Spark plug

A spark plug and insulator technology, applied in the field of spark plugs, can solve the problem of the overheated front end of the spark plug becoming a spark source, and achieve the effect of promoting fouling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

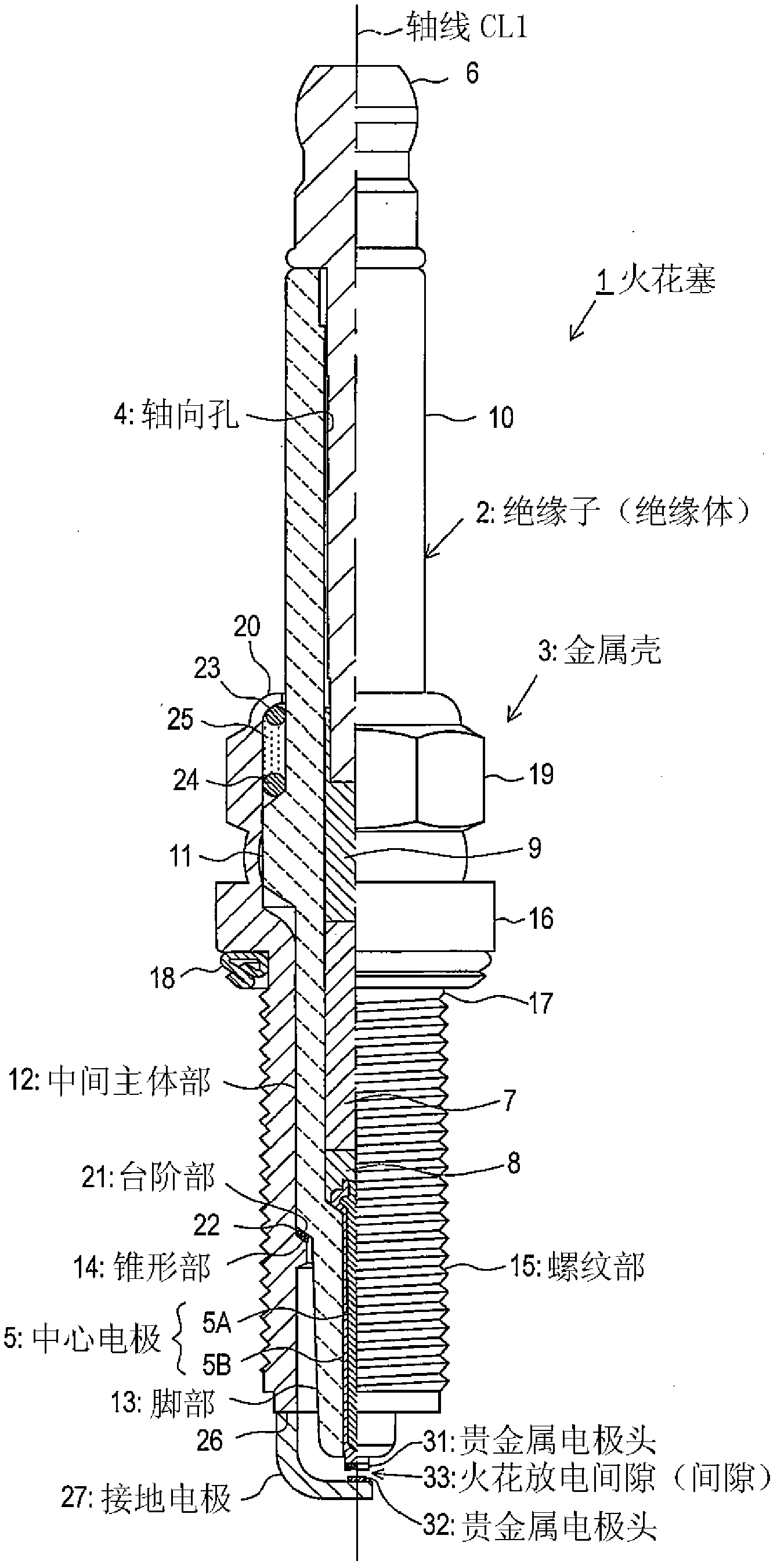

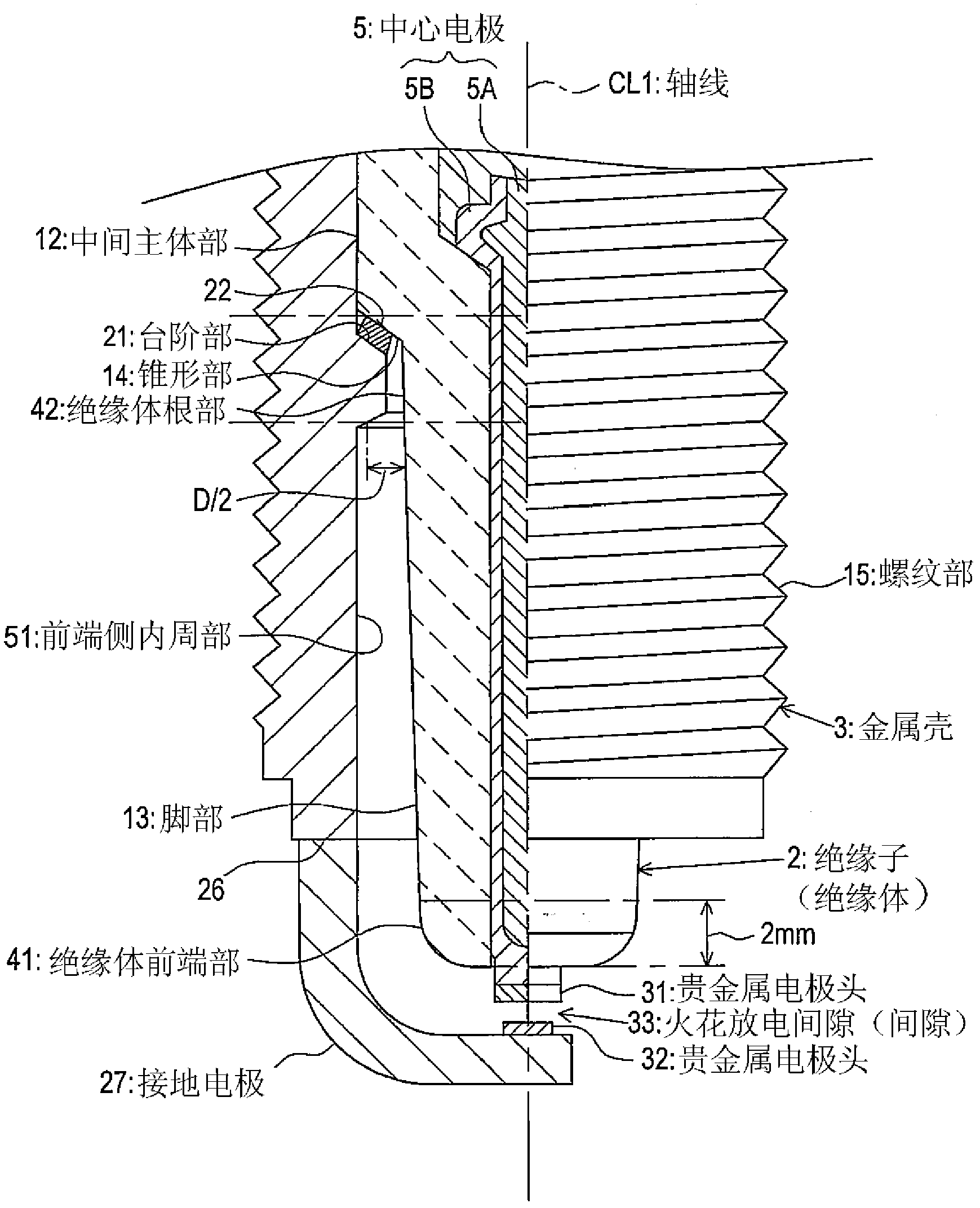

[0054] Hereinafter, embodiments will be described with reference to the drawings. figure 1 It is a partially cutaway front view showing the structure of the spark plug 1 . exist figure 1 In the description, the direction of the axis line CL1 of the spark plug 1 will be described as the vertical direction in the figure, the lower side will be the front end side of the spark plug 1 , and the upper side will be the rear end side.

[0055] The spark plug 1 is constructed of a cylindrical insulator 2 as an insulator and a cylindrical metal case 3 holding the insulator 2 .

[0056] The insulator 2 is formed of calcined alumina or the like known in the art, and includes: a rear end side main body portion 10 formed on the rear end side in the profile portion; a large diameter portion 11 on the rear end side The main body part 10 is formed to protrude outward in the radial direction at a position near the front end side; the middle main body part 12 is formed with a diameter smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com