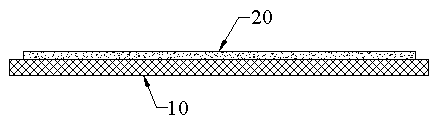

A high temperature polypropylene metallized film

A metallized film, polypropylene film technology, applied in the field of capacitors, can solve the problems of high cost and difficult to combine, and achieve the effects of less insulation defects, less breakdown, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

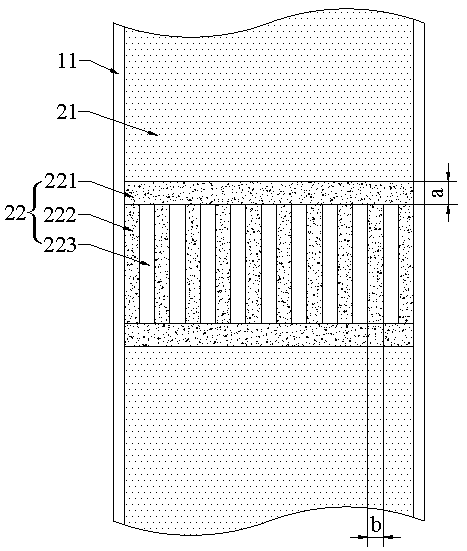

[0023] The ethanol solution (ethanol is solvent) and titanium tetrachloride that mass fraction is 1% tetrabutyl titanate are mixed uniformly according to the ratio of mass ratio 150:1 to make treatment agent, and treatment agent is coated on graphene conductive film The inner surface of 21 is placed in a room at 20°C and dried for 2 hours, and the relative humidity in the room is kept at 50% during the drying process.

[0024] Wherein, after the inner surface of the graphene conductive film 21 is surface-treated, a layer of polyacrylate pressure-sensitive adhesive is coated, and then the graphene conductive film 21 is bonded to the polypropylene film 10 by a pressure roller, and the pressure roller is pressed against the graphene. The pressure of conductive film 21 and polypropylene film 10 is 0.1kg / cm 2 . After the polyacrylate pressure-sensitive adhesive is cured, the peel strength between the graphene conductive film 21 and the polypropylene film 10 is 12.6N / mm; The peel ...

Embodiment 2

[0026] The ethanol solution (ethanol is solvent) and titanium tetrachloride that mass fraction is 1% tetrabutyl titanate are mixed uniformly according to the ratio of mass ratio 150:1.08 to make treatment agent, and treatment agent is coated on graphene conductive film The inner surface of 21 is placed in a room at 23°C for 2.5 hours to dry, and the relative humidity in the room is kept at 45% during the drying process.

[0027] Wherein, after the inner surface of the graphene conductive film 21 is surface-treated, a layer of polyacrylate pressure-sensitive adhesive is coated, and then the graphene conductive film 21 is bonded to the polypropylene film 10 by a pressure roller, and the pressure roller is pressed against the graphene. The pressure of conductive film 21 and polypropylene film 10 is 0.1kg / cm 2 . After the polyacrylate pressure-sensitive adhesive is cured, the peel strength between the graphene conductive film 21 and the polypropylene film 10 is 13.5N / mm; The pee...

Embodiment 3

[0029]The ethanol solution (ethanol is solvent) and titanium tetrachloride that mass fraction is 1% tetrabutyl titanate are mixed evenly according to the ratio of mass ratio 150:1.1 to make treatment agent, treatment agent is coated on graphene conductive film The inner surface of 21 is placed in a room at 25°C and dried for 3 hours, and the relative humidity in the room is kept at 40% during the drying process.

[0030] Wherein, after the inner surface of the graphene conductive film 21 is surface-treated, a layer of polyacrylate pressure-sensitive adhesive is coated, and then the graphene conductive film 21 is bonded to the polypropylene film 10 by a pressure roller, and the pressure roller is pressed against the graphene. The pressure of conductive film 21 and polypropylene film 10 is 0.1kg / cm 2 . After the polyacrylate pressure-sensitive adhesive is cured, the peel strength between the graphene conductive film 21 and the polypropylene film 10 is 12.9N / mm; The peel streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com