Polypropylene film and film capacitor

A polypropylene film and breakdown voltage technology, applied in the field of polypropylene film, can solve the problems of low withstand voltage, low stretching ratio, unevenness, etc., achieve high withstand voltage and reliability, and suppress insulation breakdown voltage. , the effect of less insulation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

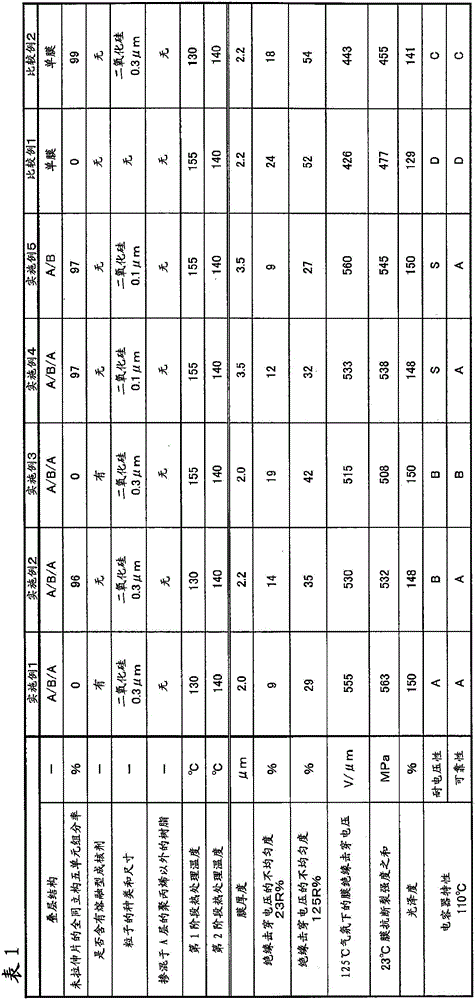

[0164] With respect to 100 parts by mass of polypropylene resin polymerized with a Ziegler-Natta catalyst, having an isotactic pentad fraction of 0.98, a melting point of 167° C., and a melt flow rate (MFR) of 2.6 g / 10 minutes, Kneading and extruding was carried out with an extruder set at 240°C so that the concentration of "α crystal nucleating agent manufactured by Milliken; NX8000", which is a noni alcohol-based melting type nucleating agent, was 0.3 parts by mass, and the bar The solids were water-cooled and then fragmented as polypropylene resin raw material (B). As the polypropylene resin for layer A, with respect to 100 parts by mass of PP resin having an isotactic pentad fraction of 0.98, a melting point of 167° C., and a melt flow rate (MFR) of 2.6 g / 10 minutes, Kneading and extruding was carried out with an extruder set at 240° C. so that “silica particles with an average particle diameter of 0.3 μm manufactured by Denki Kagaku Kogyo Co., Ltd.: SFP-20MHE (silane coup...

Embodiment 2

[0166]A polypropylene film having a thickness of 2.2 μm was obtained in the same manner as in Example 1 except that the polypropylene resin of the B layer did not contain a melt-type nucleating agent. The characteristics and capacitor characteristics of the polypropylene film of this example are shown in Table 1, and the reliability as a capacitor is very excellent, and the withstand voltage is at a level that is not problematic in practical use.

Embodiment 3

[0168] Except having set the conditions of the heat treatment temperature after biaxial stretching to the conditions described in Table 1, it carried out similarly to Example 1, and obtained the polypropylene film. The characteristics and capacitor characteristics of the polypropylene film of this example are shown in Table 1, and both the withstand voltage and reliability as a capacitor are at levels that are not problematic in practical use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com