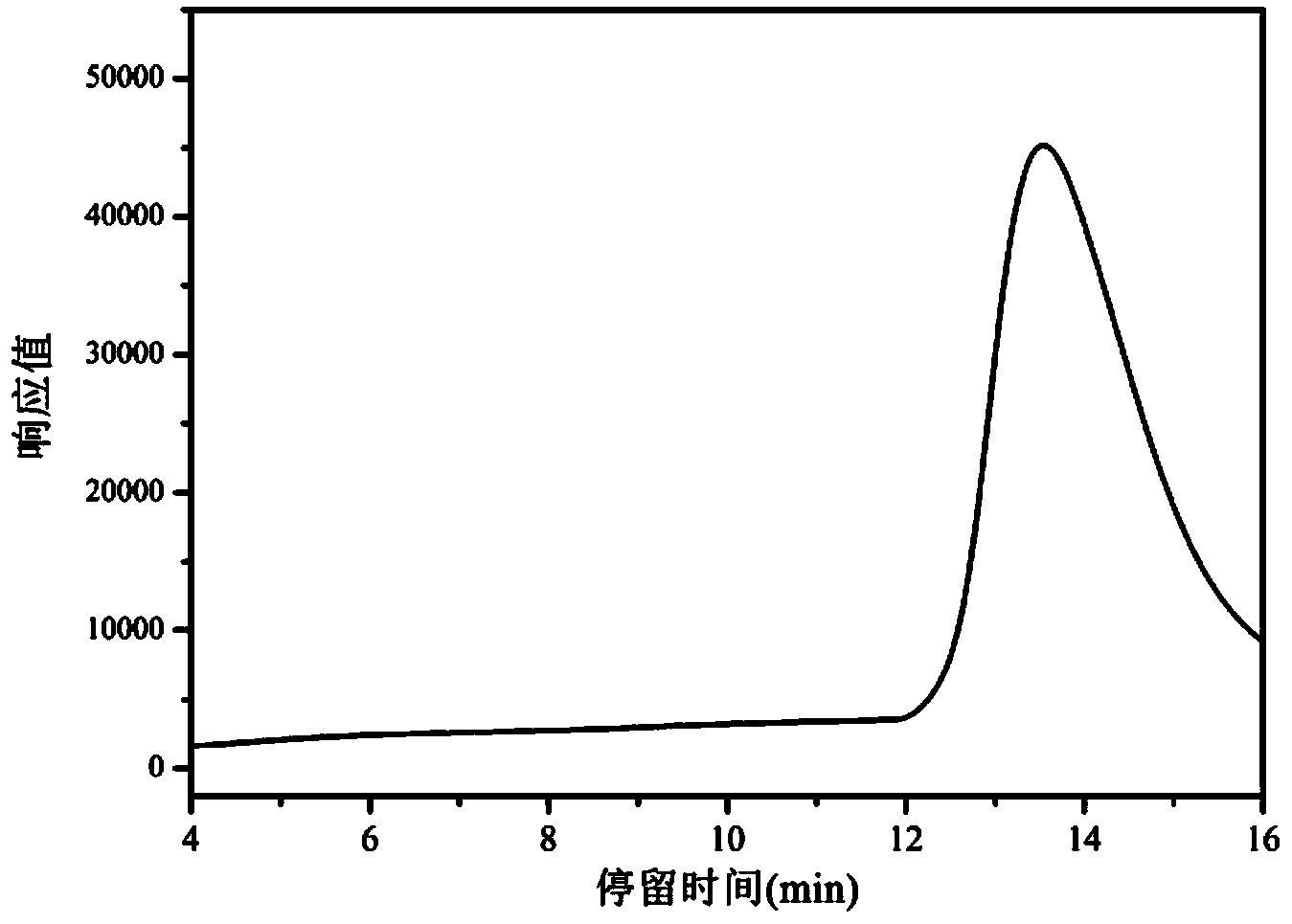

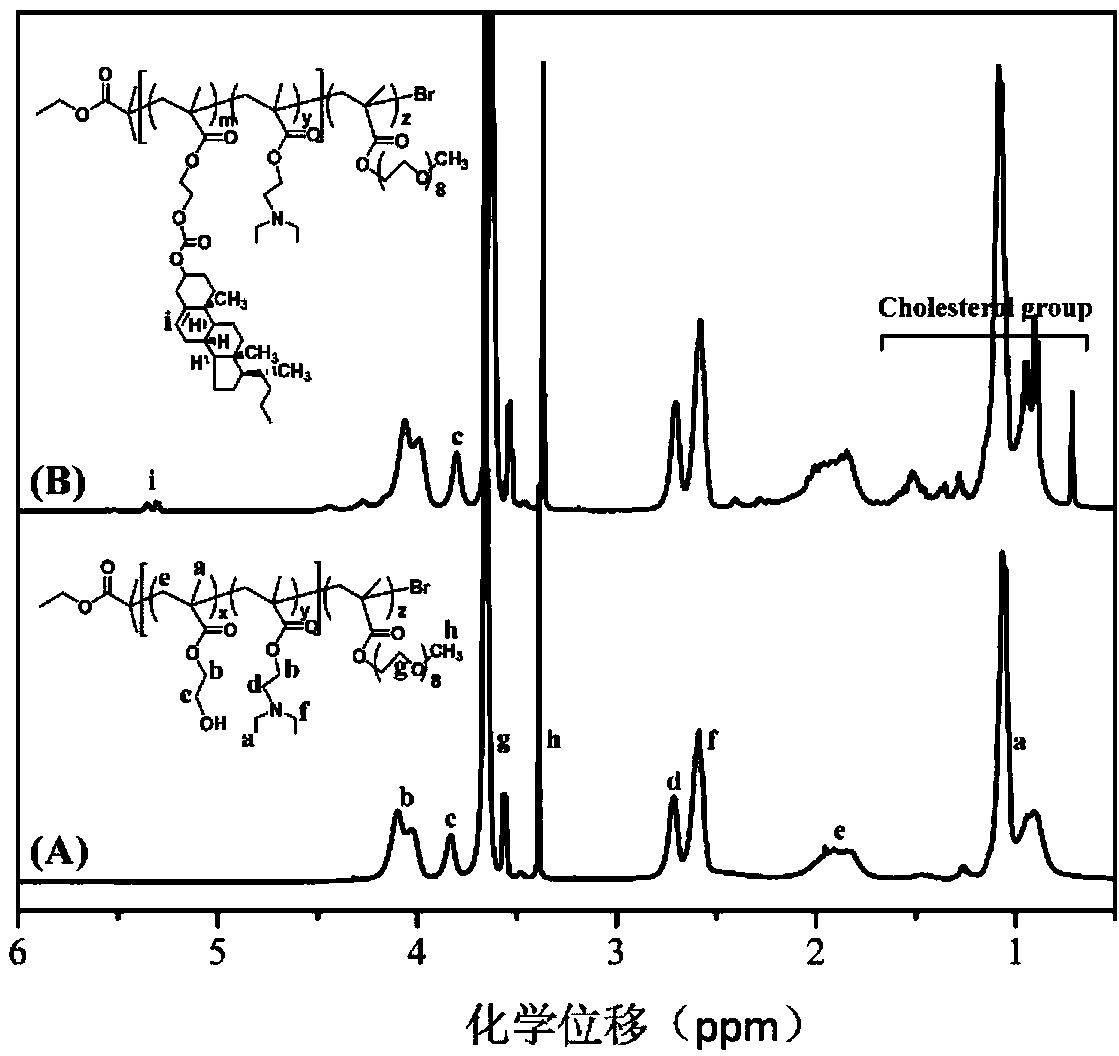

[0057] Example 1: Preparation of cholesterol-modified amphiphilic pH-responsive brush copolymer Chol-P(HEMA-co-DEA)-b-PPEGMA

[0058] (1) Preparation of amphiphilic pH-responsive brush copolymer P(HEMA-co-DEA)-b-PPEGMA: a stir bar and copper bromide (22.3mg, 1.0mmol) were placed in a 50mL dry eggplant-shaped bottle, Seal it with a reverse rubber stopper, vacuumize and pass argon three times. The solvent toluene (20mL), monomer HEMA (1.30g, 10mmol), DEA (6.48g, 35mmol), and ligand HMTETA (0.31mL, 1.2mmol) were sequentially added into the bottle with a syringe, and stirred for 10min to form the catalyst complex. Then the reducing agent Sn(Oct) 2 (0.40 g, 1.0 mmol) was dissolved in 2 mL of toluene and added to the reaction flask. After stirring for 5min, the initiator EBriB (0.15mL, 1.08mmol) was quickly added dropwise with a syringe. After stirring and reacting in an oil bath at 60°C for 6h, the monomer PEGMA (4.75g, 10mmol) was added, and the reaction was continued for 30h. ...

Embodiment 2

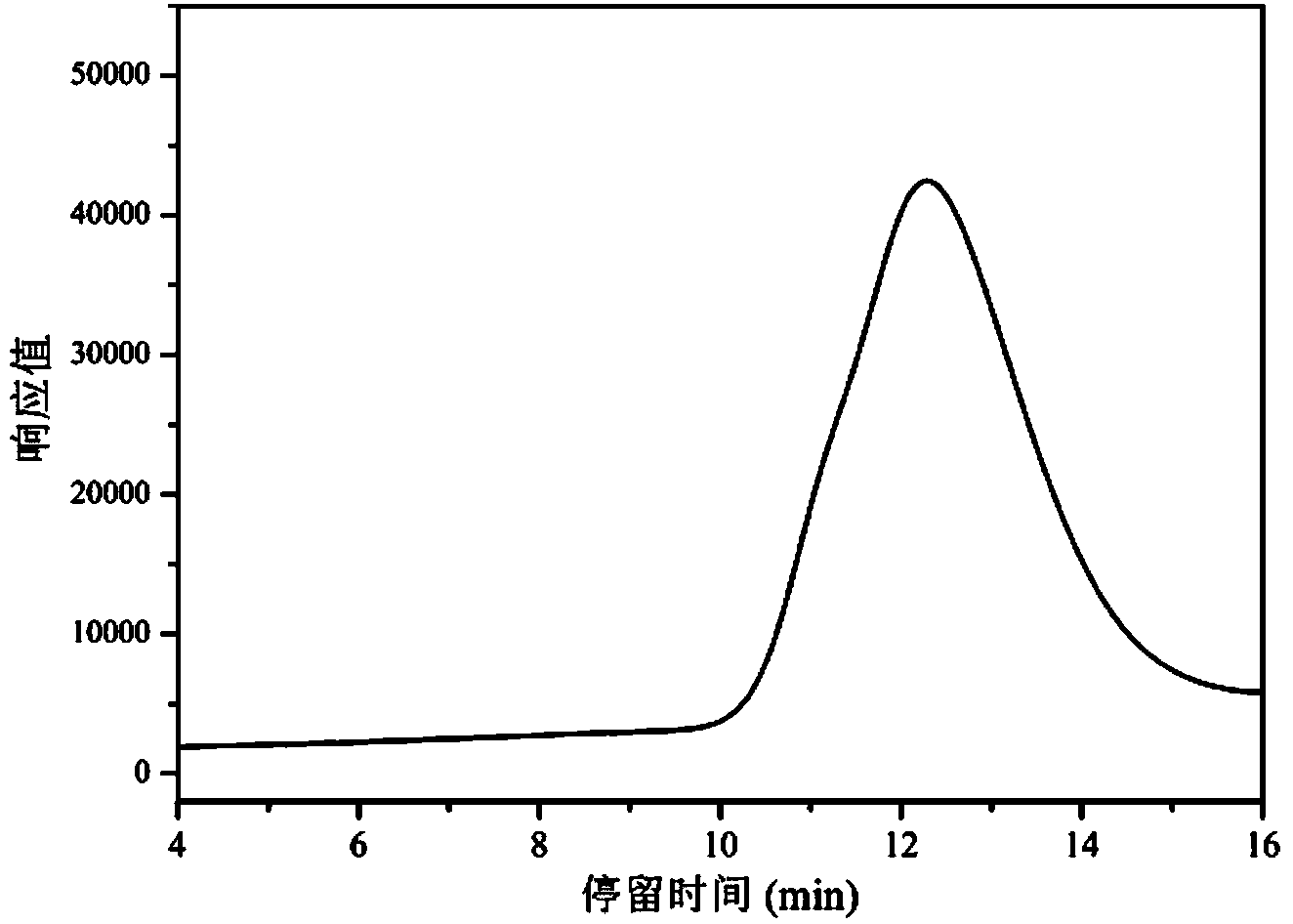

[0062] Example 2: Preparation of cholesterol-modified amphiphilic pH-responsive brush copolymer Chol-P(HEMA-co-DEA)-b-PPEGMA

[0063] (1) Preparation of amphiphilic pH-responsive brush copolymer P(HEMA-co-DEA)-b-PPEGMA: a stir bar and copper bromide (26.8mg, 0.8mmol) were placed in a 50mL dry eggplant-shaped bottle, Seal it with a reverse rubber stopper, vacuumize and pass argon three times. The solvent toluene (20mL), monomer HEMA (1.30g, 10mmol), DEA (6.475g, 40mmol), and ligand HMTETA (0.31mL, 1.2mmol) were sequentially added into the bottle with a syringe, and stirred for 10min to form the catalyst complex. Then the reducing agent Sn(Oct) 2 (0.486 g, 1.2 mmol) was dissolved in 2 mL of toluene and added to the reaction flask. After stirring for 5min, the initiator EBriB (0.17mL, 1.2mmol) was quickly added dropwise with a syringe. After stirring and reacting in an oil bath at 70°C for 5h, the monomer PEGMA (14.25g, 30mmol) was added and the reaction was continued for 24h. ...

Embodiment 3

[0065] Example 3: Preparation of cholesterol-modified amphiphilic pH-responsive brush copolymer Chol-P(HEMA-co-DEA)-b-PPEGMA

[0066](1) Preparation of amphiphilic pH-responsive brush copolymer P(HEMA-co-DEA)-b-PPEGMA: a stir bar and copper bromide (26.8mg, 0.12mmol) were placed in a 50mL dry eggplant-shaped bottle, Seal it with a reverse rubber stopper, vacuumize and pass argon three times. The solvent toluene (20mL), monomer HEMA (4.68g, 36mmol), DEA (2.775g, 15mmol), and ligand HMTETA (0.31mL, 1.2mmol) were sequentially added into the bottle with a syringe, and stirred for 10min to form the catalyst complex. Then the reducing agent Sn(Oct) 2 (0.486 g, 1.2 mmol) was dissolved in 2 mL of toluene and added to the reaction flask. After stirring for 5min, the initiator EBriB (0.17mL, 1.2mm o l), after stirring and reacting in an oil bath at 90° C. for 7 h, the monomer PEGMA (14.25 g, 30 mmol) was added, and the reaction was continued for 48 h. Cool the reaction solution to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical micelle concentration (mass) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com