Patents

Literature

97results about How to "Cost of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimensionally-sensitive moisture sensor and an alarm system for an absorbent article

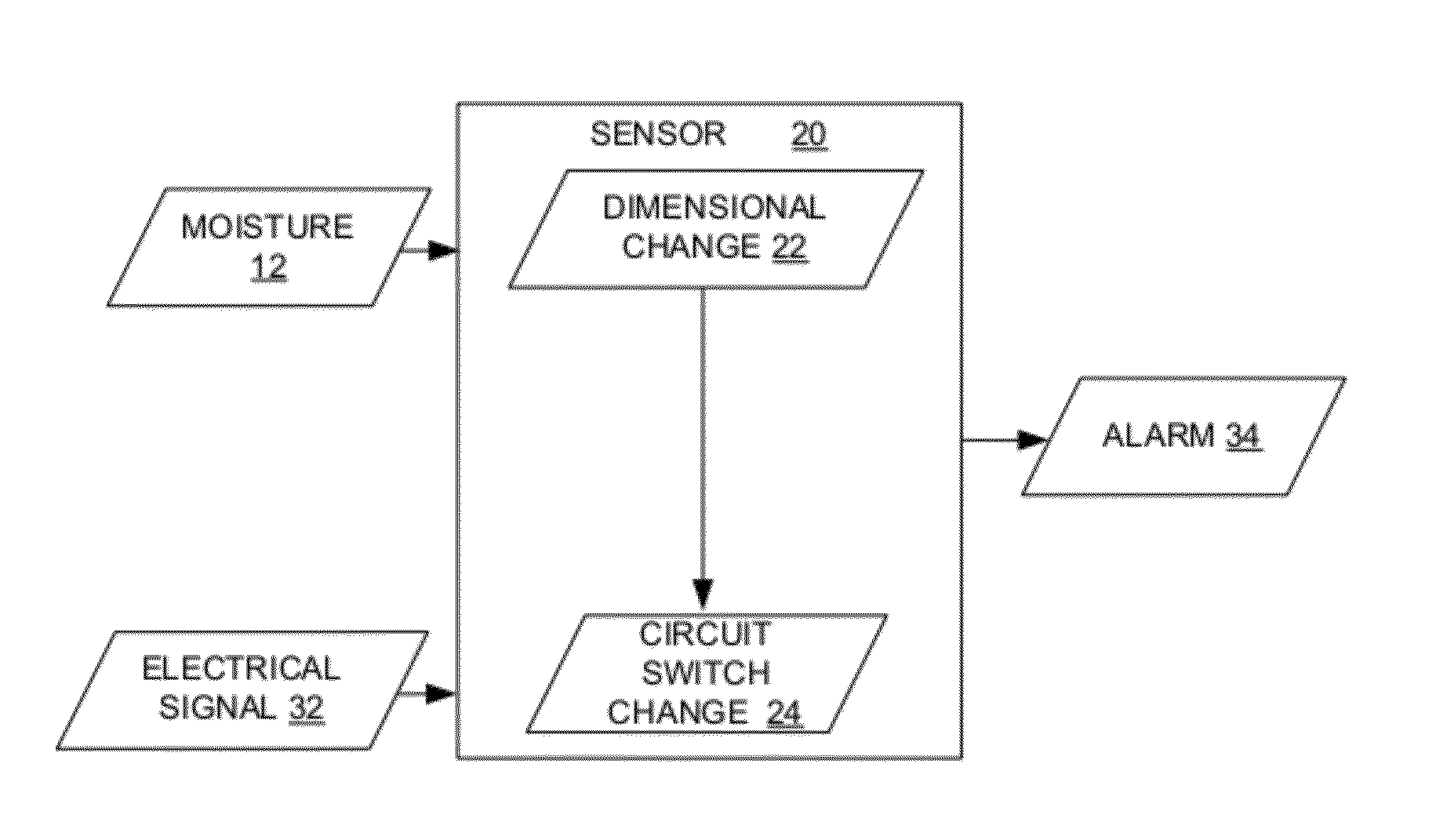

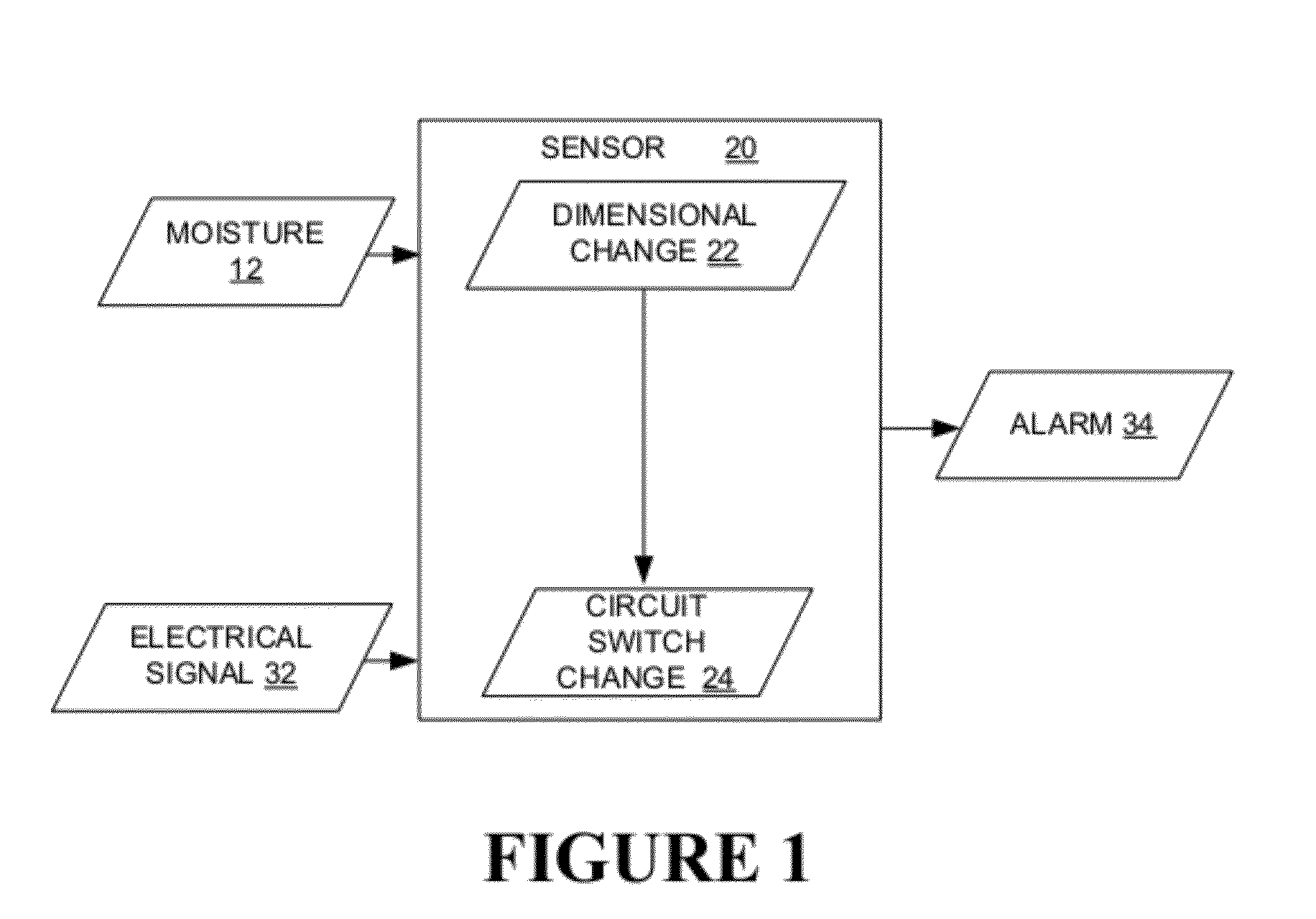

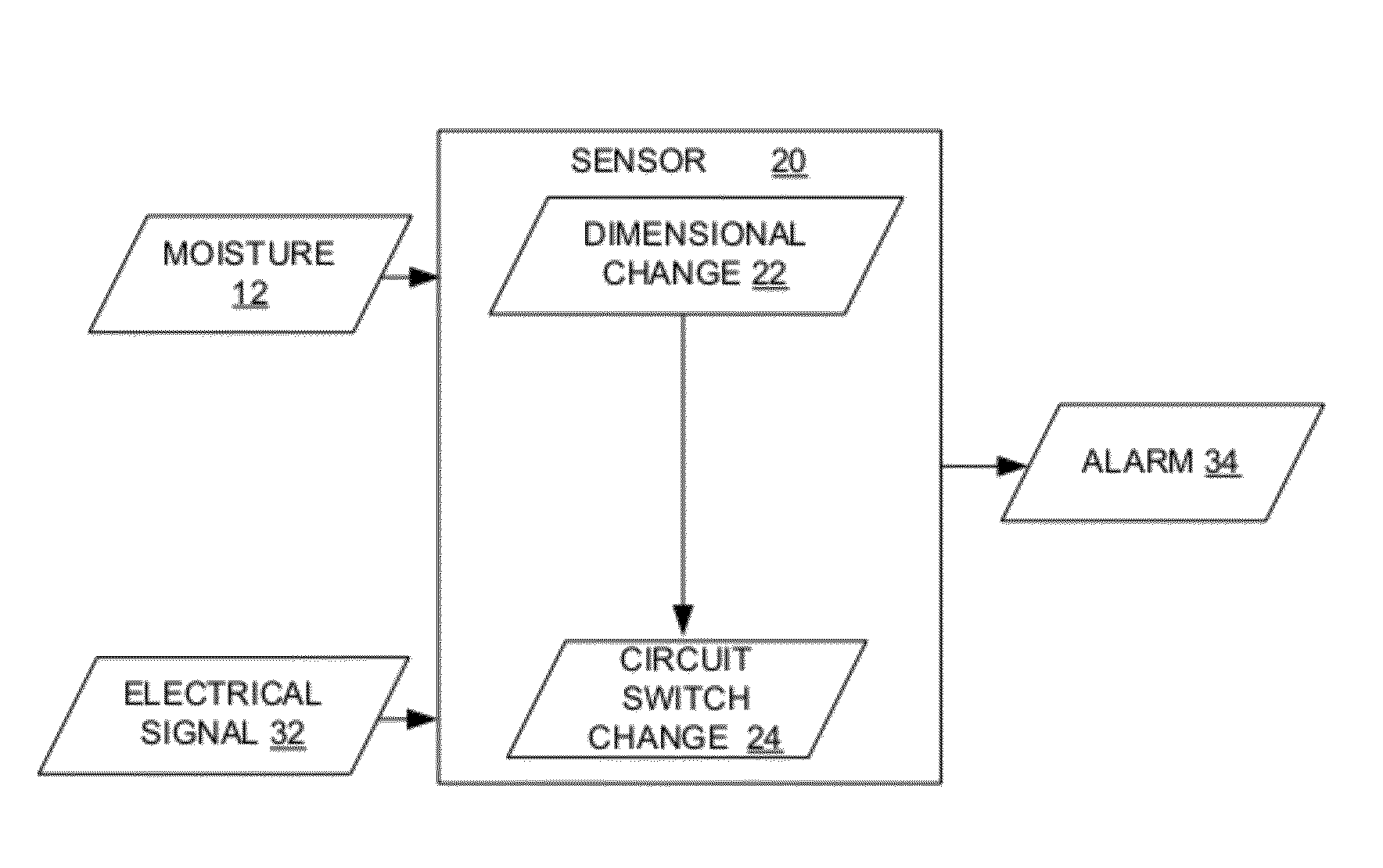

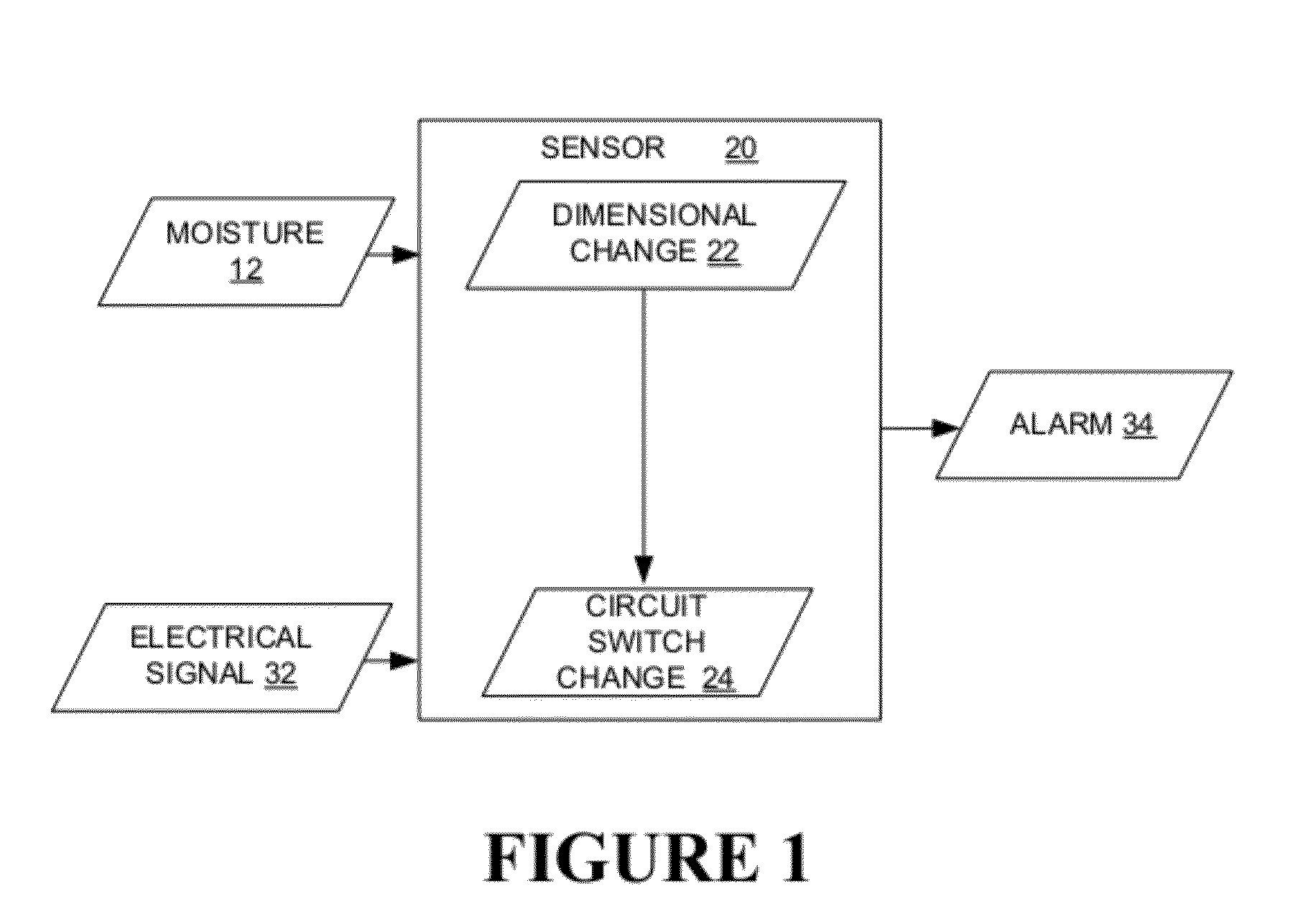

An apparatus and method for detecting moisture in a diaper is disclosed. A moisture sensor apparatus is comprised of a housing made of material dimensionally-sensitive to moisture, such that the housing will expand or contract. Electrically conductive contacts disposed on / in the housing, are selectively coupled to, or decoupled from, each other based on a dimensional change of the sensor device when it comes into contact with moisture. An electrical signal routable through the electrically conductive contacts detects a change in state, e.g., from open to closed, and activates a local or remote alarm to indicate the presence of moisture. The consumable low-cost sensor and the optional non-metallic leads and contacts, that are at least partially biodegradable, are coupled via a convenient slidable brush connector to a resusable alarm system having optional low duty cycle transmitting capability to a receiver base station, thereby providing a cost-effective, eco-friendly and user-friendly system.

Owner:NOVAK GUY R

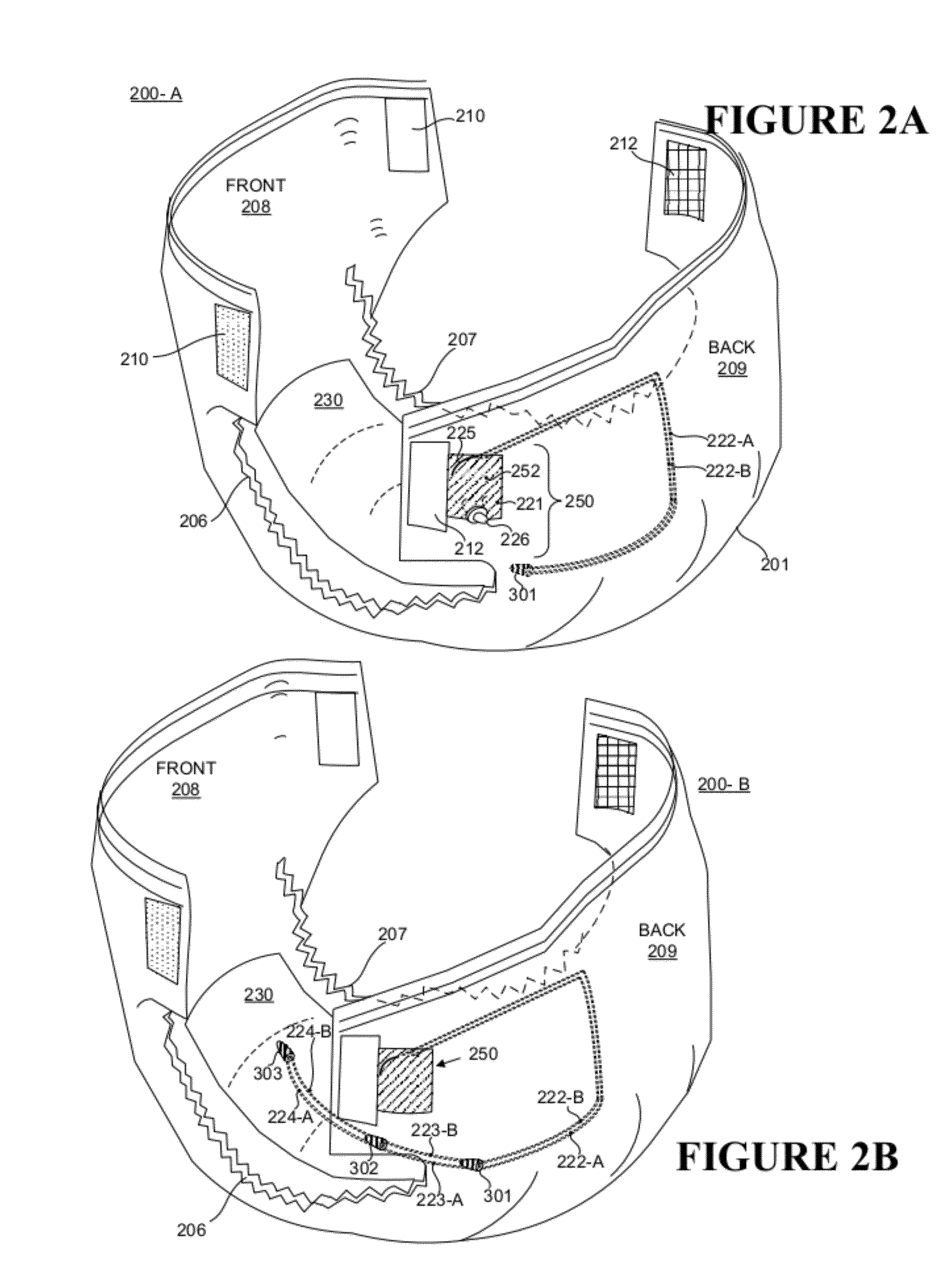

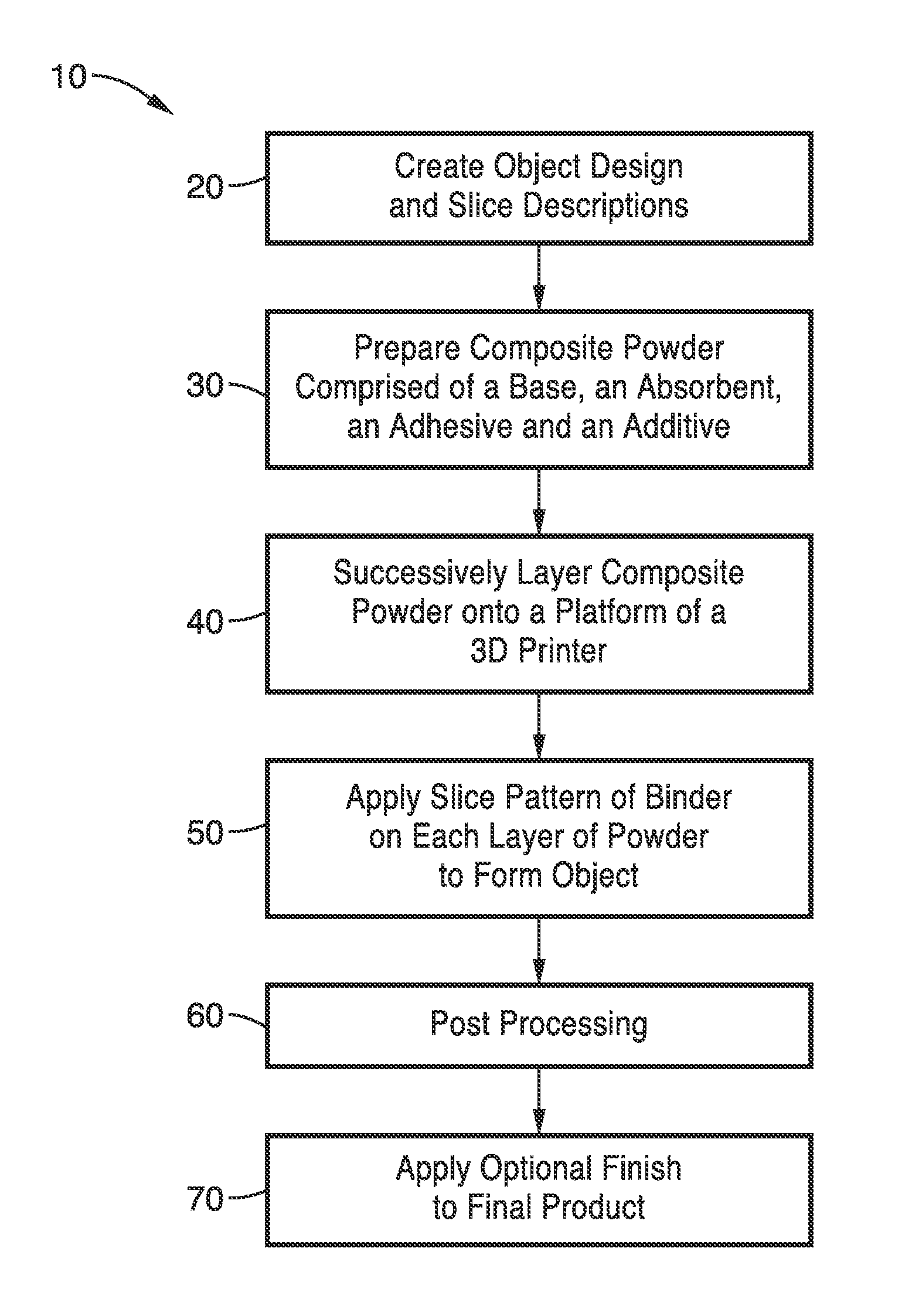

3D printing powder compositions and methods of use

ActiveUS20140252672A1Low costWide scaleSolid waste managementCeramic shaping apparatusCompressive strengthUltimate tensile strength

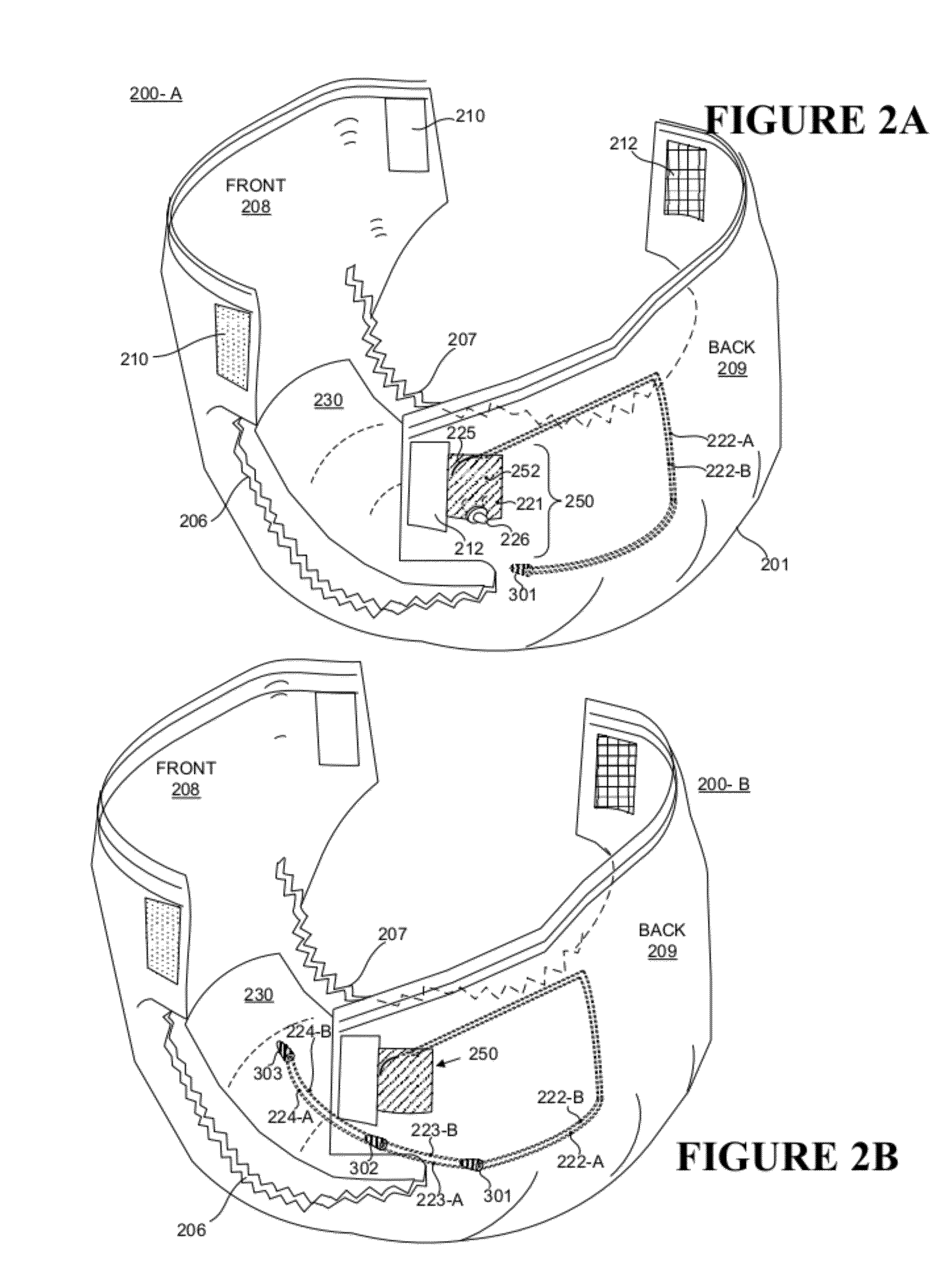

Powder compositions that can be used with traditional 3D printing technology and methods for producing 3D printed building materials that have comparable compressive strength to standard concrete and tensile strength up to 70% greater than standard concrete.

Owner:RGT UNIV OF CALIFORNIA

Dimensionally-sensitive moisture sensor and an alarm system for an absorbent article

ActiveUS8884769B2Improve conductivityLow costAbsorbent padsAlarmsEnvironmental resistanceMoisture sensor

An apparatus and method for detecting moisture in a diaper is disclosed. A moisture sensor apparatus is comprised of a housing made of material dimensionally-sensitive to moisture, such that the housing will expand or contract. Electrically conductive contacts disposed on / in the housing, are selectively coupled to, or decoupled from, each other based on a dimensional change of the sensor device when it comes into contact with moisture. An electrical signal routable through the electrically conductive contacts detects a change in state, e.g., from open to closed, and activates a local or remote alarm to indicate the presence of moisture. The consumable low-cost sensor and the optional non-metallic leads and contacts, that are at least partially biodegradable, are coupled via a convenient slidable brush connector to a resusable alarm system having optional low duty cycle transmitting capability to a receiver base station, thereby providing a cost-effective, eco-friendly and user-friendly system.

Owner:NOVAK GUY R

3D printing powder compositions and methods of use

ActiveUS9388078B2Low costWide scaleSolid waste managementCeramic shaping apparatusCompressive strengthUltimate tensile strength

Powder compositions that can be used with traditional 3D printing technology and methods for producing 3D printed building materials that have comparable compressive strength to standard concrete and tensile strength up to 70% greater than standard concrete.

Owner:RGT UNIV OF CALIFORNIA

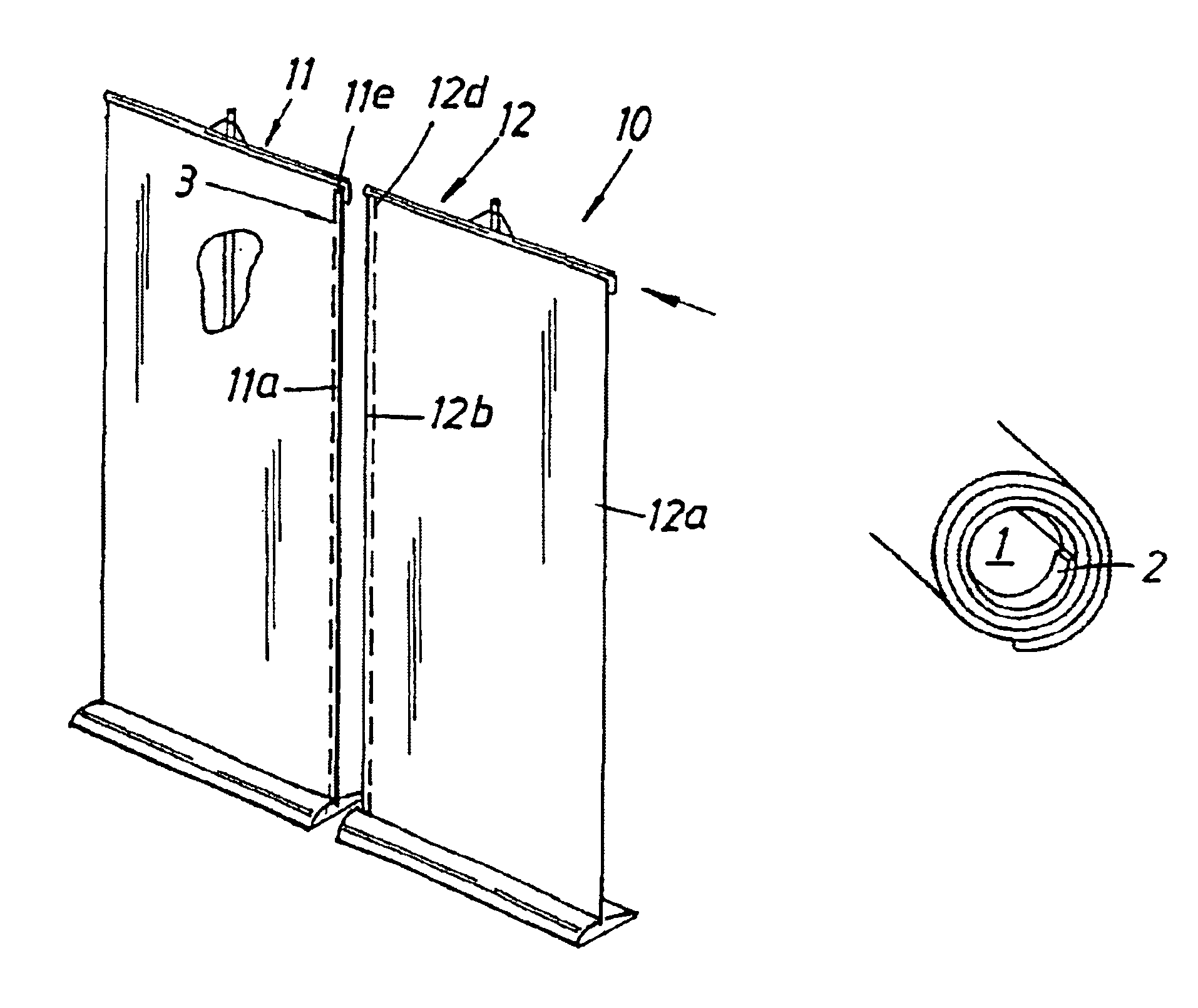

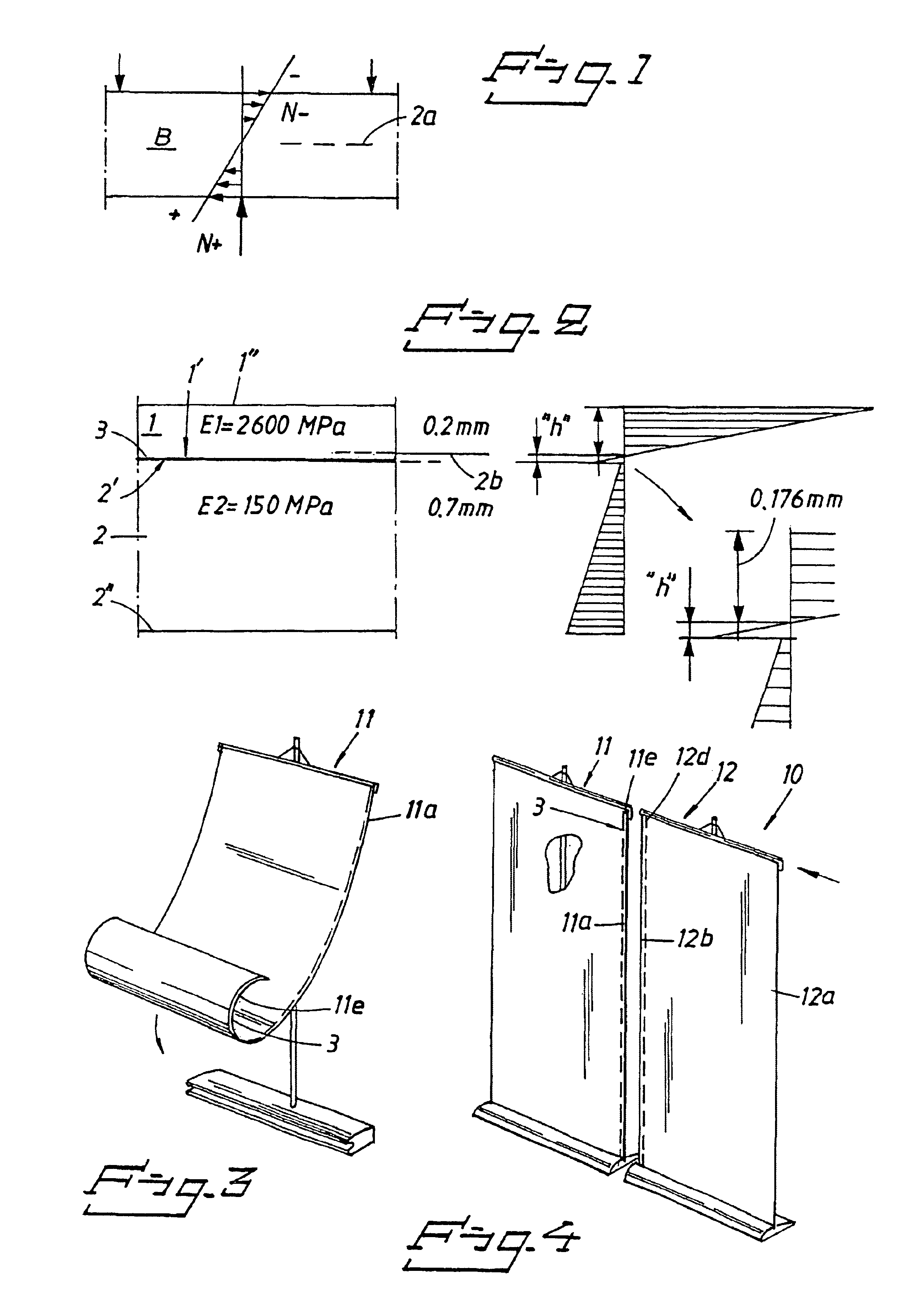

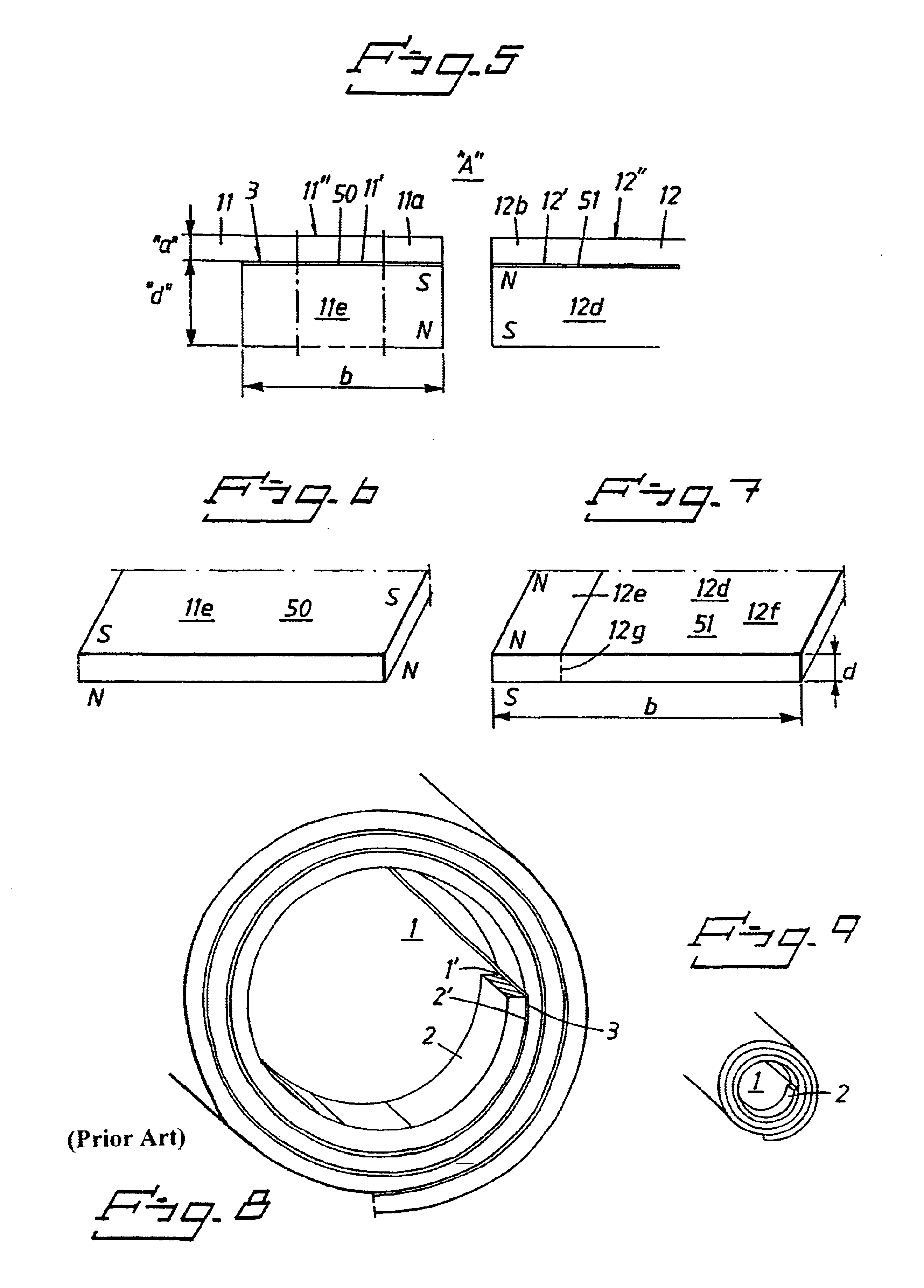

Arrangement utilizing a magnetic attractive force

The present invention relates to an arrangement enabling edge-to-edge joining, by means of a magnetic attractive force, of a first edge portion 811a) of a first panel (11) in a display system to a second edge portion (12b) of a second panel (12), a first magnetised strip (11e) being applied to said first edge portion (11a) and a second magnetised strip (12b) being applied to said second edge portion (12b). The magnetised strips (11e, 12d) are assigned such magnetisation directions (s-n; n-s) that, in a position where the edge portions are in proximity and / or co-operating with each other, they assume a position attracted to each other. Said strips (11e, 12d) consist of a material different from the material of the panel (11, 12). The modulus of elasticity and the thickness (2600 MPa; 0.2 mm) of said panel (11) and the modulus of elasticity and the thickness (100 MPa; 0.7 mm) of said strips (11e, 12d) are such that only small axial stress related forces, or none at all, will act within the attachment means (50, 51). Said strips (11e, 12d) are assigned a thickness (“d”) of less than 1.0 mm.

Owner:EXPAND INT

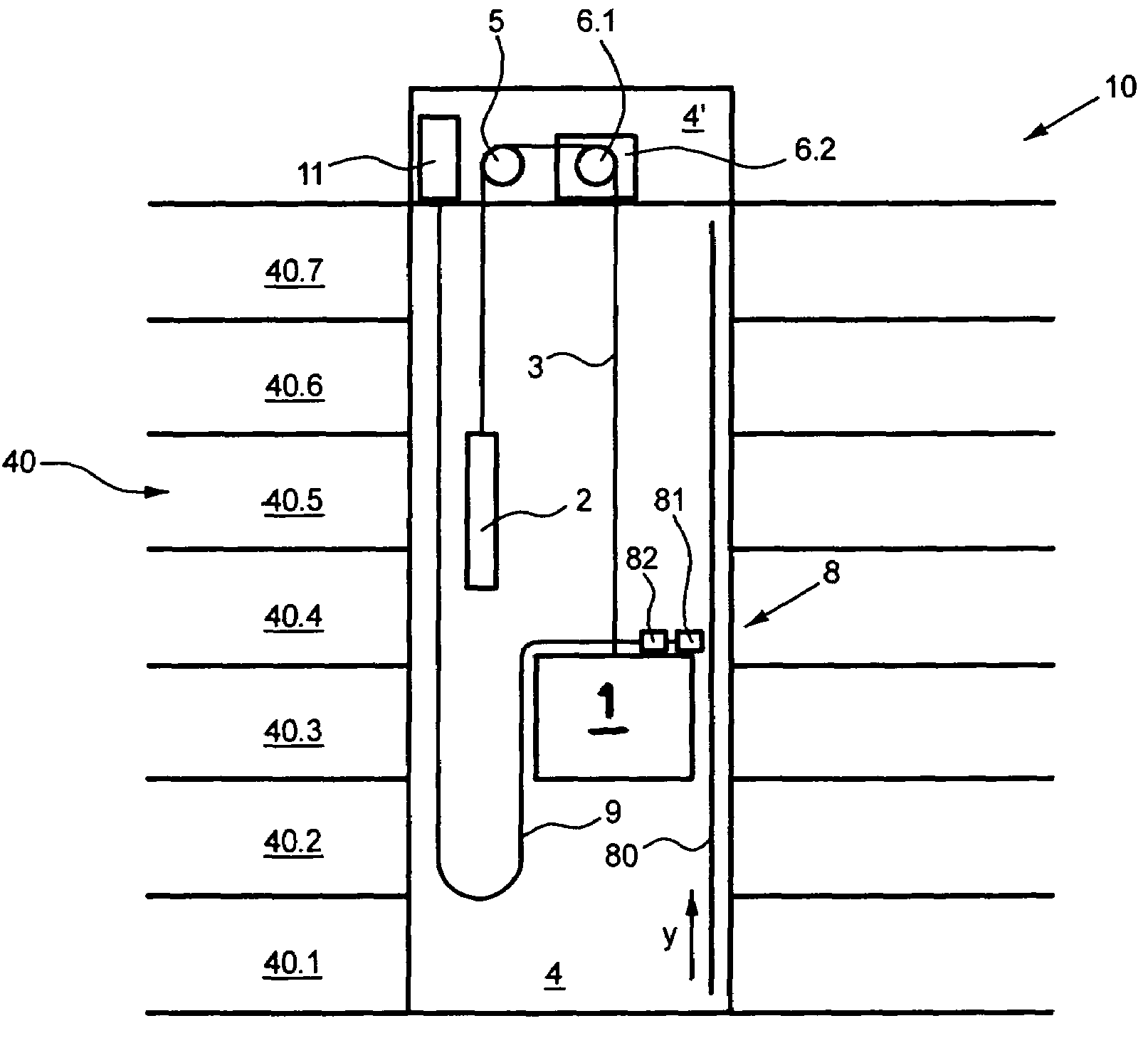

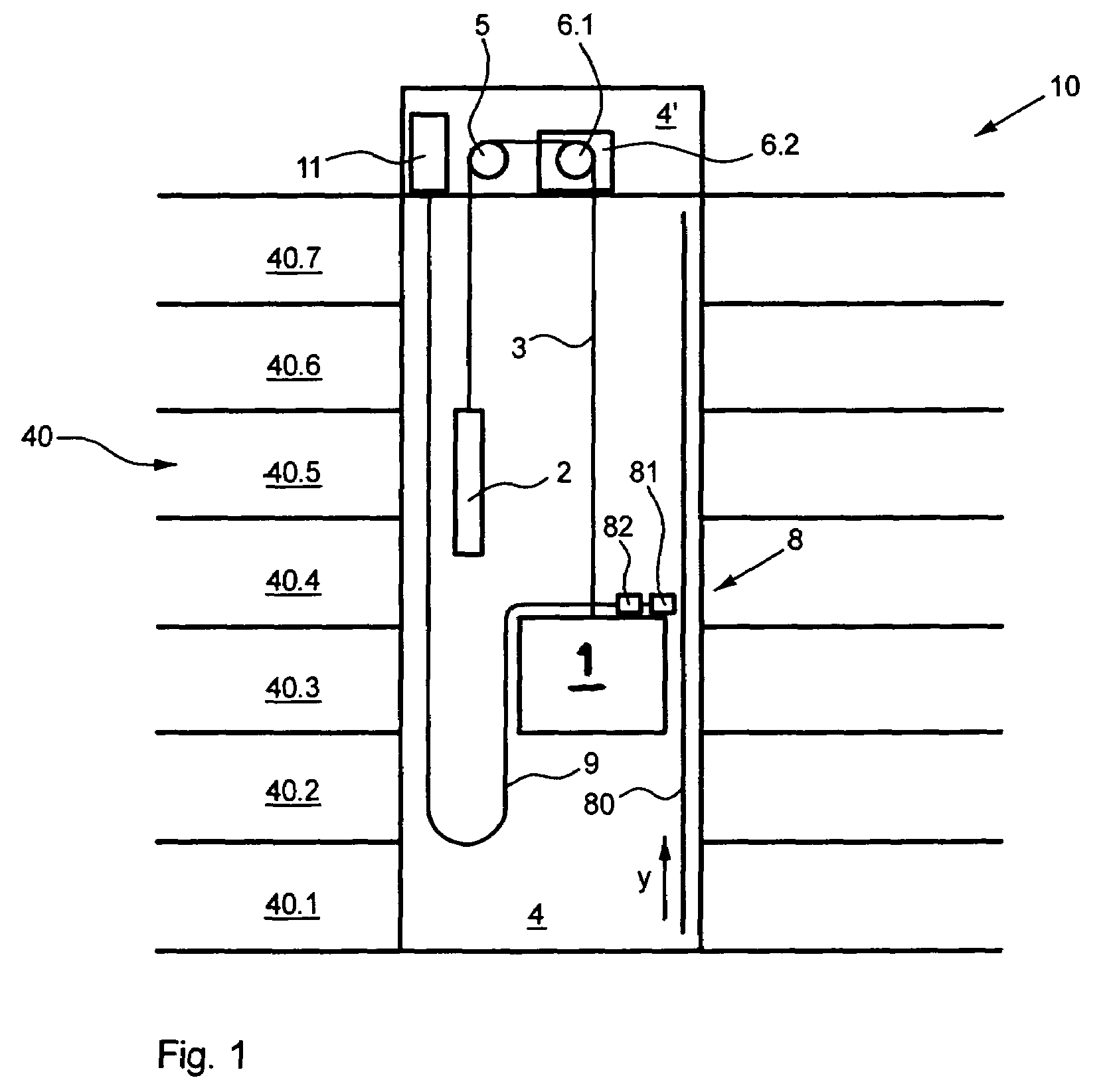

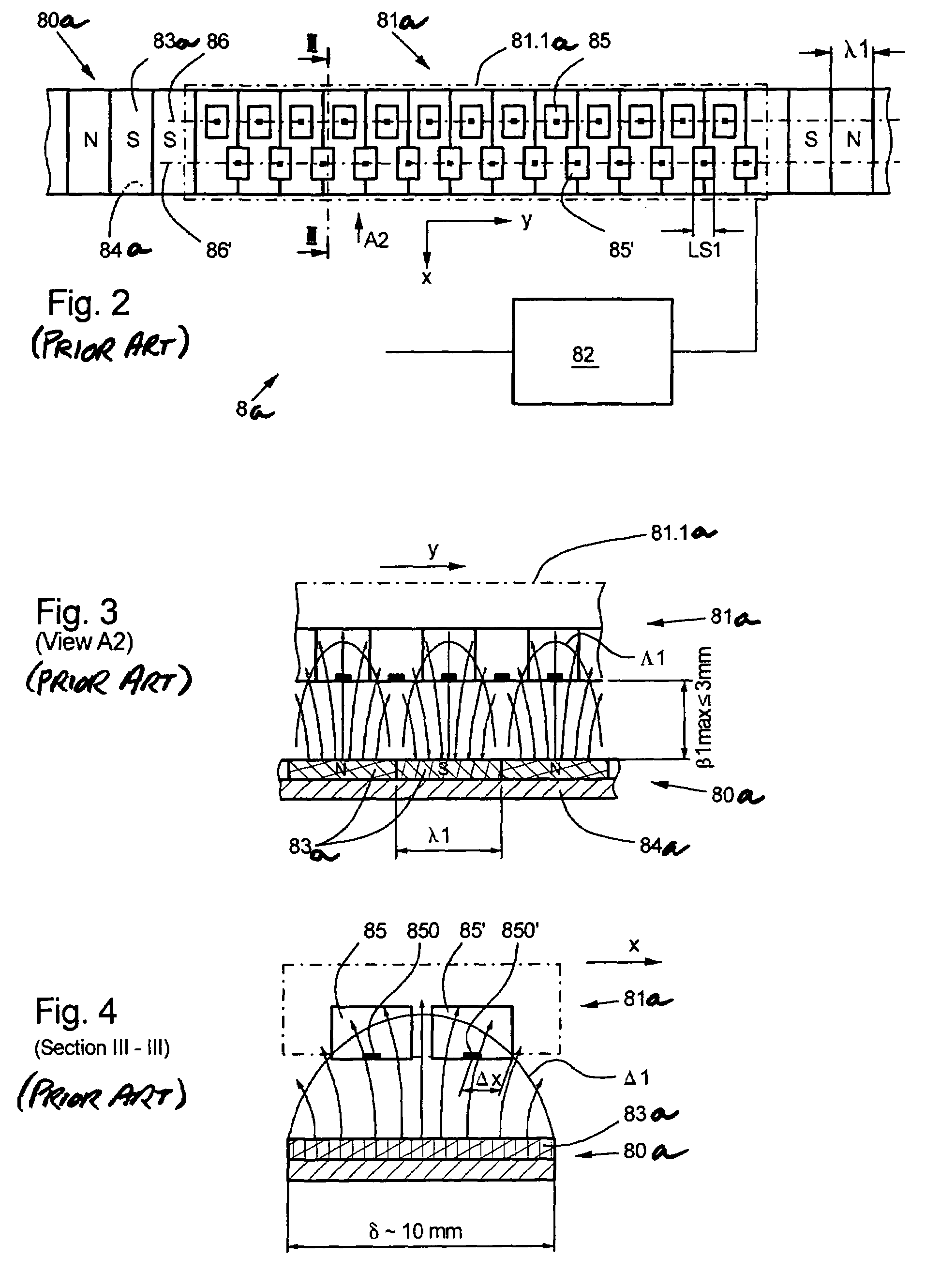

Elevator installation and method for determining and analyzing an elevator car position

ActiveUS7562747B2Improve reliabilitySmall widthWalking sticksUsing electrical meansLateral displacementEmbedded system

An elevator installation with at least one car includes at least one device for determining a position of the car and a method of operating such an elevator installation. The position determining device has a code mark pattern and a sensor device. The code mark pattern is arranged along the length of travel of the car and consists of a multiplicity of code marks. The sensor device is mounted on the car and has sensors contactlessly scanning the code marks. The code marks are arranged in a single line and the sensor device comprises at least two sensor groups which are separated from each other perpendicular to the line of the code marks, which makes reading the code marks possible even if there are lateral displacements between the sensor device and the line of the code marks.

Owner:INVENTIO AG

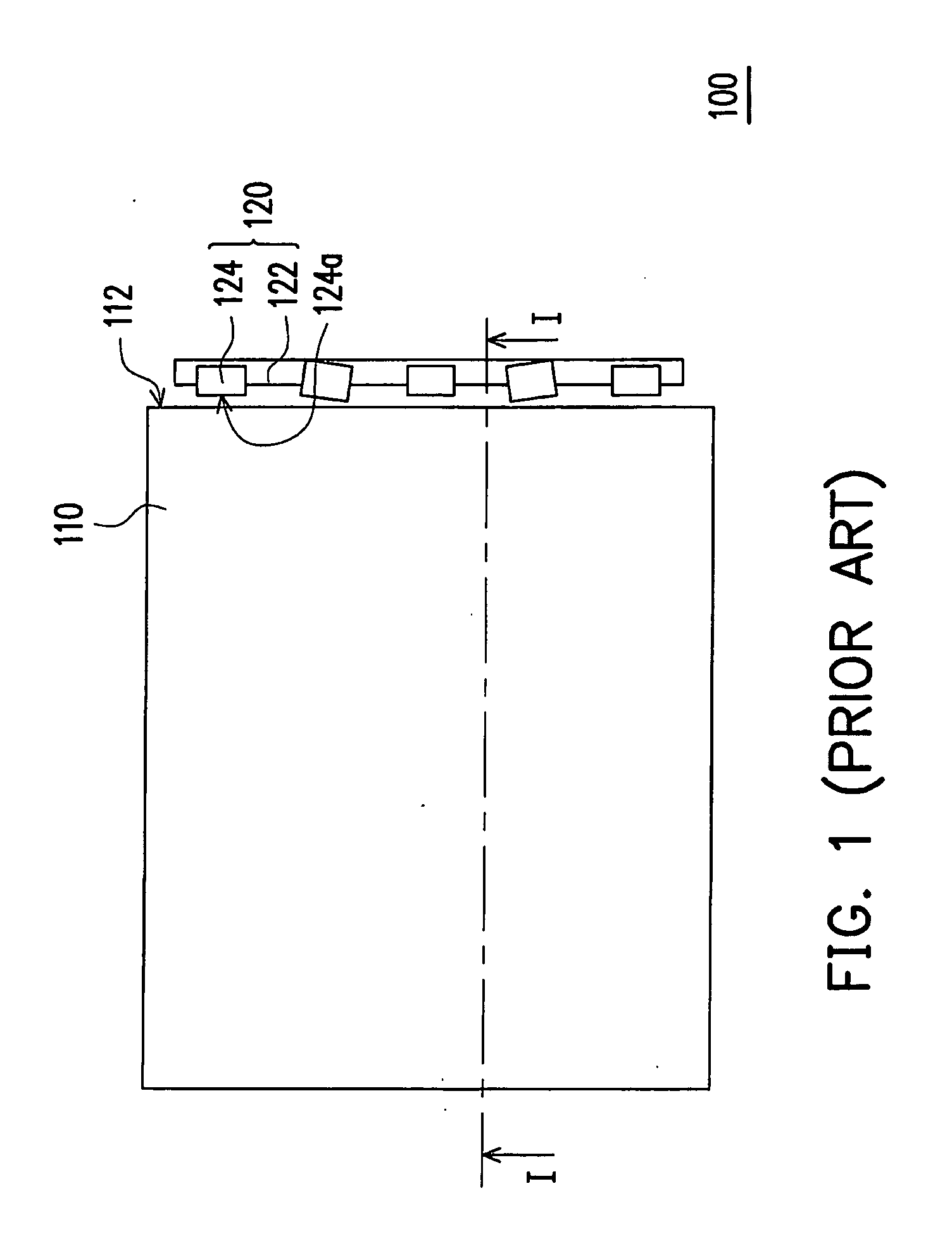

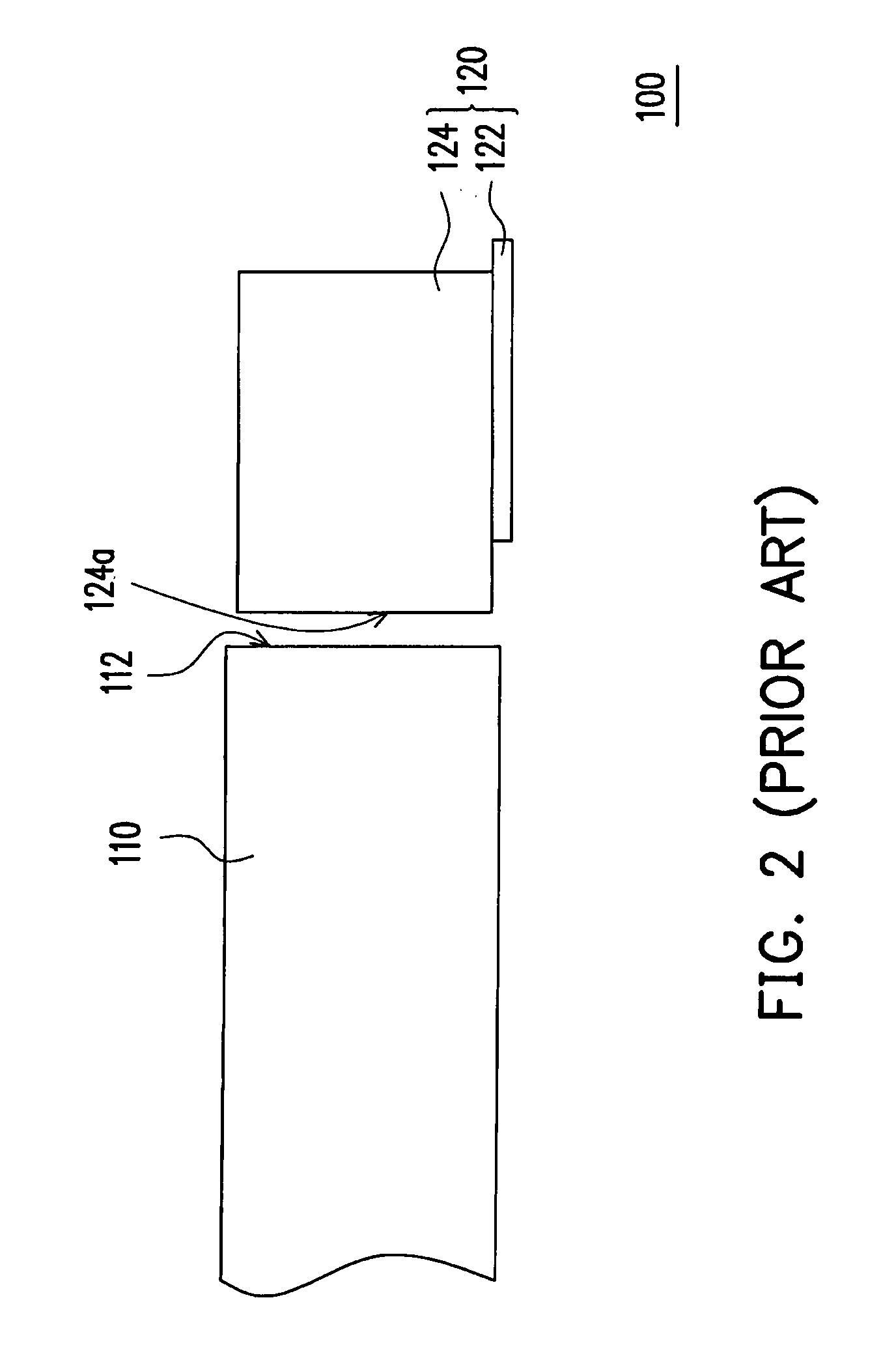

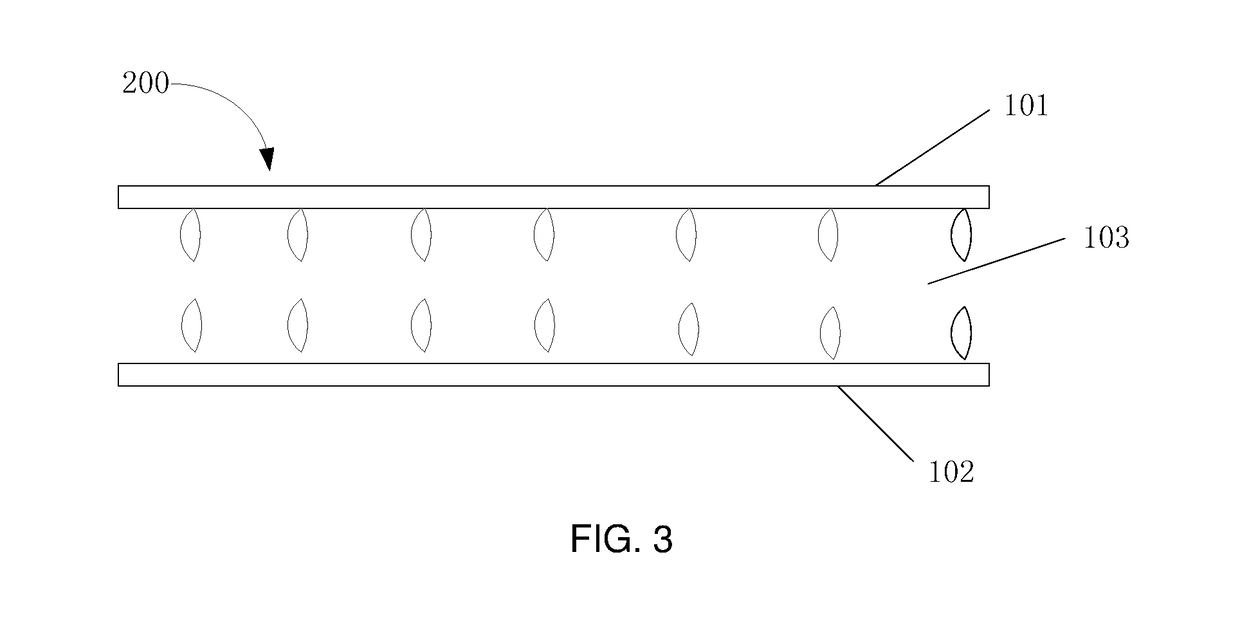

Backlight module and liquid crystal display using the same

InactiveUS20090051852A1Low production costImprove luminous efficiencyMechanical apparatusLight guides for lighting systemsElectricityElastomer

A backlight module including a light guide plate, a light source and a transparent elastomer is provided. The light guide plate has a first light emitting surface, a bottom surface opposite to the first light emitting surface and at least a light incident surface contacting the first light emitting surface and the bottom surface. The light source is disposed adjacent to the light incident surface and includes a circuit board and a plurality of light emitting diode devices. Each of the light emitting diode devices is capable of emitting light passing through the light incident surface. The light emitting diode devices are electrically connected to the circuit board. The transparent elastomer is disposed between the light incident surface and each of the light emitting diode devices.

Owner:NANO PRECISION

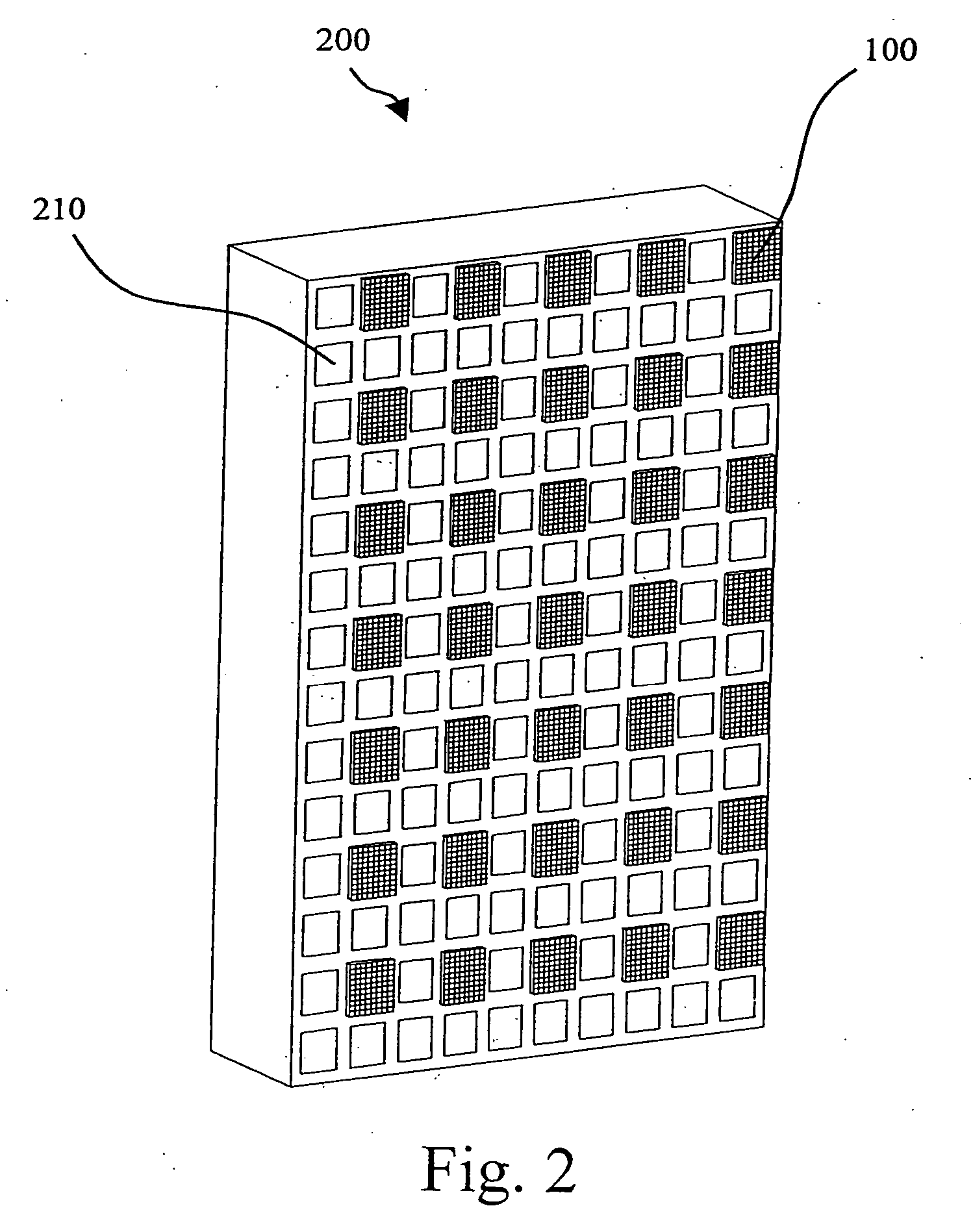

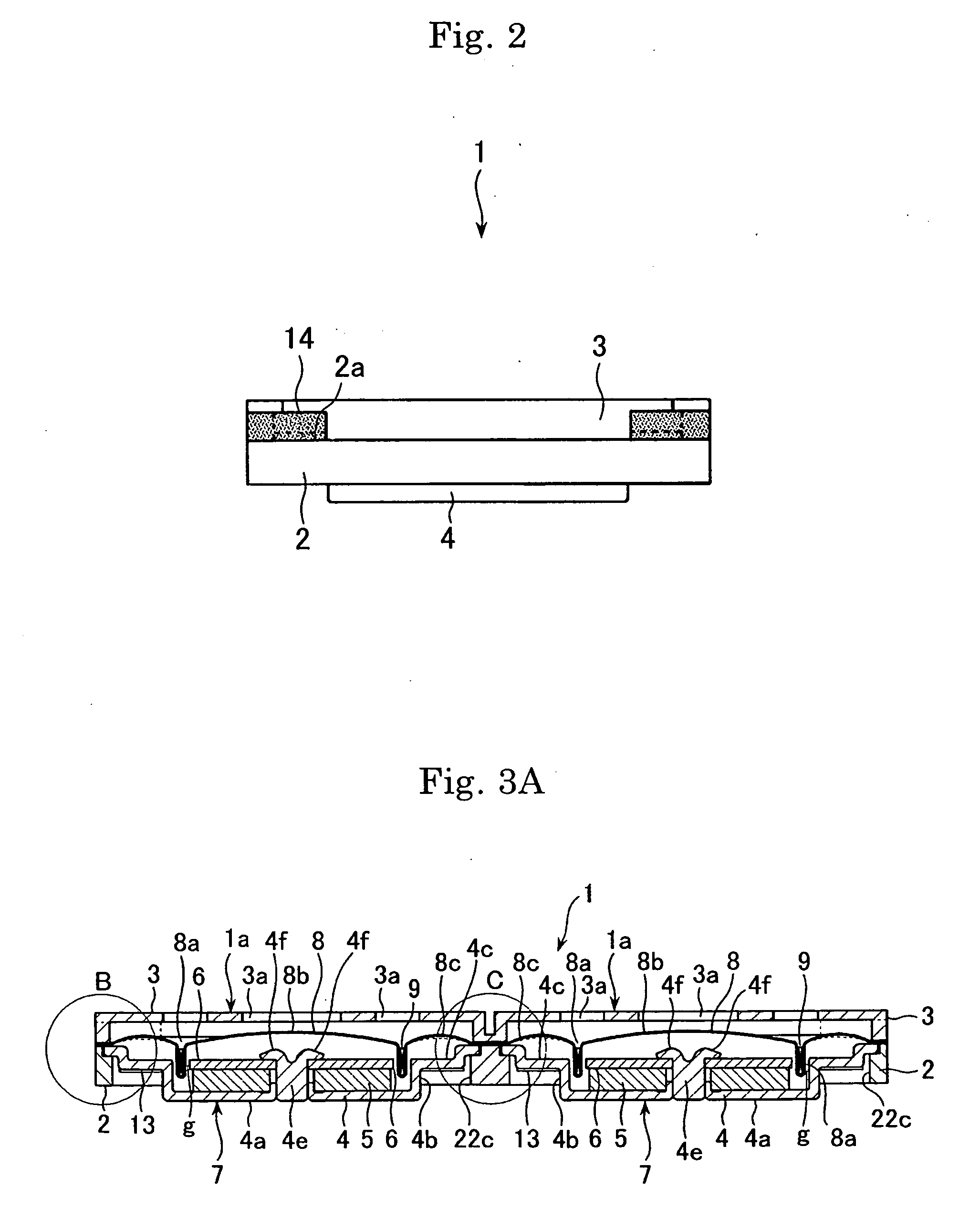

Display element and mechanical mounting interface used therein

InactiveUS20060077669A1Cost of productionTelevision system detailsLighting support devicesEngineering

Owner:BARCO NV

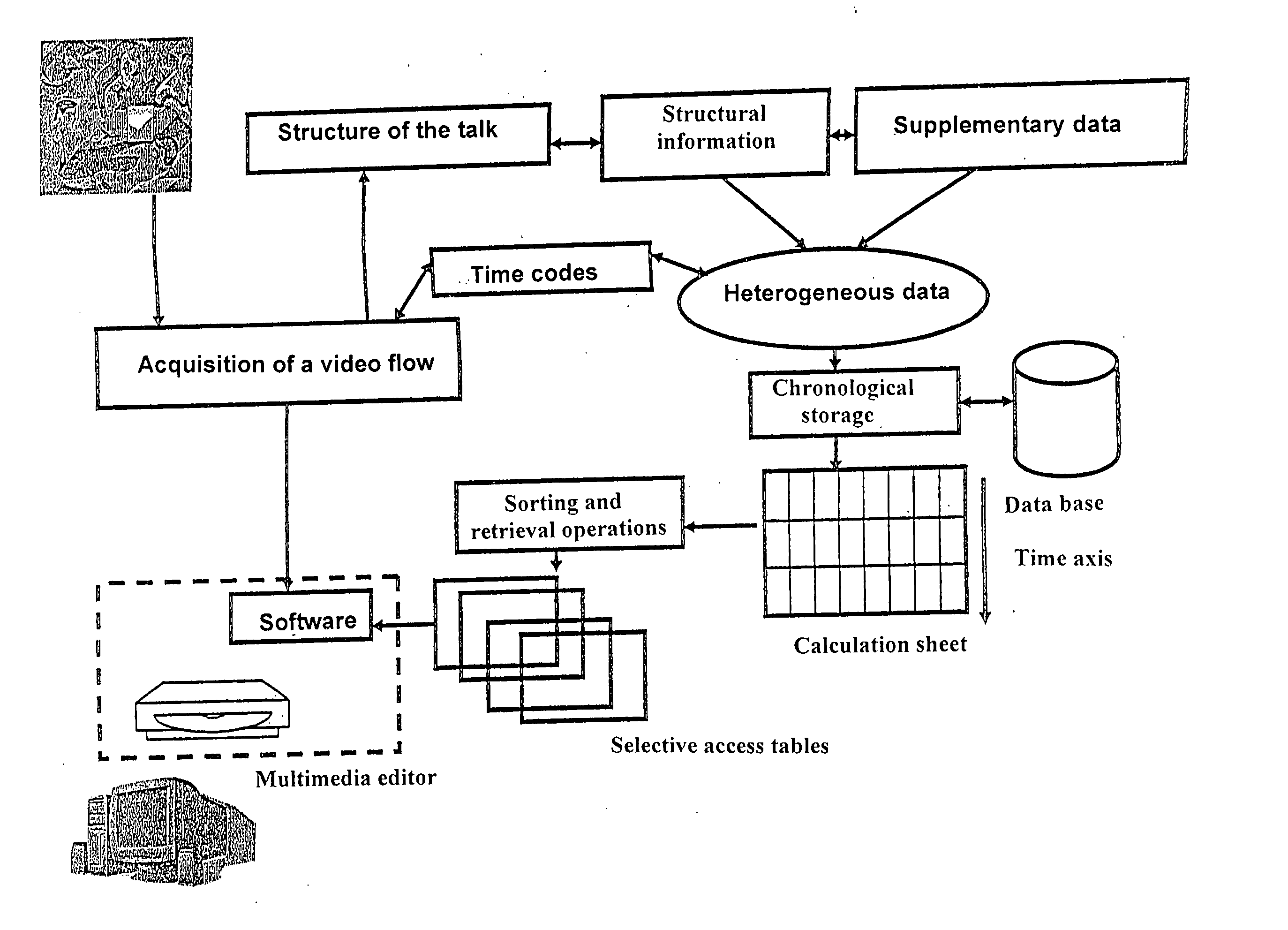

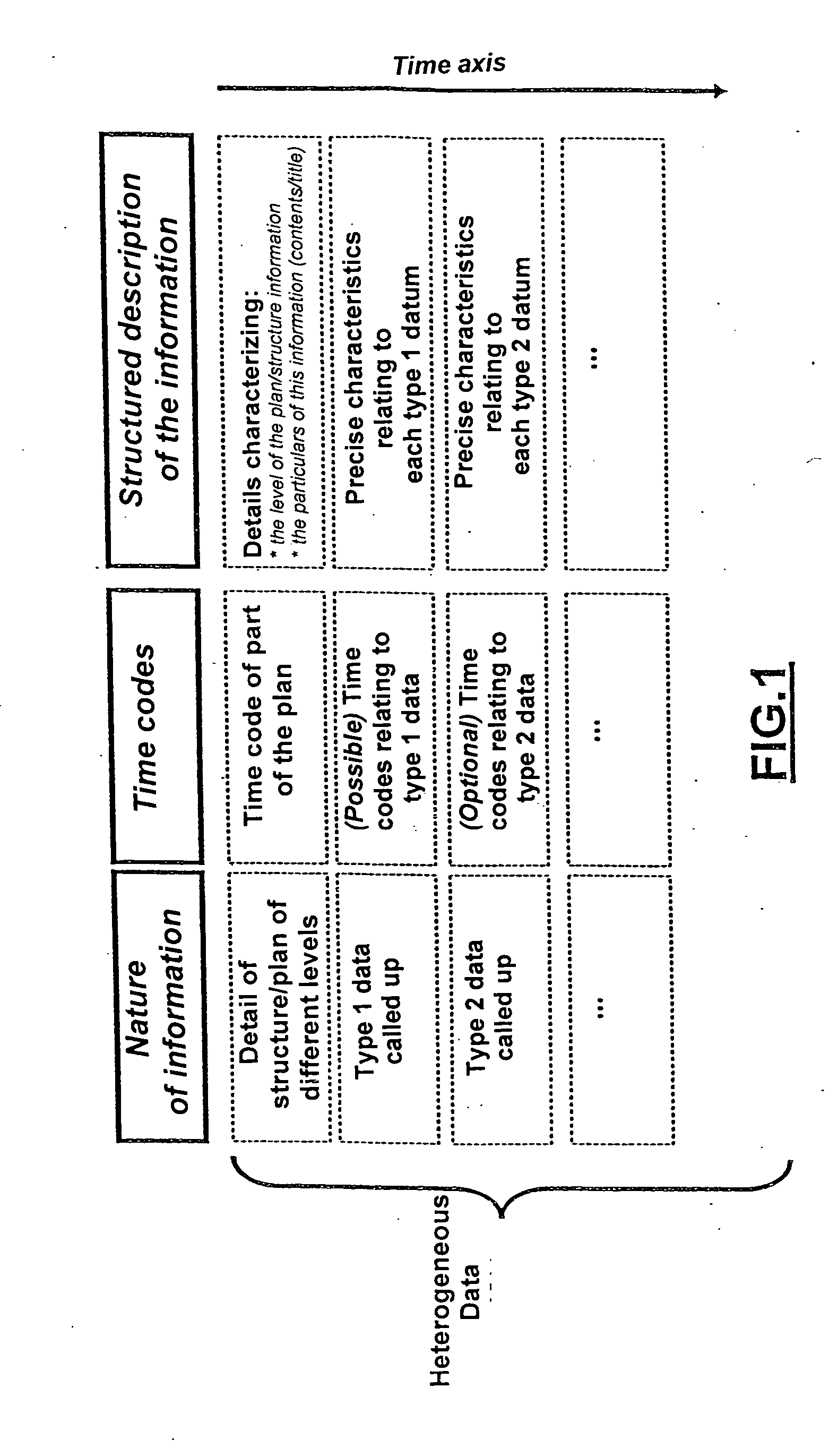

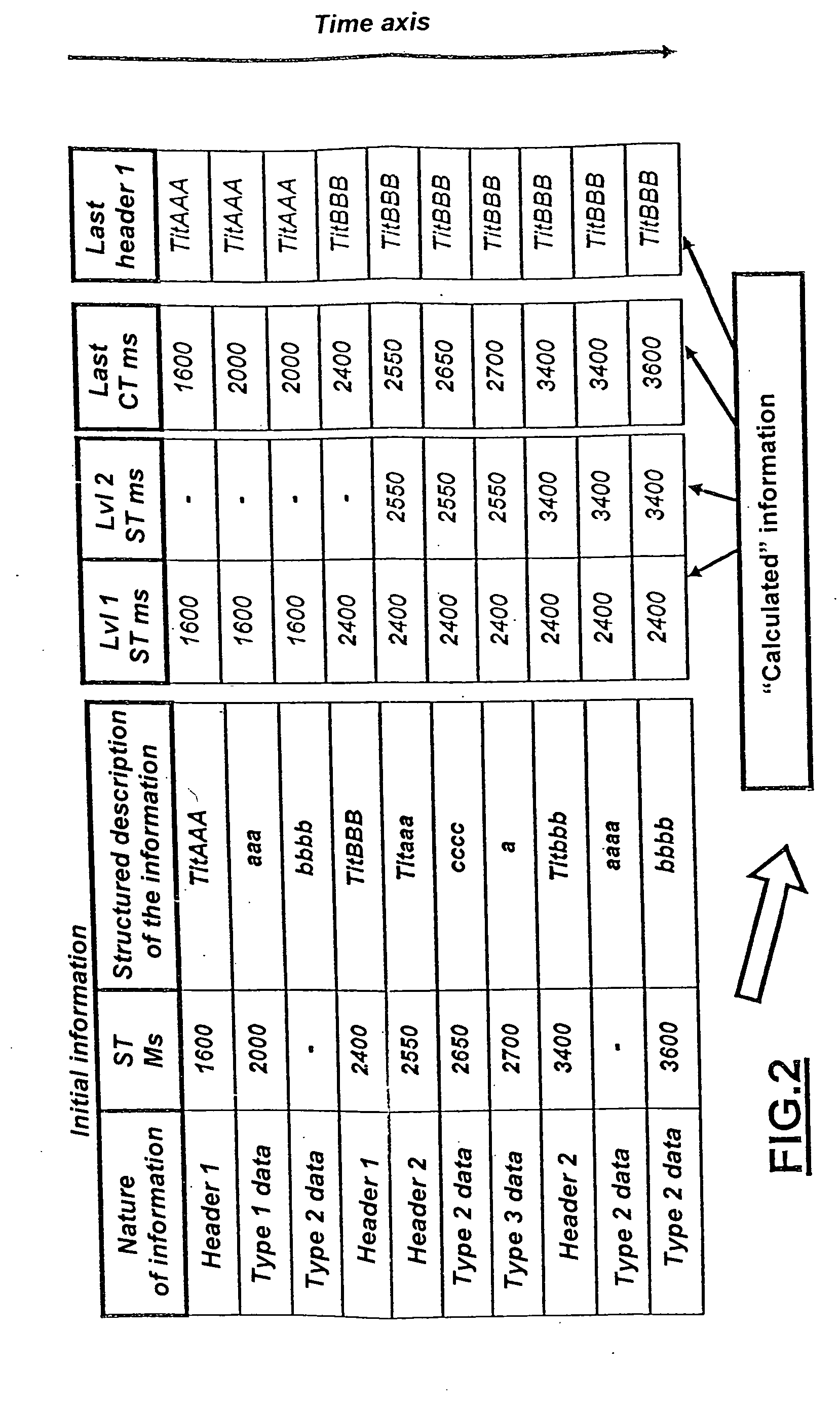

Process and system for the production of a multimedia edition on the basis of oral presentations

InactiveUS20050044480A1Good flexibilityGreat ease of access to informationDigital data information retrievalTwo-way working systemsElectronic formVideo sequence

Process for the production of a multimedia edition on the basis of oral presentations, from information contained in a previously recorded audio and / or video flow, and data and reference documents associated with the audio and / or video information. It includes both an indexing of the audio and / or video flow, in particular from the structure of the information contained, and an indexing of the supplementary data and reference documents. Heterogeneous data including information about the formal structure of an audio and / or video sequence contained in the audio and / or video flow, and data relating to reference documents associated with the audio and / or video sequence are stored chronologically in a common database. These heterogeneous data are then processed in a spreadsheet, along a time axis representing the passage of time in the time flow, and reworked in order to produce a complex indexing of the audio and / or video information and the supplementary data.

Owner:DROIT IN SITU

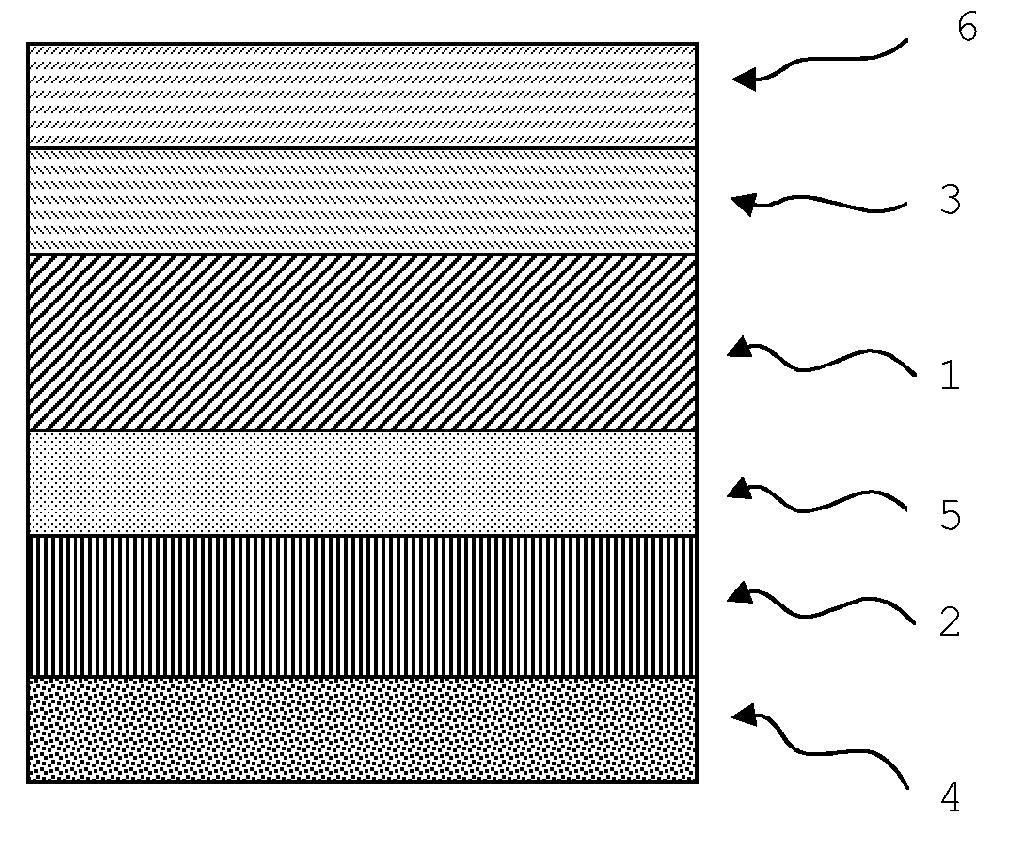

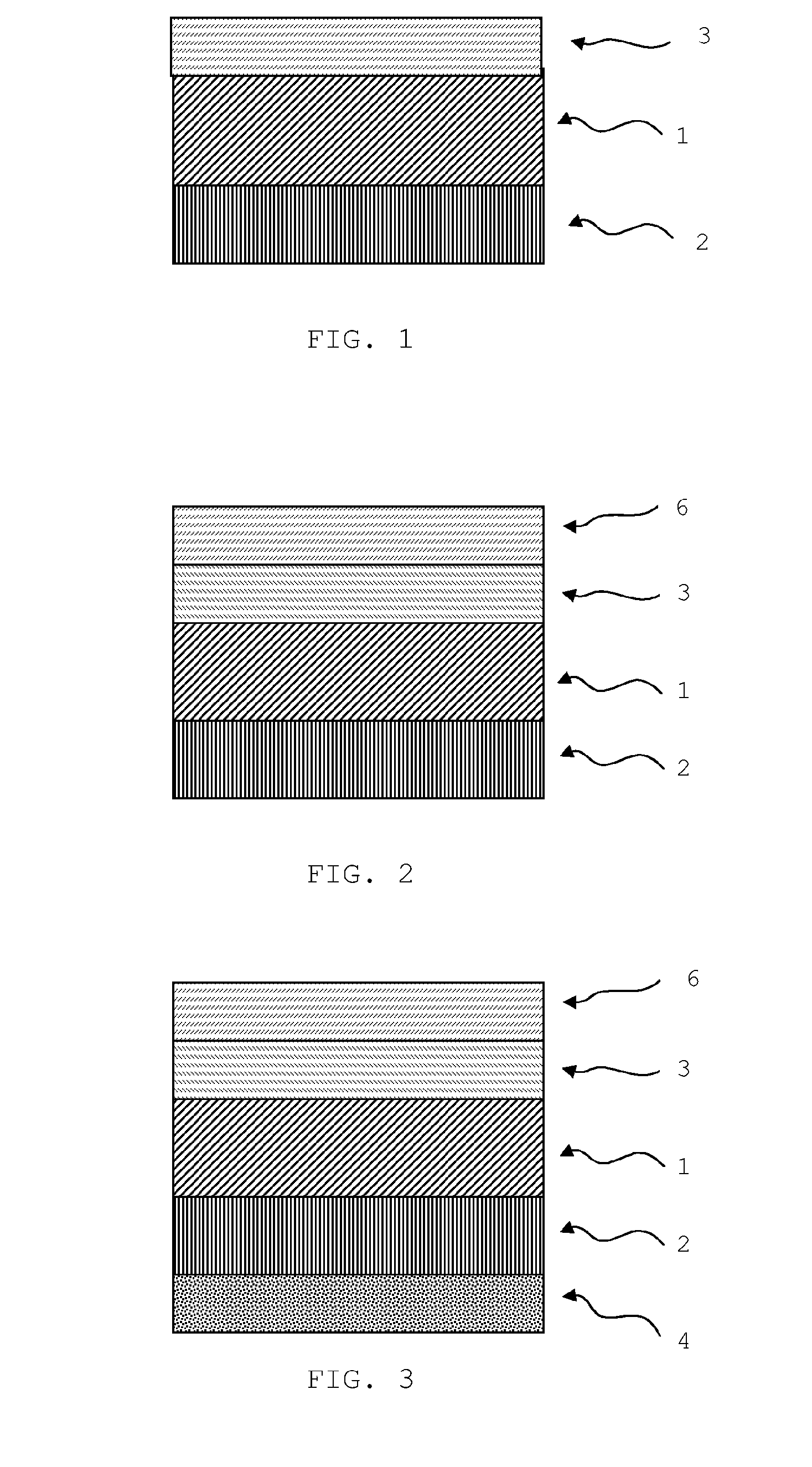

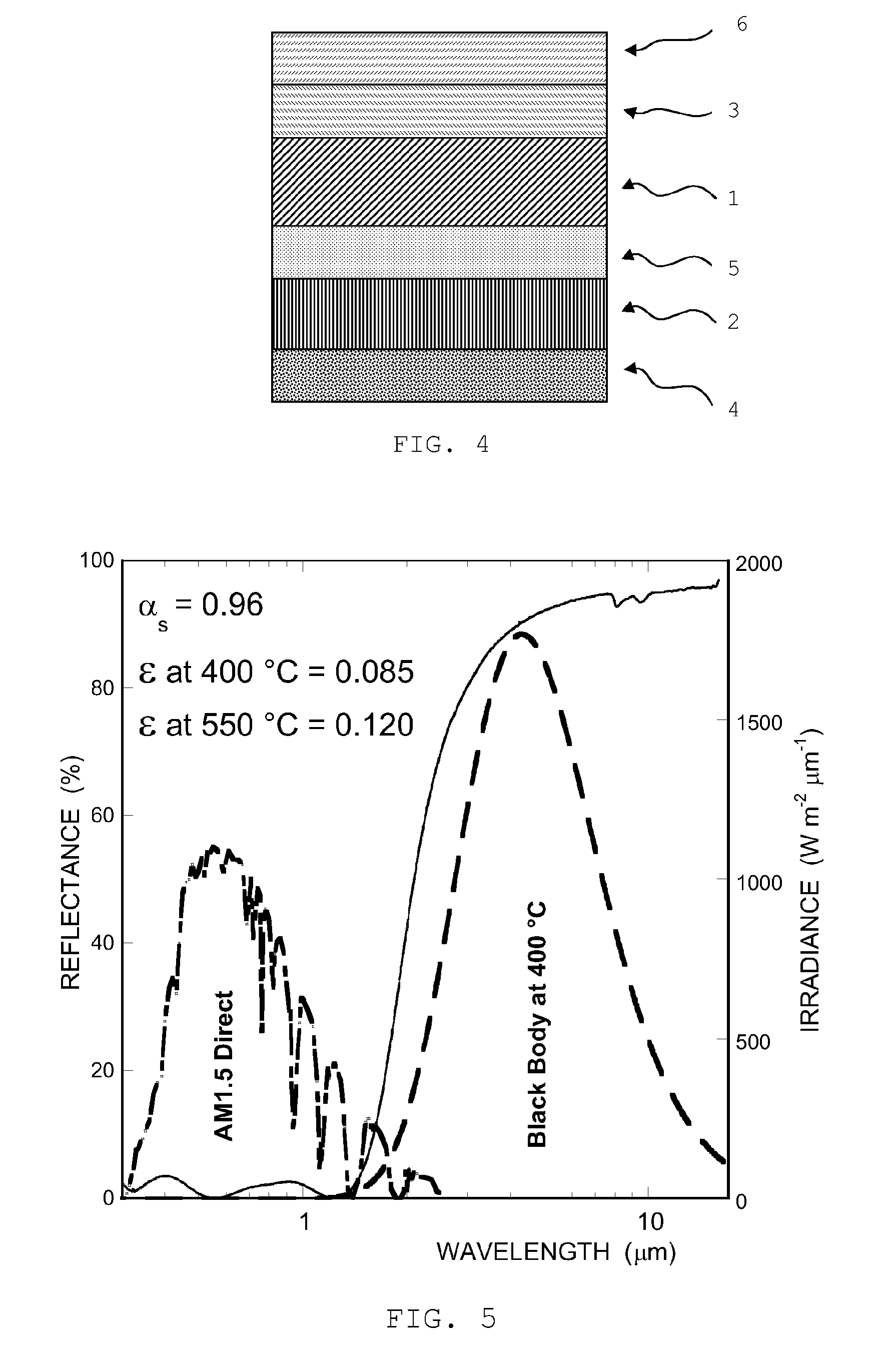

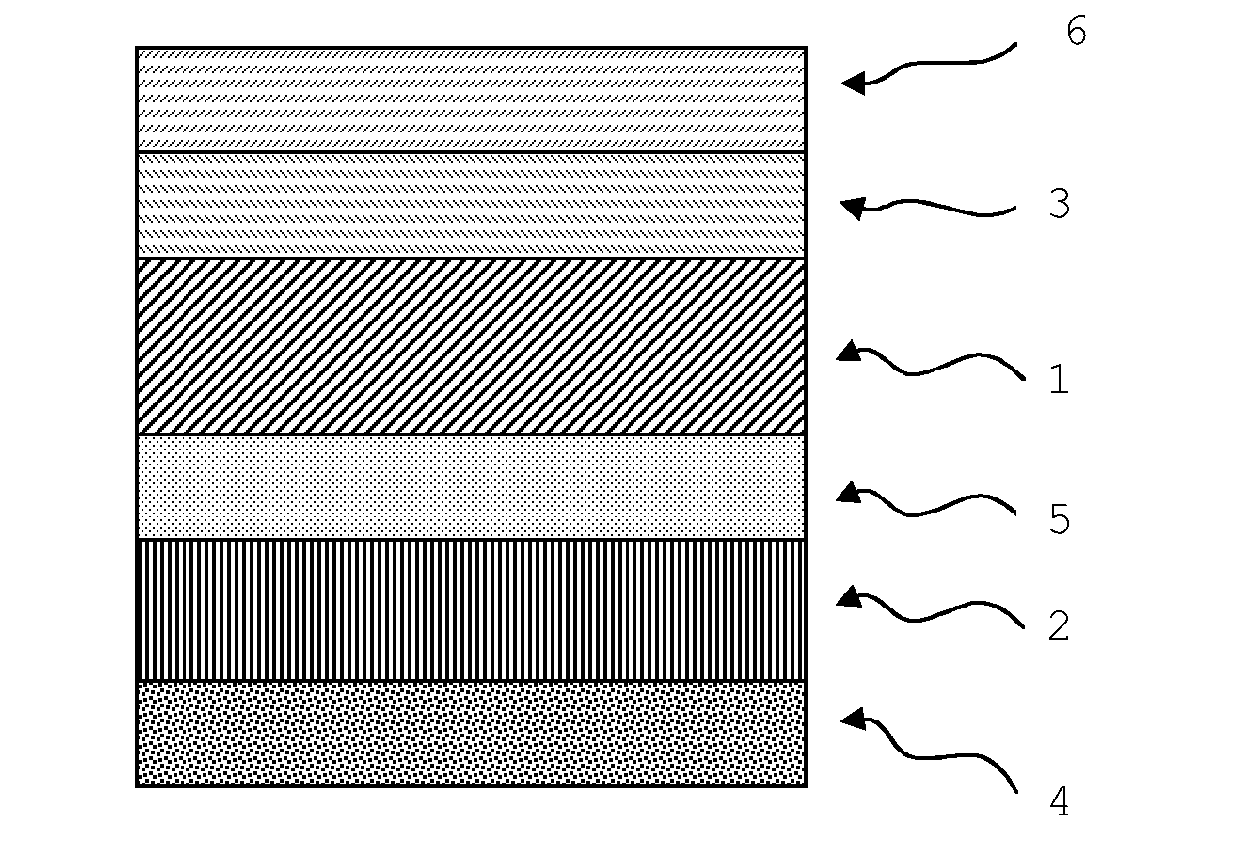

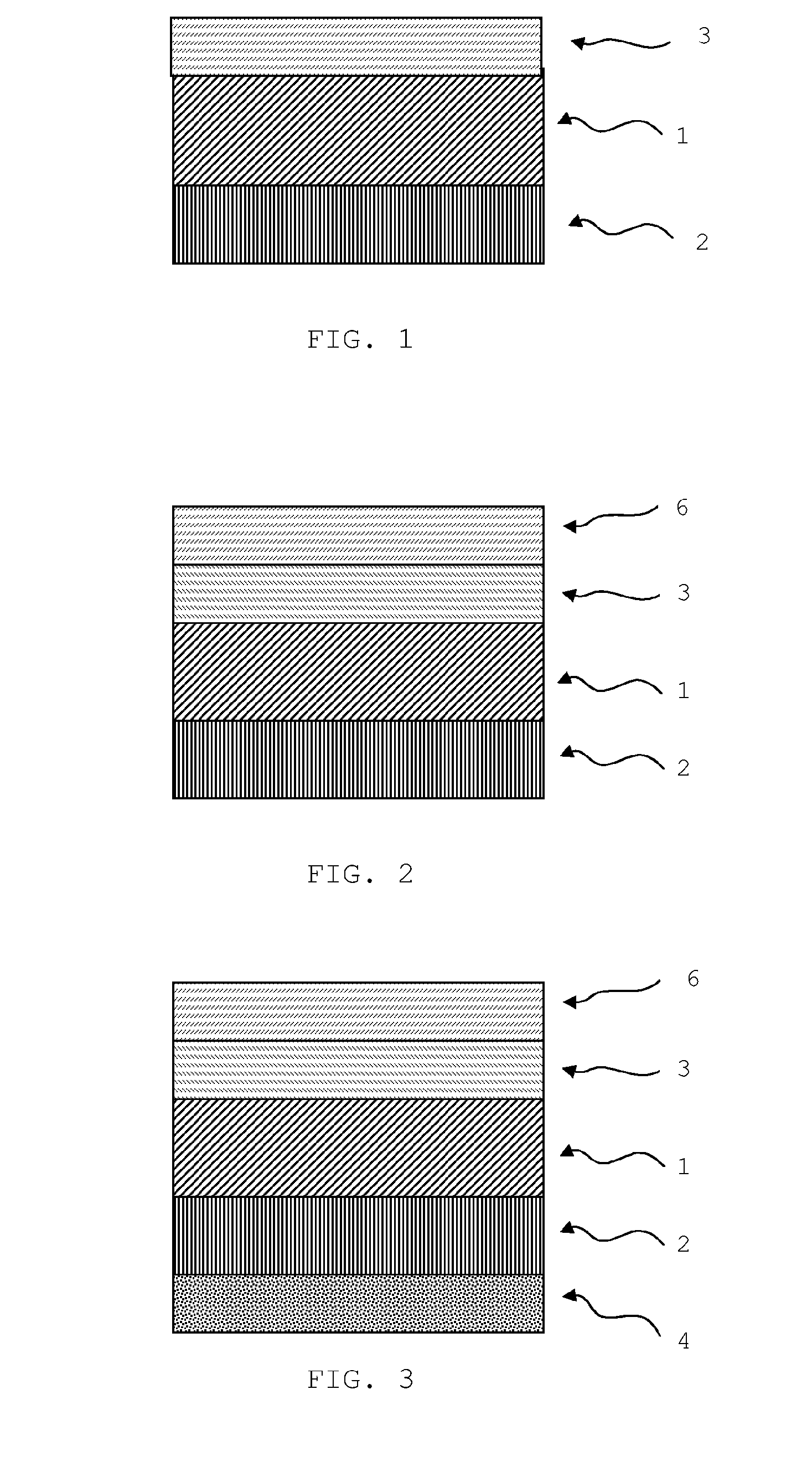

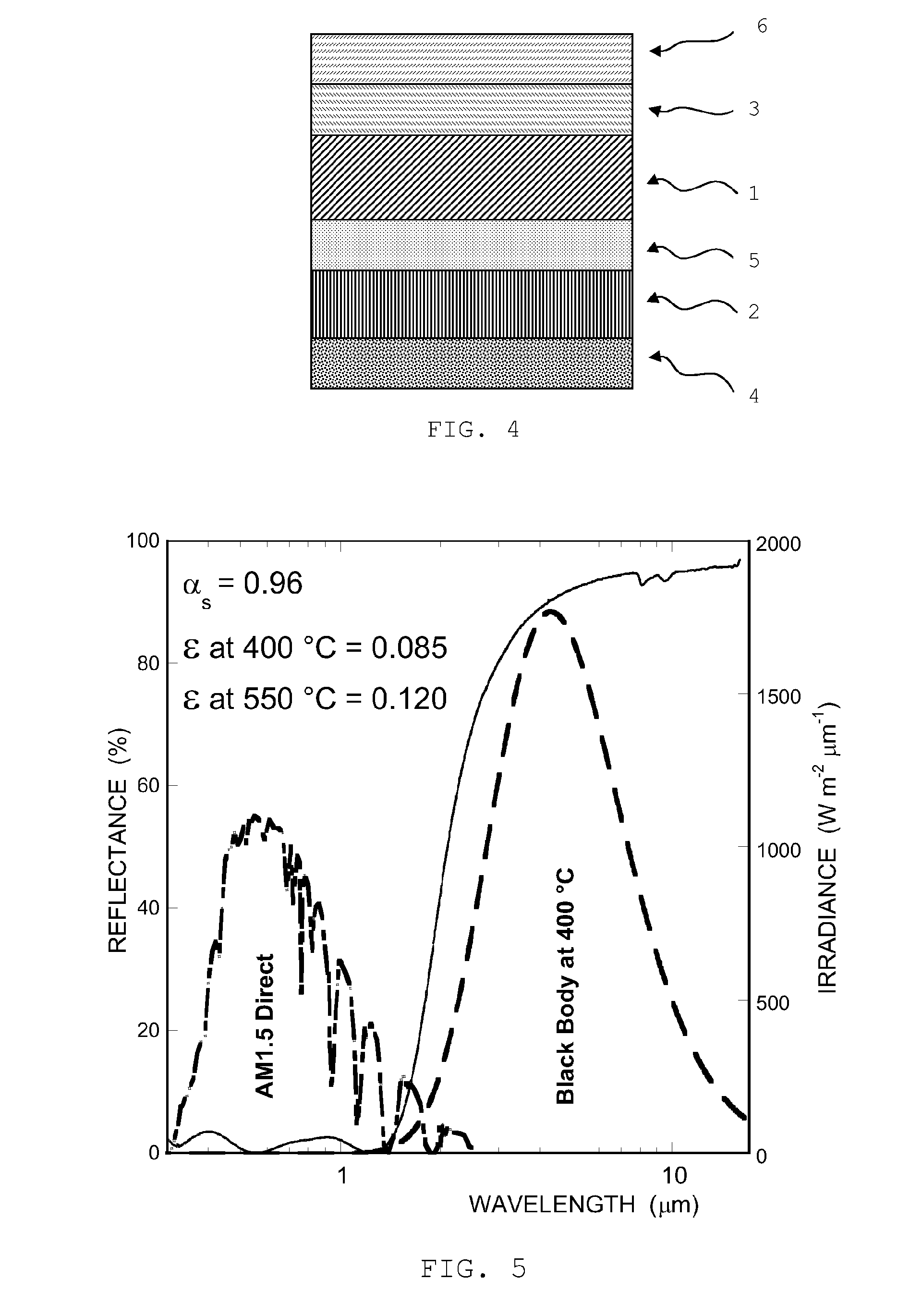

Solar selective absorber based on double nitride composite material and process for its preparation

ActiveUS9469896B2Improve performanceIncrease absorbanceMirrorsSolar heat devicesChemical measurementMaterials science

A thin-film spectrally selective coating for receiver tube of vacuumed type for use in thermodynamic solar installations and operating both at medium temperature (up to 400° C.) and at high temperature (up to 550° C.), coating where the optically absorbing layer is a multilayer of cermet material of type: WyN—AlNx or MoyN—AlNx, material prepared with reactive co-sputtering technique from an Al target and a W or Mo target, process conducted under a transition regimen, under PFM (Plasma Emission Monitoring) or CVM (Cathode Voltage Monitoring) monitoring for the sole Al target, with inletting near the Al target of a N2 amount adequate for obtainment of a high-transparency, high growth rate sub-stoichiometric ceramic AlN and with inletting near the W or Mo target of a N2 amount adequate for obtainment of the sole W2N or Mo2N phase, phase very stable at high temperature, such as to make the cermet material as close as possible to the formulation W2N—AlNx or Mo2N—AlNx (with x comprised between 0.90 and 1.00, preferably 0.95) and, therefore, cermet material employable at least up to the temperature of 550° C.

Owner:ENTE PER LE NUOVE TECH LENERGIA E LAMBIENTE ENEA

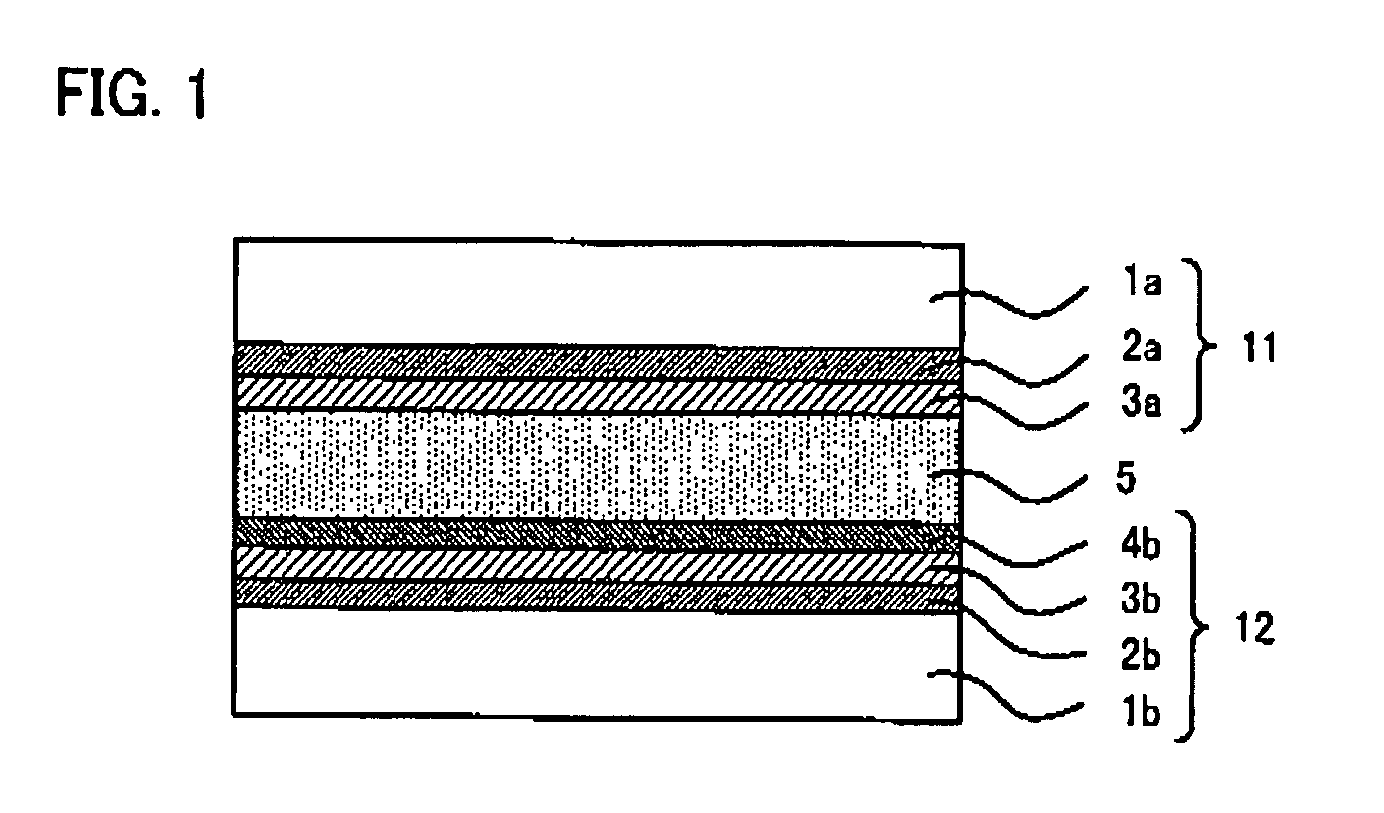

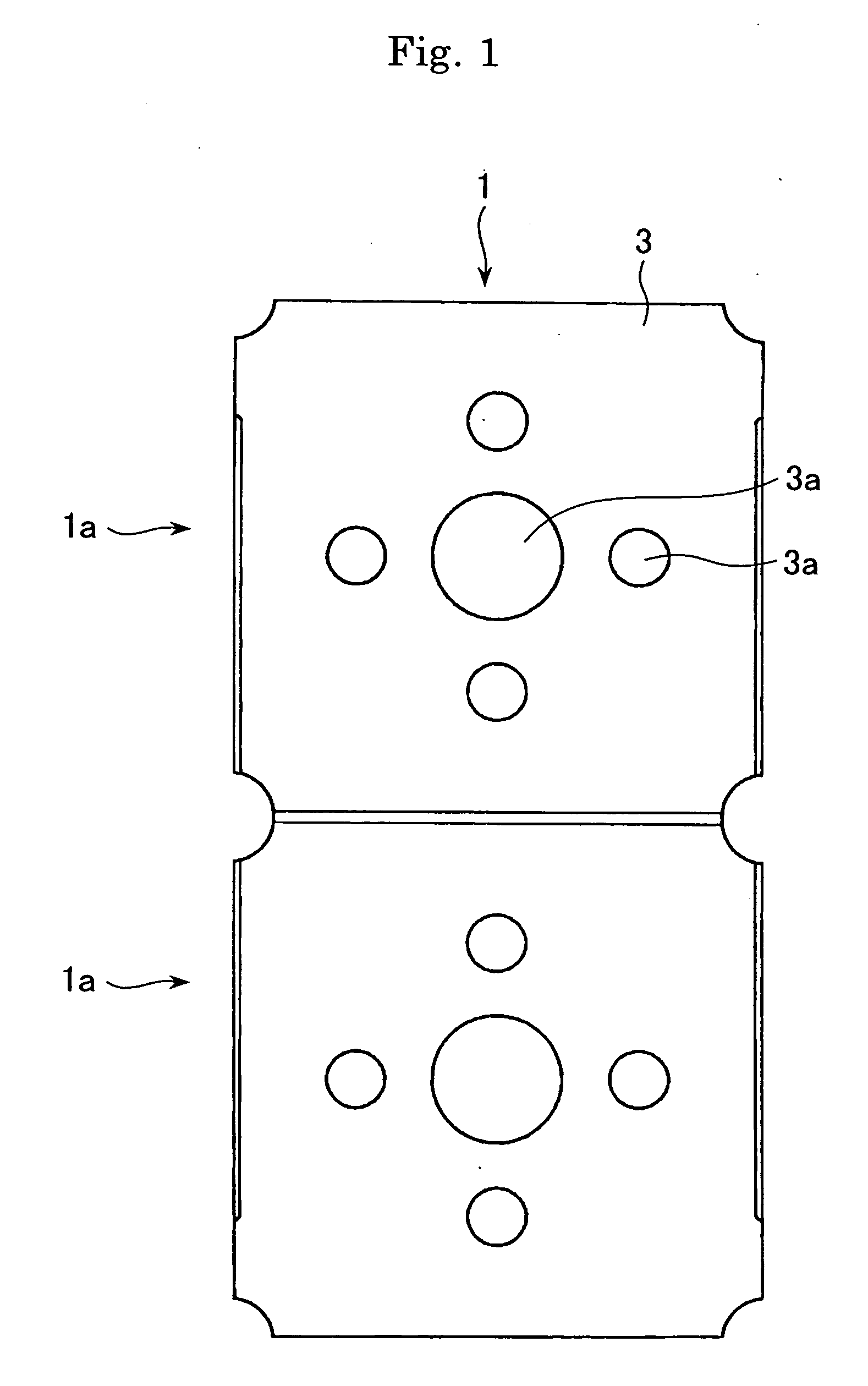

Liquid crystal display

InactiveUS20060083865A1Accurate color displayHigh quality displayLiquid crystal compositionsThin material handlingLiquid-crystal displayTransmittance

The main object of the present invention is to control the alignment of the ferroelectric liquid crystal by a simple method without the need of an alignment process such as the rubbing process and the photo alignment process in a liquid crystal display using a ferroelectric liquid crystal; to solve better the light scattering generated at the interface between the polarizing plate and the other functional layers compared with the case of separately providing the polarizing plate by the use of an alignment layer having the alignment function of controlling the alignment of the ferroelectric liquid crystal and the polarizing function of changing a non polarized light beam to a linear polarized light beam and thereby restrain the deterioration of the light transmittance, to achieve a thin shape and a light weight of the liquid crystal display. The invention achieves the object by using a columnar alignment layer having a column structure with plate-like molecule having the photo dichroism in the visible light range as one of the alignment layers for controlling the alignment of the ferroelectric liquid crystal and forming a reactive liquid crystal layer produced by fixing a reactive liquid crystal including a polymerizable liquid crystal material on the side to be contacted with the ferroelectric liquid crystal on the columnar alignment layer, showing the nematic phase on the columnar alignment layer.

Owner:DAI NIPPON PRINTING CO LTD +1

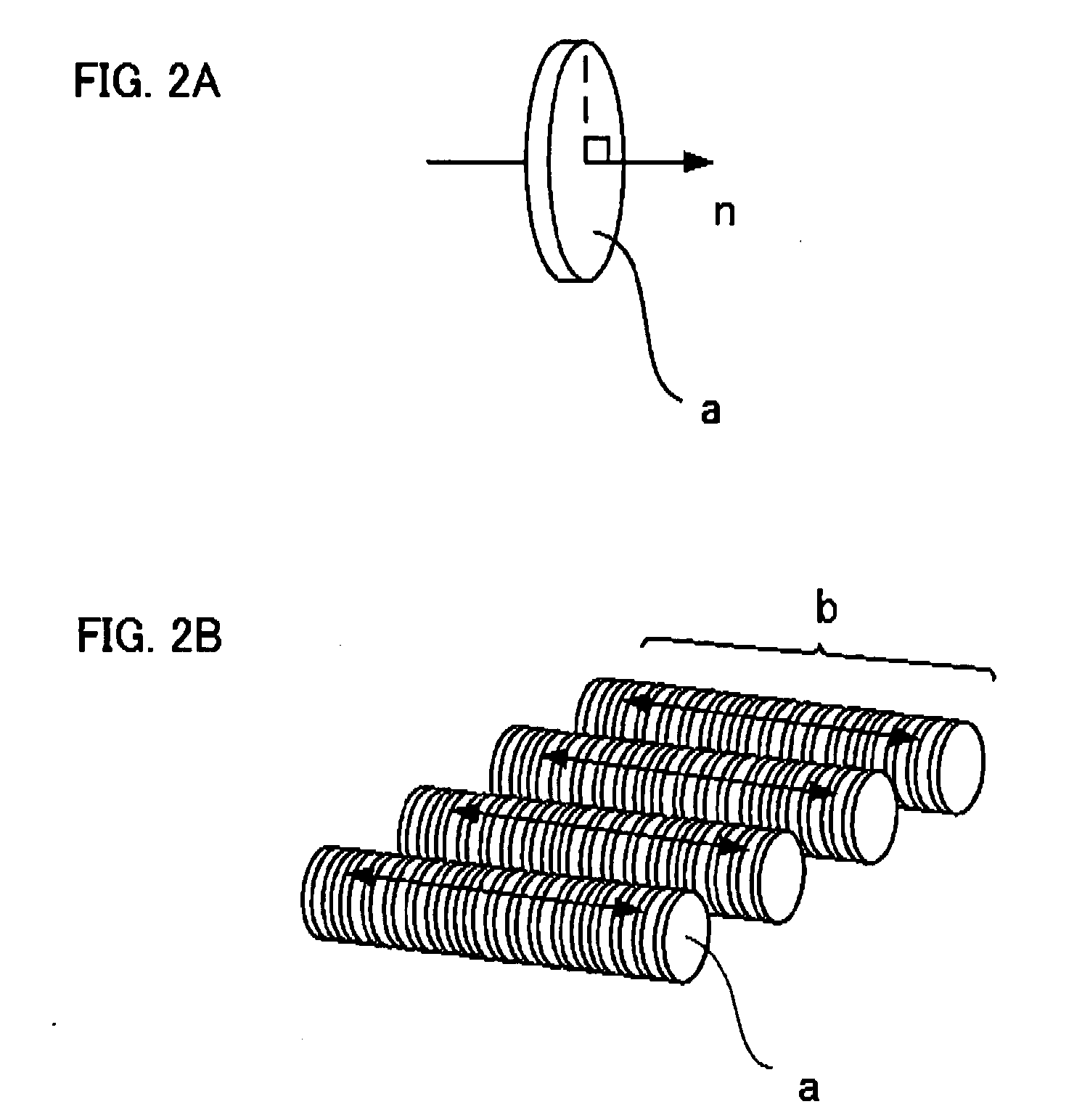

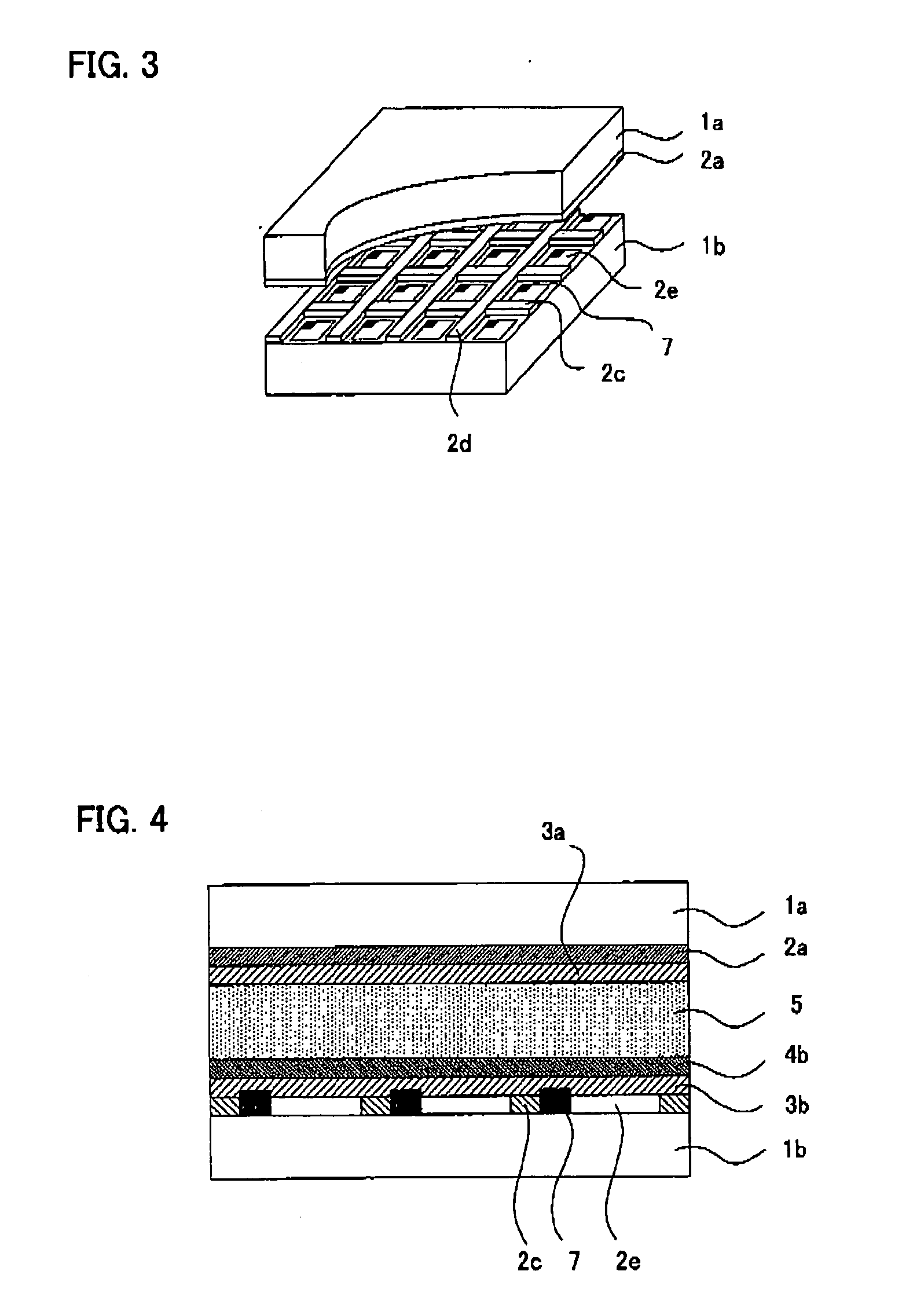

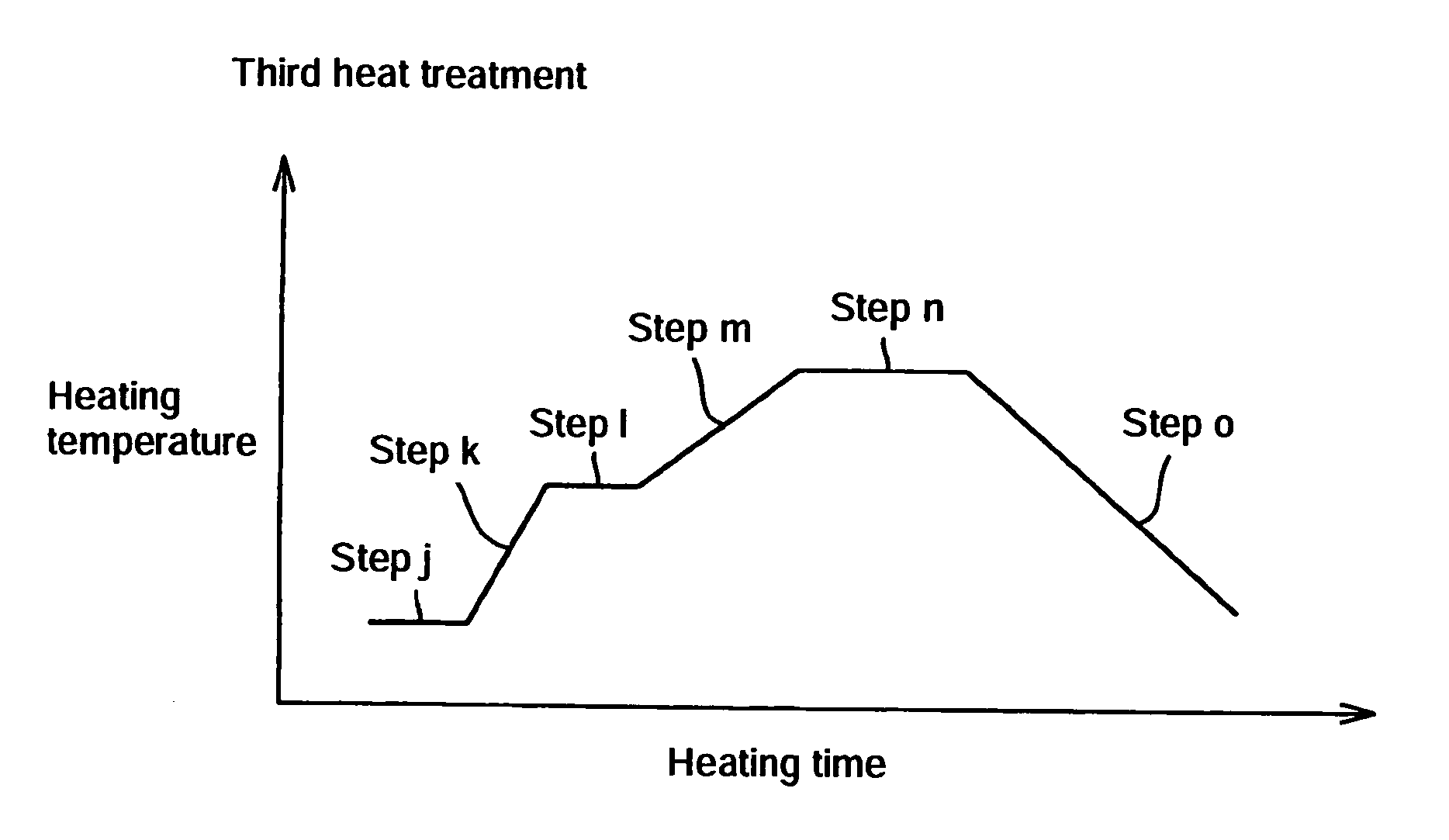

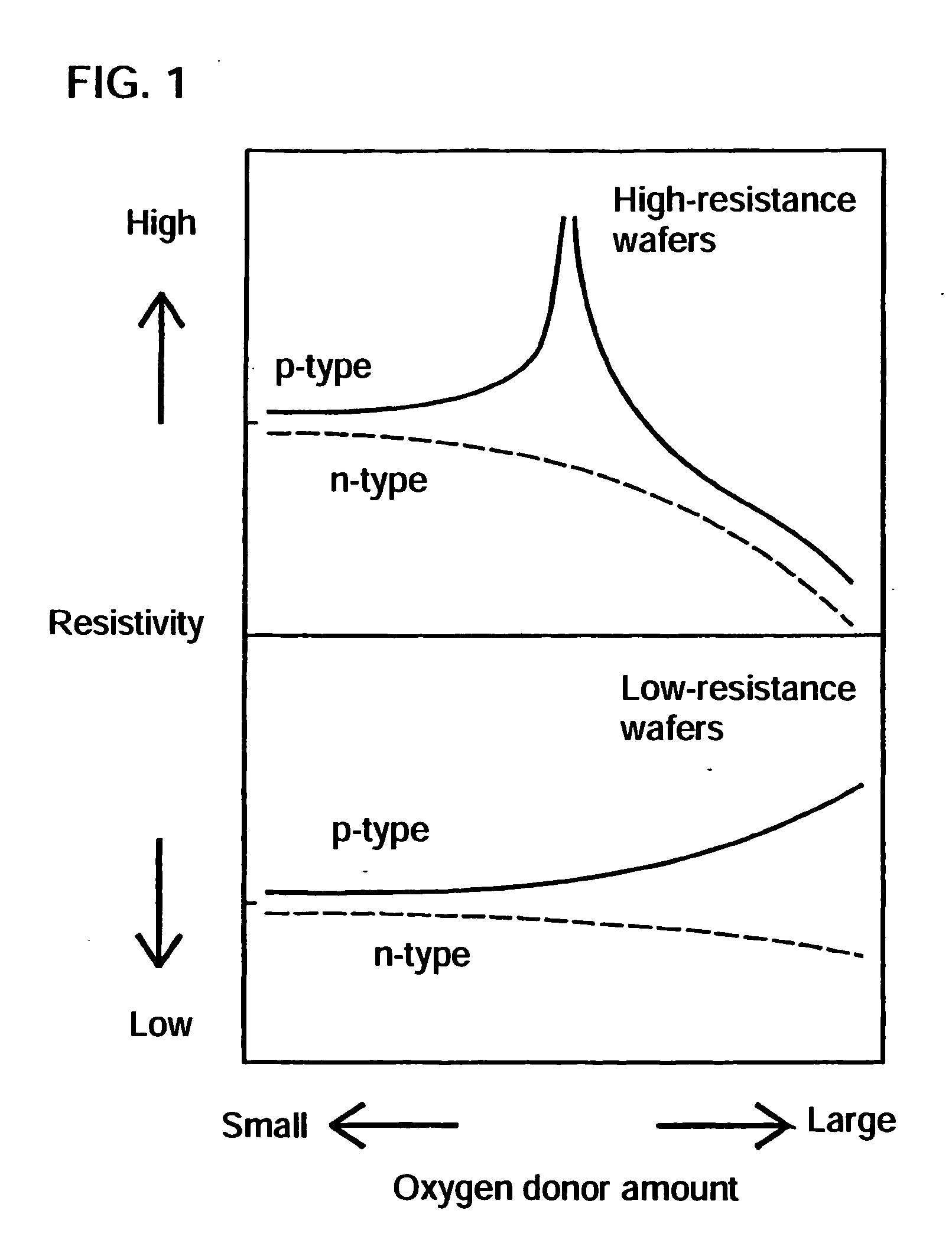

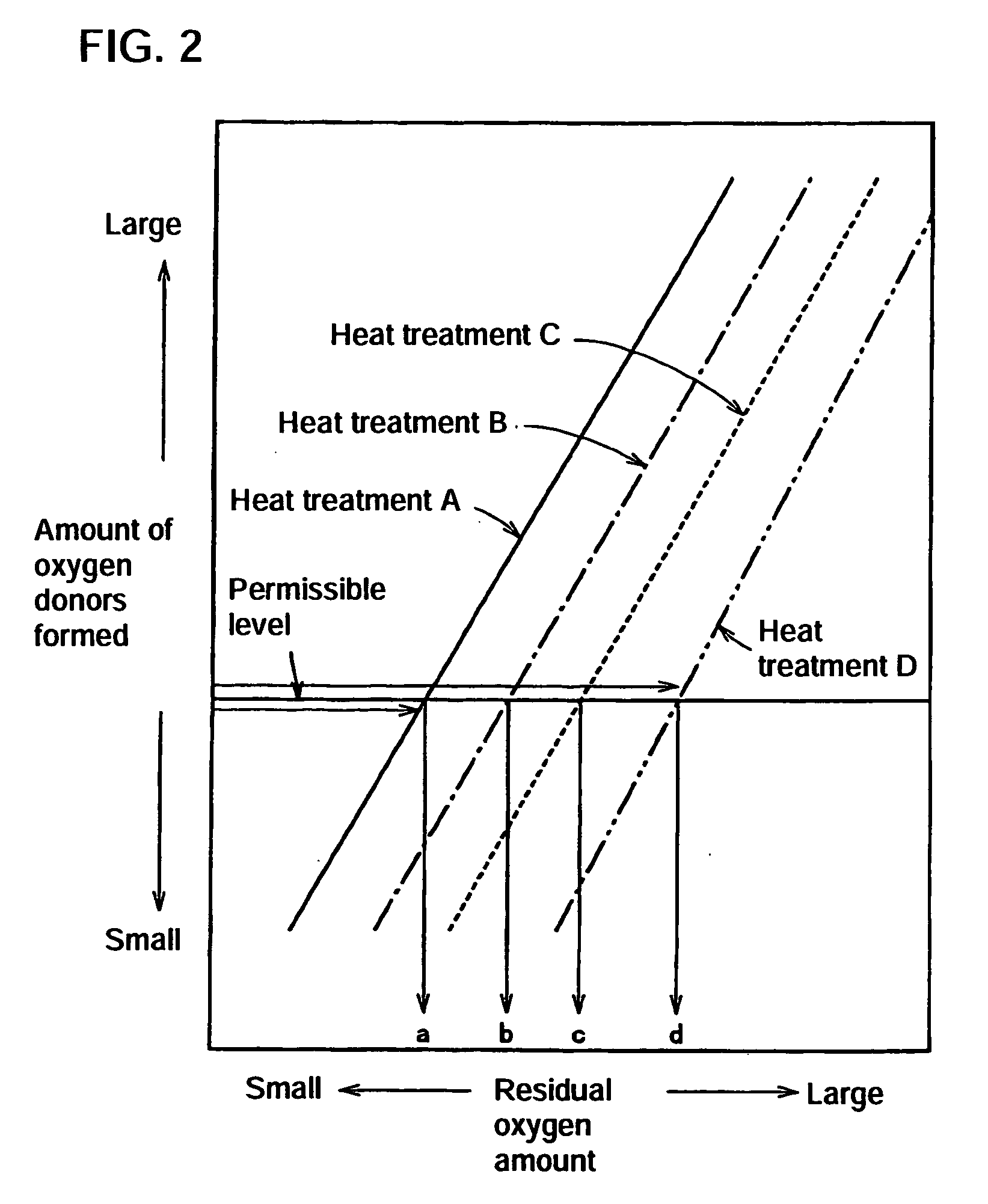

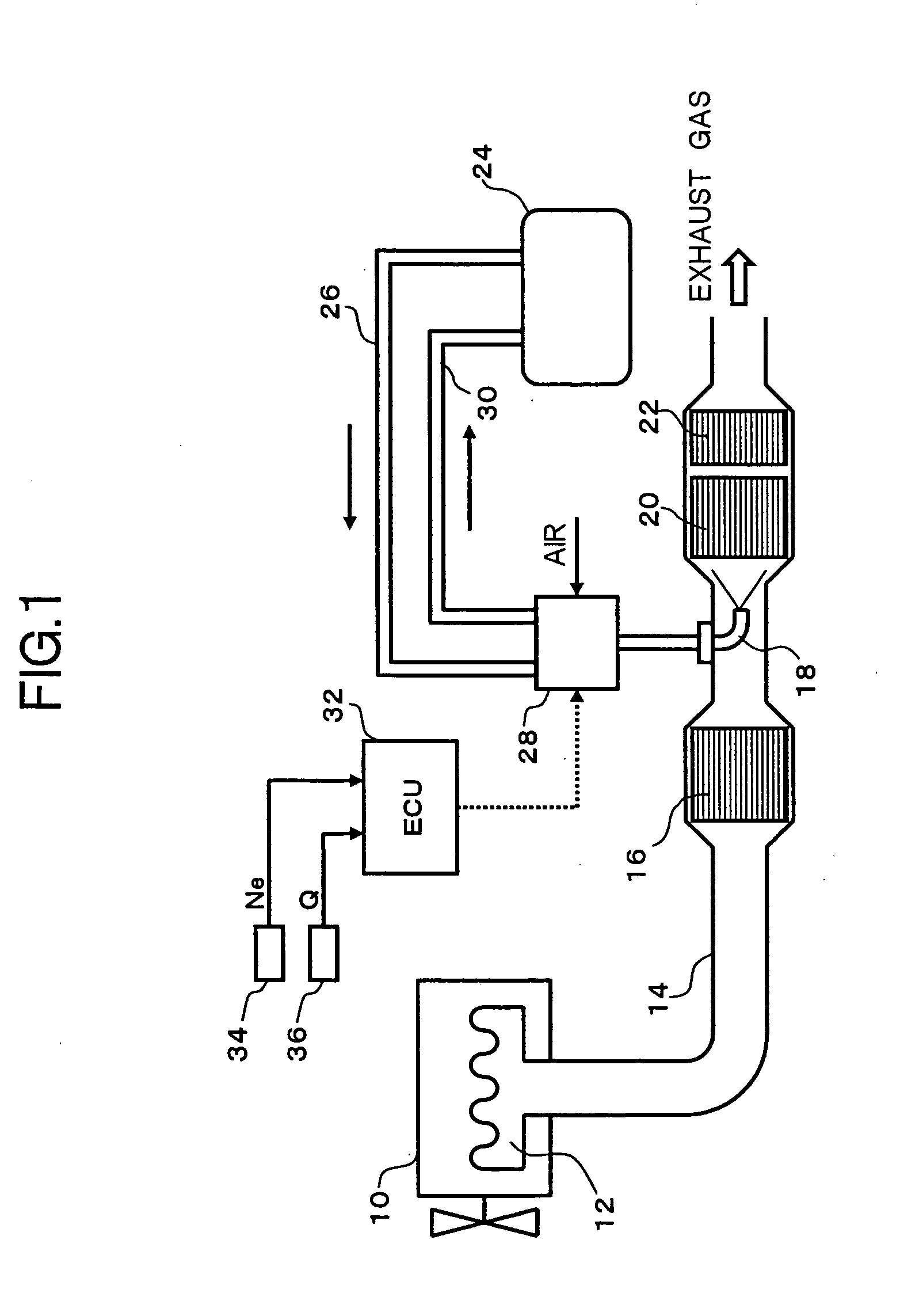

Process for producing high-resistance silicon wafers and process for producing epitaxial wafers and soi wafers (as amended)

ActiveUS20070066033A1Low production costAvoid it happening againPolycrystalline material growthAfter-treatment detailsHigh resistanceElectrical resistance and conductance

By using oxygen-containing silicon wafers obtained by the CZ method and by combining the first heat treatment comprising controlled heat-up operation (ramping) with the second heat treatment comprising high-temperature heat treatment and medium temperature heat treatment in accordance with the process for producing high-resistance silicon wafers according to the present invention, it is possible to obtain high-resistance silicon wafers capable of maintaining their high resistance even after heat treatment in the process of device manufacture while efficiently inhibiting the formation of oxygen donors and preventing changes in resistivity. Further, excellent epitaxial wafers and SOI wafers can be produced using those high-resistance silicon wafers and, therefore, they can be applied in a wide field including high-frequency communication devices and analog / digital hybrid devices, among others.

Owner:SUMCO CORP

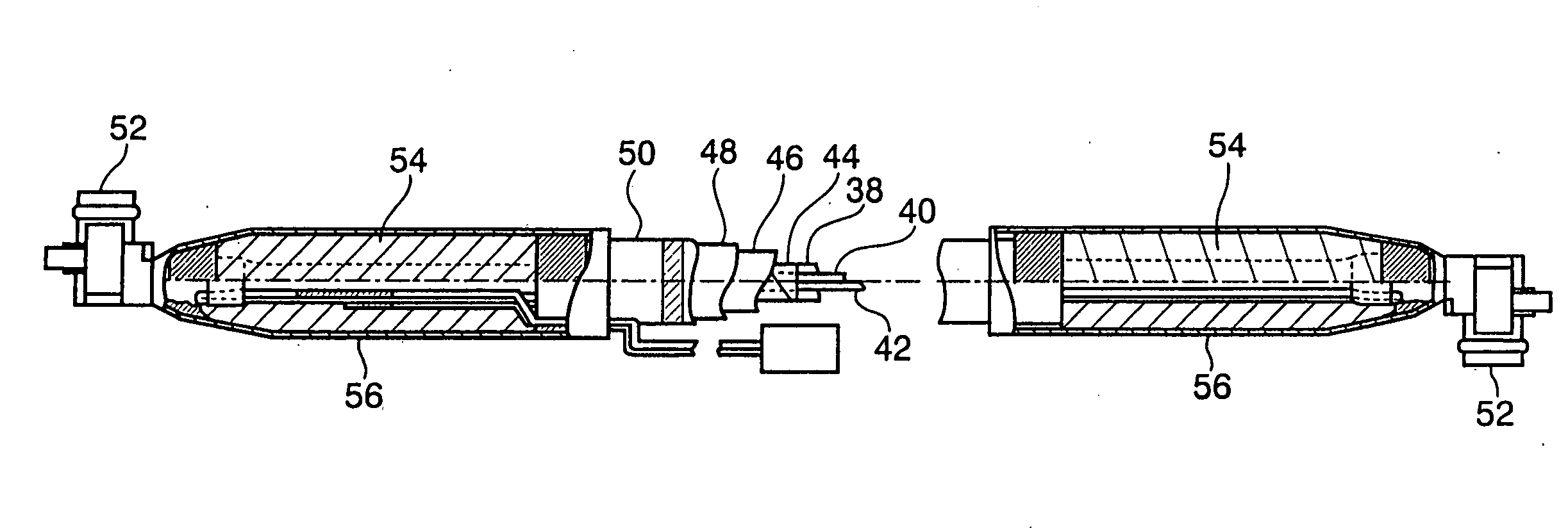

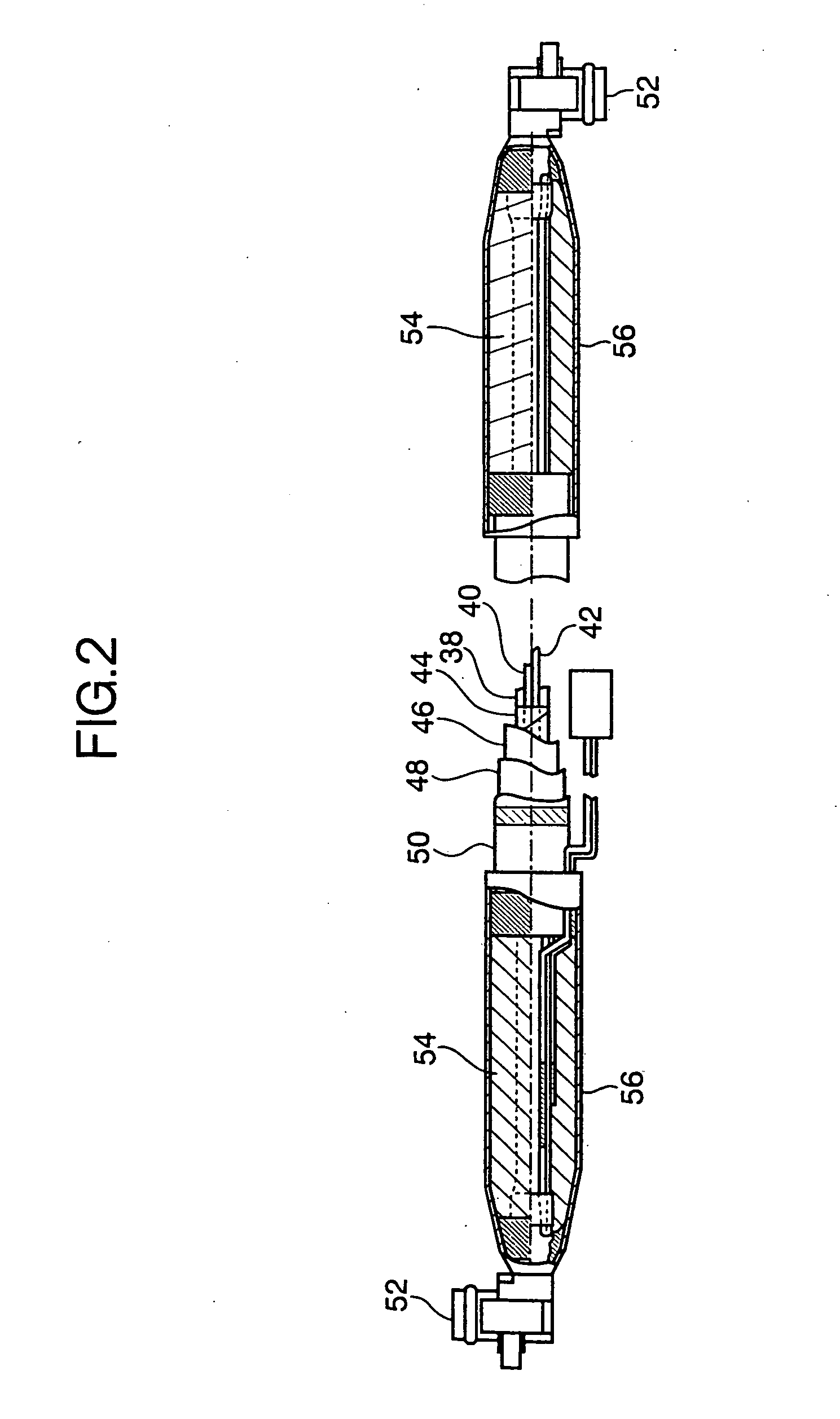

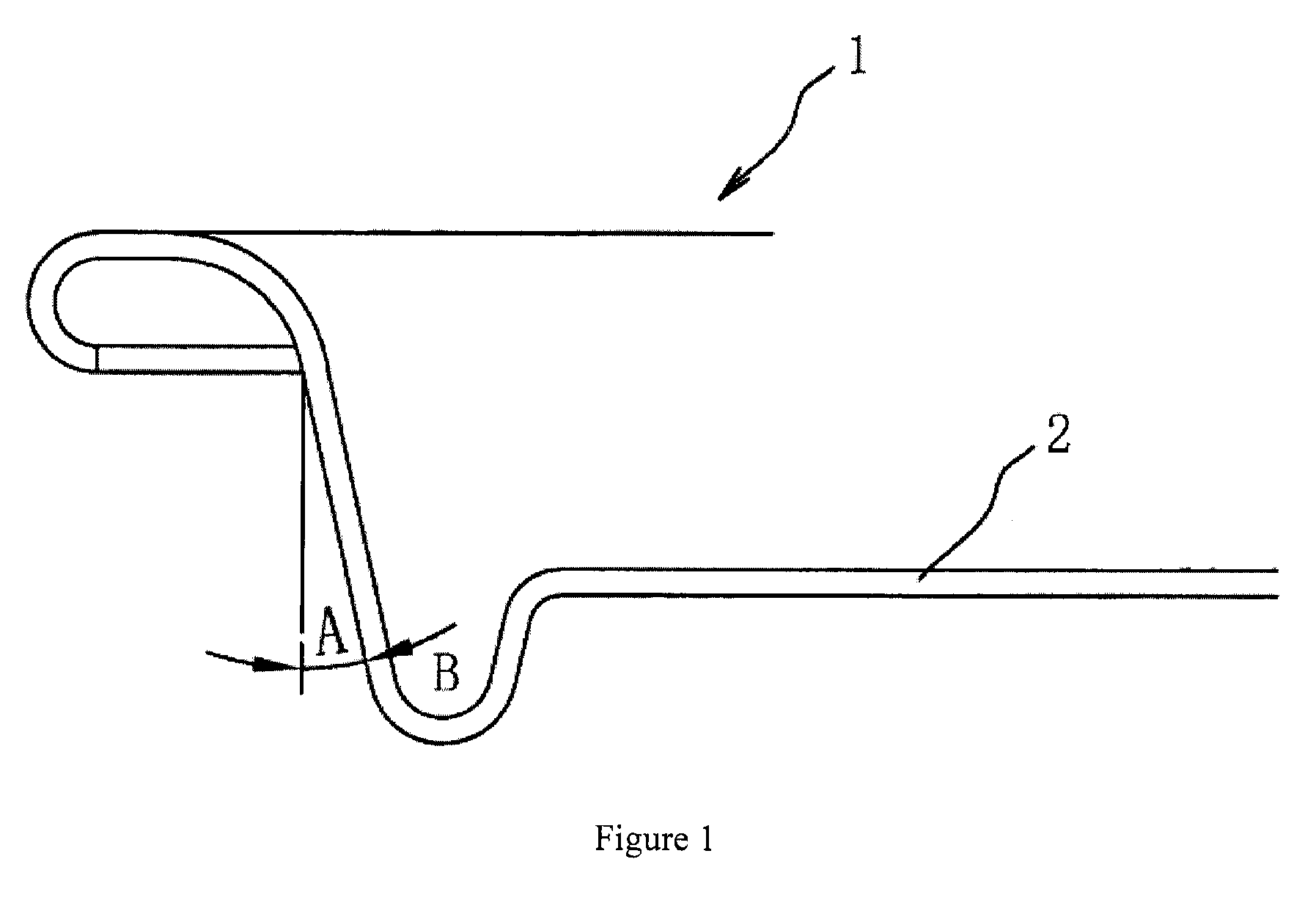

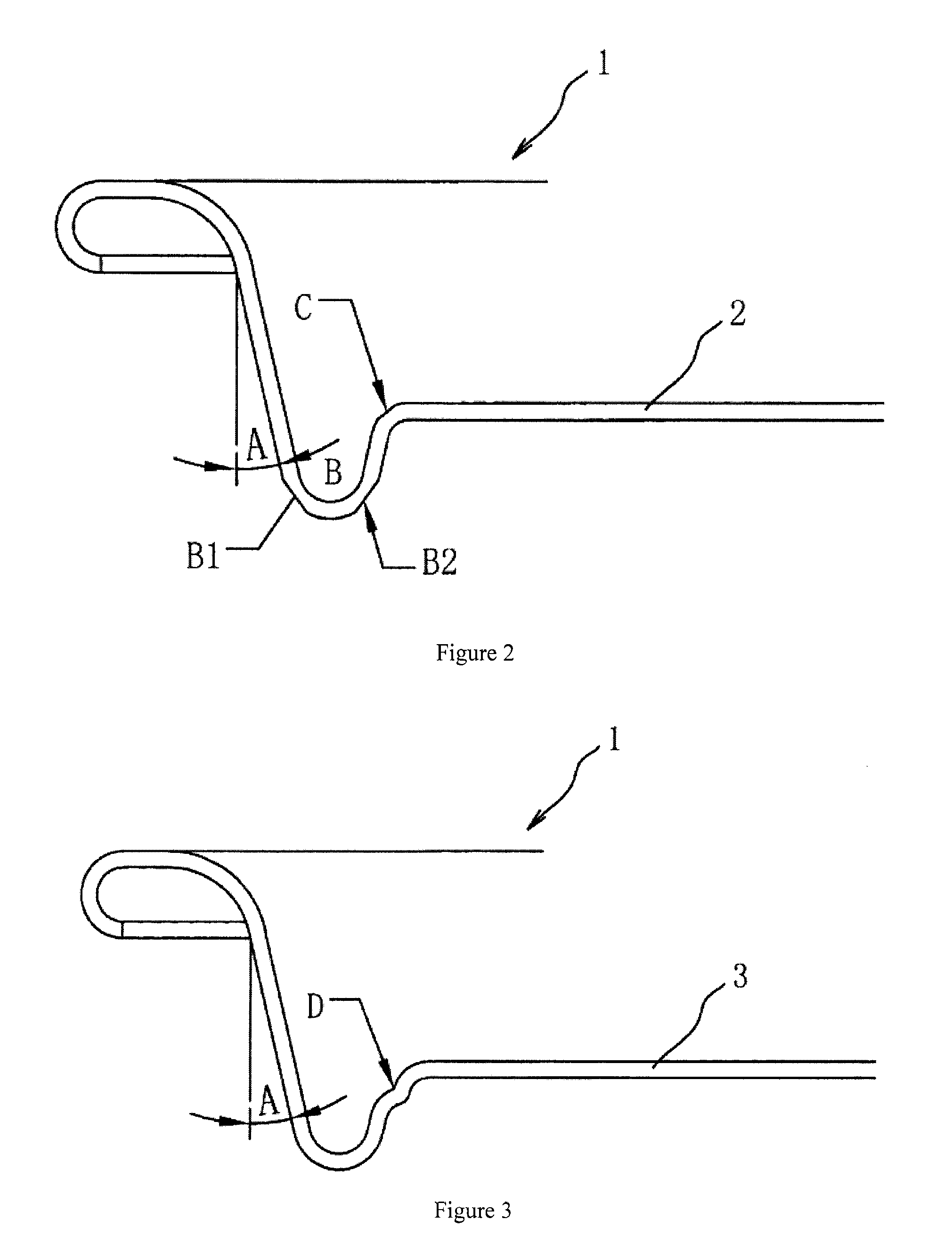

Piping with heater and connecting method of the piping

InactiveUS20080041841A1Reduce manufacturing costEasily realizedHeating element shapesLower limitTube forming

A heater-attached piping having, a cord-like heater disposed along substantially entire length of a nylon tube forming a pipe for transferring a fluid, and at least a heat-retaining layer disposed around the nylon tube and the cord-like heater. The cord-like heater located at the end of the nylon tube may be, for example, folded back and formed in a duplex arrangement. With this arrangement, heat generating at the end of the heater-attached piping increases and is duplicated to result in suppression of power consumption of the cord-like heater to a possible lowest limit, and the heat-retaining ability and defrosting ability in the end of the heater-attached piping can be enhanced.

Owner:NISSAN DIESEL MOTOR CO +1

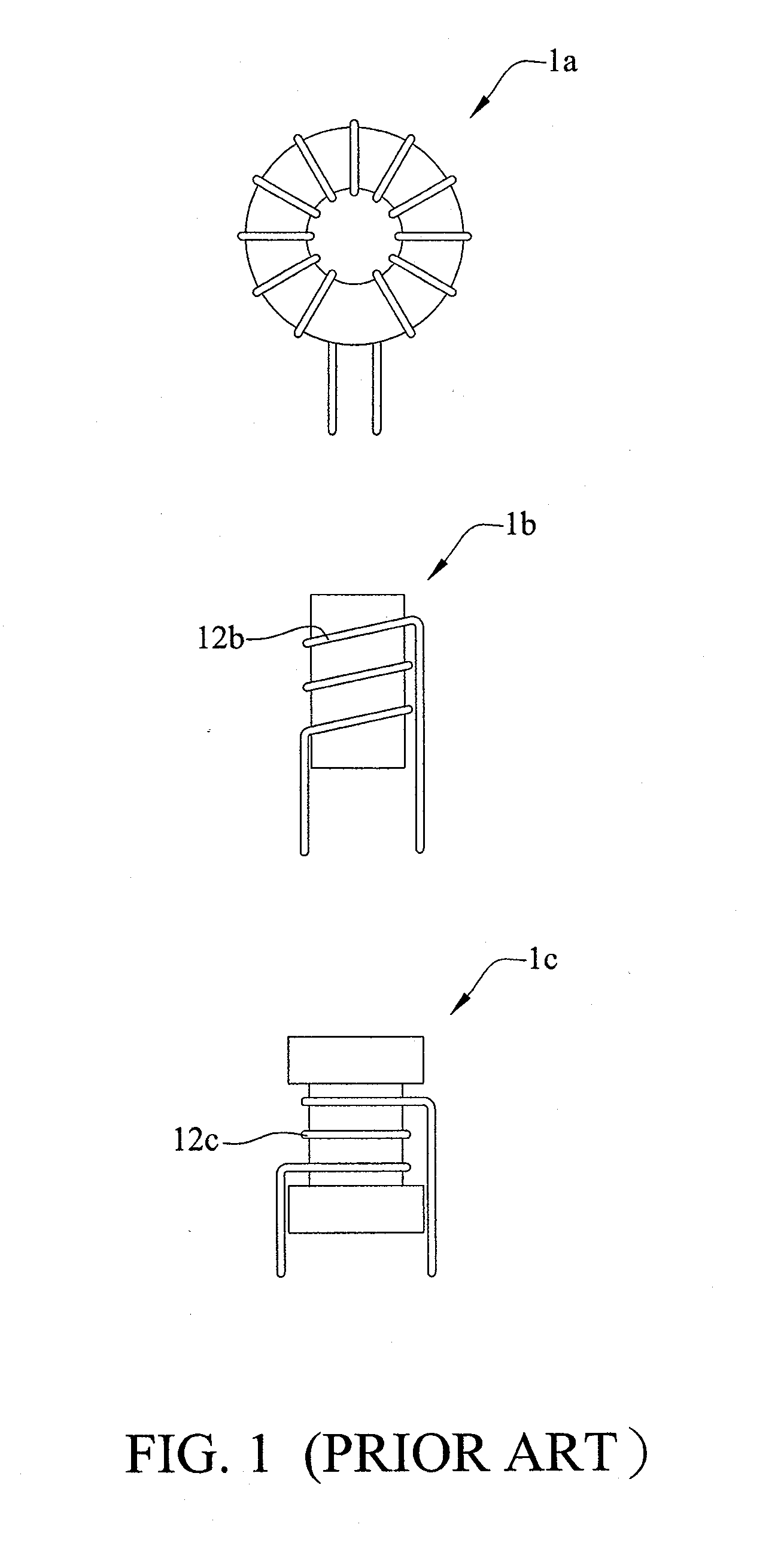

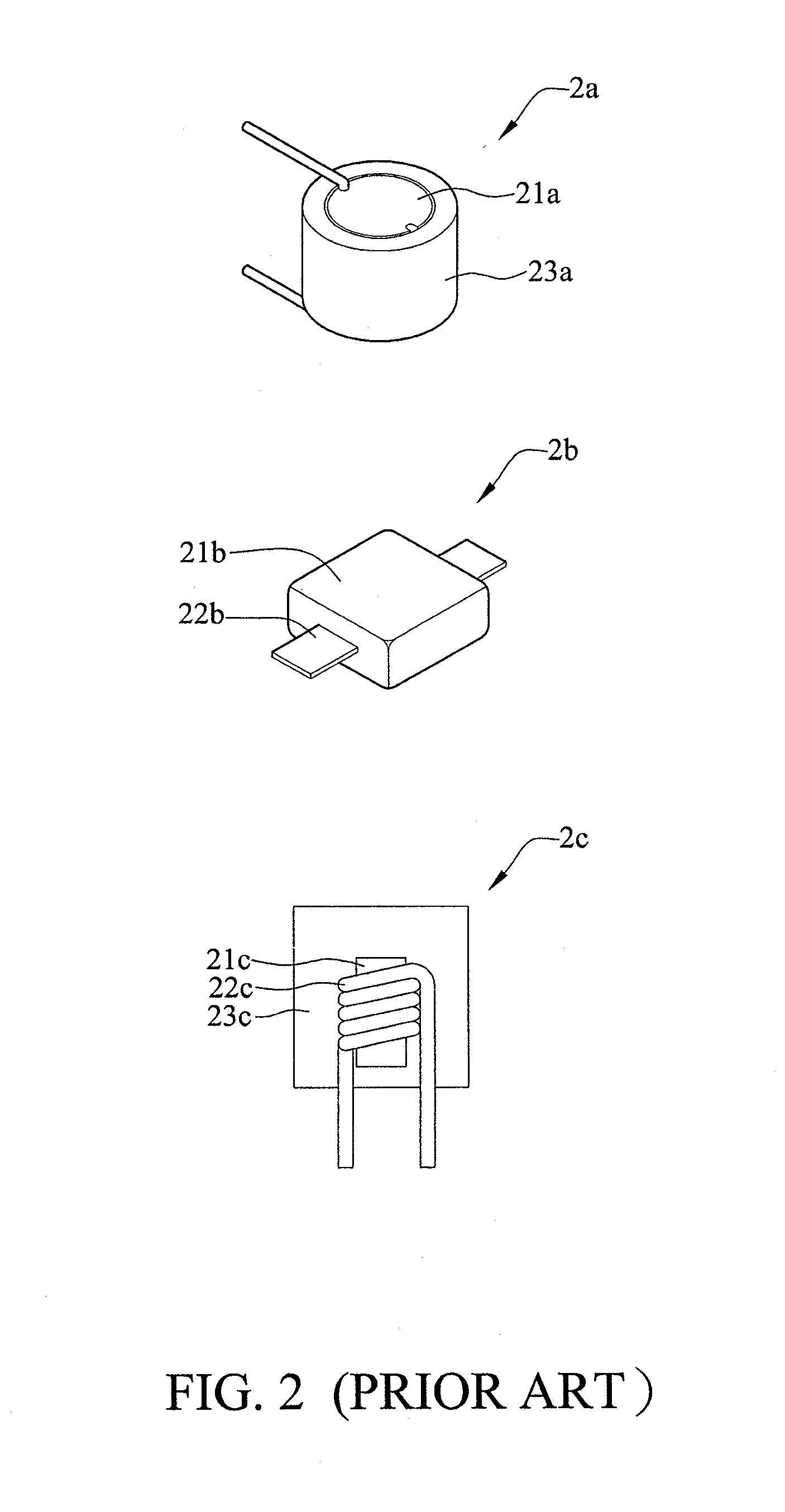

Coil electrical component and method of manufacturing the same

ActiveUS20120262265A1Economize production costQuality improvementTransformers/inductances casingsElectromagnetsElectrical elementMaterials science

A coil electrical component and a method of manufacturing the same. Magnetic material powder and adhesive powder are mixed in a predetermined proportion to form a solid mixture. The solid mixture and an object, such as a coil or a core material surrounded by the coil, are filled in a mold having a predetermined shape. The solid mixture in the mold is heated such that the magnetic material powder is adhered by the adhesive powder and covers the object, so as to form the coil electrical component. The coil electrical component corresponds in shape to the mold. Therefore, the coil electrical component has stable quality, and can be manufactured with less time and lower cost.

Owner:MAGIC TECH

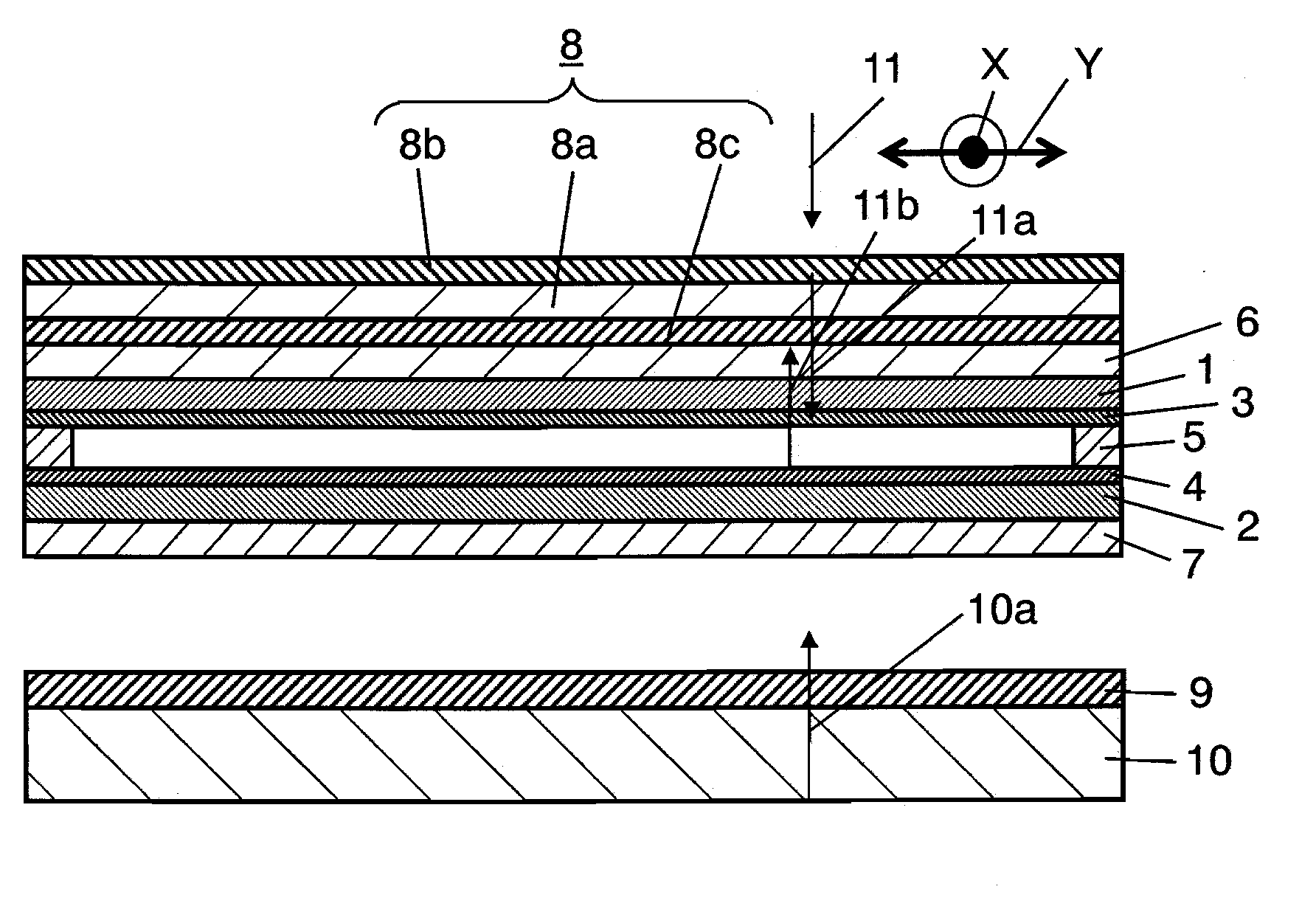

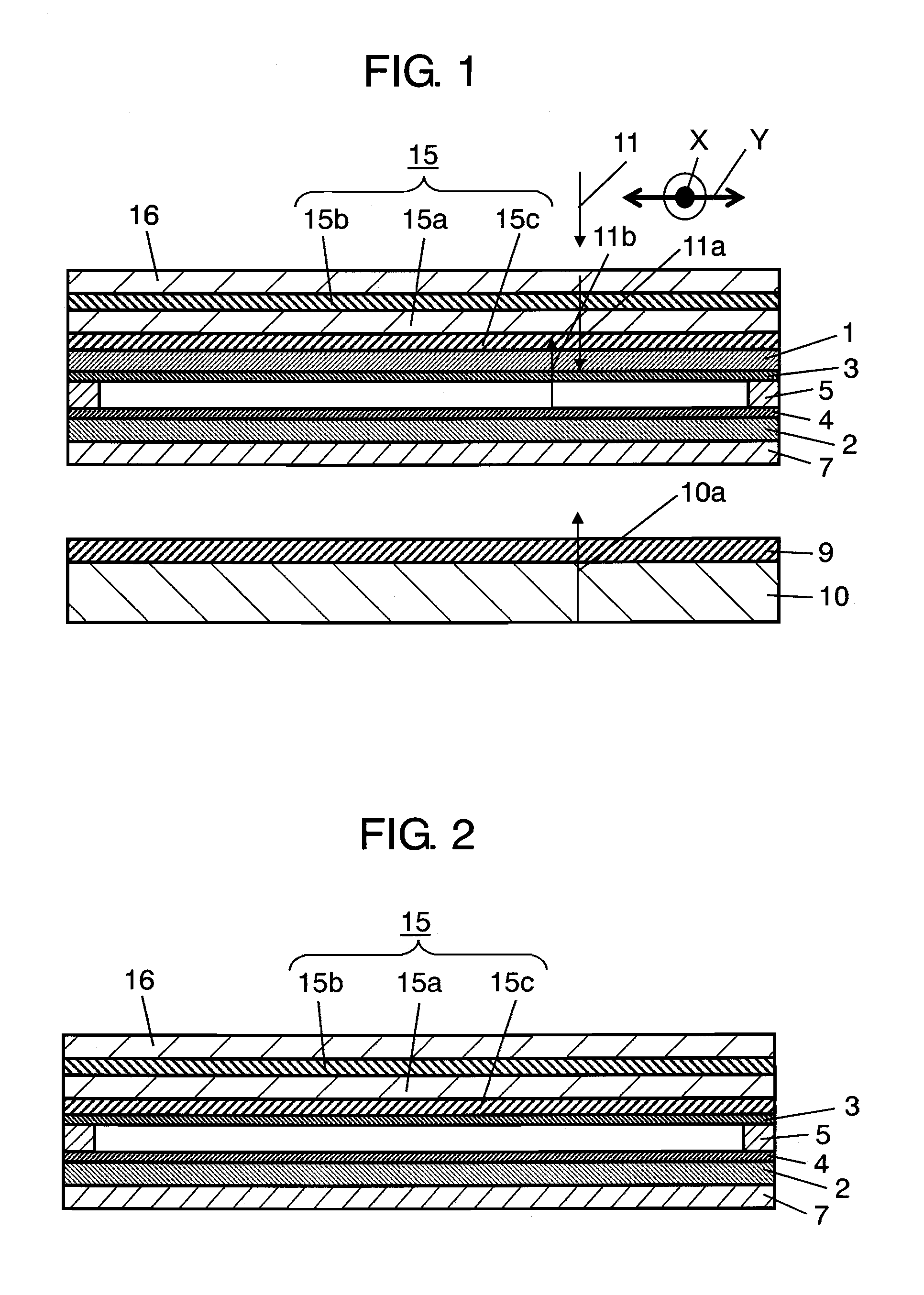

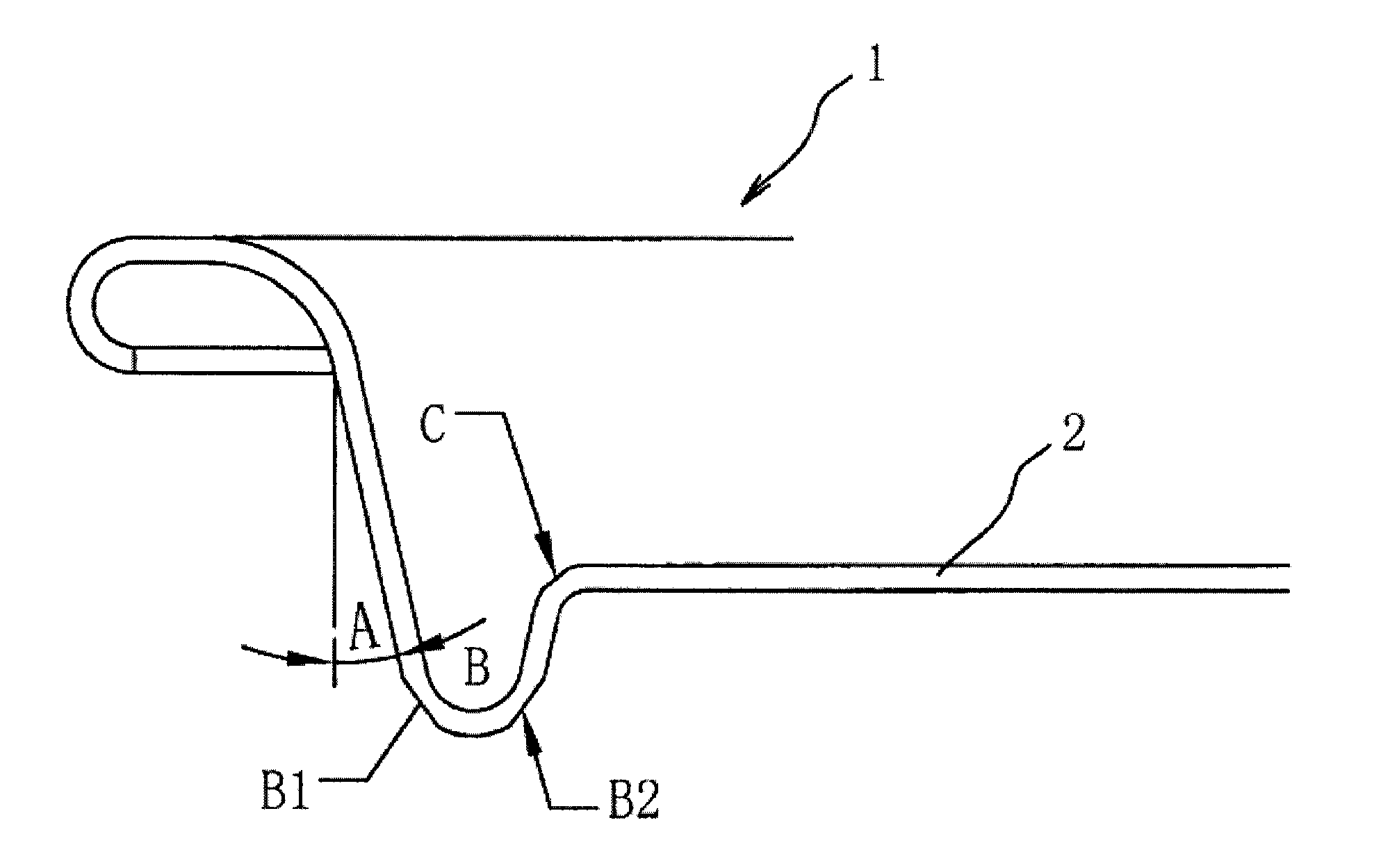

Touch panel

InactiveUS20080204610A1Improve visibilityCost of productionNon-linear opticsVisibilityPhase difference

Disclosed here is a touch panel with improved visibility. Polarizing plate (15) of the touch panel has a laminated structure in which polarizing layer (15a) is sandwiched between upper protective layer (15b) and lower protective layer (15c). Of the three layers, lower protective layer (15c) is formed as a phase-difference layer with ¼ wavelength made of a cycloolefin-based polymer. The structure protects polarizing plate (15) from distortion and deterioration, offering good visibility. At the same time, the structure above contributes to reduced parts count and accordingly cost-reduced touch panel.

Owner:PANASONIC CORP

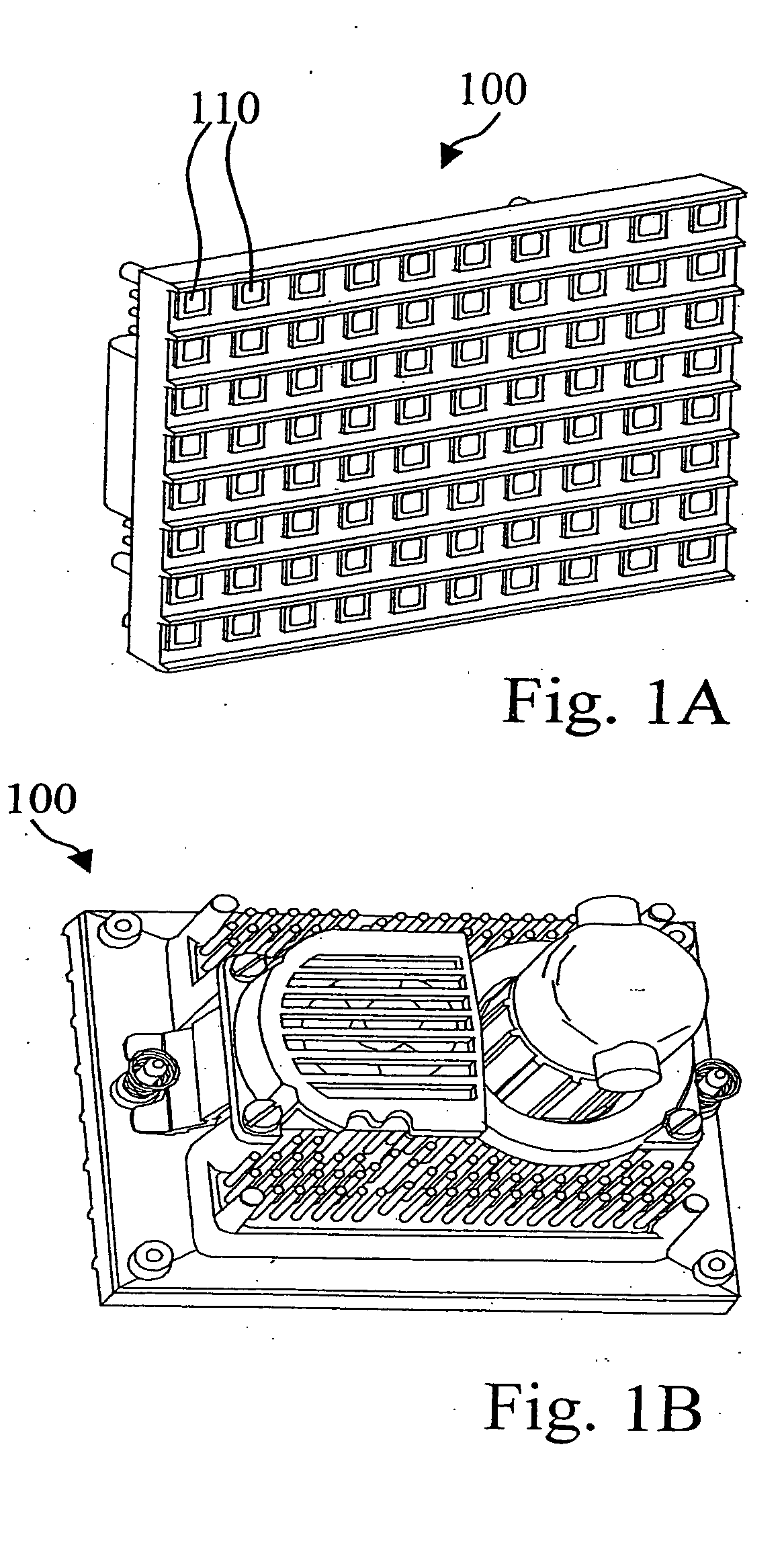

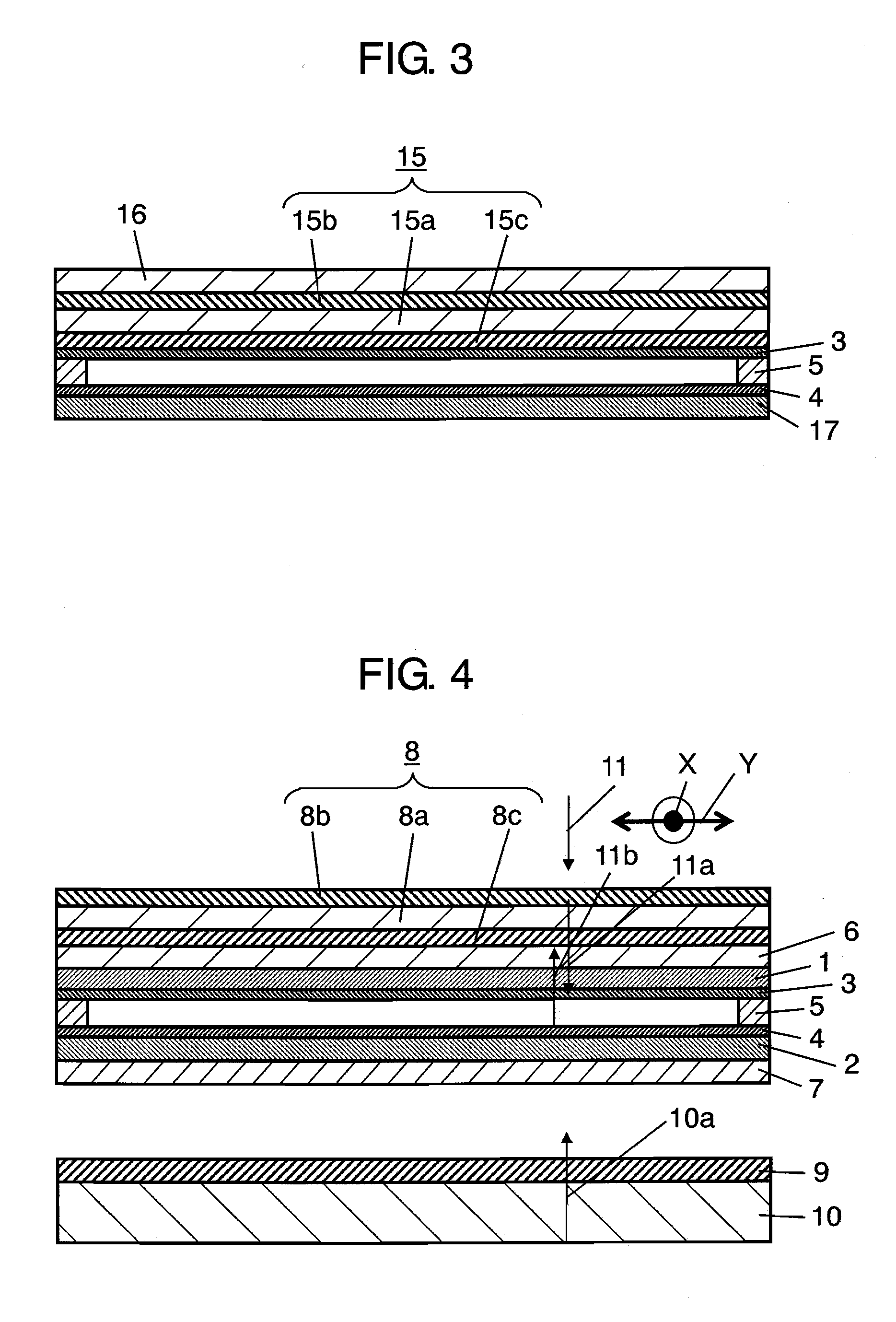

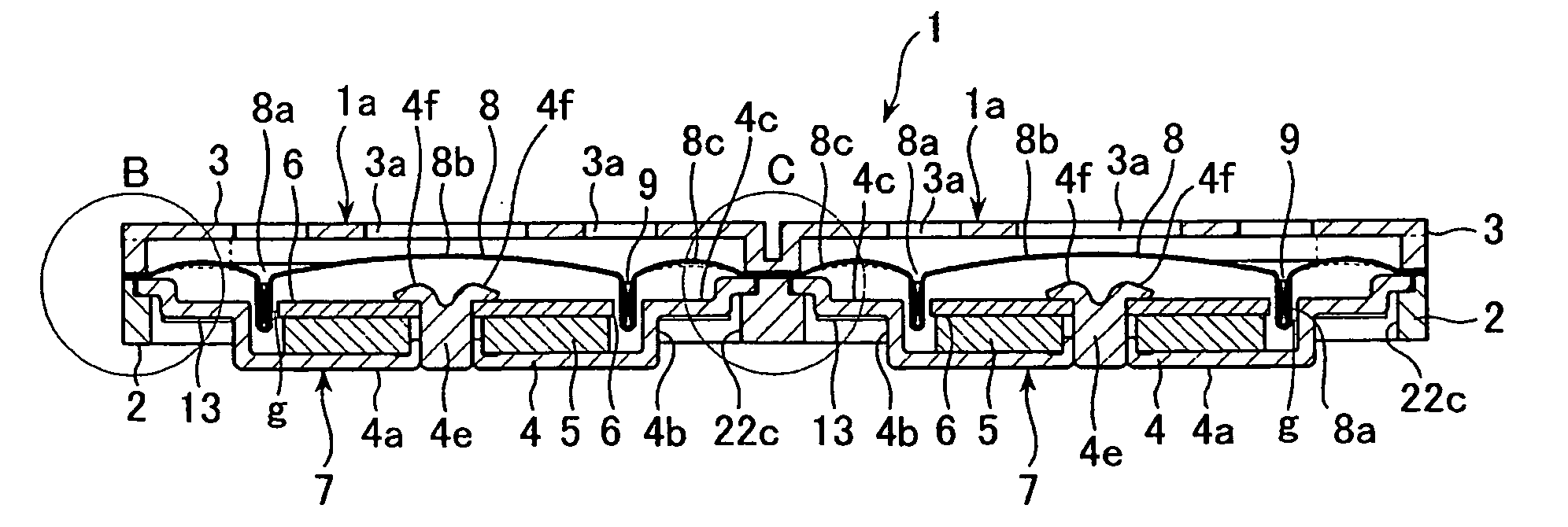

Speaker and method for manufacturing the speaker

InactiveUS20060177092A1Efficient preparationLess number of production stepTransducer detailsEngineeringLoudspeaker

A method of manufacturing a speaker includes providing an integral set of frames each with a receptacle opening, mounting a plurality of magnetic circuit units in the respective receptacle openings of the integral set of frames, mounting an integral set of diaphragms to the integral set of frames with diaphragms aligned with respective frames, mounting a plurality of voice coils to the integral set of diaphragms with the voice coils operatively connected to the respective magnetic circuit units to form an integral set of speaker units each comprising the frame, the magnetic circuit unit, the diaphragm and the voice coil, and dividing the integral set of speakers into individual speakers each with at least one speaker unit.

Owner:CITIZEN ELECTRONICS CO LTD

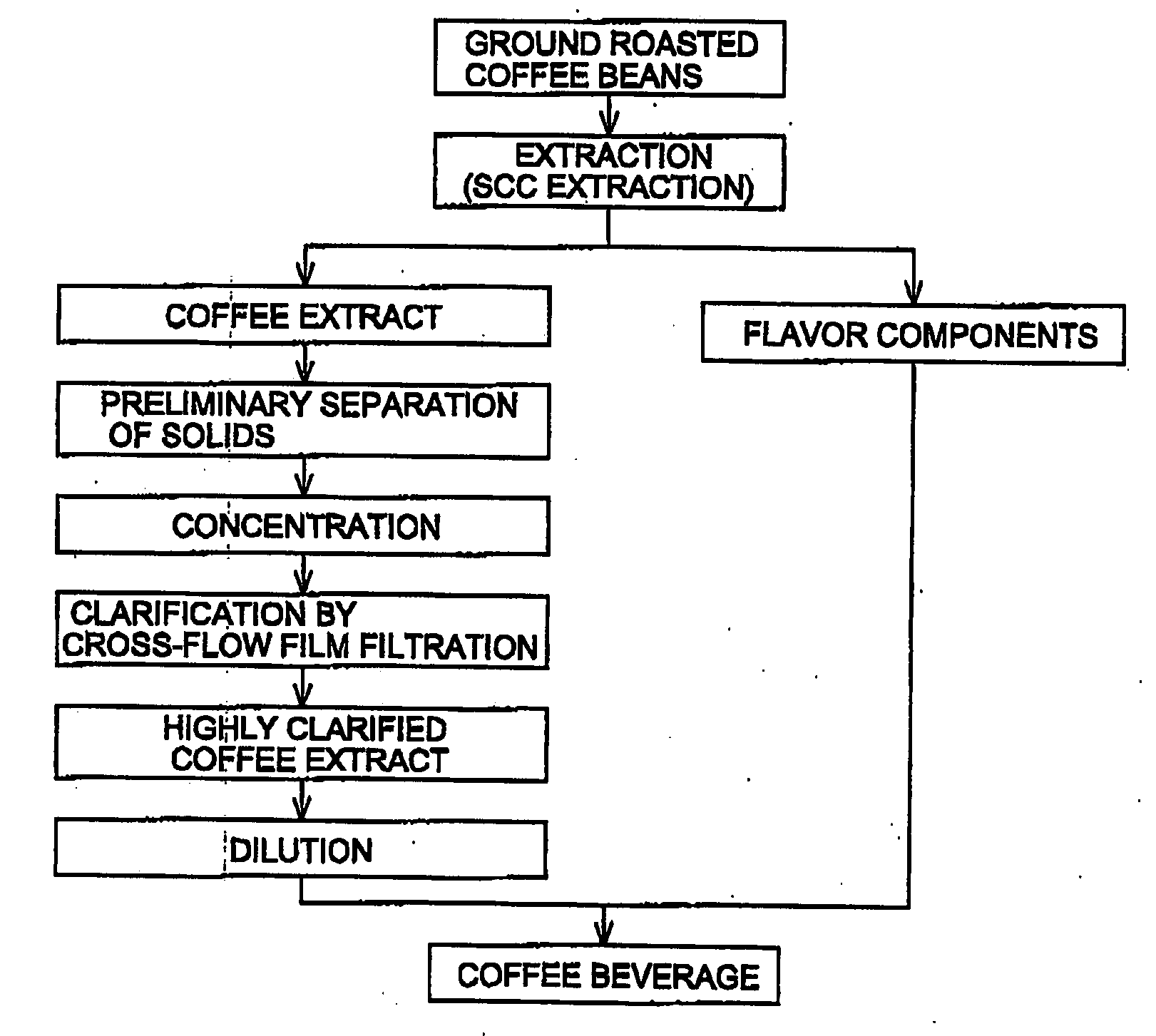

Method for Manufacturing Coffee Beverage Using Filtered Extract

InactiveUS20080260911A1Small volumeConvenient for shipping and storageCocoaMeat/fish preservation by freezing/coolingAdditive ingredientCross-flow filtration

A method for manufacturing a coffee beverage is provided that is capable of efficiently removing precipitating components and turbid components from a highly concentrated coffee extract 1, and that is also capable of addressing increases in the production volume of the coffee beverage without particularly large changes being made to the scale of the equipment. The coffee extract 1 obtained from an extraction process performed on ground roasted coffee beans is diluted in the method for manufacturing a coffee beverage, and the coffee extract 1 is filtered using a cross-flow filtering apparatus before dilution.

Owner:SUNTORY HLDG LTD

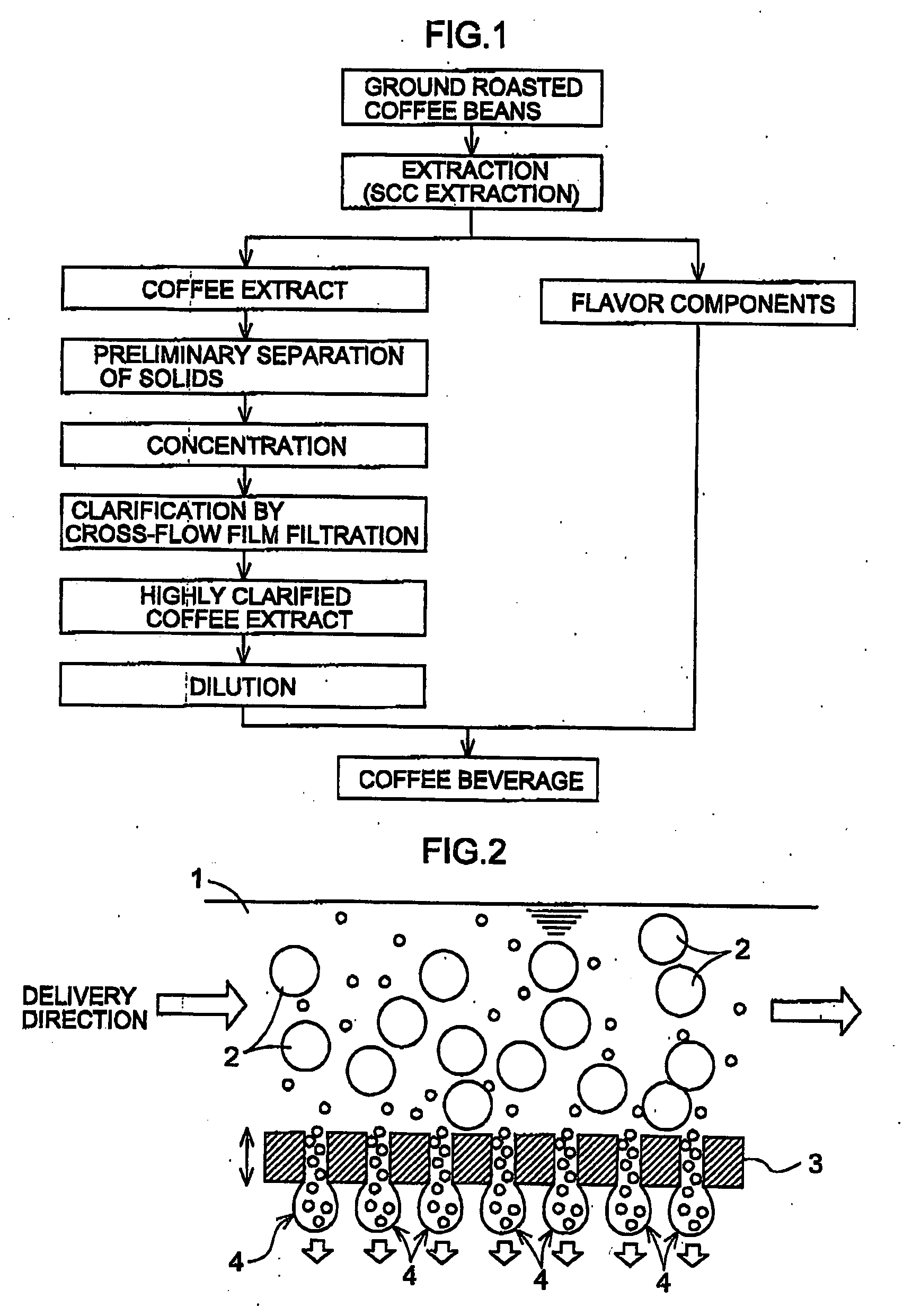

Internal Gas Pressure Resistant Metal Pop-Top Cover and Method of Making

ActiveUS20100059517A1Reduce the overall diameterSave materialRigid containersHollow articlesCold hardeningEngineering

A gas pressure-resistant metal pop-top cover comprised of two parts, a lid (1) and a pull-ring, the pull-ring being riveted to the lid (1), there being a concave countersink that begins at the circumferential edge of the lid (1) and extends toward its center, and at the center of the concave countersink there being a round convex platform (2), wherein the angle of inclination A of the countersink is 15-60°, and the arc-shaped segments B1 and B2 of the bottom part of the convex platform and the corner portion of the rise segment C rotate around the center of the lid (1) and are subjected to cold hardening treatment through forging and pressing. Through a new design, the conflict between material-saving and maintaining pressure resistance in a pop-top cover has been solved, with the result that greater resistance to high pressure is provided as the notch diameter and thickness of materials in the pop-top cover are decreased.

Owner:SUZHOU SLAC PRECISION EQUIP CO LTD

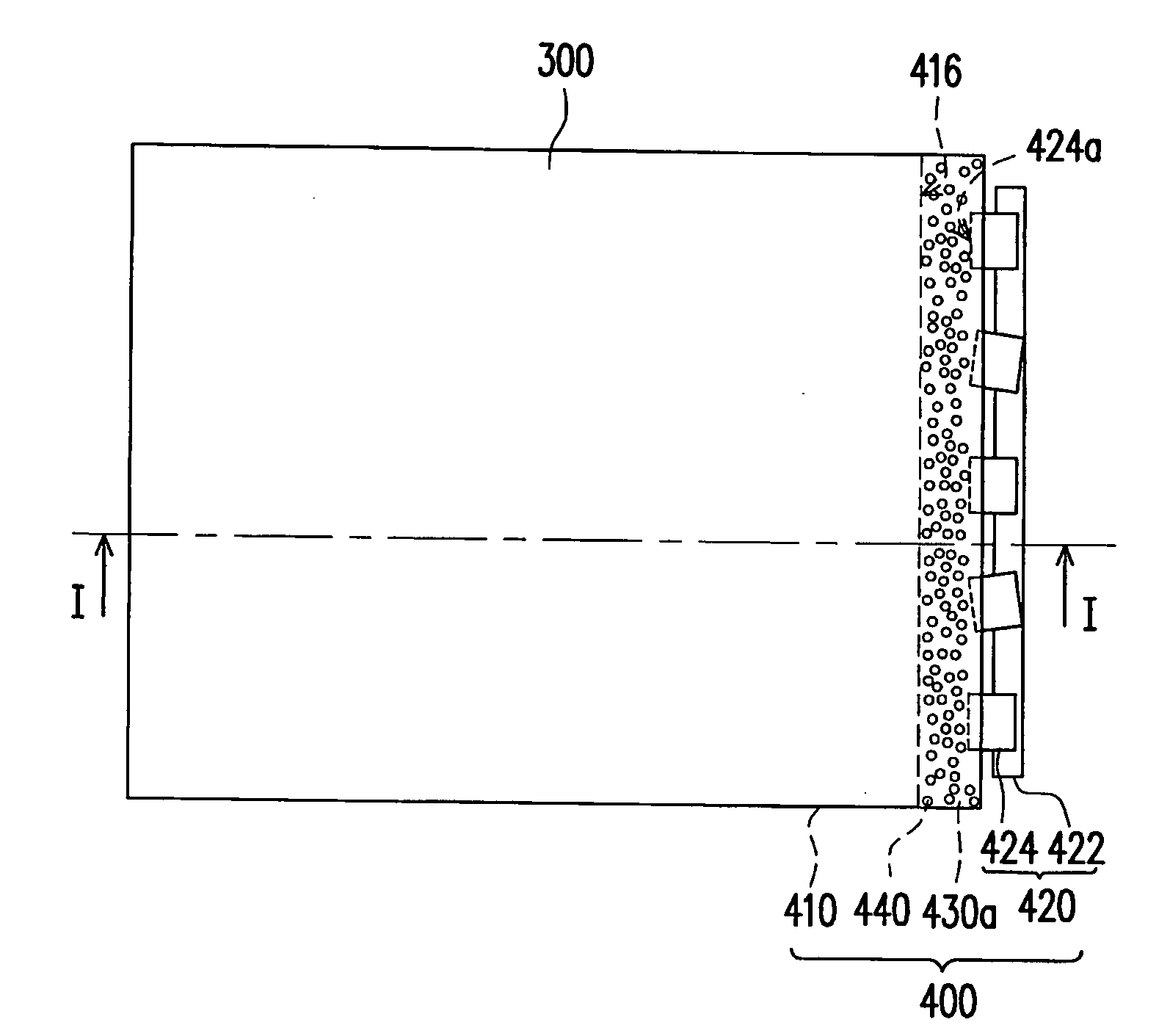

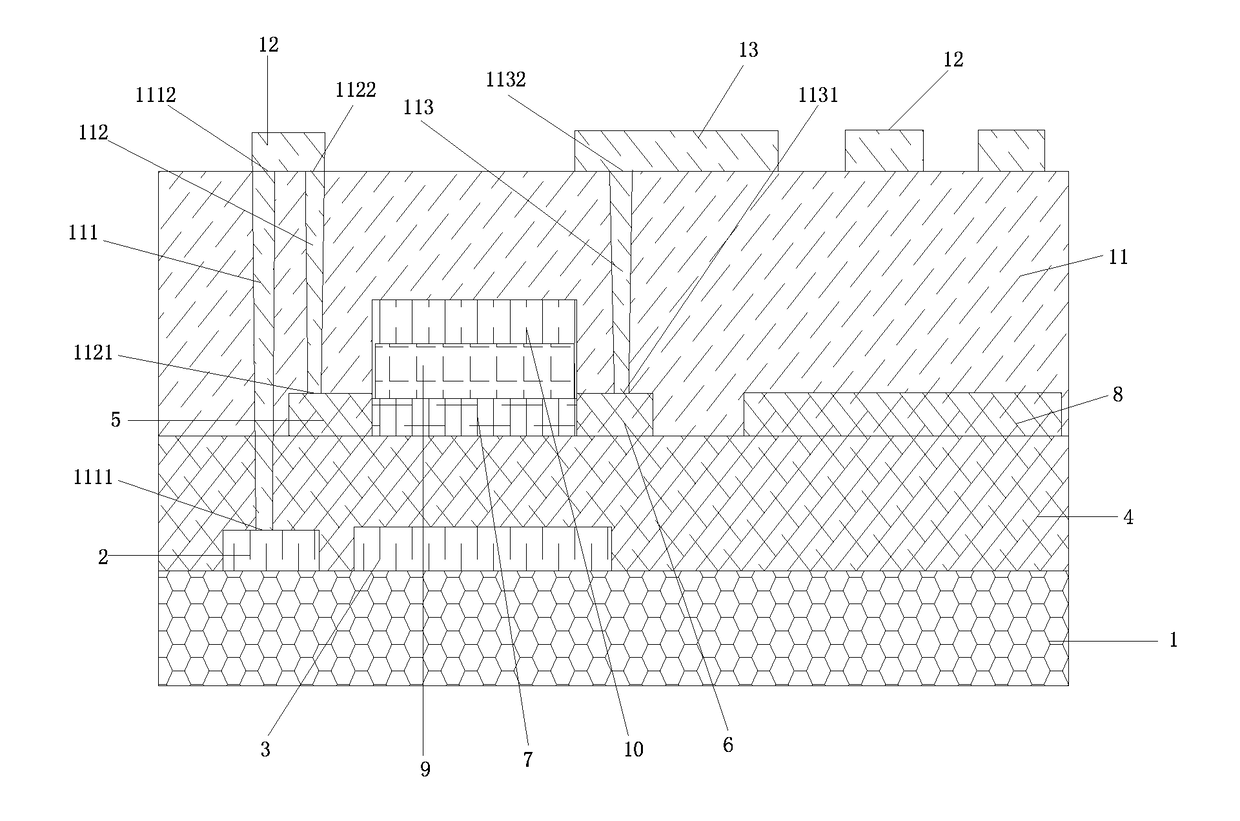

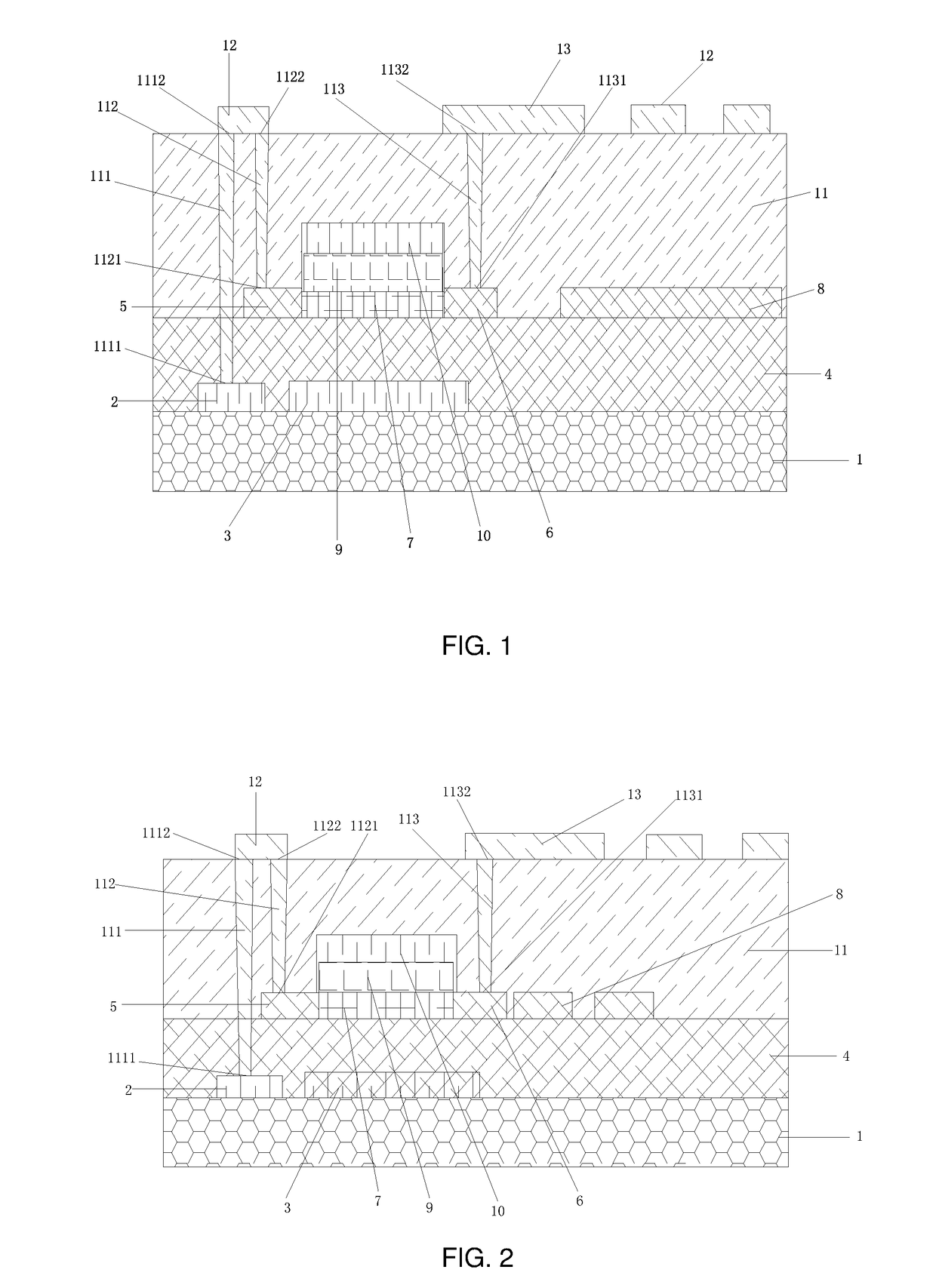

Array substrate, liquid crystal display panel and manufacturing method

ActiveUS20180217458A1Improve conductivityReduce the amount requiredTransistorSolid-state devicesLiquid-crystal displayDoped oxide

The disclosure discloses an array substrate, a liquid crystal display panel and a manufacturing method, the array substrate includes designing a data line layer and a light shield layer on a same layer, moreover, a source electrode layer, a drain electrode layer, an oxide semiconductor layer and a common electrode layer are designed on a same layer, the source electrode layer, the drain electrode layer and the common electrode layer are formed by doping the oxide semiconductor material, the source electrode layer, the drain electrode layer and the common electrode layer can be conductive by increasing conductivity thereof. By the method above, the disclosure can reduce the amount of masks in processes and costs in production significantly.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

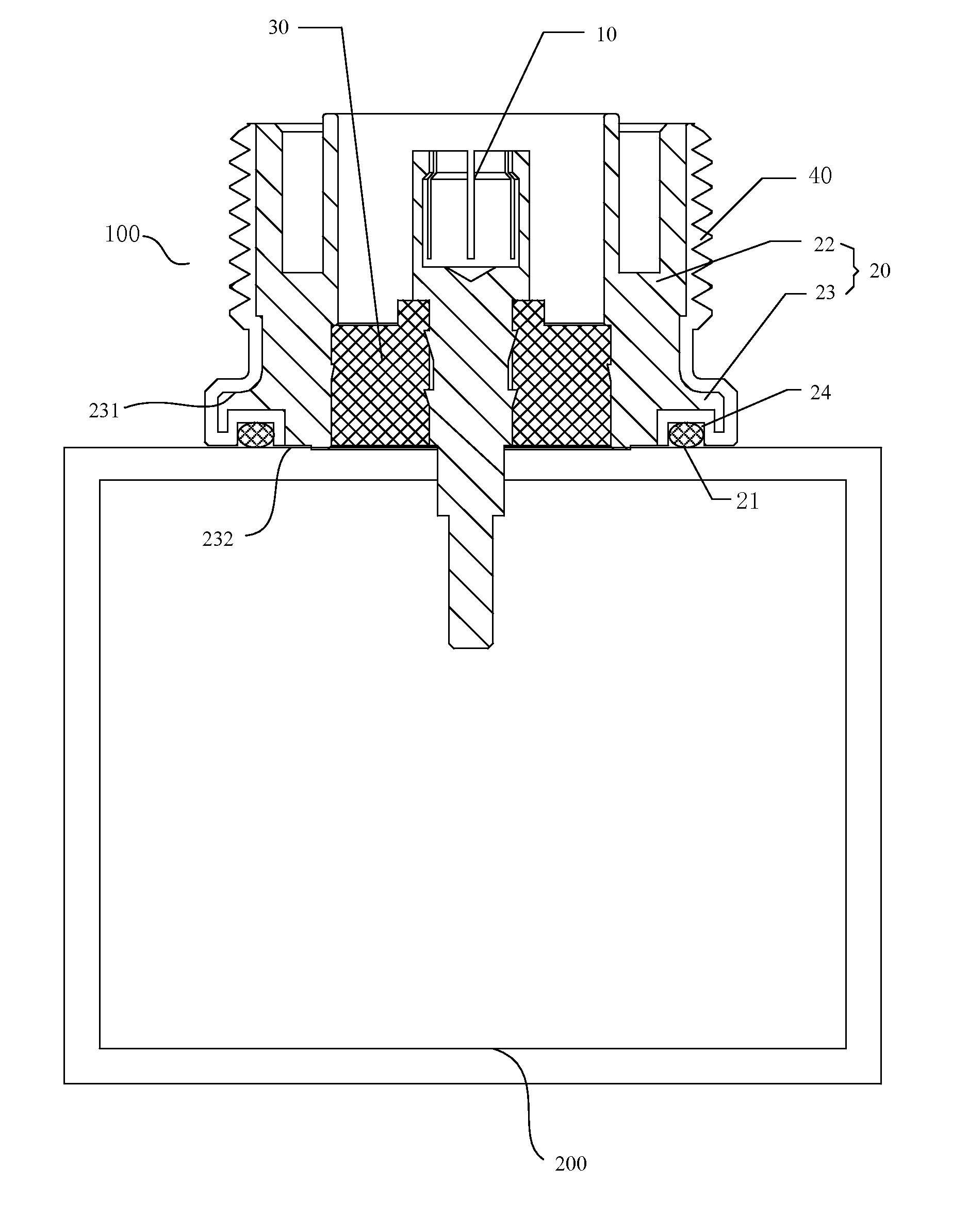

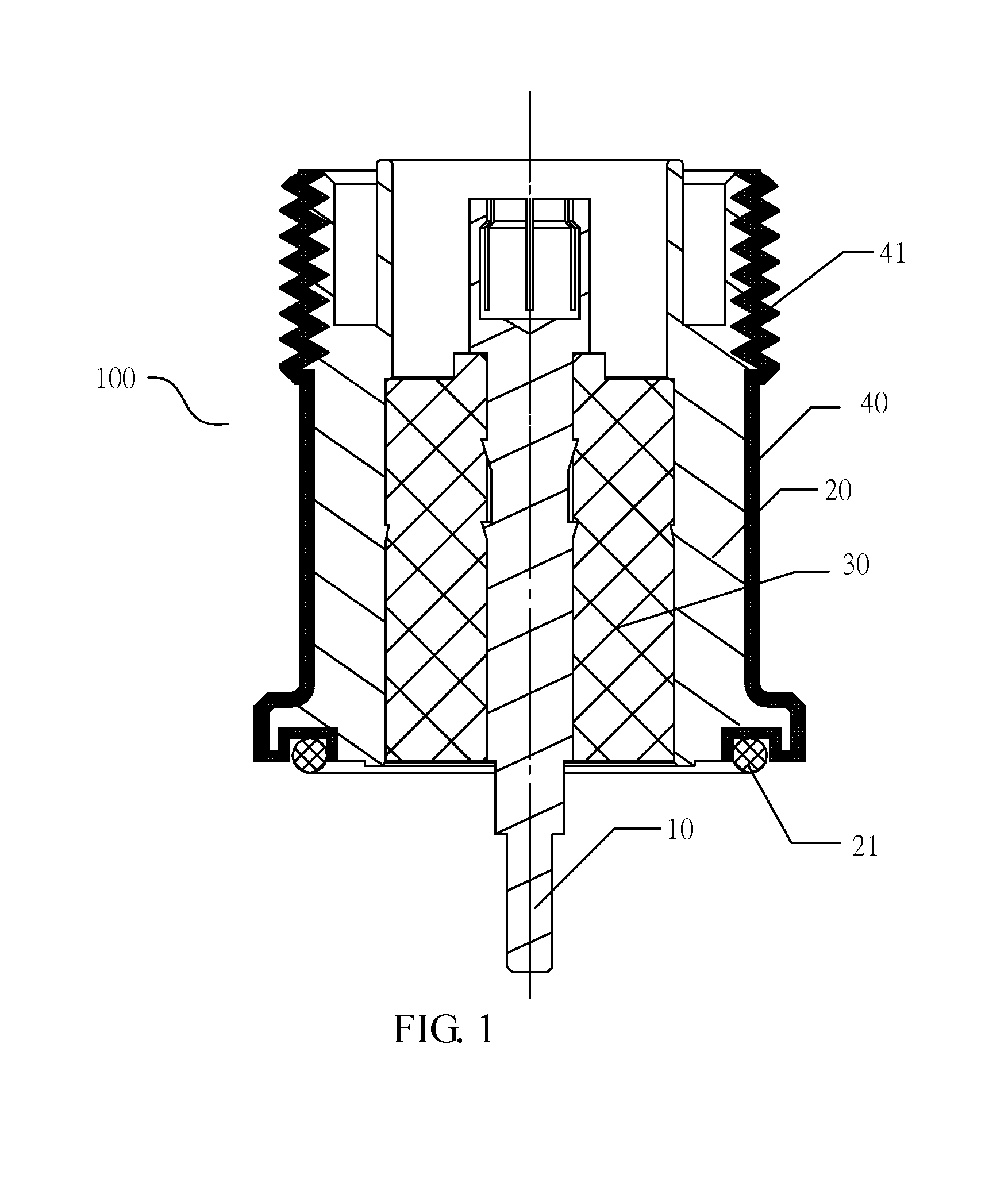

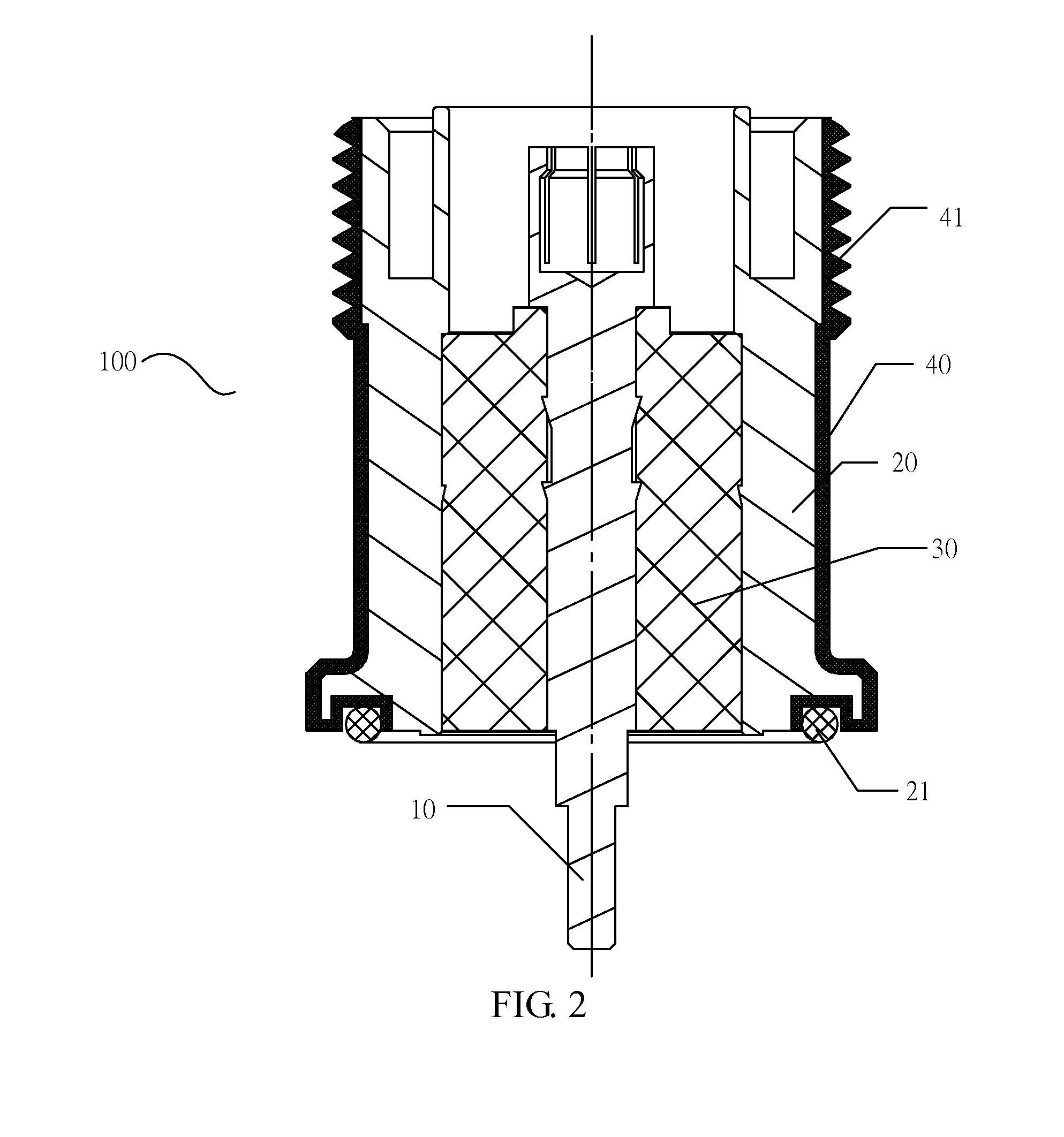

Cavity filter, connector and manufacturing processes thereof

ActiveUS20150061794A1Improve the environmentLess human interventionLine/current collector detailsCoupling contact membersElectrical conductorManufacturing technology

The present disclosure relates to a cavity filter, a connector and manufacturing processes thereof. The cavity filter comprises a cavity, a cover plate and a connector disposed on the cavity or the cover plate; an end of the connector is connected with internal devices inside the cavity filter and the other end of the connector is connected with external communication devices; and the connector comprises an inner conductor and a metal enclosure disposed coaxially and an insulation medium disposed between the metal enclosure and the inner conductor, and a non-metal layer is disposed on an outer peripheral surface of the metal enclosure. The connector of the present disclosure is formed with a non-metal layer on the outer peripheral surface of the metal enclosure thereof, which can improve the moisture-proof capability, the salt-mist-proof capability, the mould-proof capability and the reliability of the connector and the cavity filter.

Owner:ANHUI TATFOOK TECH CO LTD

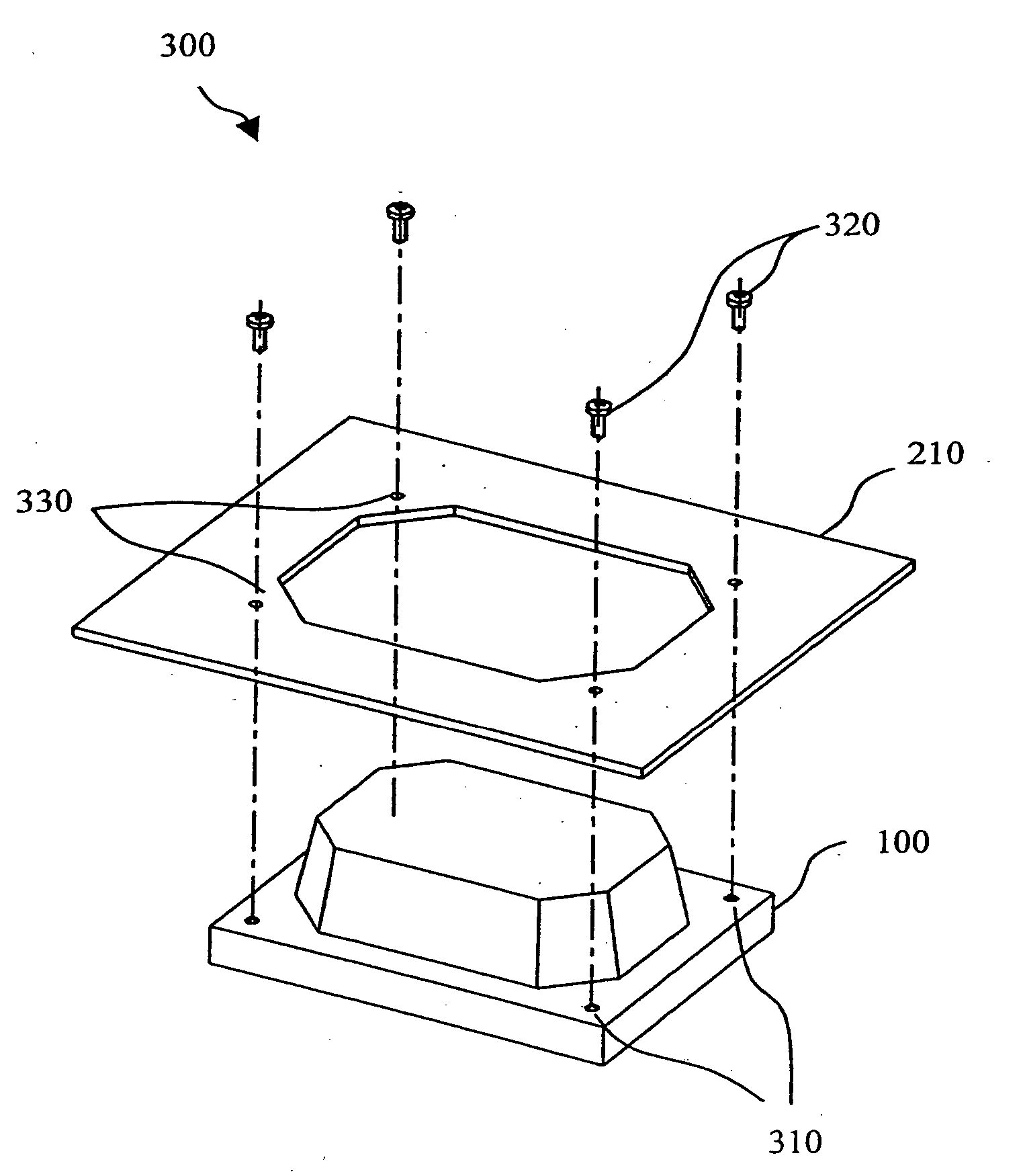

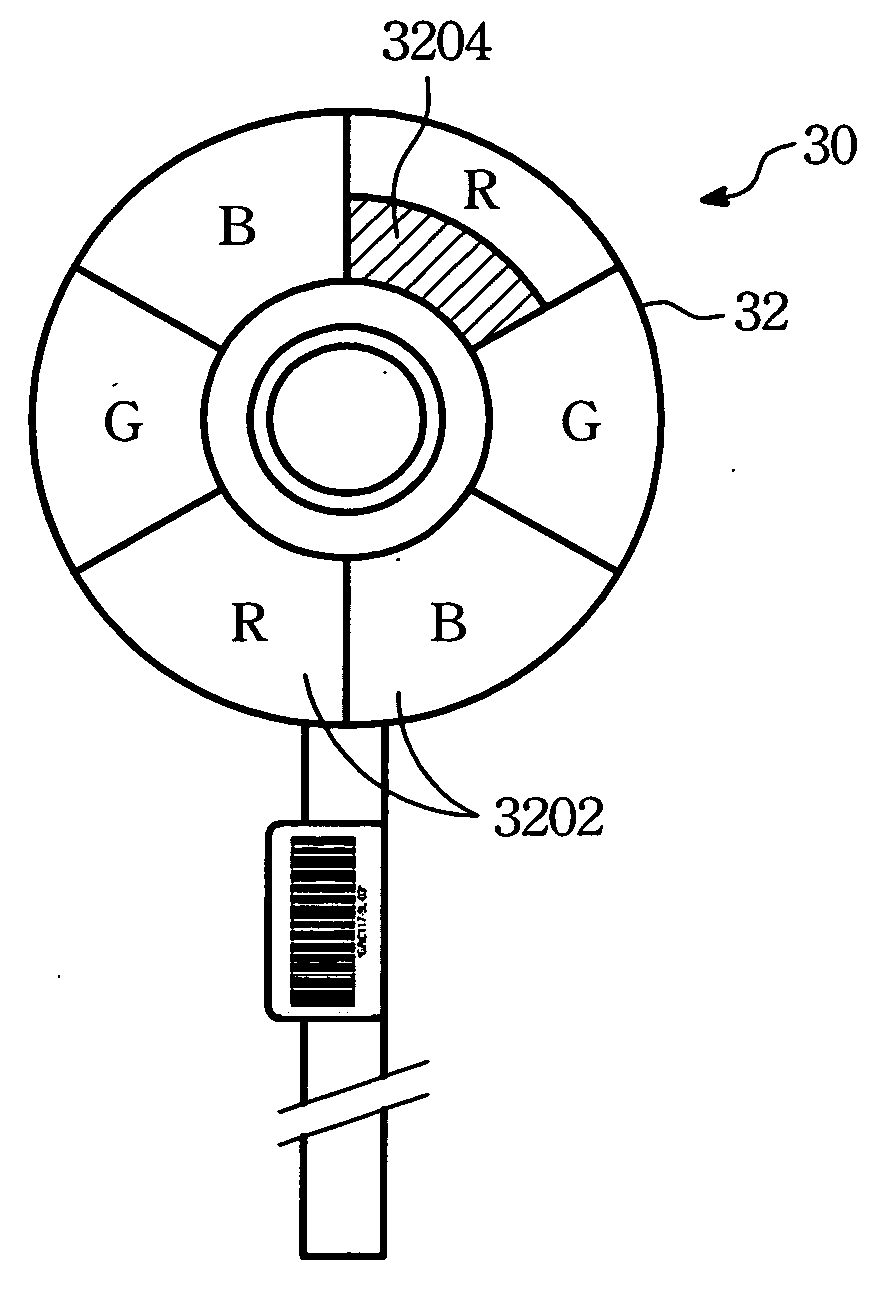

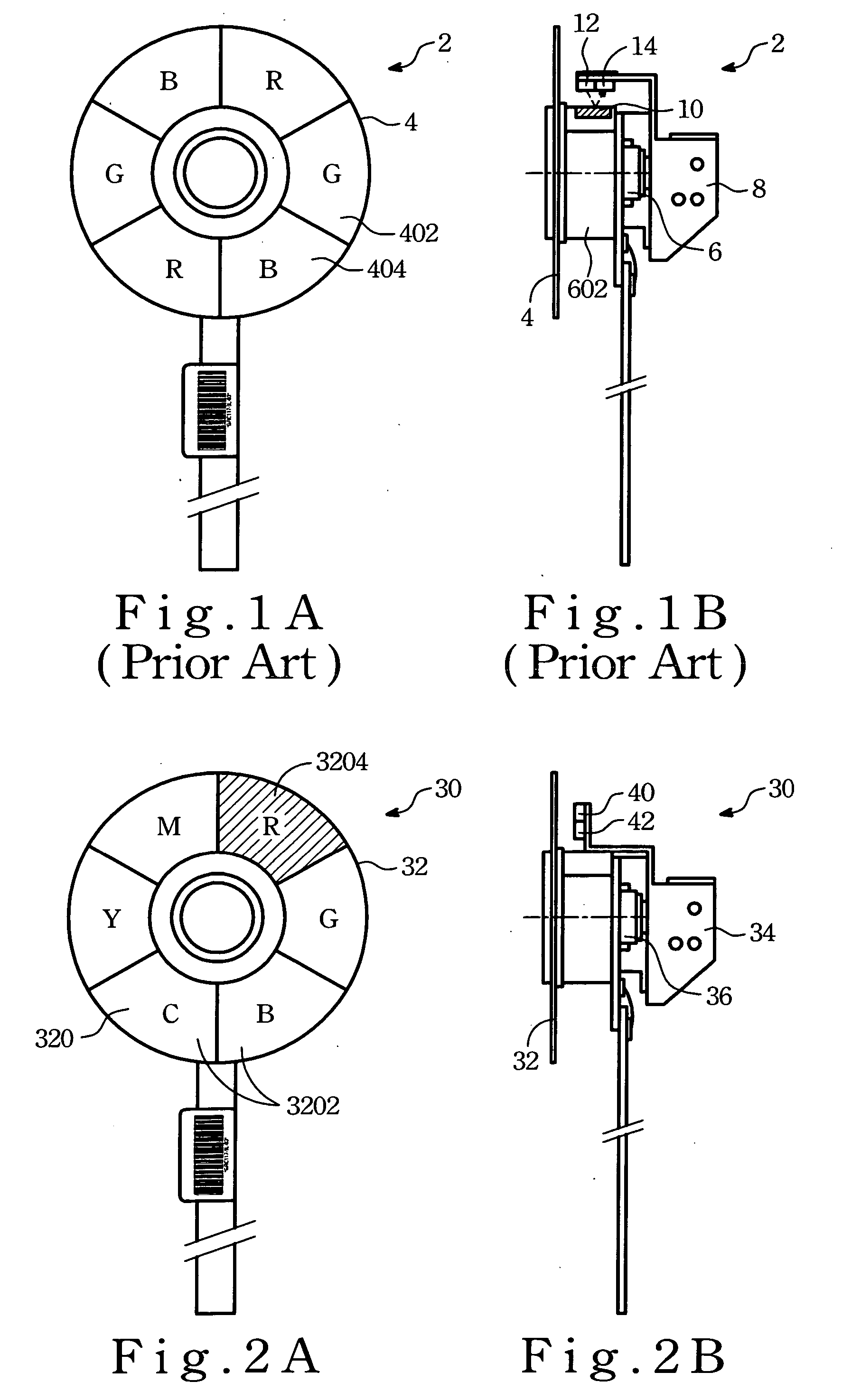

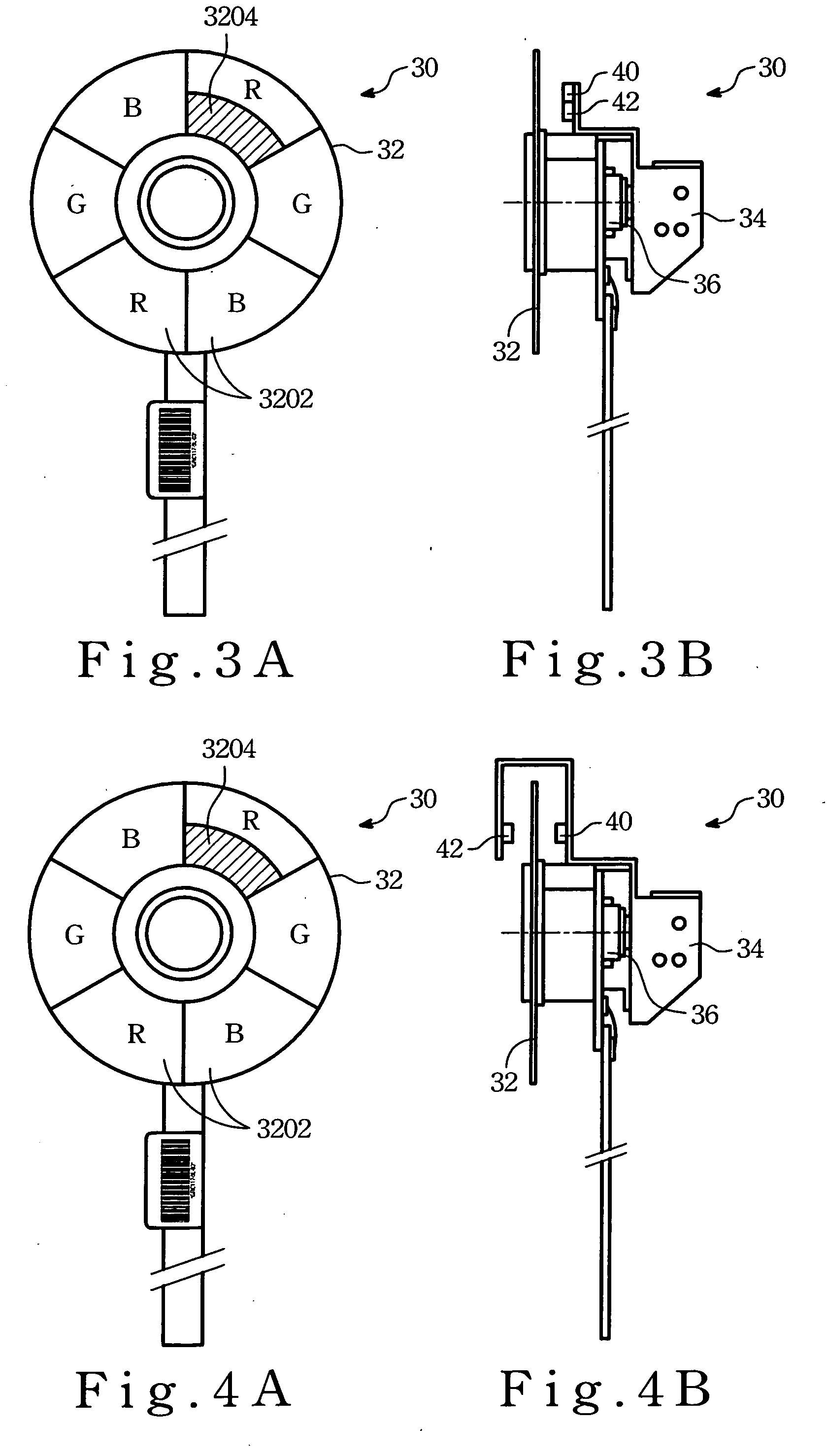

Color wheel module for a projection apparatus

InactiveUS20070102637A1Easy to detectEconomizing production costRadiation pyrometryProjectorsLight beamColor wheel

A color wheel module includes a color wheel having a side face defining a plurality of color regions and a detection region, a light source for emitting light beams toward the side face of the color wheel and a light detection device for detecting the light beams from the color regions and the detection region in order to locate position of the color regions and the detection region.

Owner:YOUNG OPTICS

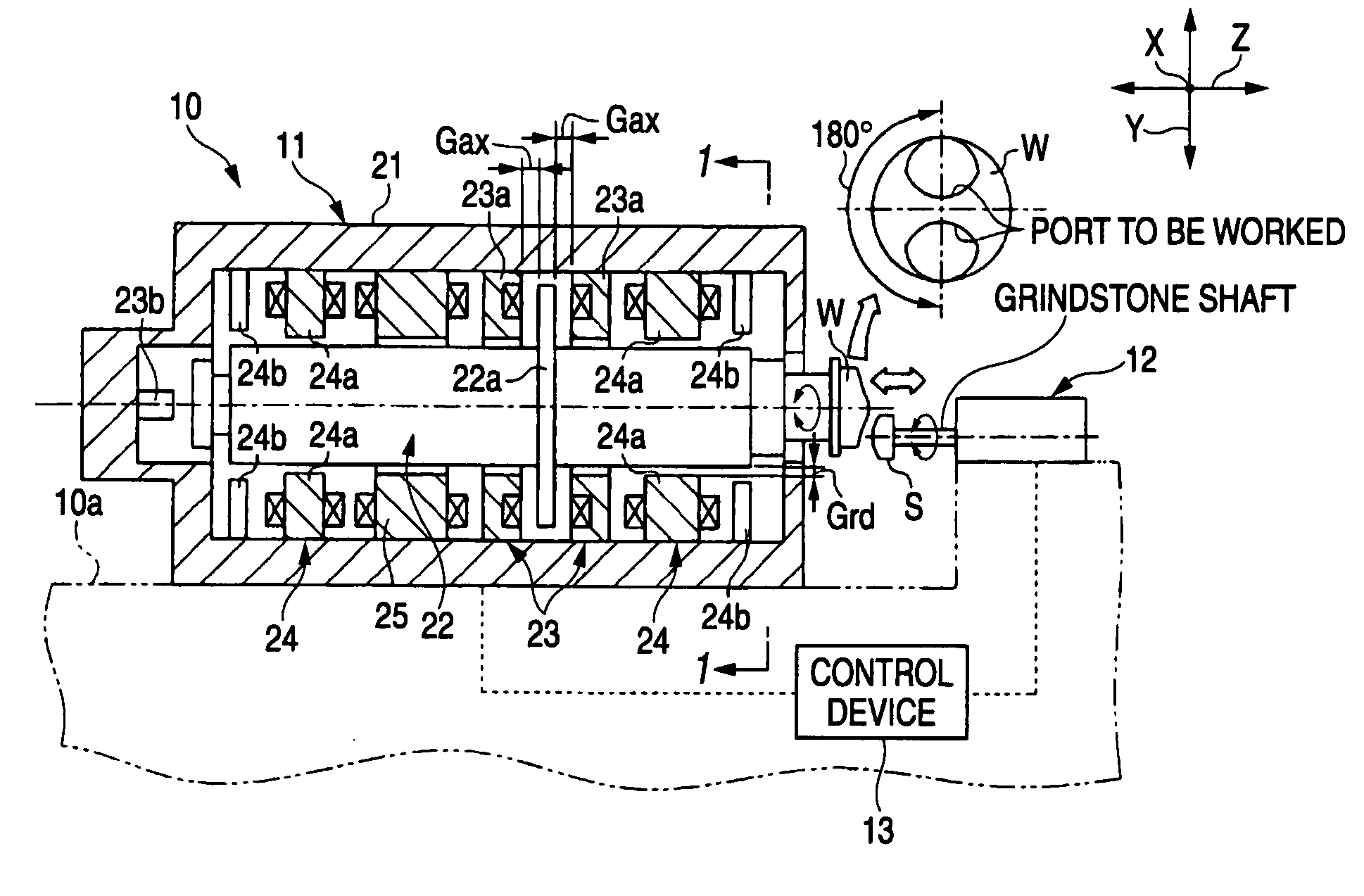

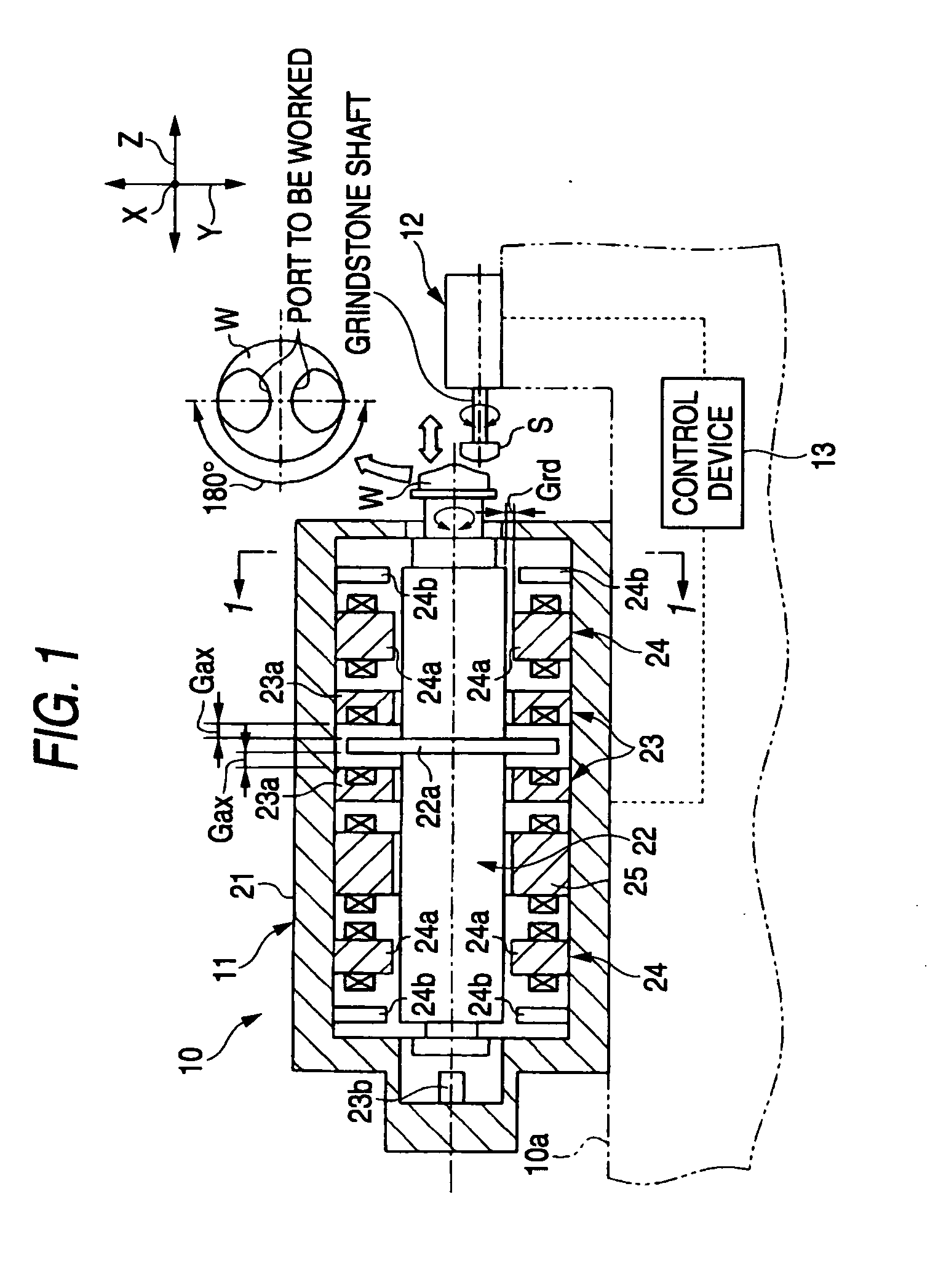

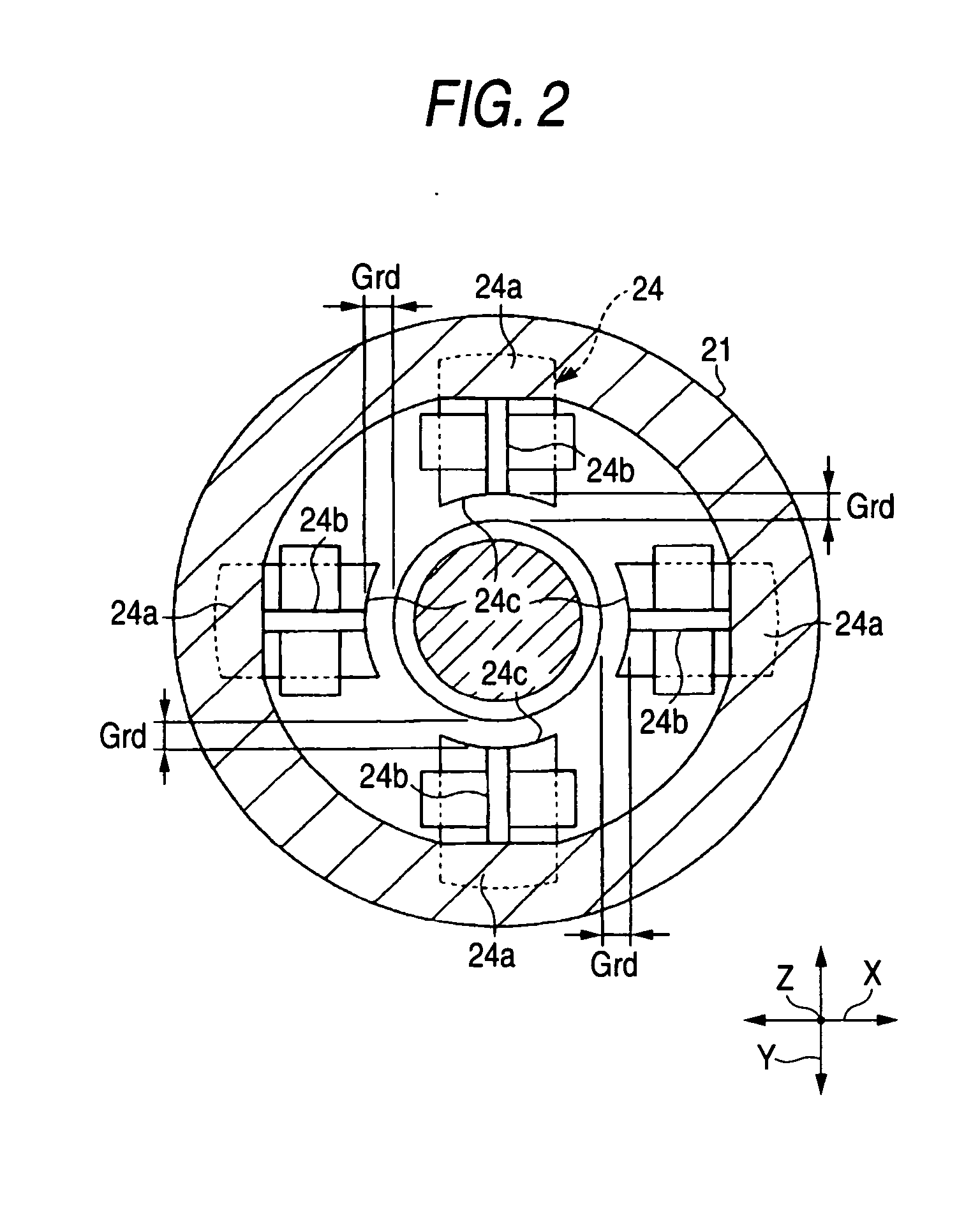

Magnetic bearing spindle device for machine tool

InactiveUS20080246358A1Increase speedImprove accuracyShaftsMeasurement/indication equipmentsMagnetic bearingBall screw

The control device displaces the main shaft in the axial direction and in the radial direction within the range of the gap between the rib member of the main shaft and the axial magnetic bearing and the gap between the main shaft and the radial magnetic bearings, by controlling the attraction forces of the axial electromagnets and the radial electromagnets, whereby the main shaft can be positioned. By controlling the axial magnetic. bearing and the radial magnetic bearings, it becomes possible to freely displace only the main shaft in the axial direction and in the radial direction, and therefore, the main shaft can be positioned at high speed and with high precision. Moreover, there is no necessity of providing the feeding mechanism in which the ball screw mechanism and linear motor etc. are employed for the purpose of displacing the magnetic bearing spindle device, and hence, reduction of the production cost for the grinding apparatus can be achieved.

Owner:JTEKT CORP

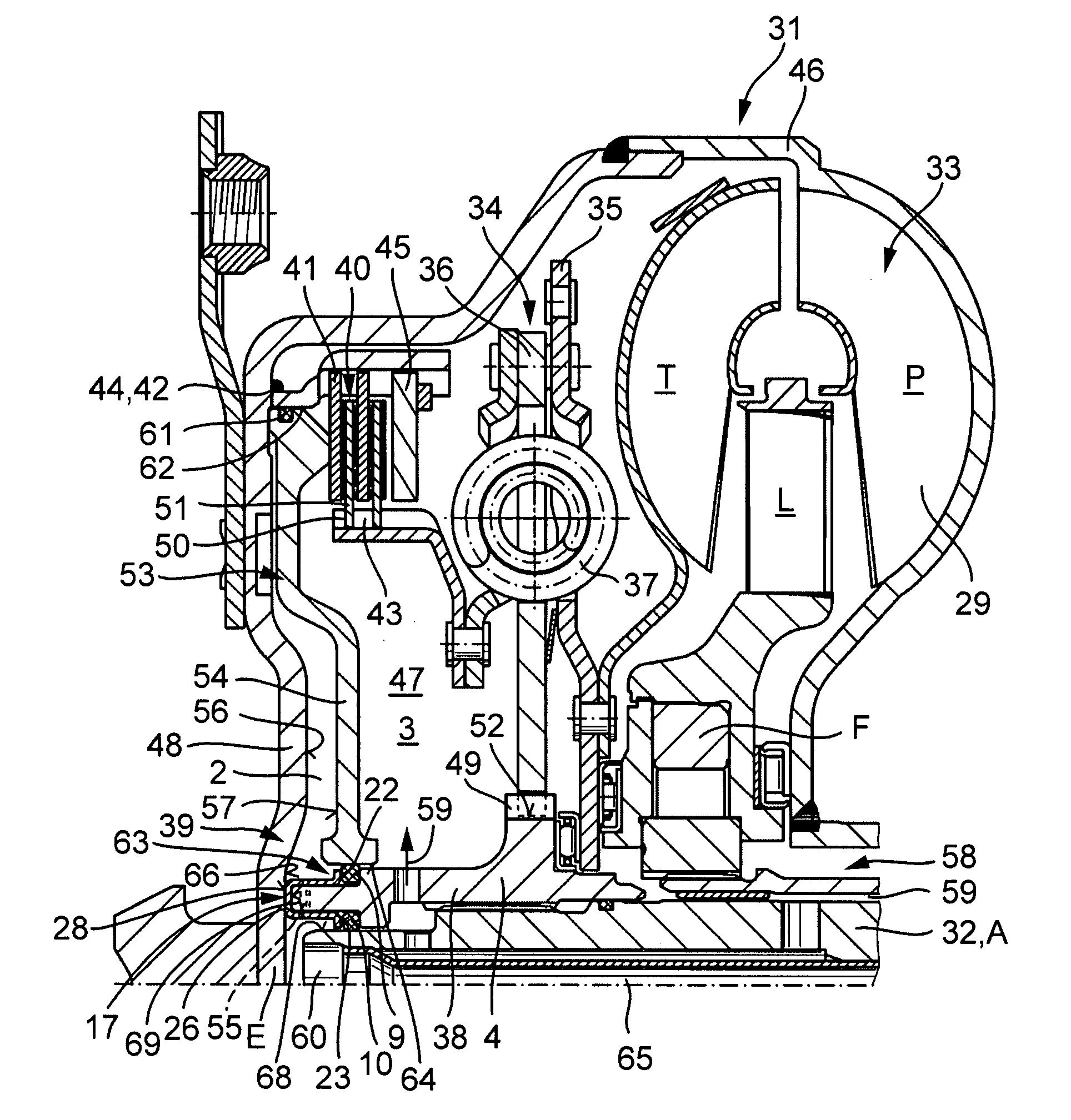

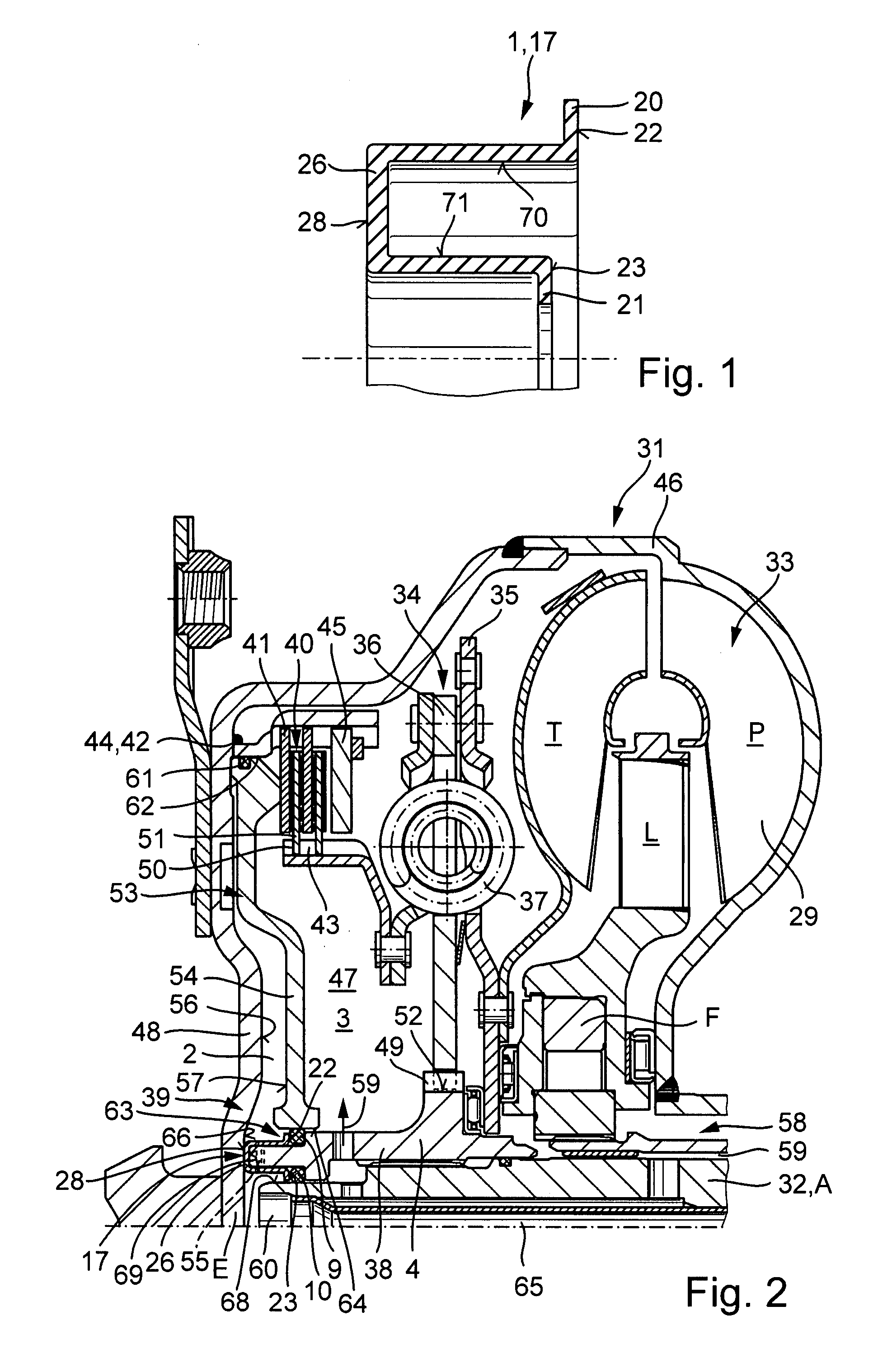

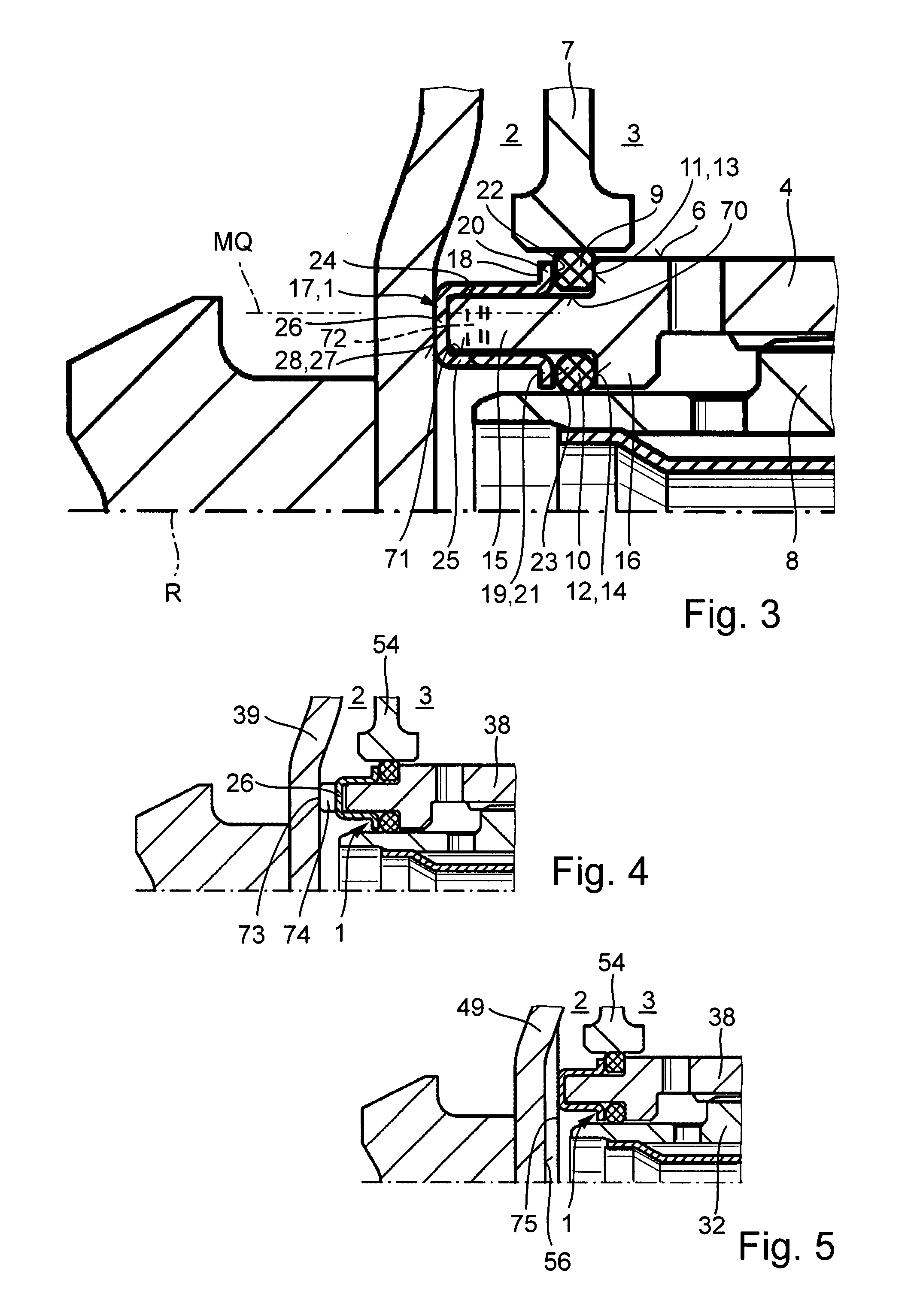

Seal retainer device and power transmission unit with seal retainer device

InactiveUS20080156129A1Possible effortPossible expenseEngine sealsYielding couplingEngineeringMechanical engineering

A seal retainer device for fixing the position of at least one sealing device, comprising at least one contact surface for fixing the position of a seal in the radial and / or axial direction, a first functional surface for linking to a component, and at least one second functional surface to form an axial or radial bearing sliding surface. In addition, the invention relates to a power transmission unit having a seal retainer that holds seals for sealing off two pressure chambers.

Owner:SCHAEFFLER TECH AG & CO KG

Solar selective absorber based on double nitride composite material and process for its preparation

ActiveUS20140130794A1Improve performanceIncrease absorbanceMirrorsSolar heat devicesThin membraneAbsorption layer

A thin-film spectrally selective coating for receiver tube of vacuumed type for use in thermodynamic solar installations and operating both at medium temperature (up to 400° C.) and at high temperature (up to 550° C.), coating where the optically absorbing layer is a multilayer of cermet material of type: WyN—AlNx or MoyN—AlNx, material prepared with reactive co-sputtering technique from an Al target and a W or Mo target, process conducted under a transition regimen, under PFM (Plasma Emission Monitoring) or CVM (Cathode Voltage Monitoring) monitoring for the sole Al target, with inletting near the Al target of a N2 amount adequate for obtainment of a high-transparency, high growth rate sub-stoichiometric ceramic AlN and with inletting near the W or Mo target of a N2 amount adequate for obtainment of the sole W2N or Mo2N phase, phase very stable at high temperature, such as to make the cermet material as close as possible to the formulation W2N—AlNx or Mo2N—AlNx (with x comprised between 0.90 and 1.00, preferably 0.95) and, therefore, cermet material employable at least up to the temperature of 550° C.

Owner:ENTE PER LE NUOVE TECH LENERGIA E LAMBIENTE ENEA

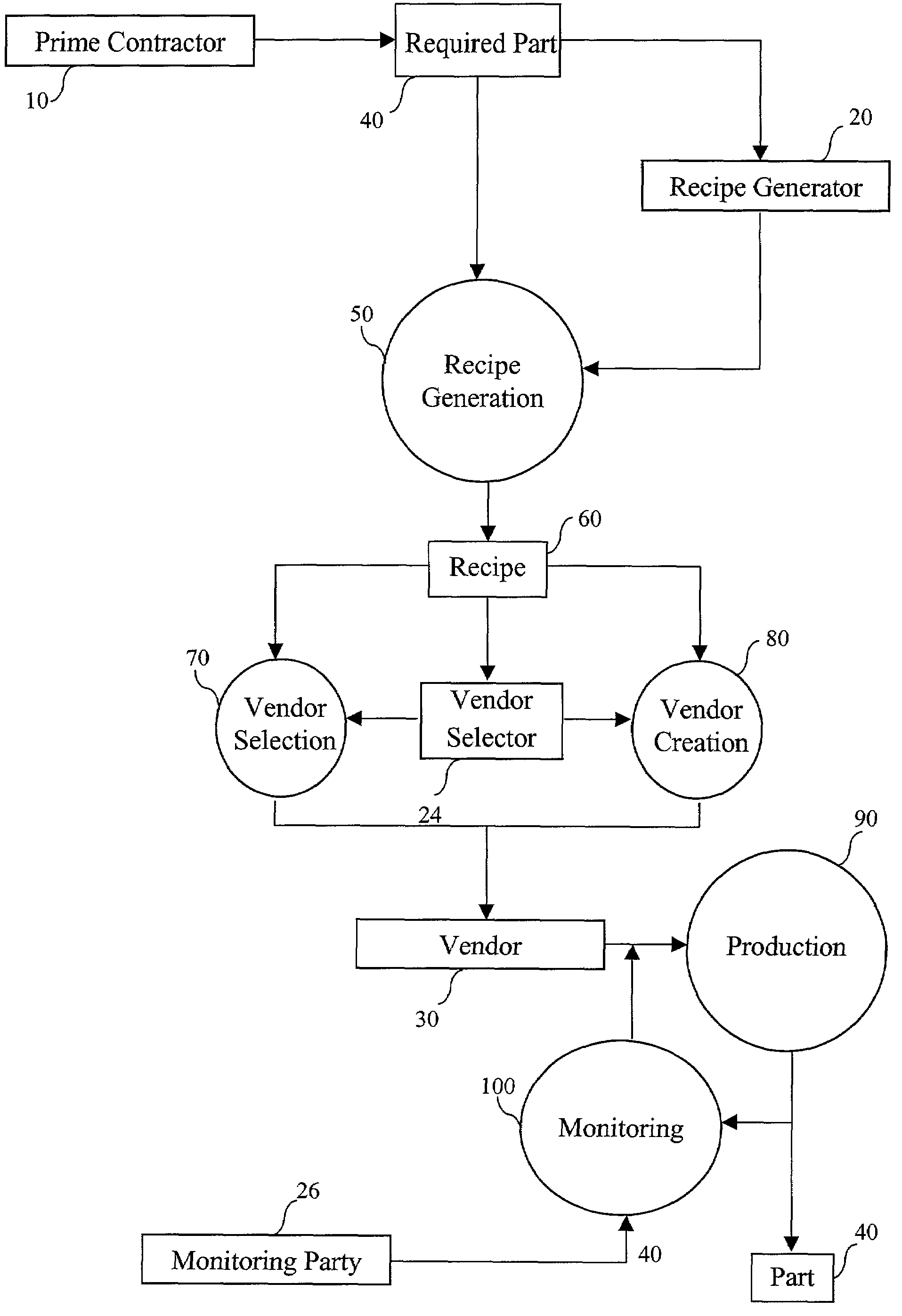

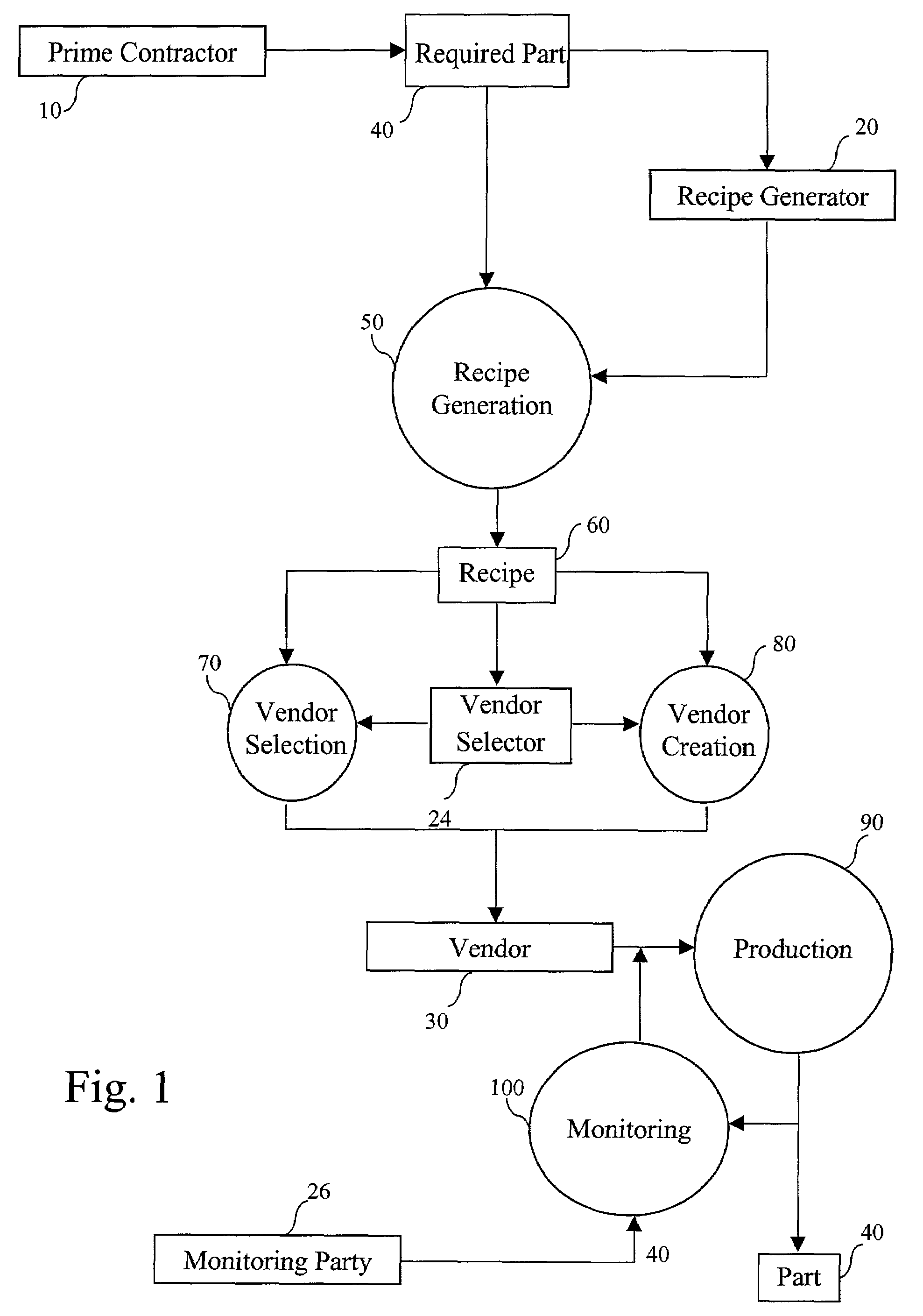

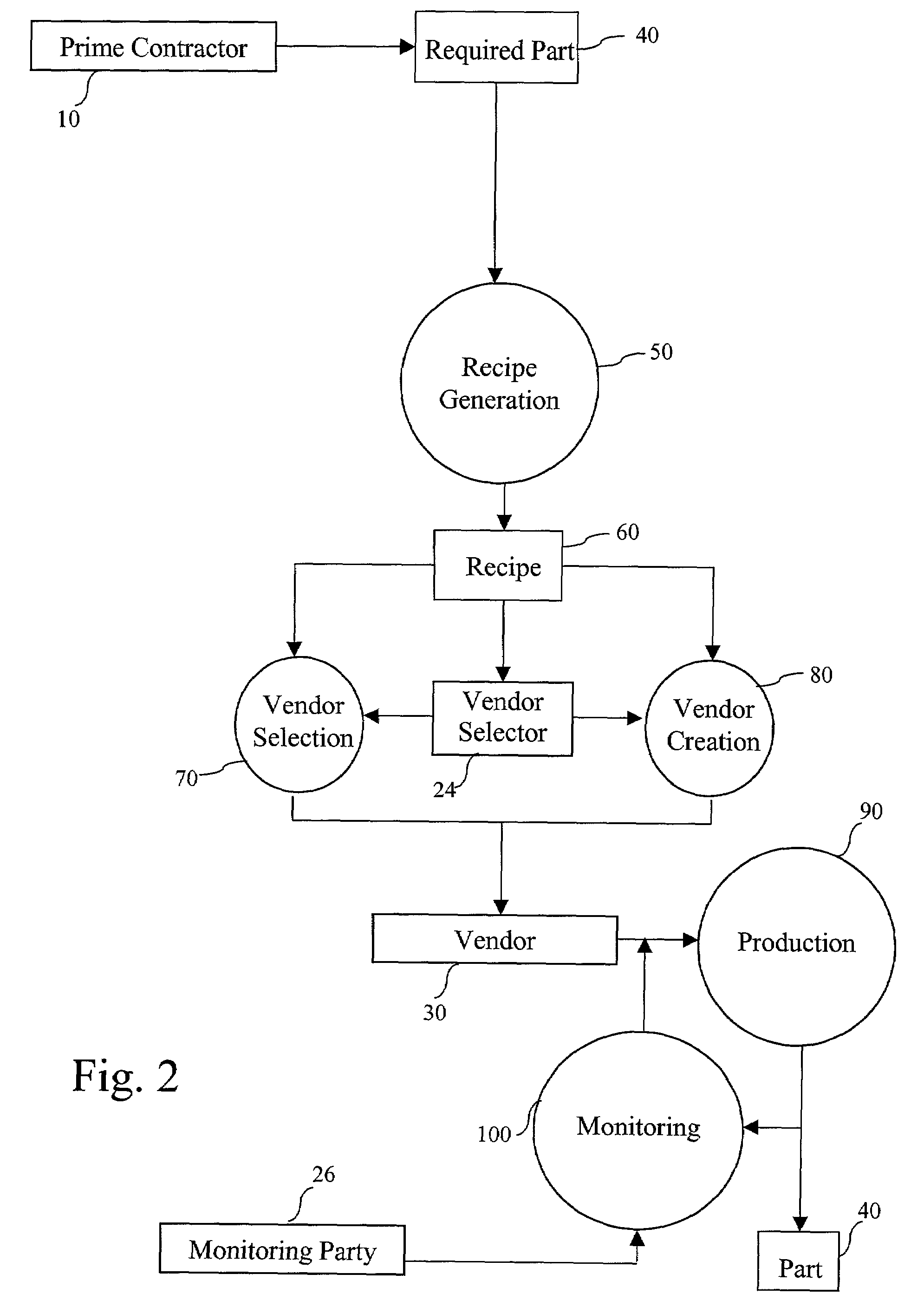

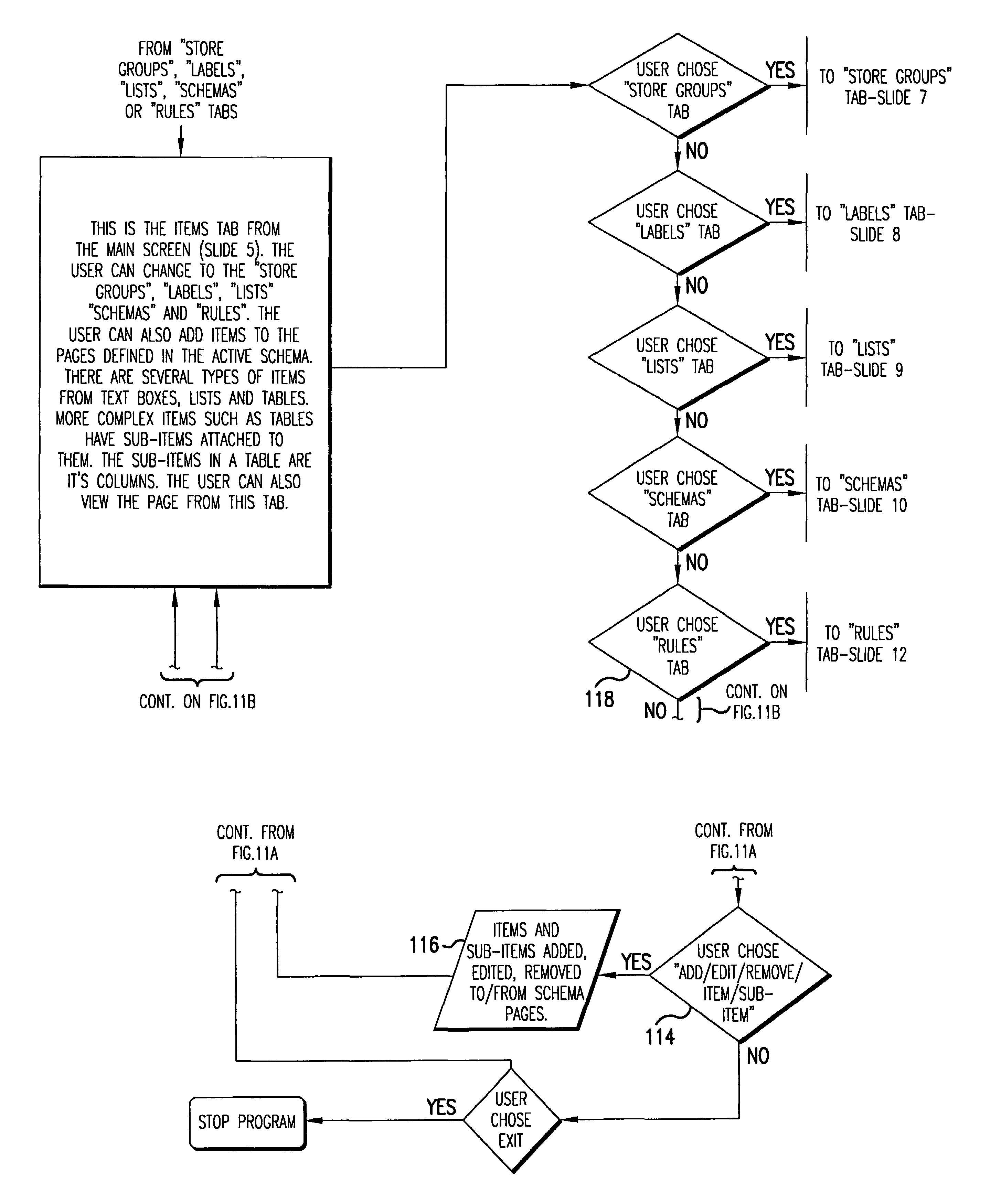

Method and system for optimizing manufacture of parts

InactiveUS7177713B2Efficient production processOptimally combineDigital data processing detailsBuying/selling/leasing transactionsOptimal combinationManufacturing engineering

The present invention discloses a method and system comprised of a combination of submethods and subsystems relating to the manufacture of parts. By these submethods and subsystems, the present invention discloses using part data, machine data, and tool data to create a recipe for the production of a part. Also included in the recipe is an optimal combination of machine and tooling derived from a database of machine and tooling performance measurements. Further included in the recipe are a process plan and production settings. A party can select or create a vendor by using the recipe and a database of vendor information. Also disclosed by the present invention is monitoring of the machining setup and production to ensure manufacture of the part according to the recipe. The present invention can be implemented in numerous methods and systems, including sales of the recipe and licensing of the part production according to the recipe.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT

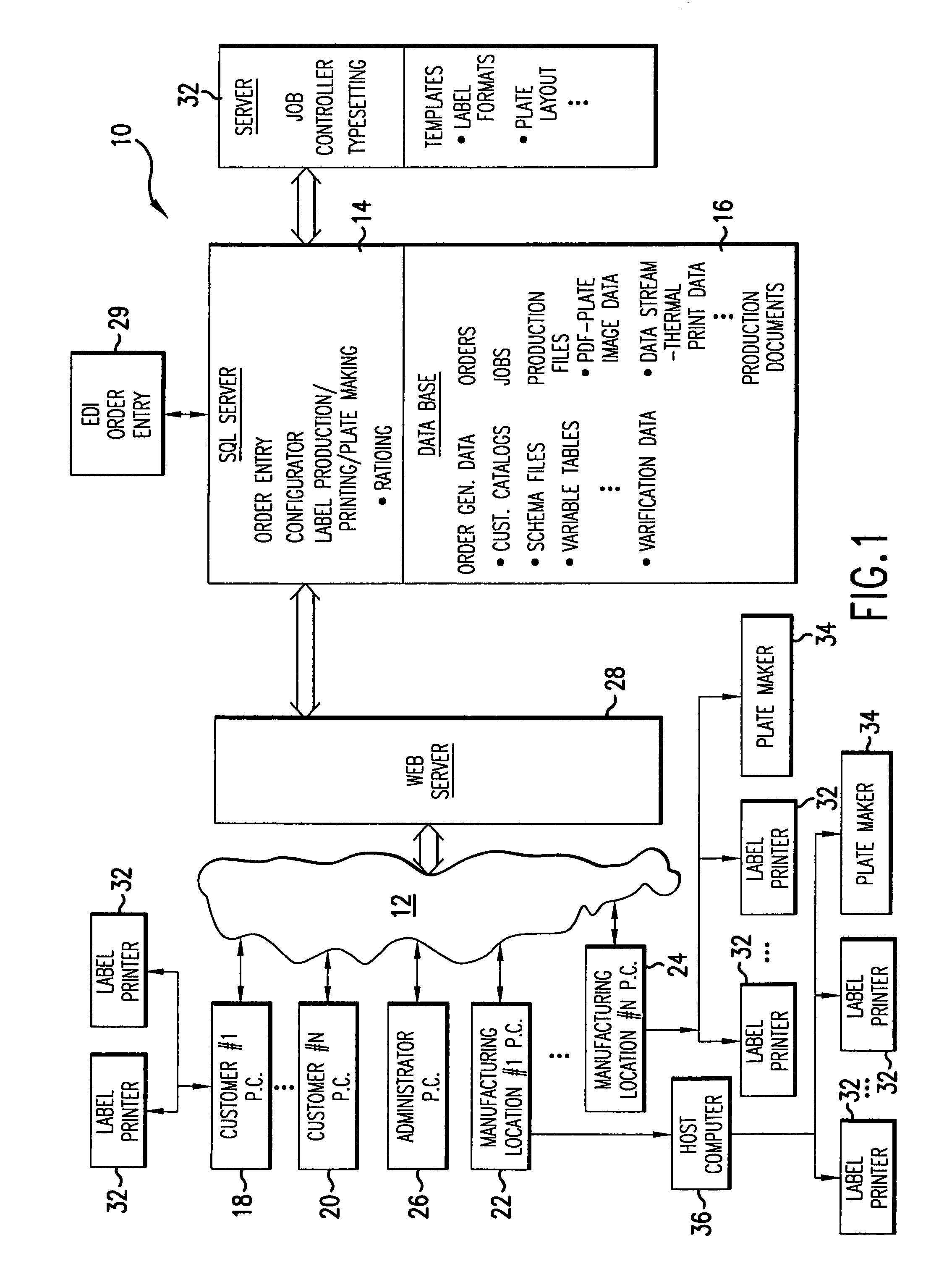

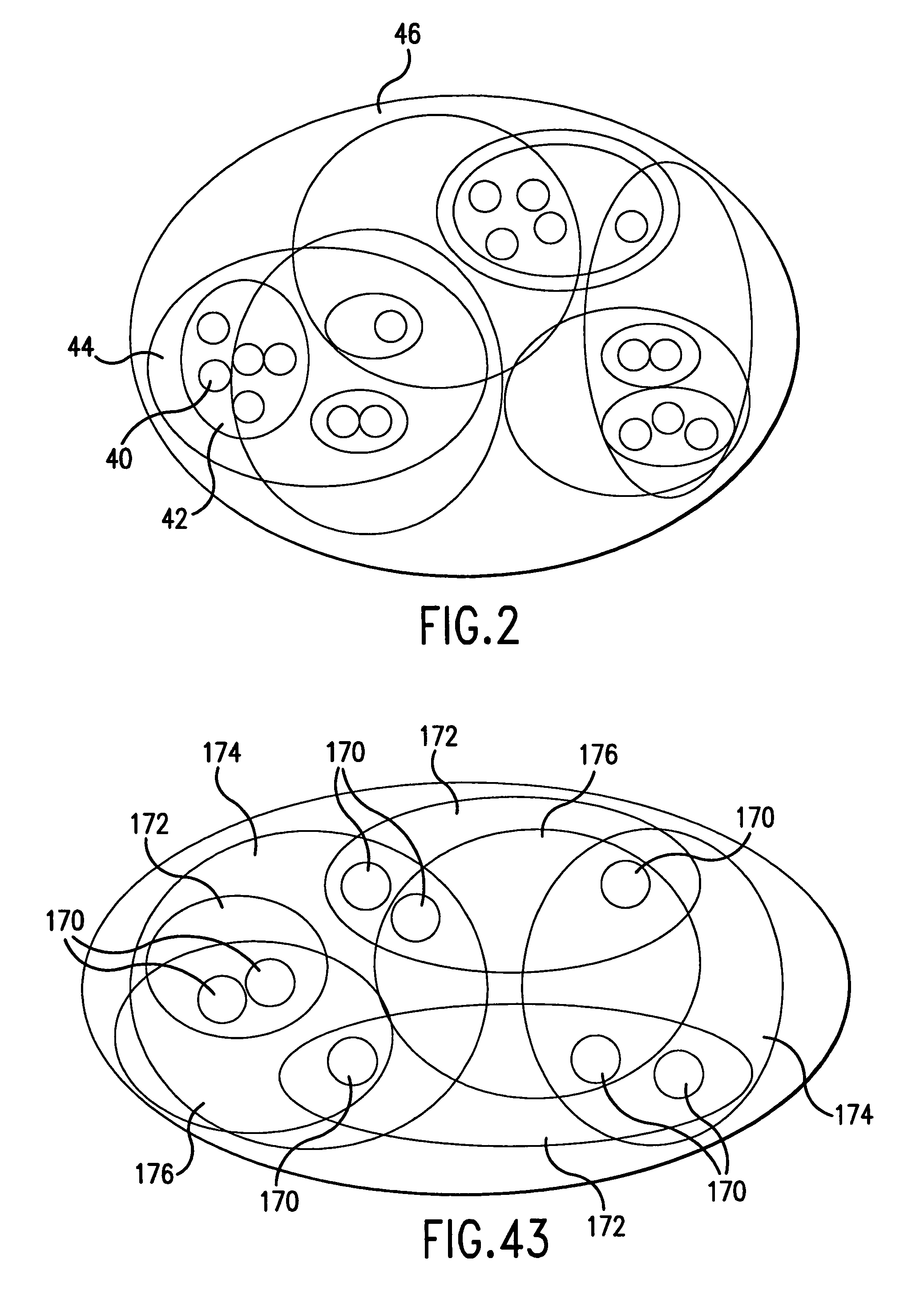

Internet label production system

InactiveUS7117211B2Overcome disadvantagesMinimize the numberData processing applicationsNatural language data processingData fileThe Internet

A system and method of producing labels at remote locations worldwide in communication with a server and central database via the internet is shown and described. The system and method also allows the ordering of labels at remote locations worldwide in communication with the server and central database via the internet. Automatic typesetting for label production is provided wherein various types of production, image data files are generated in accordance with different requirements from various customers and wherein the generated production files can be used directly by the production machines for which they were generated, different types of production files being automatically generated for different types of production machines or printing methods. The system and method of the present invention accommodates vastly different printing methods including thermal printing, lithographic printing, etc.

Owner:PAXAR CORP

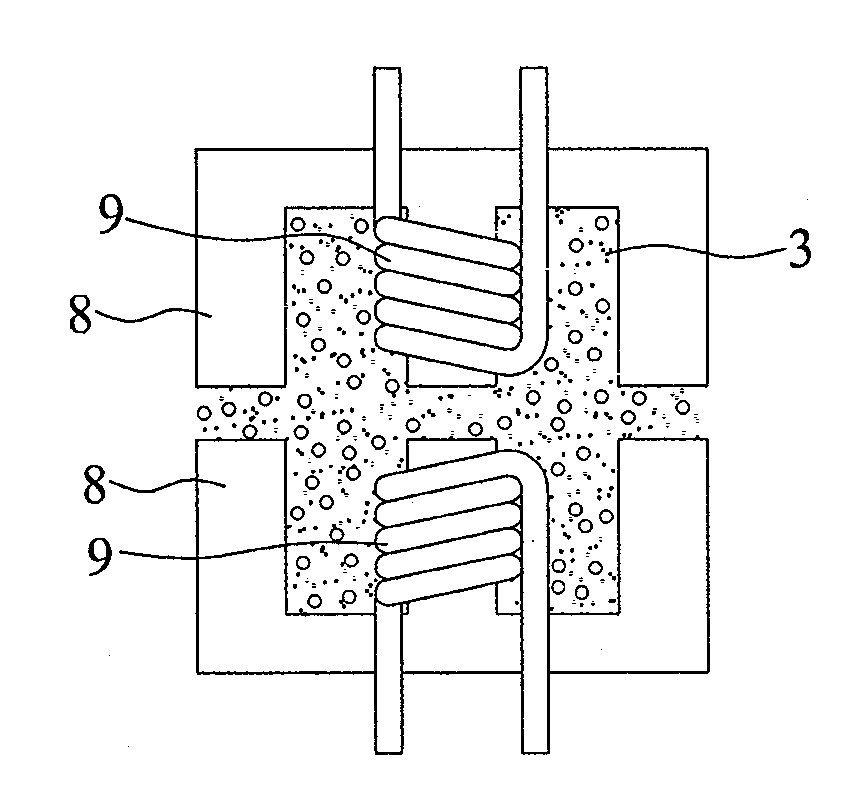

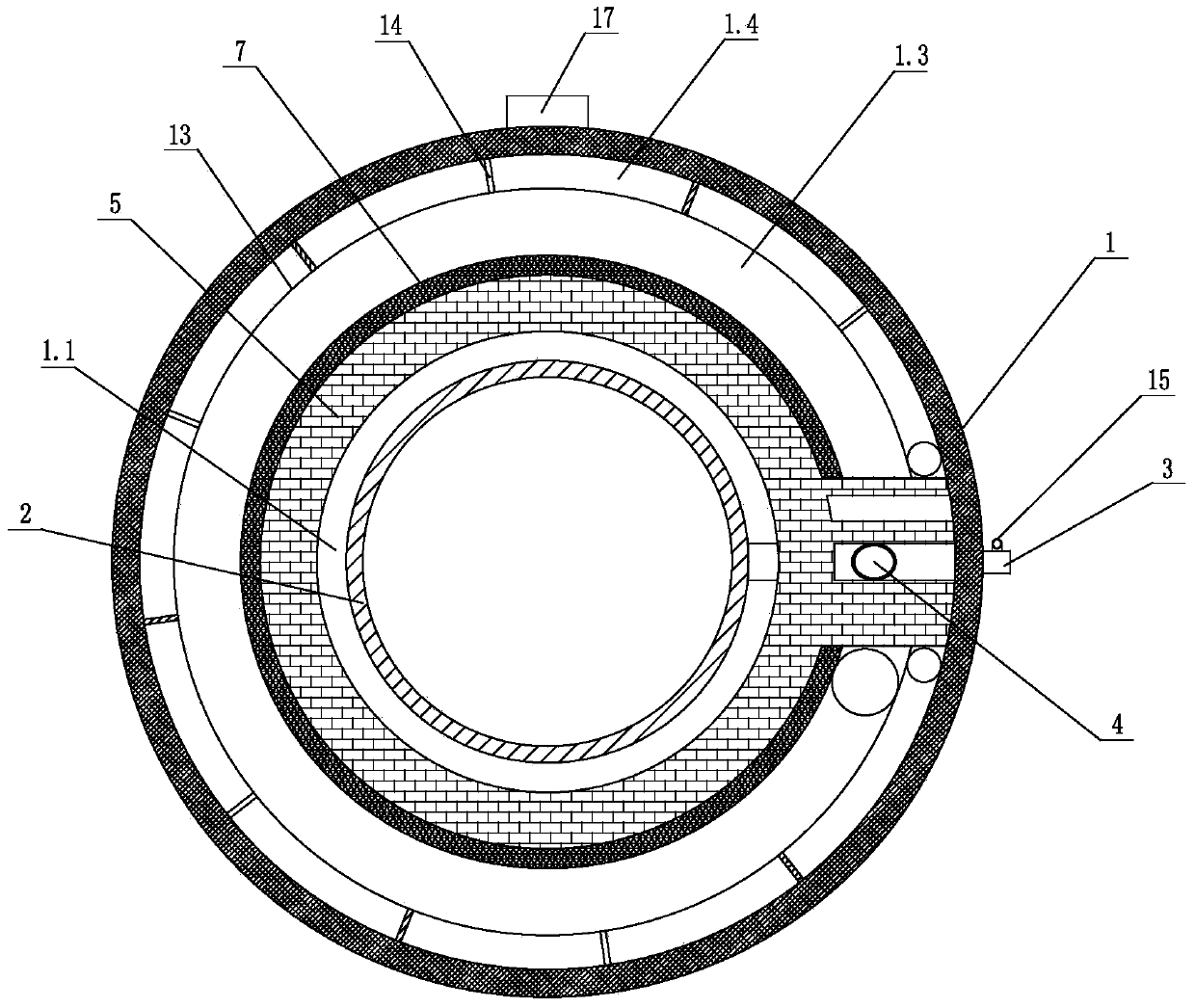

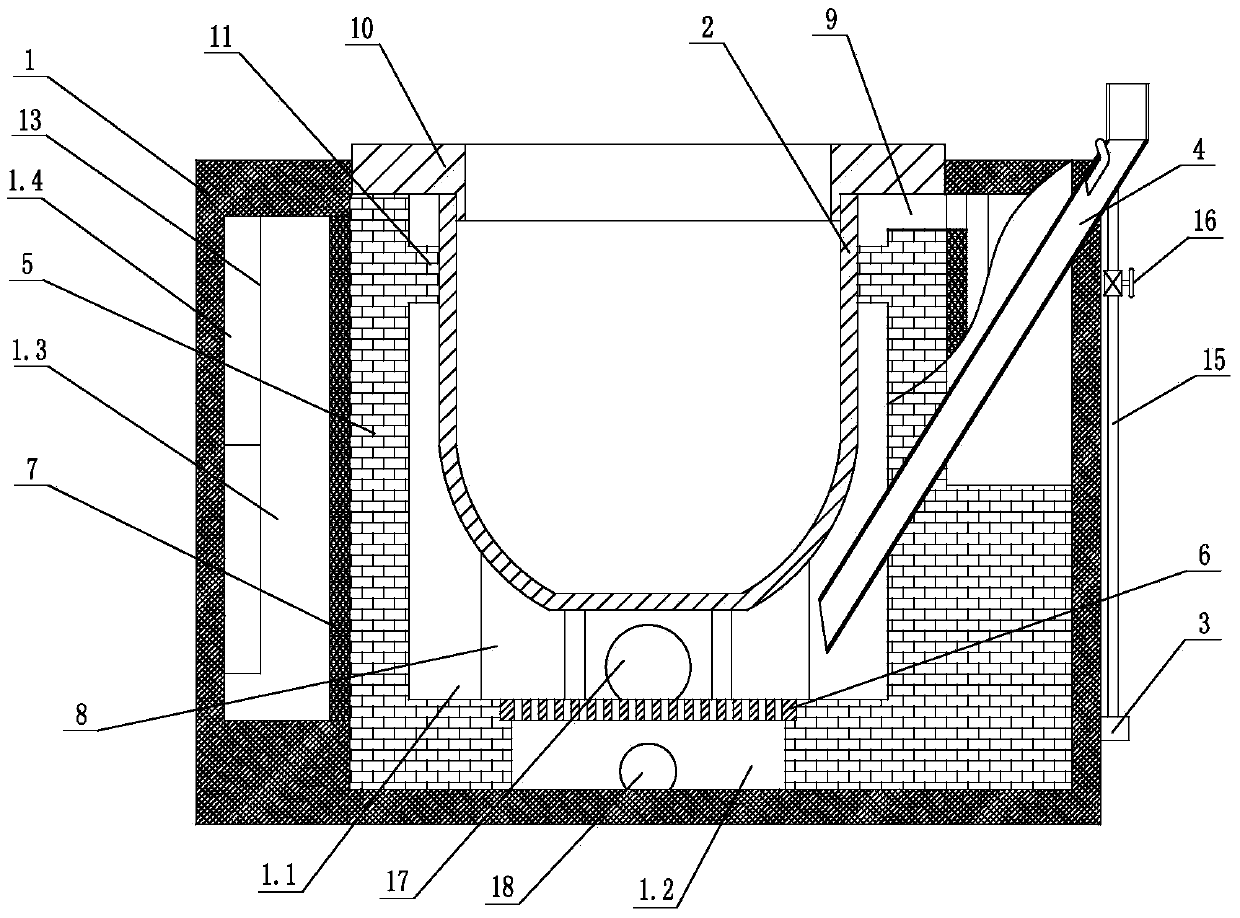

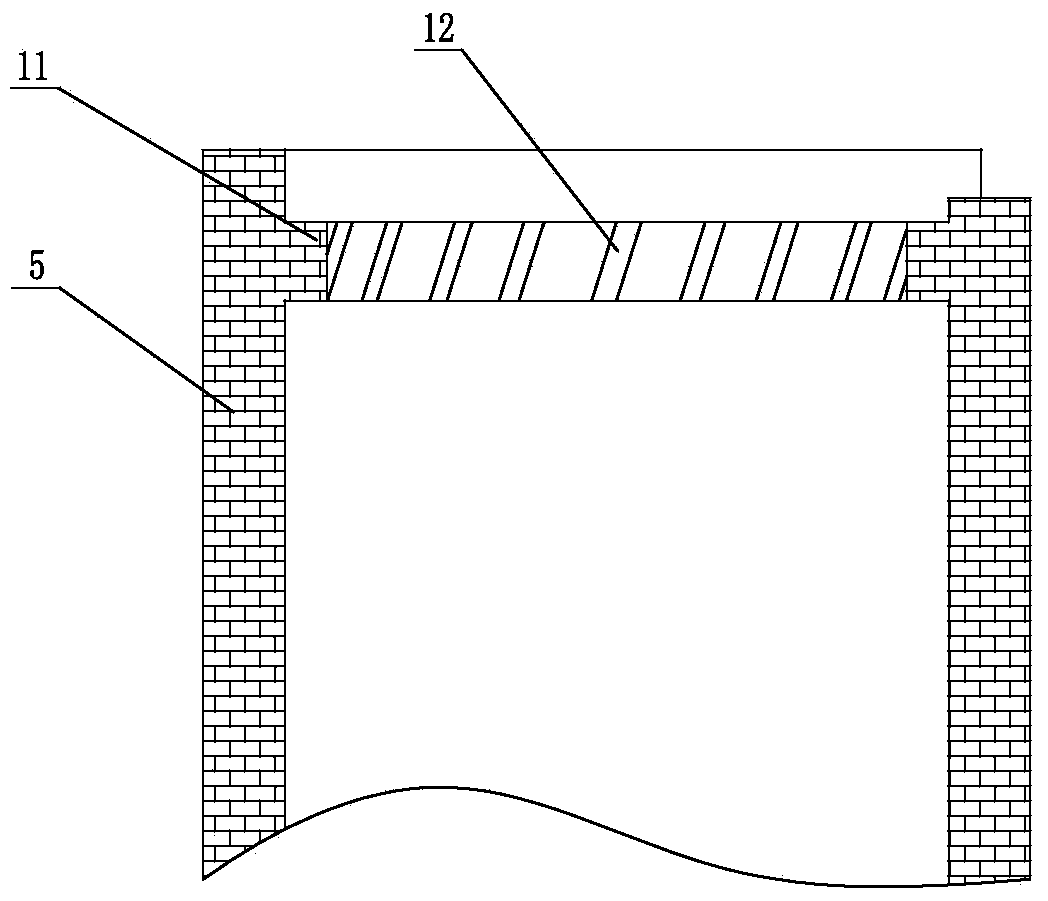

Biomass fuel aluminum melting furnace

InactiveCN103994658AImprove heat utilizationReduce energy consumptionCrucible furnacesFlueCombustion chamber

A biomass fuel aluminum melting furnace comprises a furnace body (1), a crucible (2), an air inlet (3) and a feeding pipe (4). A cavity is arranged in the furnace body (1) and is formed by separating the furnace body (1) through a refractory brick layer (5). A smoke channel (1.3) and a gas inlet channel (1.4) are arranged in the space between the refractory brick layer (5) and the inner wall of the furnace body (1) and is formed by separating the furnace body (1) through a heat-conducting material layer (13), wherein the inlet and the outlet of the smoke channel (1.3) are located at the two ends of a C-shaped structure respectively, the inlet and the outlet of the gas inlet channel (1.4) are also located at the two ends of the C-shaped structure respectively, the inlet of the gas inlet channel (1.4) is communicated with the air inlet (3), and the outlet of the gas inlet channel (1.4) is communicated with an ash chamber (1.2). One end of the feeding pipe (4) is located in a combustion chamber (1.1), and the other end of the feeding pipe (4) is located outside the furnace body (1). Compared with the prior art, the biomass fuel aluminum melting furnace has the advantage that the crucible is capable of being evenly heated, long in service life, high in heat exchange efficiency, low in energy consumption, good in use stability and low in aluminum melting production cost.

Owner:NINGBO YILONG NEW ENERGY CO LTD

Base material for high temperature alloy and manufacture methodthereof

ActiveUS20140224446A1Low production costLower production costAngiosperms/flowering plantsCrucibleMaterials science

The present invention relates to a base material for high temperature alloy and a process for manufacturing the same. The base material includes following components (by weight): 10-45% Cr, 0.5-12% Nb, 0.7-2.5% Ti, ≦9.0% Mo, ≦8.0% W, ≦2% Mn, ≦1.0% Si, ≦2.0% Al, ≦0.5% C, ≦0.032% O, ≦0.032% N,≦0.01% S, ≦0.02% P, and balance being Fe and unavoidable impurities. The process for manufacturing the base material for high temperature alloy includes following steps: providing raw materials according to the target composition; charging the raw materials in a crucible uniformly layer and layer according to a certain sequence, smelting in vacuum condition; after the materials being melted completely, holding the melt at a temperature; and casting ingot, and cooling to obtain a base material for high temperature alloy.

Owner:NINGXIA ORIENT TANTALUM IND

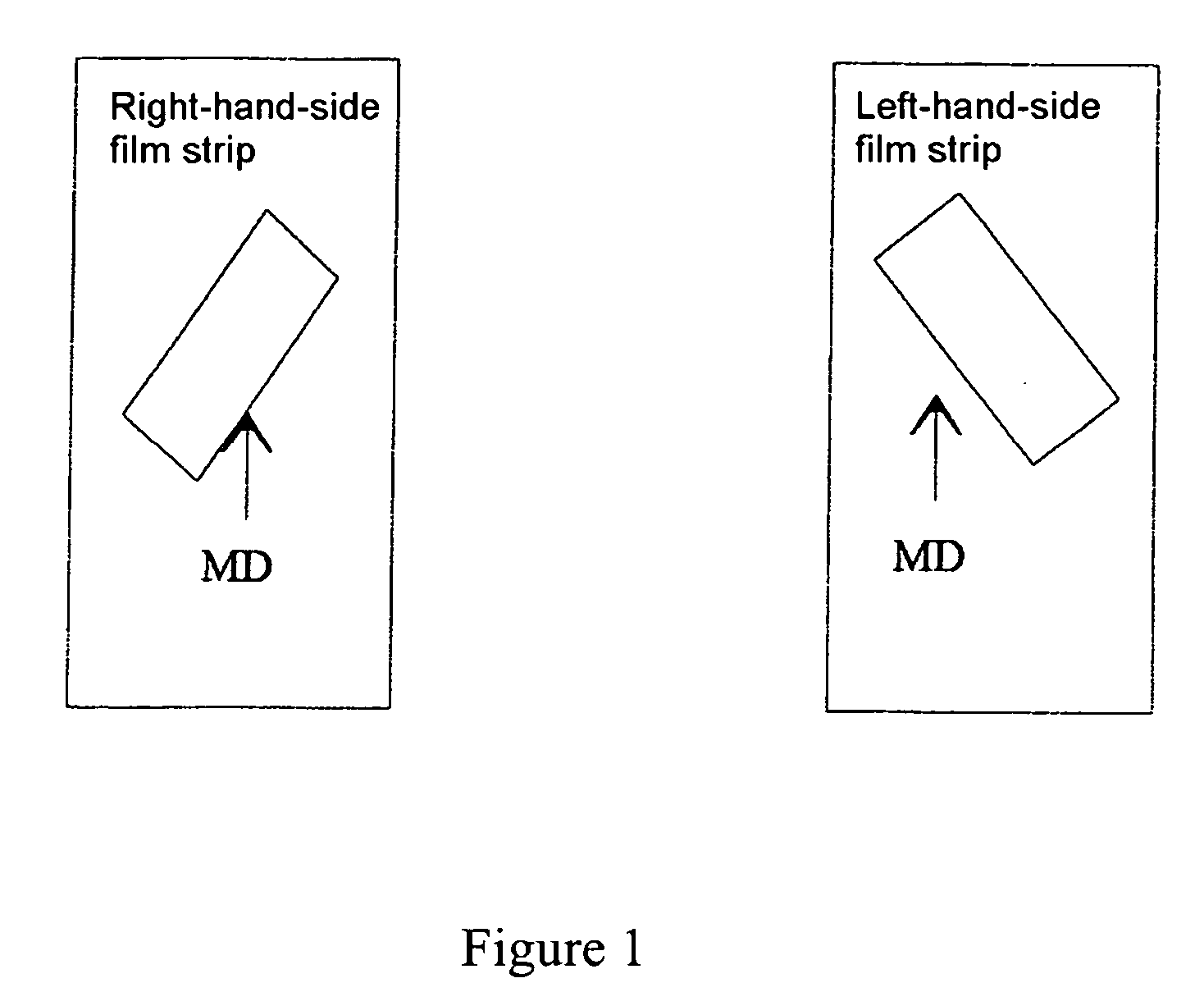

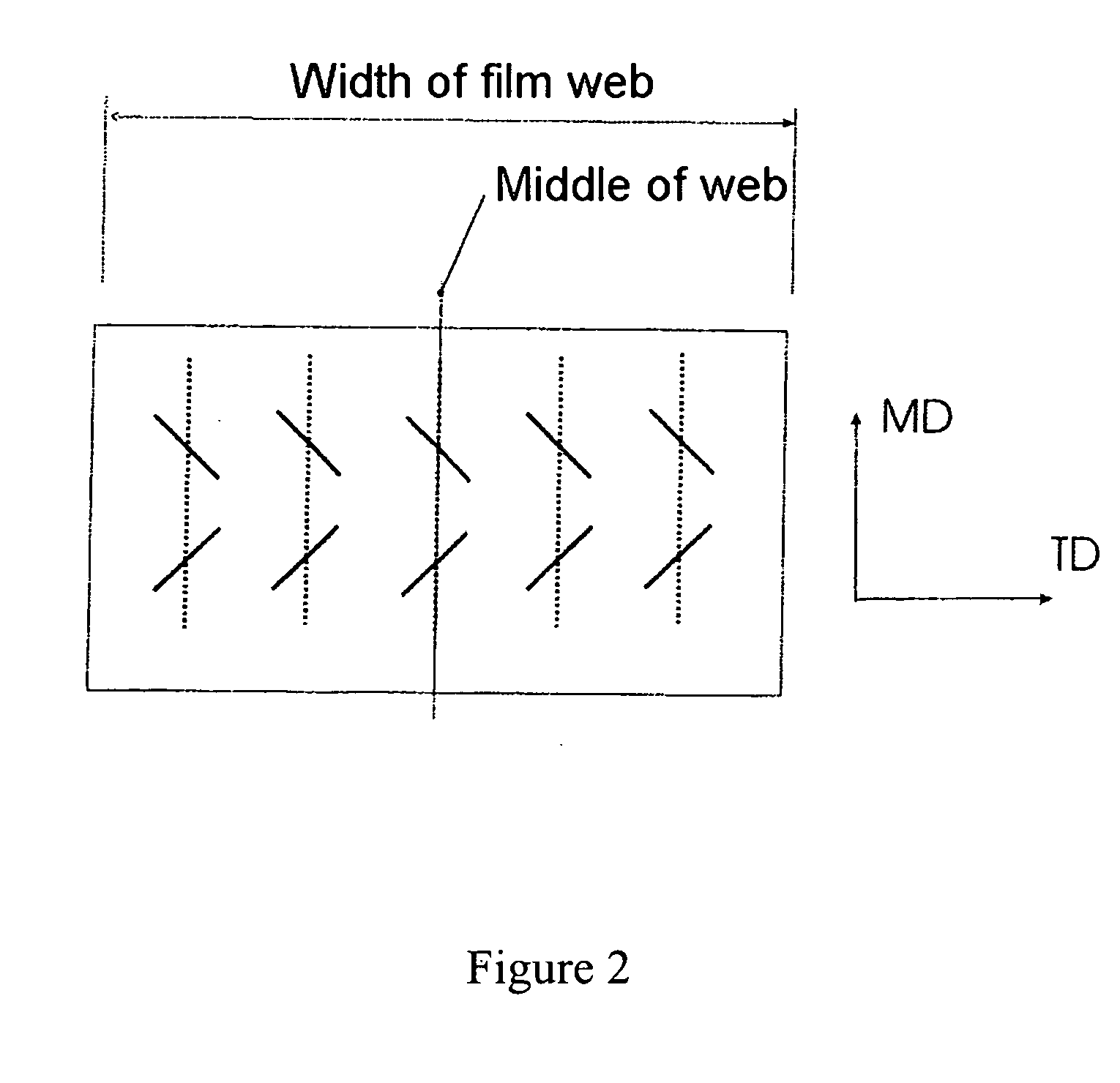

White, steam-sterilizable and extrusion-coatable polyester film

InactiveUS20050238900A1Improve adhesionGood optical performanceFlexible coversWrappersPolyesterSilanes

The invention relates to a single- or multilayer, white, biaxially oriented polyester film. Films of the invention are formed from thermoplastic polyester and are coated on at least one side with a water-soluble adhesion-promoting layer that includes a hydrolyzed amino-functional silane. The invention further relates to the use of the film and to a process for its production.

Owner:MITSUBISHI POLYESTER FILM

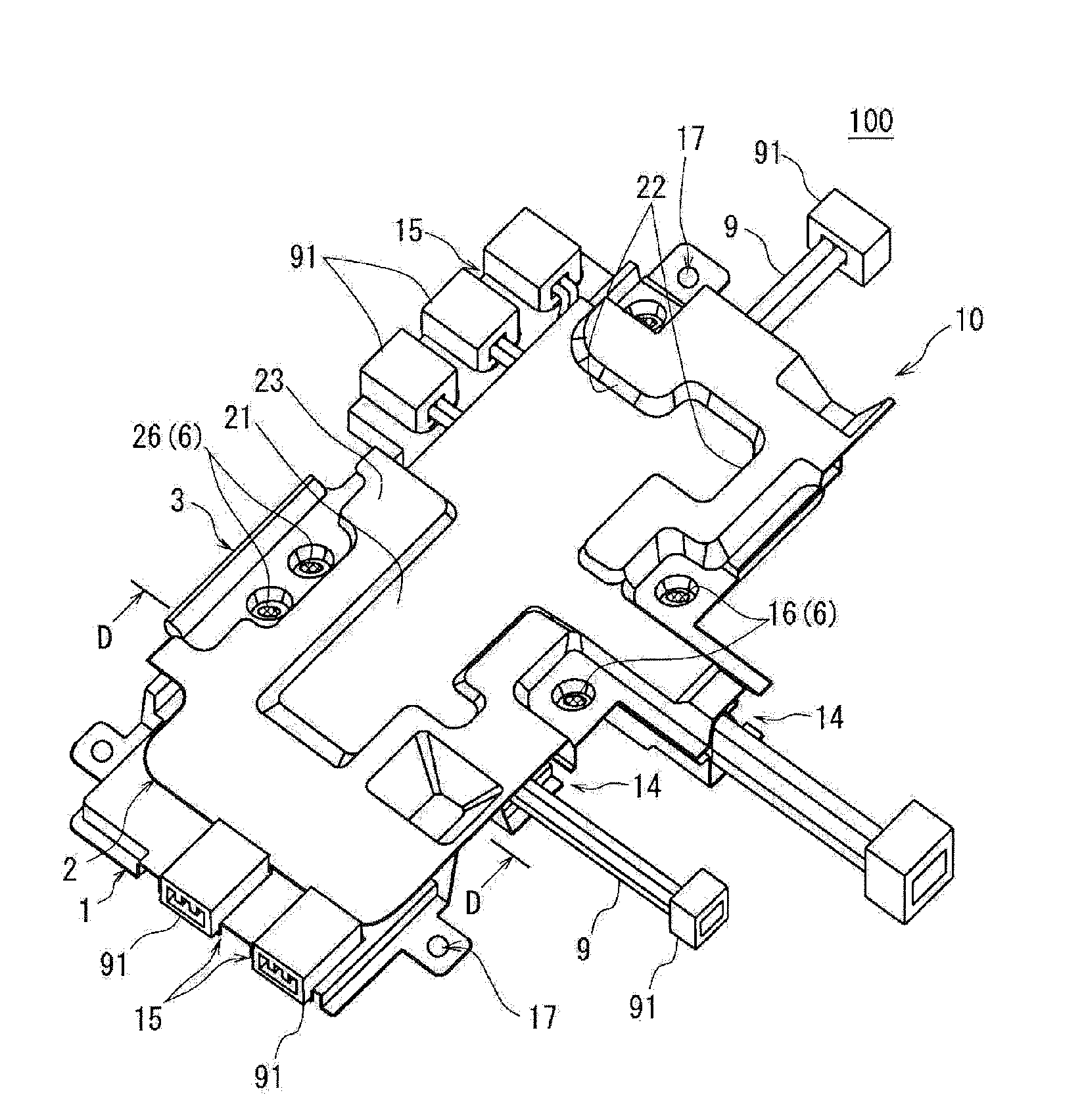

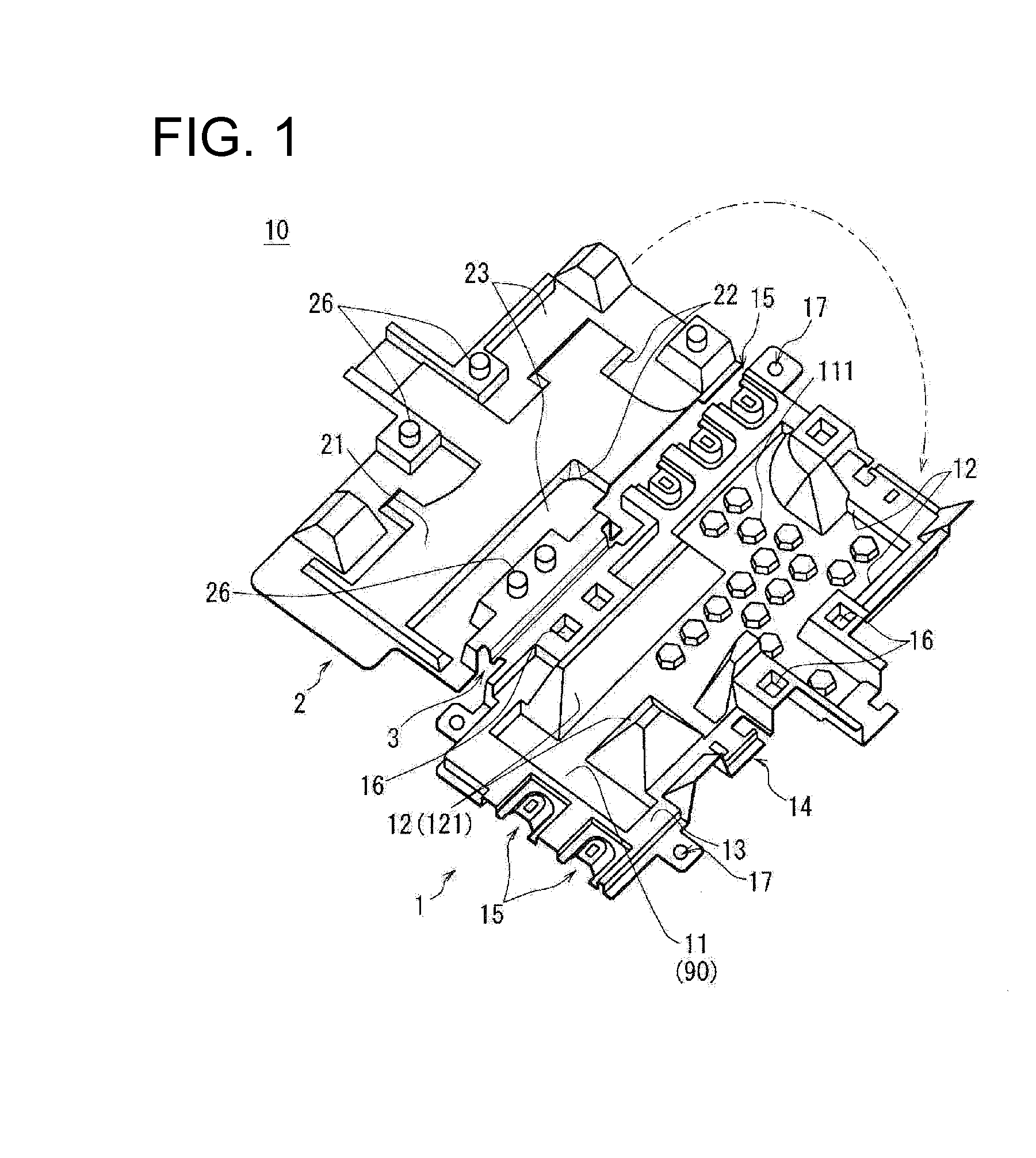

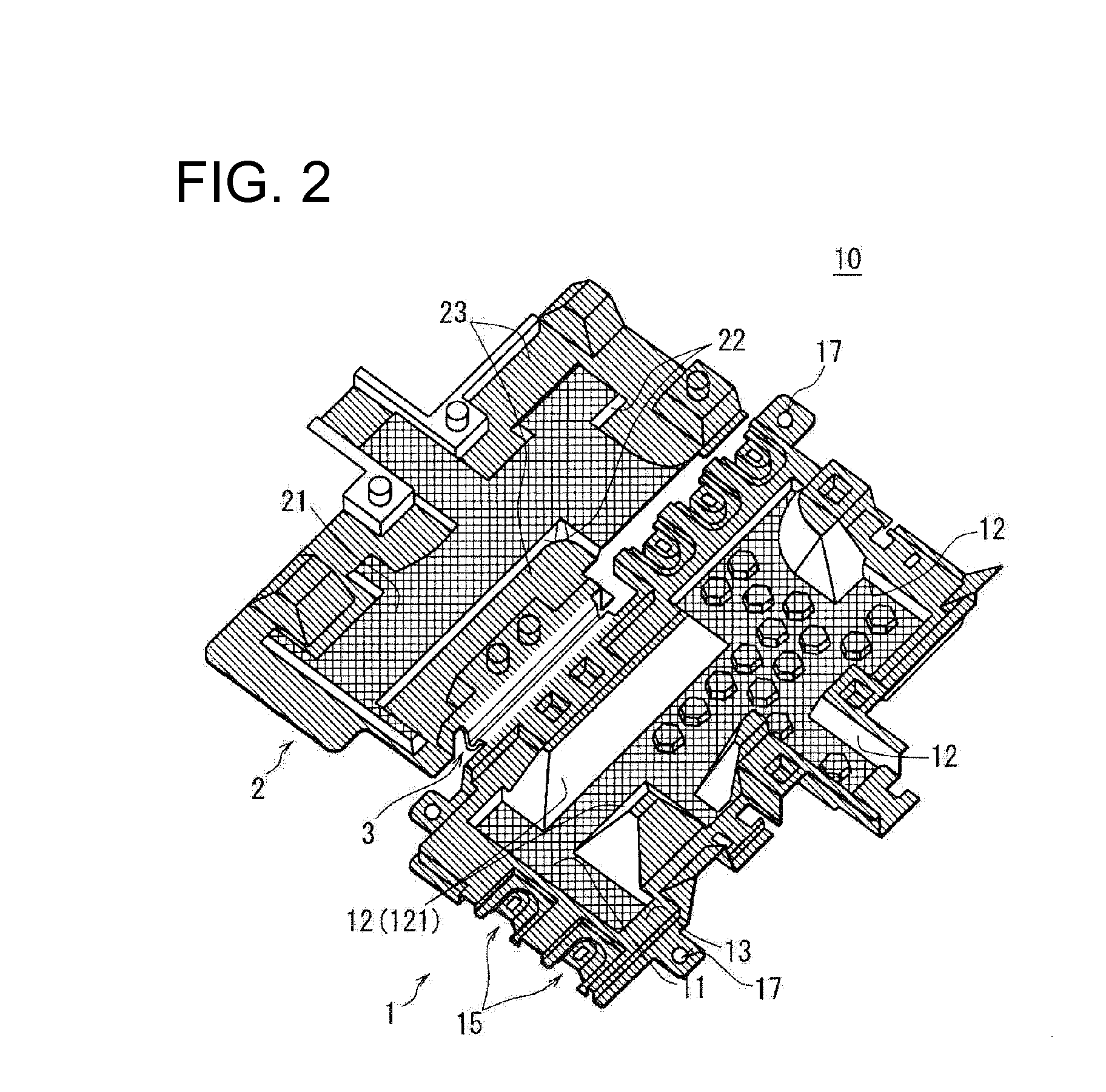

Connector supporting tool, wiring tool and wiring harness

InactiveUS20130008713A1Cost of productionImprove rigidityContact member assembly/disassemblyInsulated cablesSoftware engineeringElectric wire

A wiring tool for holding wires has a plate-like member with connector support (15) that supports a connector (91) by engaging a coupling portion (92) of the connector (91). The connector support (15) has two parallel recesses (151) that form parallel grooves extending straight in from an outer edge of the plate-like member. Two parallel projections (921) of the coupling (92) are fit into the grooves. An intermediate plate (152) of the connector support (15) is between the parallel recesses (151) and is inserted into a clearance between the outer surface of the connector (91) and a beam (922) of the coupling (92). The intermediate plate (152) has a hole (153) that engages a facing projection (923) formed on the beam (922).

Owner:AUTONETWORKS TECH LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com